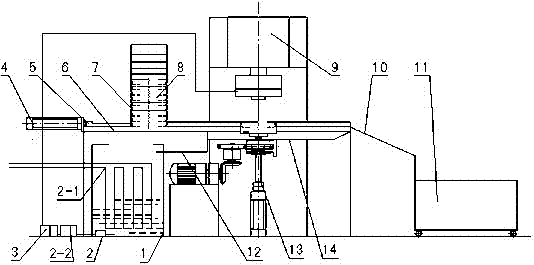

Rotary lifting-type gear sleeve automatic high frequency quenching device

A technology of rotary lifting and high-frequency quenching, which is applied in the direction of quenching device, energy efficiency improvement, process efficiency improvement, etc., to achieve the effect of reducing labor intensity and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Pushing mechanism is made of pushing cylinder and pushing plate, and pushing cylinder 4 is installed on the end face of bed 6 one side, and the piston rod end of pushing cylinder is connected with pushing plate 5, and the other end of pushing plate is provided with A V-shaped groove that abuts against the outer circle of the workpiece in the bottom of the material storage rack 7 arranged in the left and right guide rail assemblies. The bed is a plane frame.

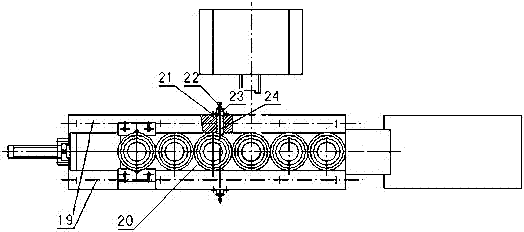

[0017] The left and right guide rail assemblies are composed of left and right guide rails, guide rail base plates, elastic fixing frames, elastic pin adjustment bolts, elastic pin springs and elastic pins. The guide rail base plate 20 is fixed on the end surface of the bed 6, and the left and right guide rails 19 are symmetrically installed on the guide rail base plate On the top, six trough stations are sequentially formed between the two guide rails along the advancing direction of the pushing plate 5 in the pus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com