High-frequency automatic quenching machine for reverse gear shafts of transmission cases

A technology for reverse gear shafts and gearboxes, which is applied in the field of high-frequency automatic quenching machines for reverse gear shafts of gearboxes, and can solve problems such as low production efficiency, high labor intensity, and inability to adapt to large-scale and large-scale production of reverse gear shafts. , to achieve the effect of improving production efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

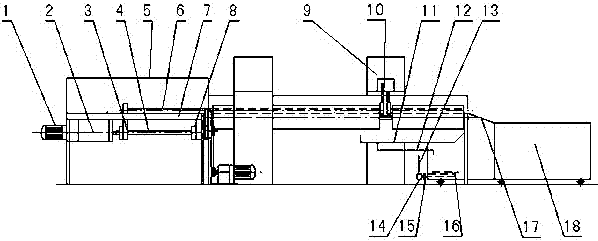

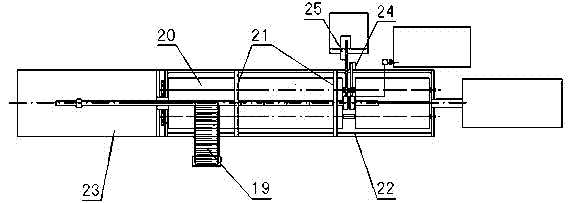

[0022] Such as figure 1 , 2 As shown, a gearbox reverse shaft high-frequency automatic quenching machine is composed of a pushing mechanism, an idler mechanism, an automatic feeding mechanism, a pressing frame mechanism, a heating power supply, a quenching and cooling device, a discharging mechanism and a PLC.

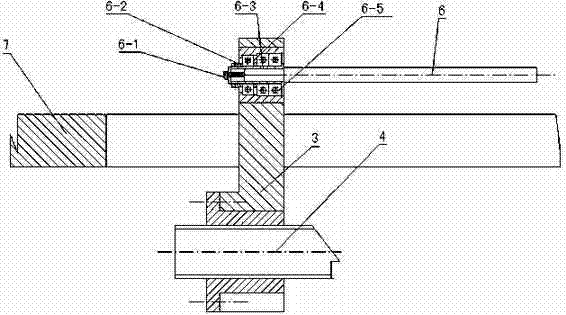

[0023] Pushing mechanism is made of pushing motor, gear box, nut seat, transmission screw mandrel, screw mandrel seat, pushing rod, upper cover plate 5 and pushing frame bed. Wherein, the pusher motor 1, transmission box 2, nut seat 3, transmission screw mandrel 4 and screw mandrel seat 8 are installed and connected to the bottom of the upper bed plate 7 of the pusher frame bed 23 in turn, and the top of the nut seat passes through the pusher frame The through groove opened in the middle of the upper bed board, the upper inner hole is equipped with a rotating sleeve 6-3 (see image 3 ), a plane bearing 6-4 and a bearing 6-5 are installed in the rotating sleeve, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com