Iron ore sampling and sample making method and system

A sample preparation system and iron ore technology, which is applied in the direction of sampling device, test sample preparation, etc., can solve the problems of difficult sample representation, large particle size, and difficult to work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

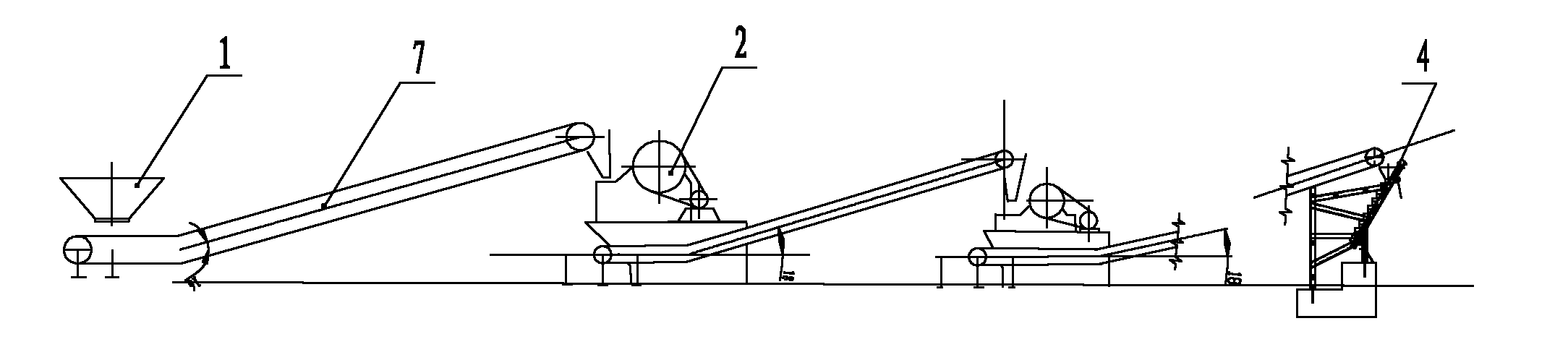

[0111] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

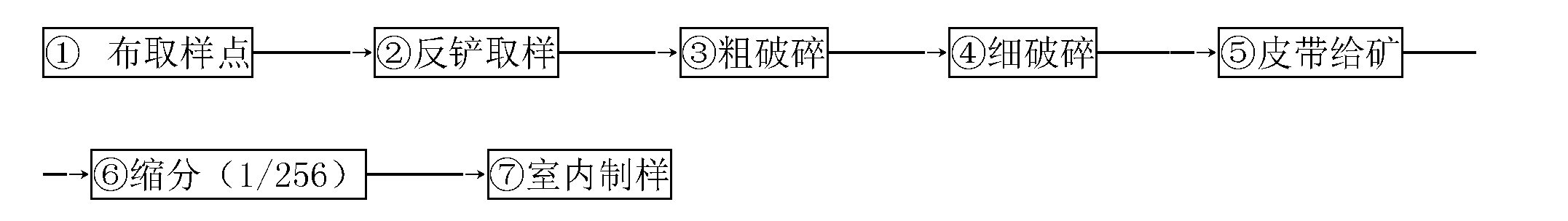

[0112] Such as figure 1 Shown, a kind of iron ore gets sample preparation method, comprises the following steps:

[0113] 1) Sampling;

[0114] 2) broken, the sampling of step 1) is broken;

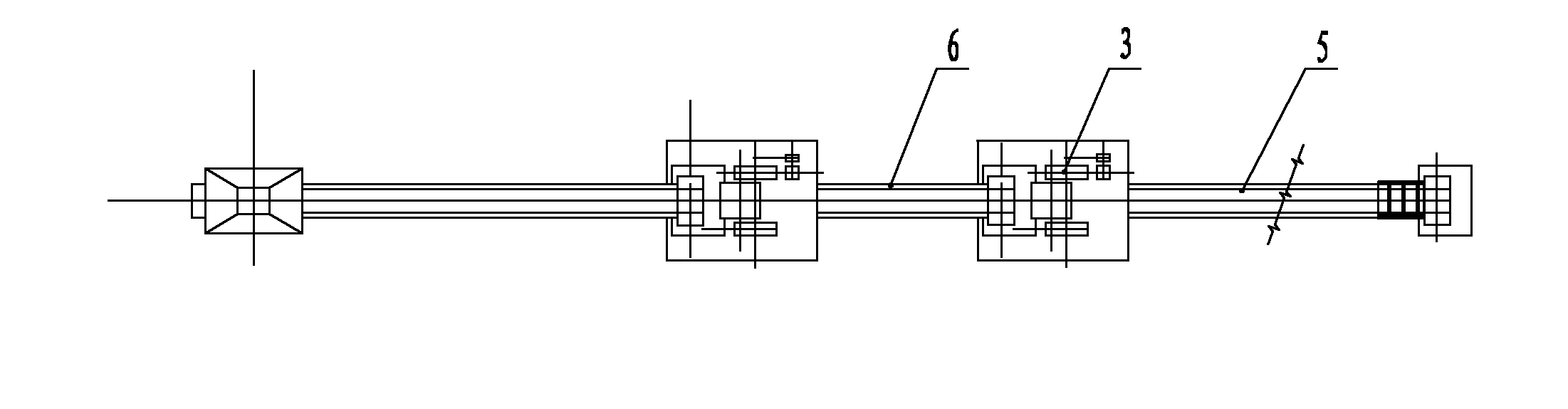

[0115] 3) shrinkage, step 2) broken sampling input shrinkage machine 4 shrinkage processing;

[0116] 4) Indoor sample preparation.

[0117] The sampling of described step 1) adopts crawler-type backhoe excavator sampling, and the width of sampling bucket mouth is 1 meter, and the depth of bucket is 1 meter, has guaranteed that 350~0 millimeter material is taken up, both can according to need in length Dots can be distributed in the direction of the thickness, and can be dug in the thickness direction as needed until the bottom of the material is dug; the samples are taken out and put into the car containing the ore samples.

[0118]The sampling sample broken ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com