Novel hydraulic piston sampling machine tool

A hydraulic piston, a new type of technology, applied in the direction of sampling devices, etc., can solve the problems of no core protection mechanism, single drilling function, and use restrictions, so as to increase the sampling speed, eliminate the suction effect at the bottom of the hole, and eliminate the hidden danger of sample falling off Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

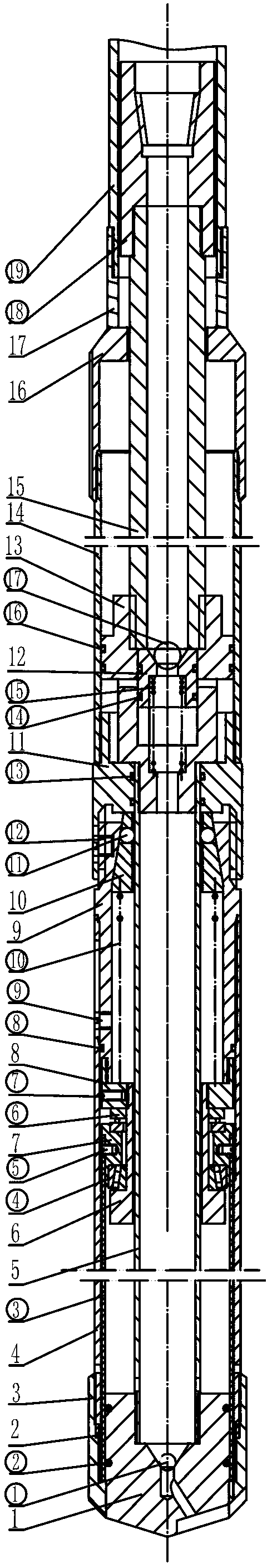

[0025] Such as figure 1 As shown, in the novel hydraulic piston sampling tool of this embodiment: the piston drill bit 1 is connected with the lower end of the hollow rod 5 with a screw, the upper end of the hollow rod 5 is connected with the lower end of the upper piston 13 with a screw, and the upper end of the upper piston 13 is connected with the lower end of the main shaft 15. Threaded connection, the main shaft 15 is a hexagonal columnar or flat active drill pipe structure, relative to the main shaft 15 and the twist joint 16 that can move axially along the main shaft 15 is set on the main shaft 15, and the twist joint 16 and the main shaft 15 are synchronized together Rotate, the lower end of the twist joint 16 is connected with the upper end of the cylinder body 14 with a screw thread, the inner diameter of the twist joint 16 is larger than the inner diameter of the cylinder body 14, the inner cavity of the cylinder body 14 is in sliding and sealing cooperation with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com