Semi-embedding type eight-shaped cavity type solar receiver and working method thereof

A solar heat absorber, embedded technology, applied to solar heat collectors, solar heat collector controllers, solar heat collector components, etc., can solve problems such as stagnation, damage, and complicated pipeline installation, and achieve low Convective heat loss, effect of reducing convective heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

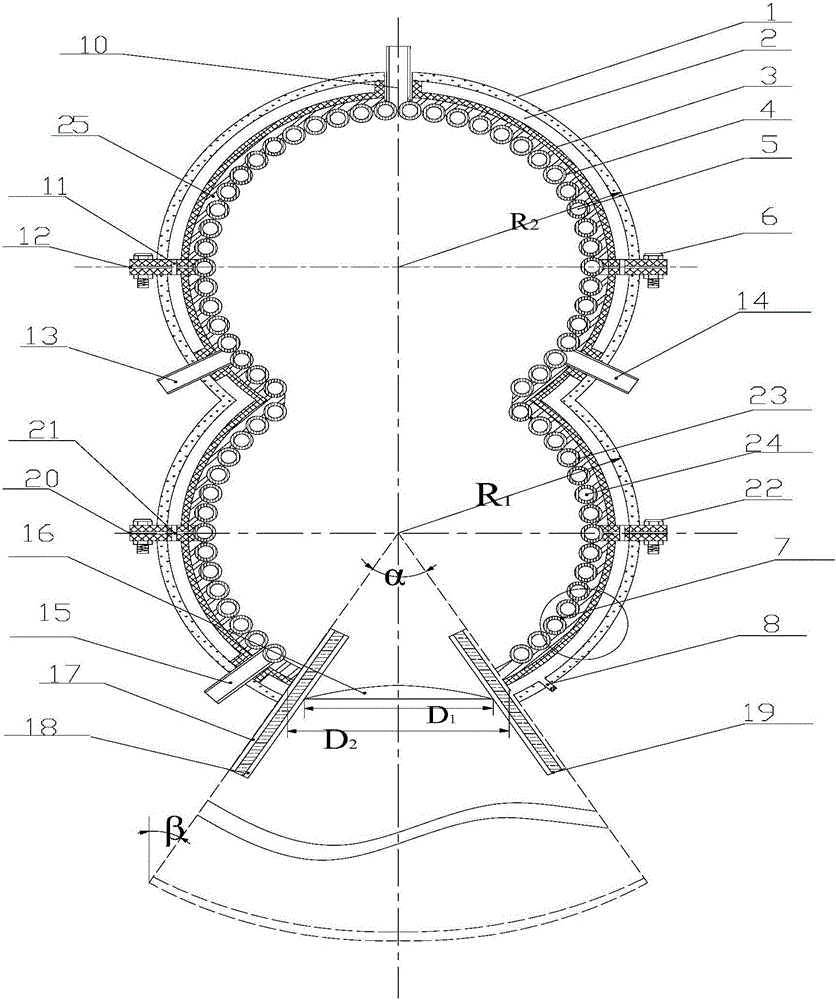

[0032] Embodiment 1: The cavity heat absorber can be used in the dish solar power generation system to convert light energy into heat energy, and its system composition is as follows Figure 5 shown. The core device of the dish solar thermal power generation system includes three parts: multi-dish concentrator, automatic tracking system, semi-embedded 8-shaped cavity solar heat absorber, in addition to energy storage device, thermoelectric conversion device , Voltage conversion device. The concentrator is a device for capturing and converting sunlight. It adopts the ultra-thin silver glass reflector produced by Sunlab in the United States. Specular reflectivity. The diameter of the selected concentrator is 5m, the focal length is 2m, the focal plane falls on the circular surface of the mouth, and the specular reflectance is 94%. The automatic tracking system adopts a dual-axis tracking system to adjust the elevation angle and azimuth angle in the horizontal coordinate syste...

Embodiment approach 2

[0033] Implementation plan 2. The photothermal conversion device and process in the solar power generation system with annual power generation of 1MW:

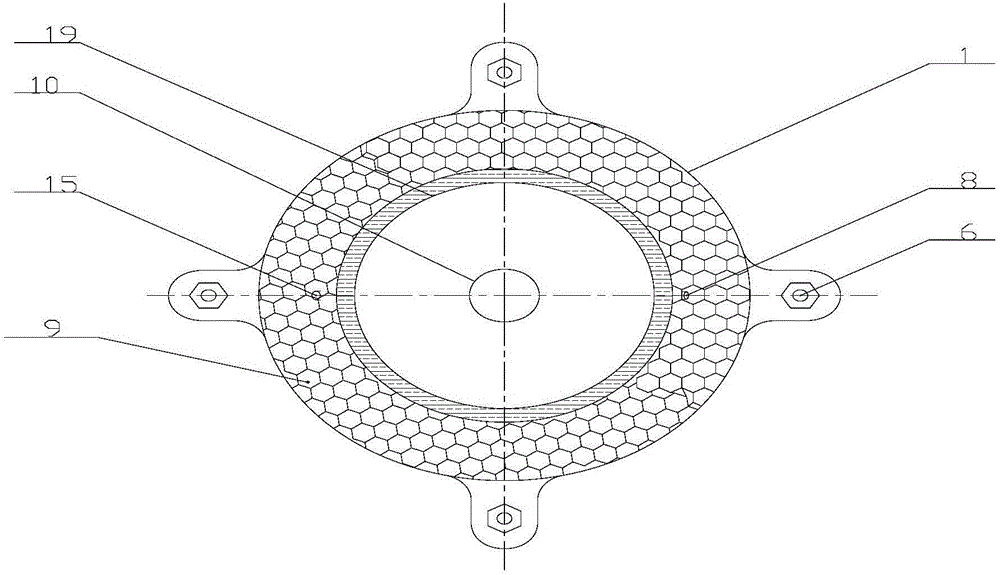

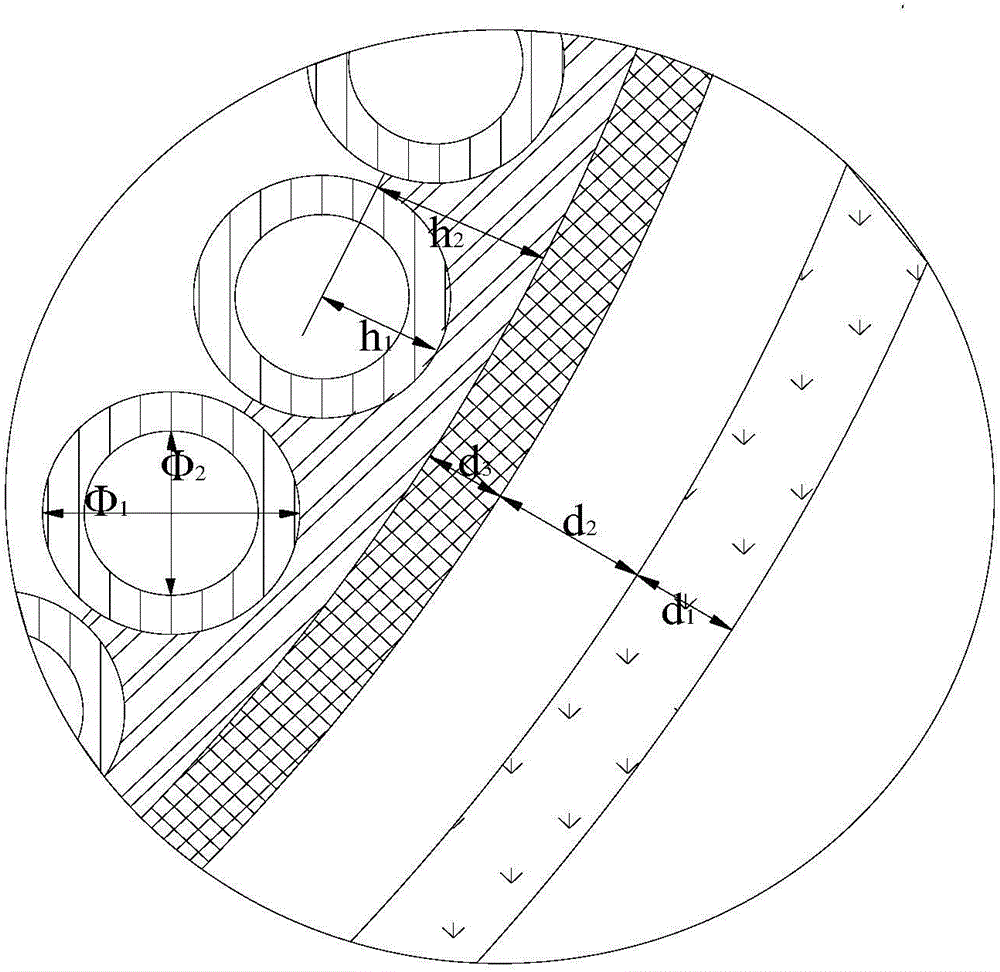

[0034] The cavity type solar heat absorber of semi-embedded figure 8 profile of the present invention (see figure 1 , 2 ), including a light collecting part, a low-temperature heating part, a high-temperature heating part, and a secondary heating part; the secondary heating part is a regular hexagonal convex mirror 9 evenly inlaid on the outer surface of the glass shell 1; the glass shell 1 and the steel inner shell 3 The interval is a heat-insulating vacuum layer 2, both of which have an 8-shaped lower end opening; the inner side of the steel inner shell 3 is a soft heat transfer layer 25 with grooves, the spiral heat exchange coil 4 in the high-temperature section, and the spiral heat exchange coil in the low-temperature section The heat coils 23 are all connected to the soft heat transfer layer 25 in a semi-embedded form; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com