Variable-angle ultrasonic impact test device and method

A technology of ultrasonic impact and testing device, which is applied in the direction of impact testing, testing material strength with one impact force, measuring device, etc. It can solve the problems that ultrasonic impact cannot be realized, and achieve the effect of simple structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. Example embodiments may be embodied in many different forms and should not be construed as limited to the embodiments set forth herein. The drawings are for illustration purposes only and are not drawn to scale.

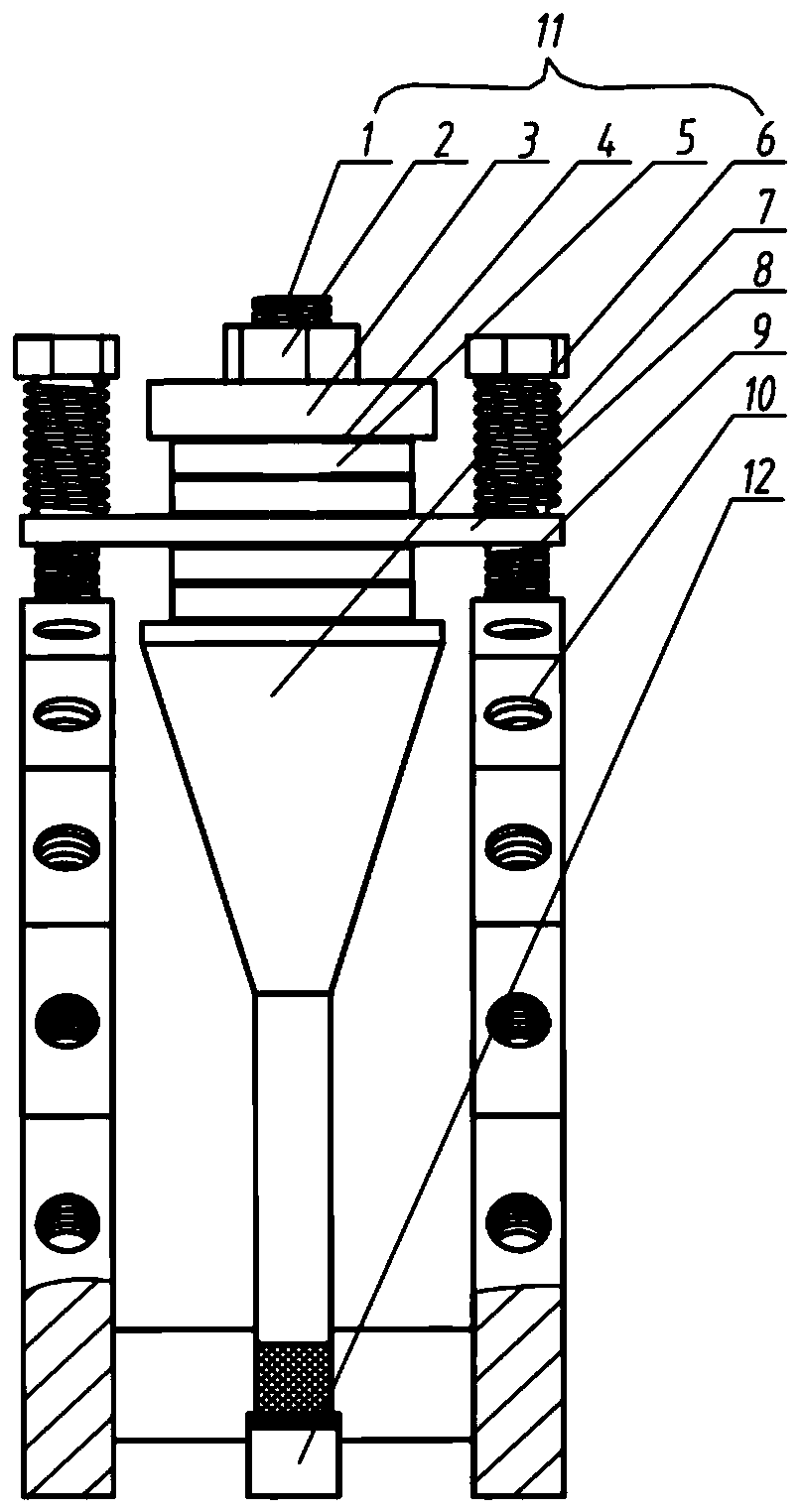

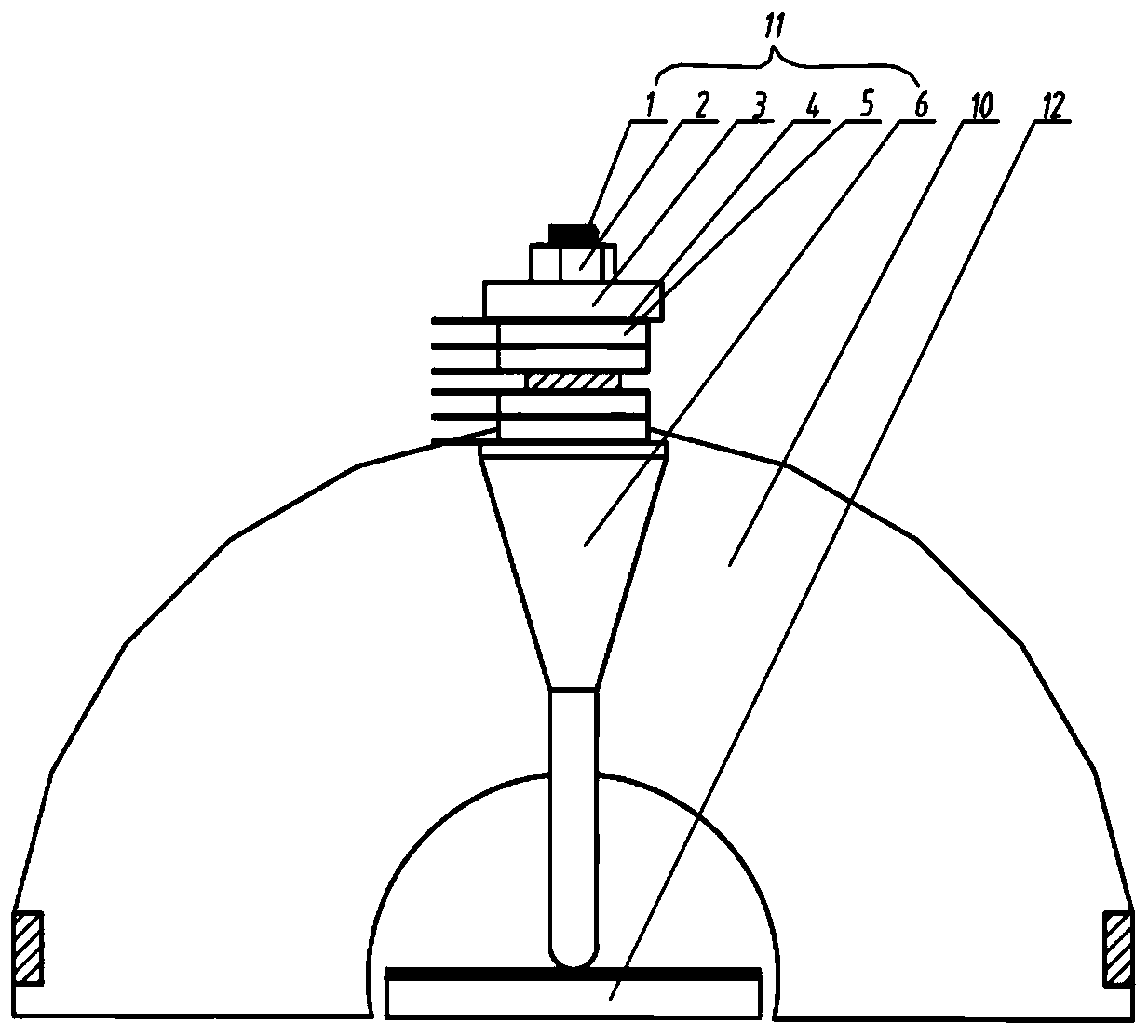

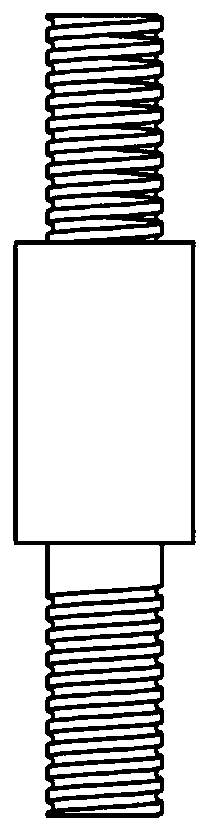

[0024] Such as figure 1 , 2 As shown, a variable-angle ultrasonic impact test device includes a Langevin vibrator 11, an impact stage 12, a spring 7, a preload plate 8, bolts 9, and a support table 10, wherein the preload plate 8 can also be a flange.

[0025] Such as Figure 5 As shown, the support platform 10 is a hollow polyhedron structure, and the center of the bottom is provided with an arc-shaped through hole. The arch principle is used to increase the support rigidity of the support platform 10, while reducing the vibration of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com