Material flowing deformation disturbed effect testing system and testing method thereof

An experimental system and effect technology, applied in the directions of flow characteristics, analyzing materials, and testing the strength of materials using a single impact force, can solve the problems of load fluctuation, expensive equipment, and small expansion multiples, and achieve stable loading, simple structure, The effect of large transmission ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

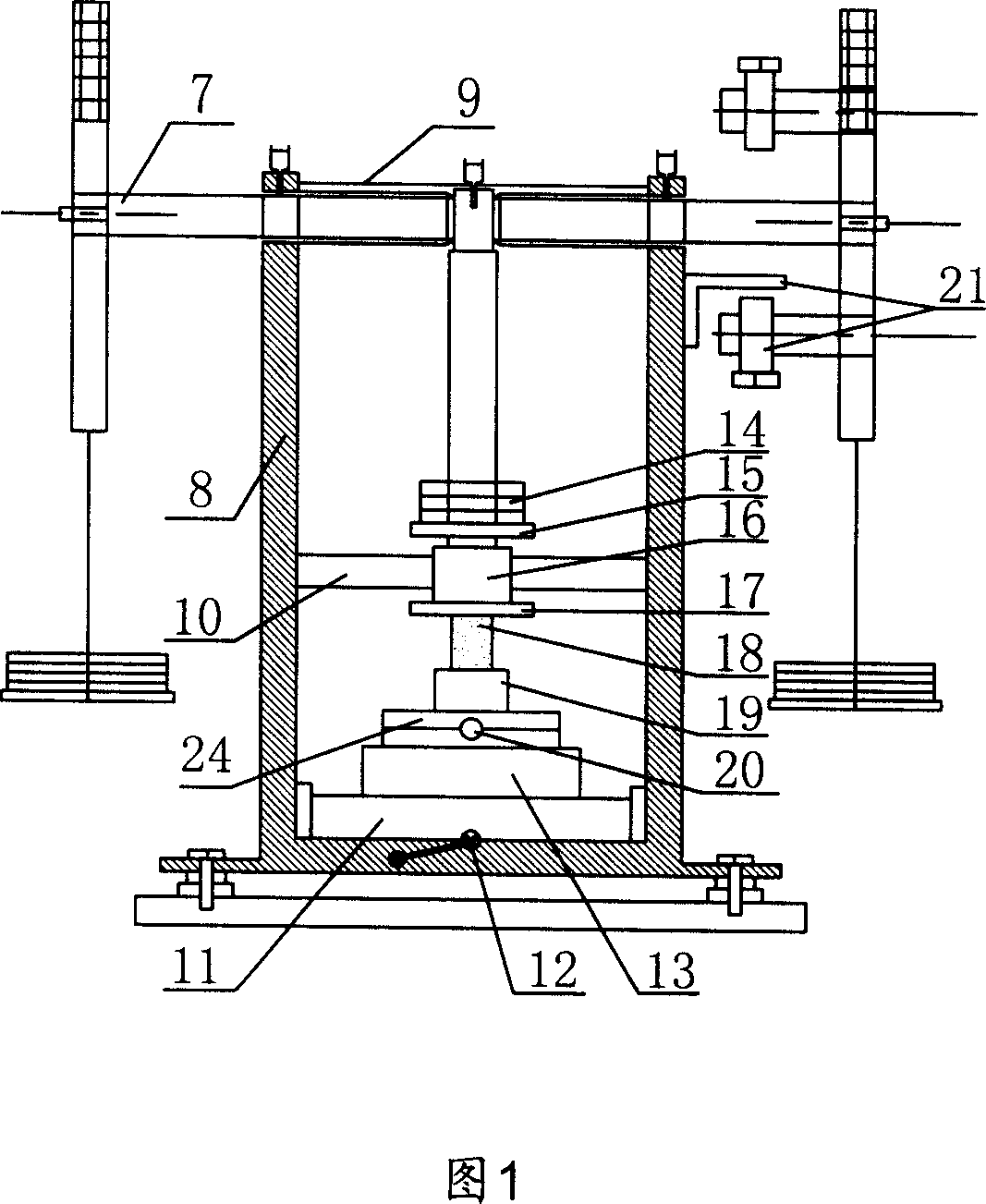

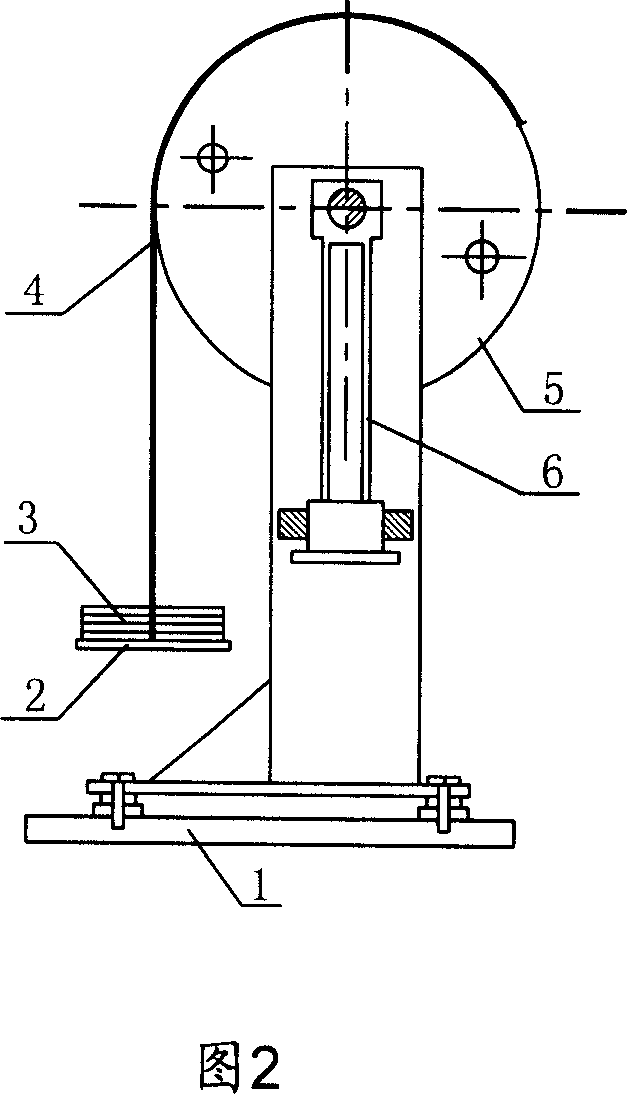

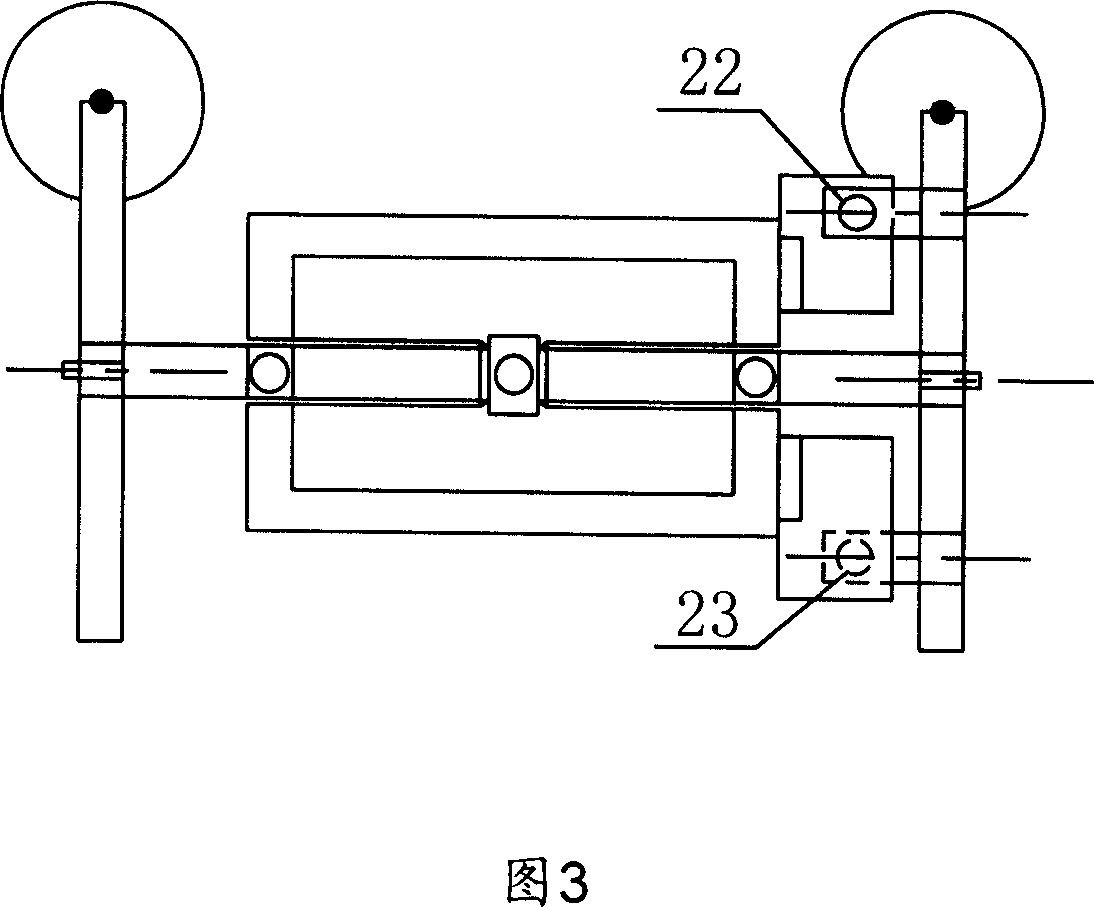

[0032] The preferred embodiment of the material rheological disturbance effect experimental system of the present invention is shown in Fig. 1, Fig. 2, Fig. 3, comprises frame 8, test bench 13, is provided with constant loading system on frame 8, described constant The loading system can apply a constant load to the test piece 18 on the test bench 13, and the described constant loading system includes a loading device, an expansion device and a force transmission connecting rod 6, and the expansion device is arranged on the frame 8, and the The loading device applies a constant load to the test piece 18 through the expansion device and the force transmission connecting rod 6 .

[0033] The loading device includes a gravity loading weight 3, and the expanding force device includes a crankshaft 7, and an eccentric wheel or a lever or a pulley or a gear expanding force can also be used.

[0034] Specifically, the main frame of the pressure experiment system is composed of the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com