Method for objectively determining crack initiation strength of rock on basis of accumulated sound emission impact times

A technology of crack initiation strength and acoustic emission, applied in the direction of strength characteristics, the use of stable tension/pressure test material strength, measuring devices, etc., can solve problems such as interference with accurate identification of crack initiation strength values, save test time, and facilitate Promote the application and ensure the effect of uniqueness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

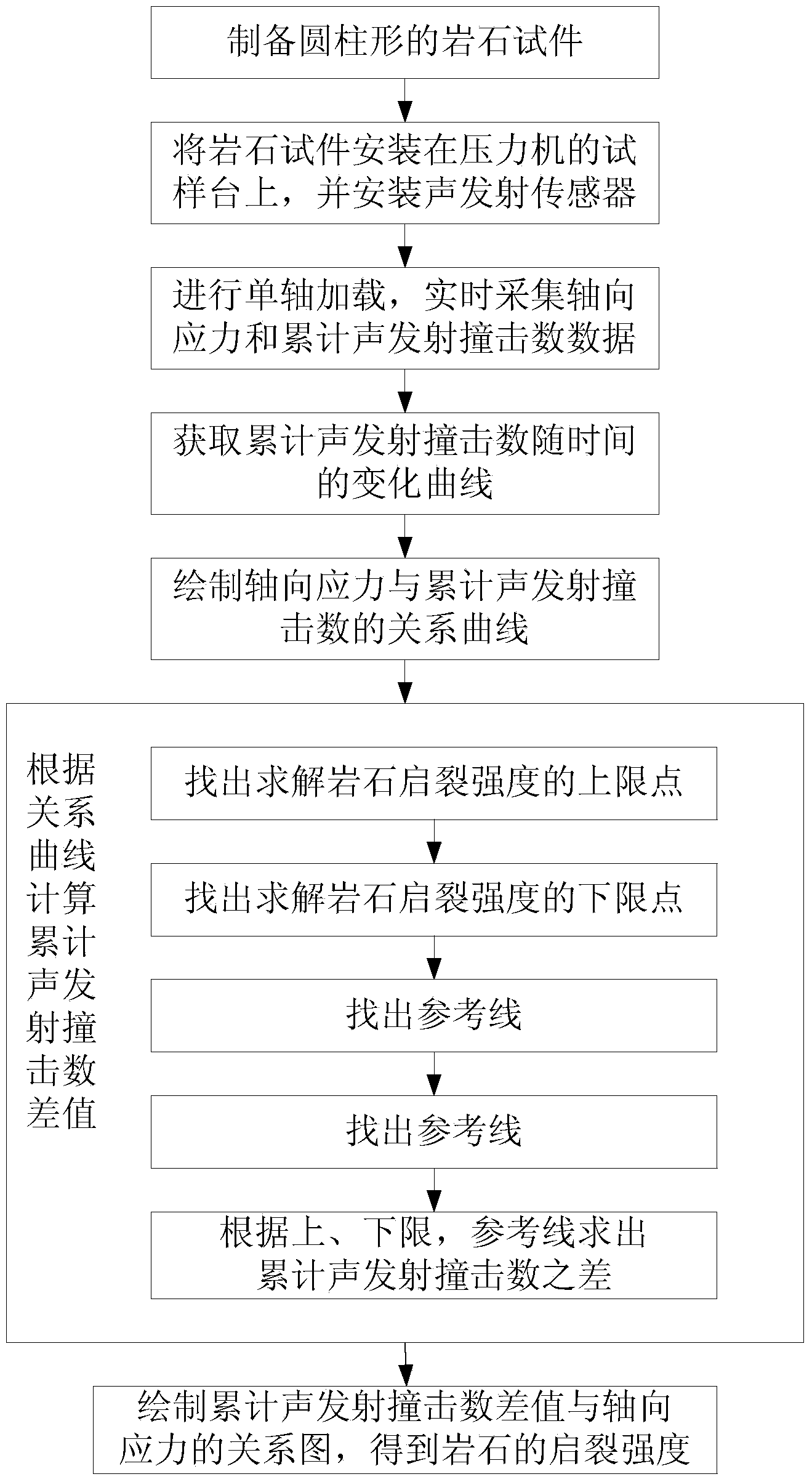

[0046] Such as figure 1 As shown, a method for objectively determining rock crack initiation strength based on the accumulated acoustic emission impact number includes the following steps in turn:

[0047] Step S1: Processing the complete core drilled on site to prepare a cylindrical rock specimen;

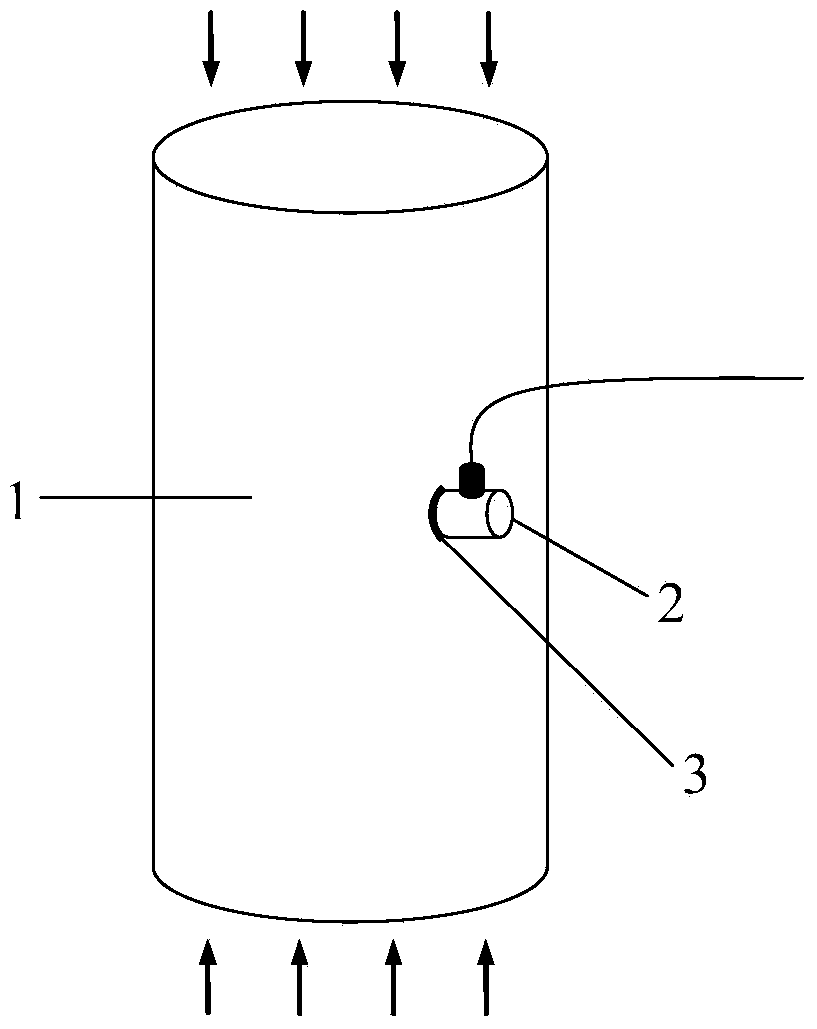

[0048] Step S2: Install the rock sample on the sample table of the press, and install the acoustic emission sensor in the middle of the rock sample. Usually, the piezoelectric ceramic surface of the acoustic emission sensor is in direct contact with the surface of the test piece, and the contact surface is coated with a thin layer Petroleum jelly as coupling agent;

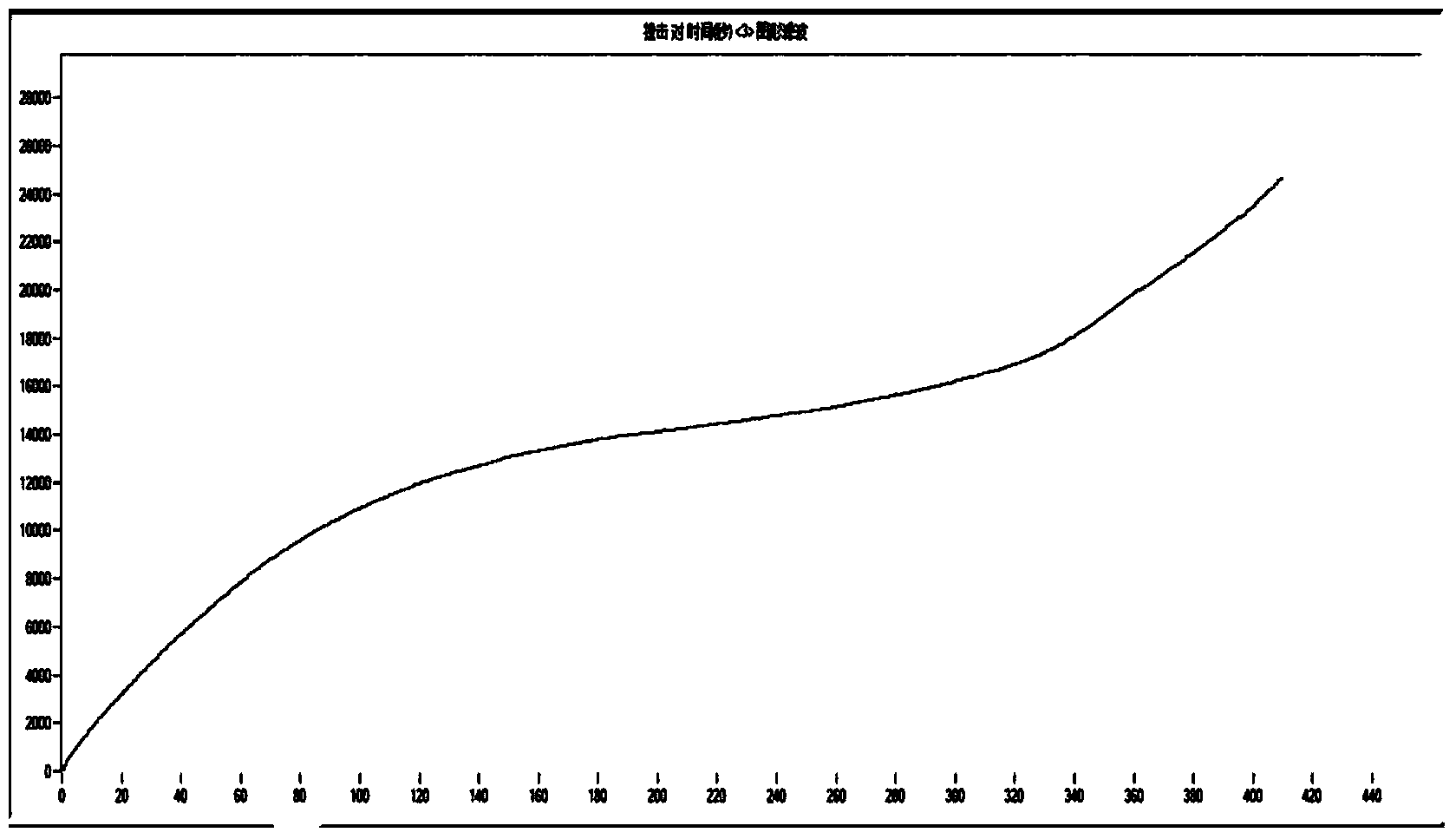

[0049] Step S3: Perform uniaxial loading on the rock specimen, keep the acoustic emission monitoring and the loading process synchronized, and collect the axial stress and the accum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com