Sound wave agglomeration-based dust removal and ultralow emission device applicable to converter gas

A converter gas and sound wave technology, applied in the field of process dust removal in the metallurgical industry, can solve the problems of occupation, long process, large installation space, etc., and achieve the effect of not easy to block, simple structure, uniform atomization or spraying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

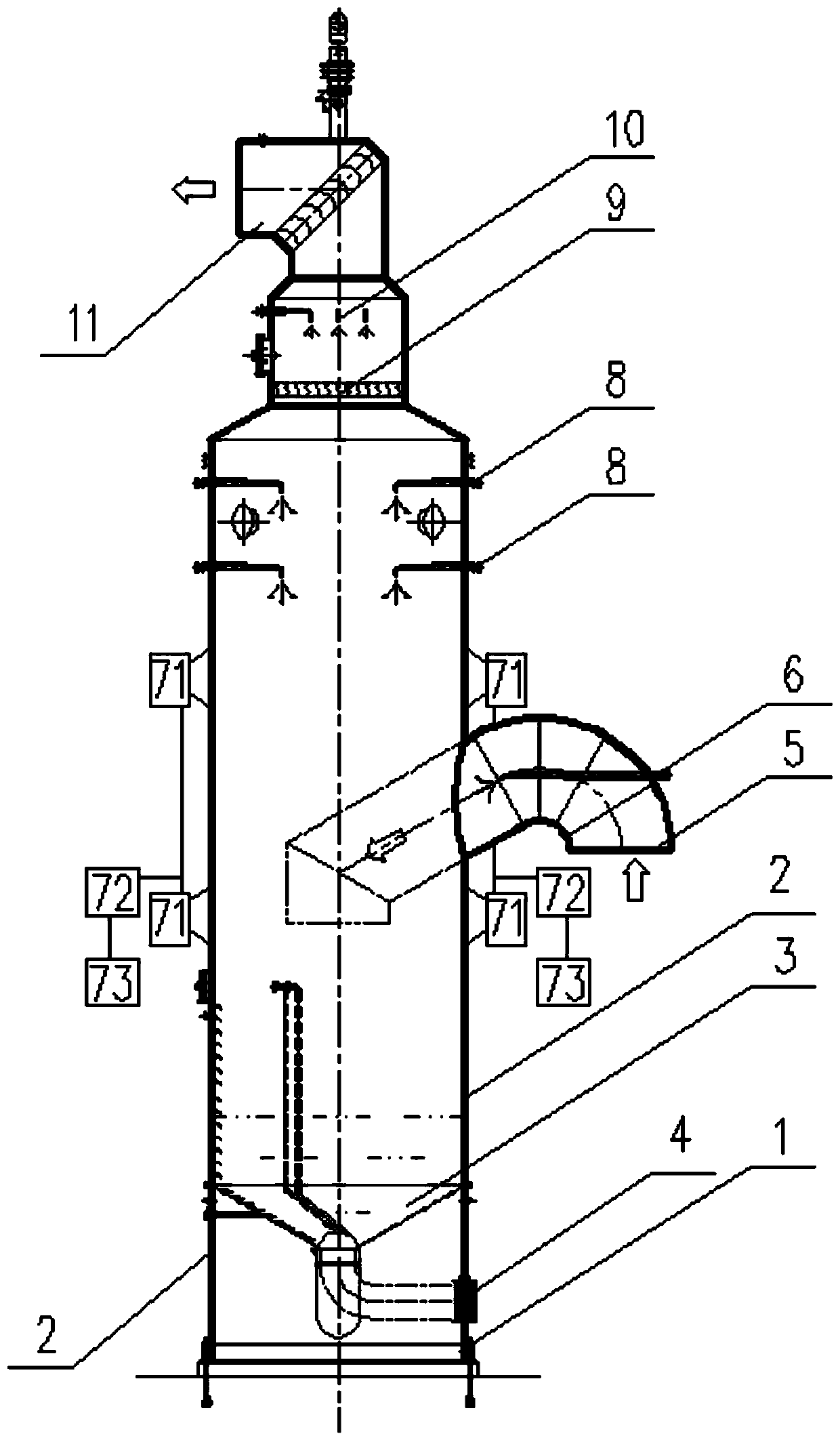

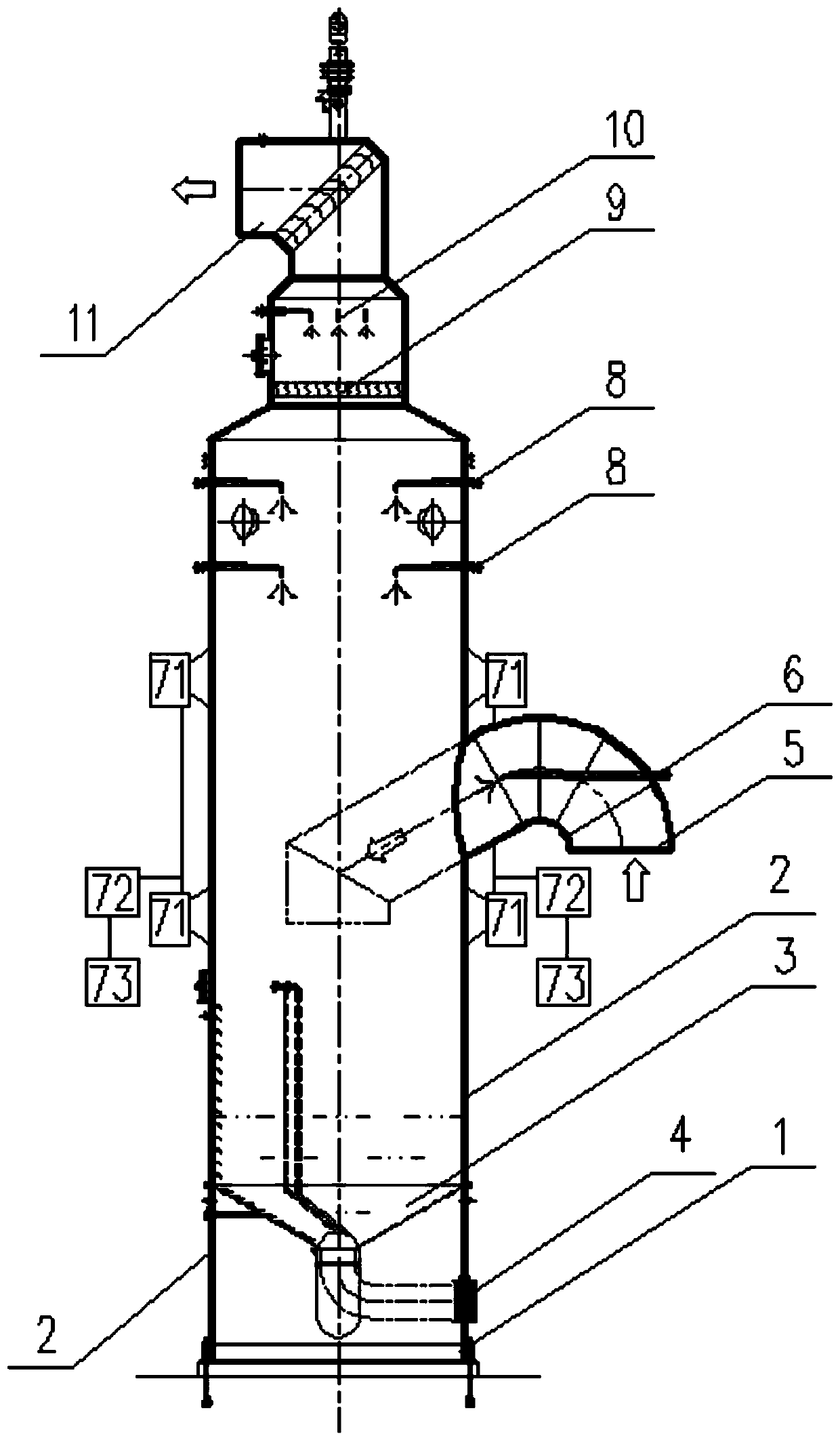

[0027] see figure 1 , is a device based on acoustic agglomeration suitable for ultra-low emission of converter gas dedusting, used to replace the gas cooler of converter gas dry dedusting system, installed between the gas fan and the switching station, including a bracket, on which there is a cylinder Body 2, the cylinder body 2 is welded with the support 1 and fixed on the civil foundation by ground angle bolts, the cylinder body 2 is a vertical cylinder or square structure welded by steel plates, the bottom of the cylinder body 2 is provided with a lower cone 3, the lower cone The body 3 is connected with a drainage pipe 4, and the drainage pipe 4 is externally connected with a turbid ring water treatment system. The cylinder body 2 is provided with a gas inlet pipe 5 and several sets of sound wave agglomeration devices 7. The gas outlet of the gas inlet pipe 5 is located lower than the sound wave agglomeration device. 7. The gas inlet pipe 5 is inserted into the cylinder bo...

specific Embodiment 2

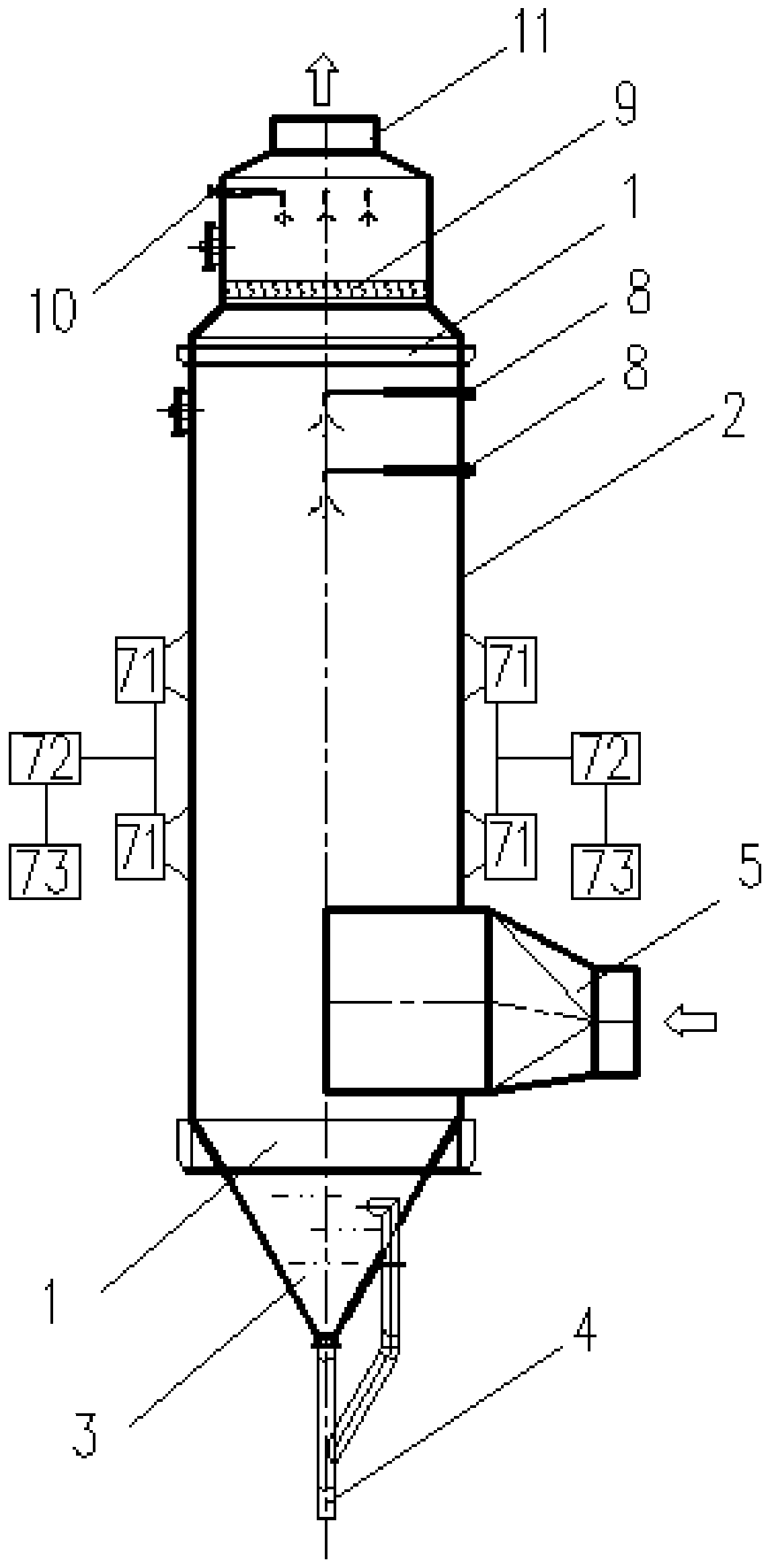

[0033] see figure 2, the present invention provides a device based on sonic agglomeration suitable for ultra-low emission in the converter gas dedusting system, which is used to replace the dehydrator of the converter gas wet dedusting system and installed in the steelmaking tower. This embodiment is different from the specific embodiment 1 The advantage is that the gas inlet pipe 5 is set to be connected to the cylinder body 2 along the tangential direction of the cylinder body 2, so that the flue gas enters the cylinder body 2 tangentially through the gas outlet of the gas inlet pipe 5, and the gas inlet pipe 5 does not need to be wetted with water mist Nozzle 6, the load of cylinder 2 is transferred from the support 1 to the corresponding platform of the steelmaking tower, and water mist dedusting nozzles 8 are arranged at different heights along the upper axis of cylinder 2 to ensure that the water mist covers the entire cylinder 2 section, lower the flue gas temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com