Loop-type multi-phase flow erosion test device

A test device and multi-phase flow technology, applied in the direction of measuring devices, piping systems, weather resistance/light resistance/corrosion resistance, etc., can solve problems such as large gaps, insufficient mechanism research, and difficult industrial pipeline erosion failures, etc., to achieve The effect of preventing oil, separating cleanly and optimizing design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

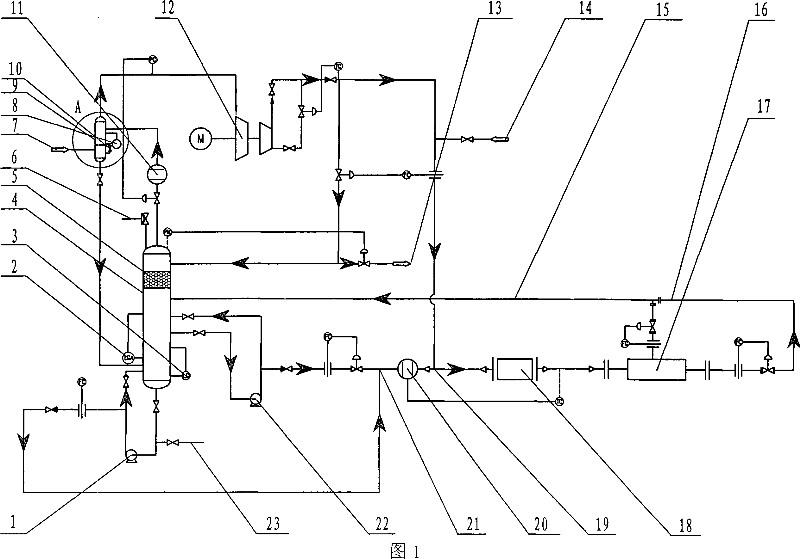

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

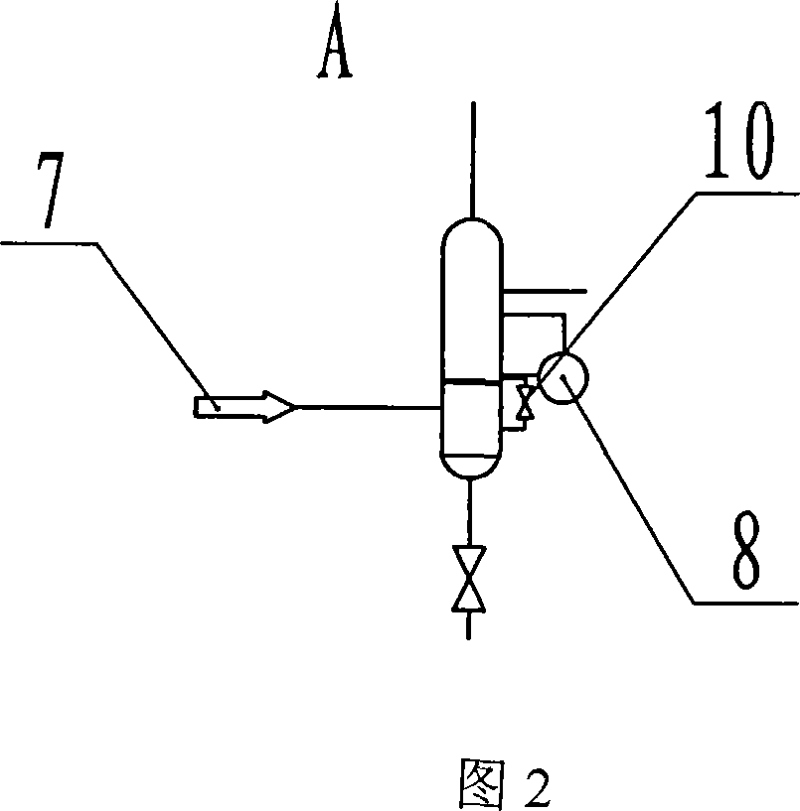

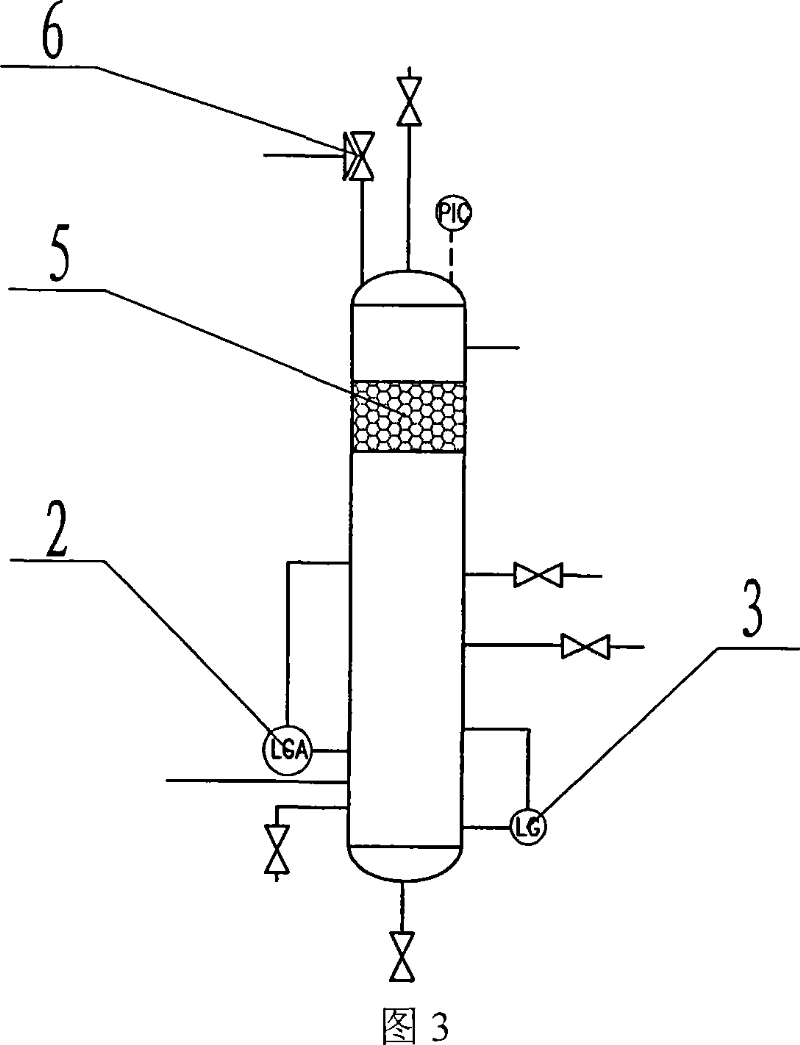

[0024] As shown in Figure 1, the present invention includes sewage metering pump 1, three-phase separation tank 4, cyclone separator 9, cooler 11 and circulating gas screw compressor 12, pipeline filter 18, heater 20, diesel magnetic drive pump 22 ; wherein the sewage metering pump 1 outlet is divided into two branches, the main branch is connected to the heater inlet 21 in series with the first flow meter and the first check valve in sequence, and the secondary branch is connected to the three-phase separation tank through the first gate valve 4 lower part; the inlet of the pad liquid line is respectively connected to the inlet of the sewage metering pump 1 through the second gate valve and connected to the bottom of the three-phase separation tank through the third gate valve; the top outlet of the three-phase separation tank 4 is sequentially connected with the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com