Spray cooling device for cooling heat source with high heat flux

A spray cooling, high heat flow technology, applied in the field of cooling devices, can solve the problem of pump power consumption and cooling capacity mismatch, and achieve the effect of ensuring normal and efficient operation, reducing flow resistance, and reducing pump power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Carry out further detailed description below in conjunction with accompanying drawing:

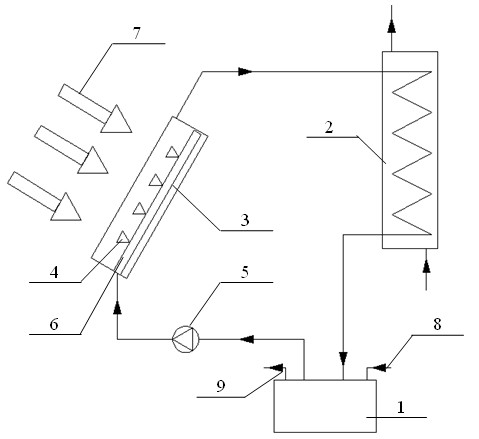

[0024] figure 1 A schematic diagram of the device of the present invention is given, a spray cooling device with a structural characteristic transmission pipeline, which is composed of a spray cooler, a condenser, a liquid reservoir and a circulation pump. The specific structure includes: a liquid reservoir 1, a condenser 2, a spray cooler 3, an atomizer 4, a circulating pump 5, and a configuration transmission pipeline 6, etc., and other main parts. In the spray cooler 3, the atomizer 4 is arranged at the outlet of the configuration transfer pipe 6, the spray cooler 3 is connected with the liquid reservoir 1 through a circulating pump 5, and the condenser 2 is arranged between the spray cooler 3 and the storage Between liquid tank 1, the whole system forms a closed cycle.

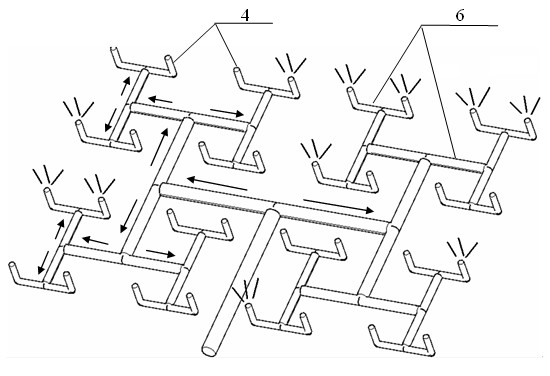

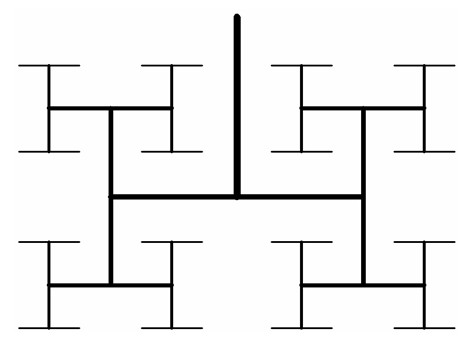

[0025] figure 2 A schematic diagram of the spray cooler structure is given. The cooling working fluid ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com