Brushless DC (direct current) motor air conditioning system control circuit

A brushless DC motor and control circuit technology, which is applied in the direction of electrical program control, electric speed/acceleration control, sequence/logic controller program control, etc. Unsatisfactory use conditions, inability to change the speed and other problems, to achieve the effects of enhanced applicability and combinability, shortened product development cycle, and stable speed control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

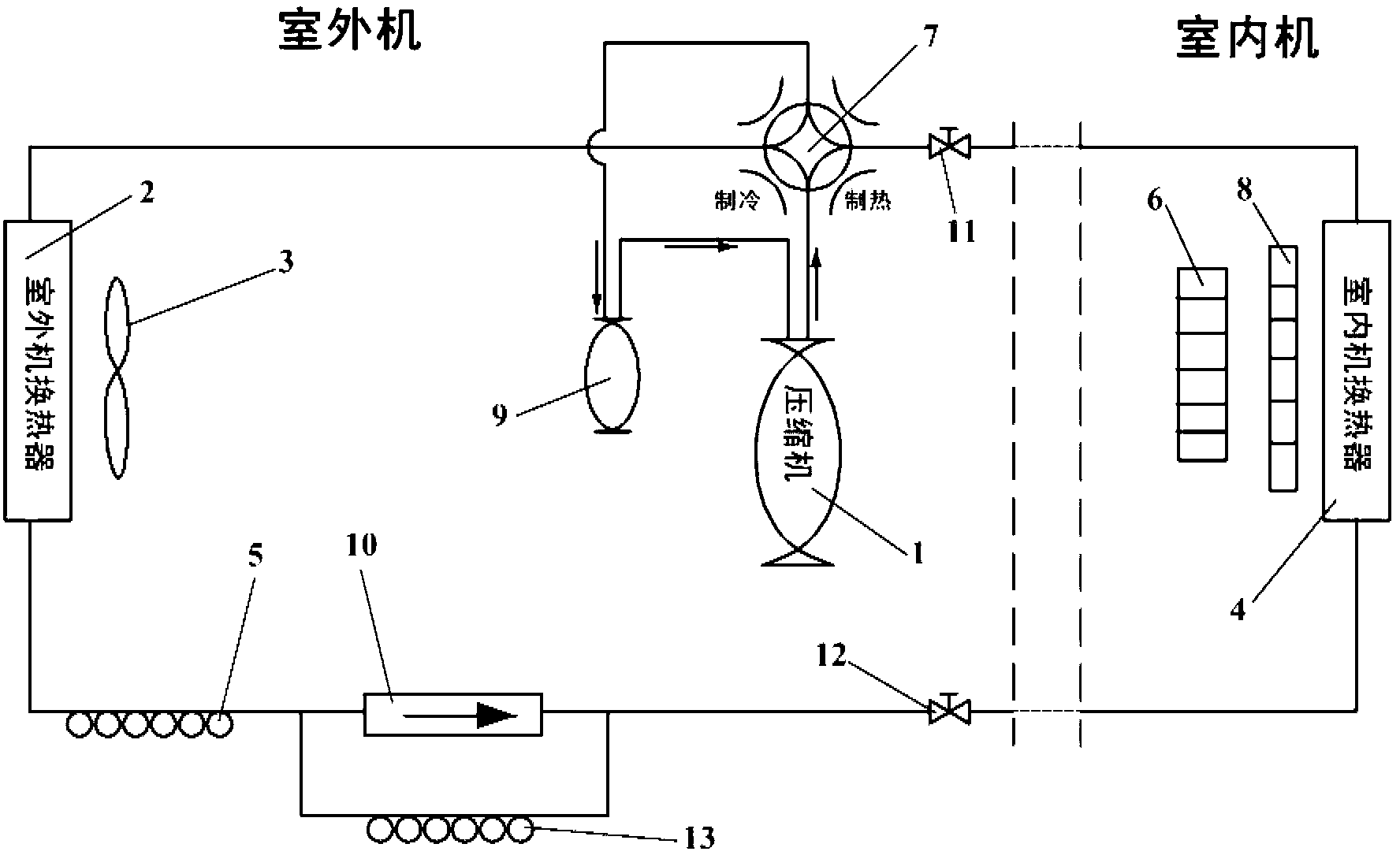

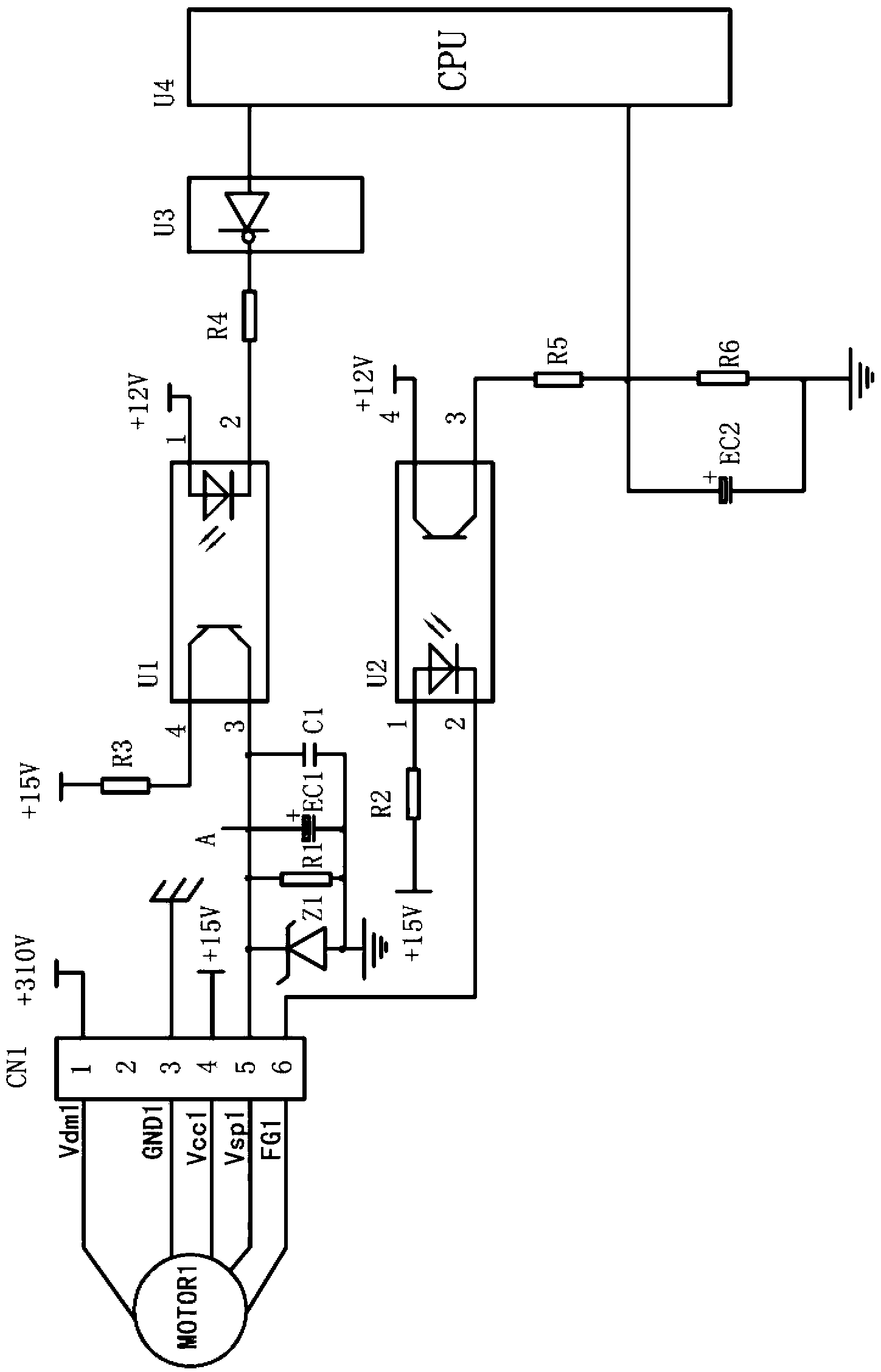

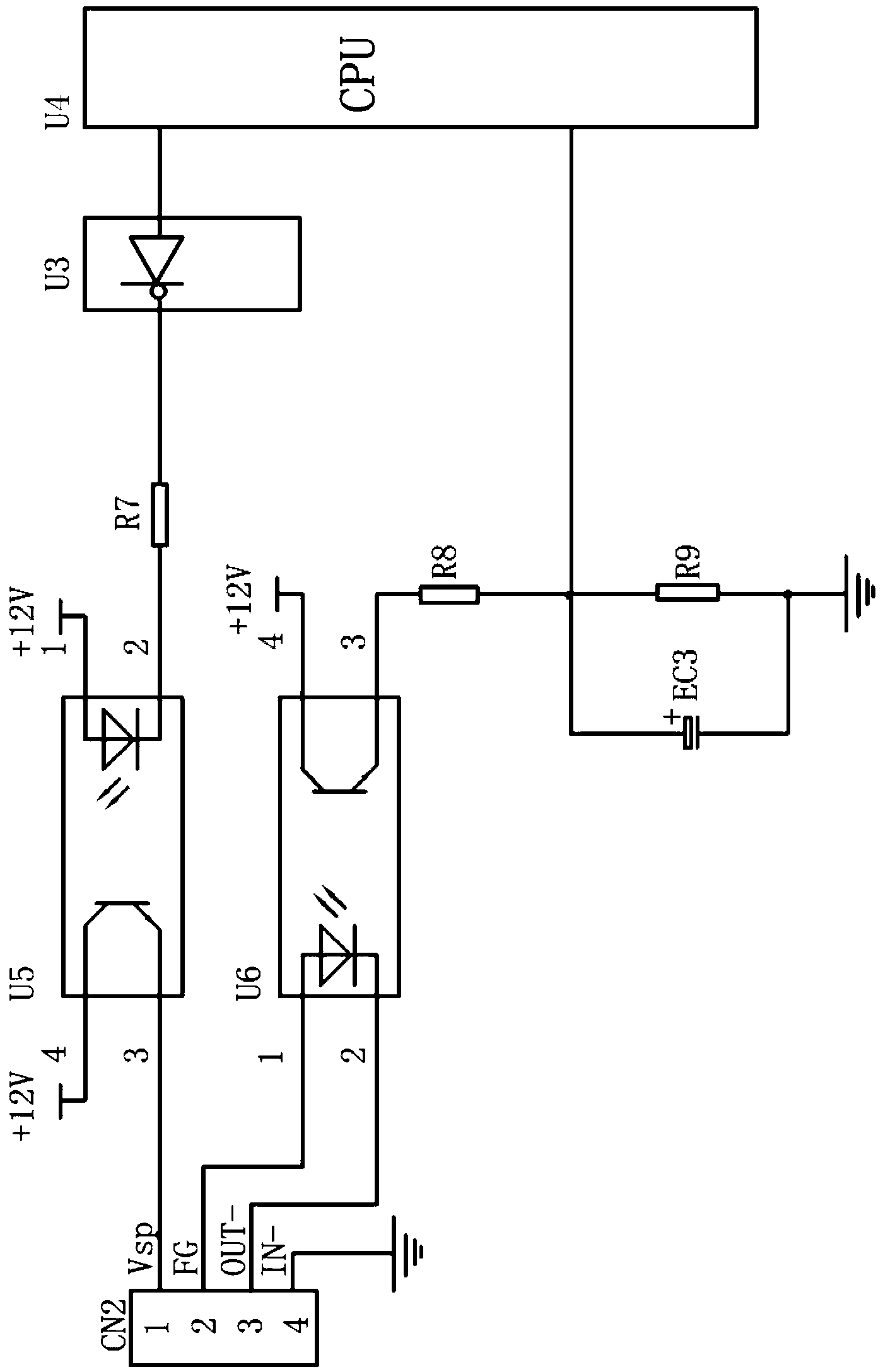

[0036] see Figure 9 , DC brushless motor air conditioning system control circuit, including microcontroller U4, indoor DC fan motor speed control circuit, outdoor DC fan motor speed control circuit, outdoor DC motor fixed speed and adjustable speed switching circuit, indoor motor speed regulation voltage cut-off Circuit, outdoor motor speed regulation voltage cut-off circuit and temperature detection circuit; the indoor DC fan motor speed control circuit, outdoor DC fan motor speed control circuit and temperature detection circuit are all connected to the microcontroller; the indoor motor speed control circuit The speed voltage cut-off circuit is connected with the indoor DC fan motor speed control circuit, and the outdoor motor speed regulation voltage cut-off circuit and the outdoor DC motor fixed speed and adjustable speed switching circuit are connected with the outdoor DC fan motor speed control circuit. connect;

[0037] The outdoor DC fan motor speed control circuit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com