Aero-engine W-shaped sealing ring manufacturing method

A technology of aero-engine and manufacturing method, which is applied in the field of sealing ring to achieve the effects of reducing production cost, high degree of process automation and low technical risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

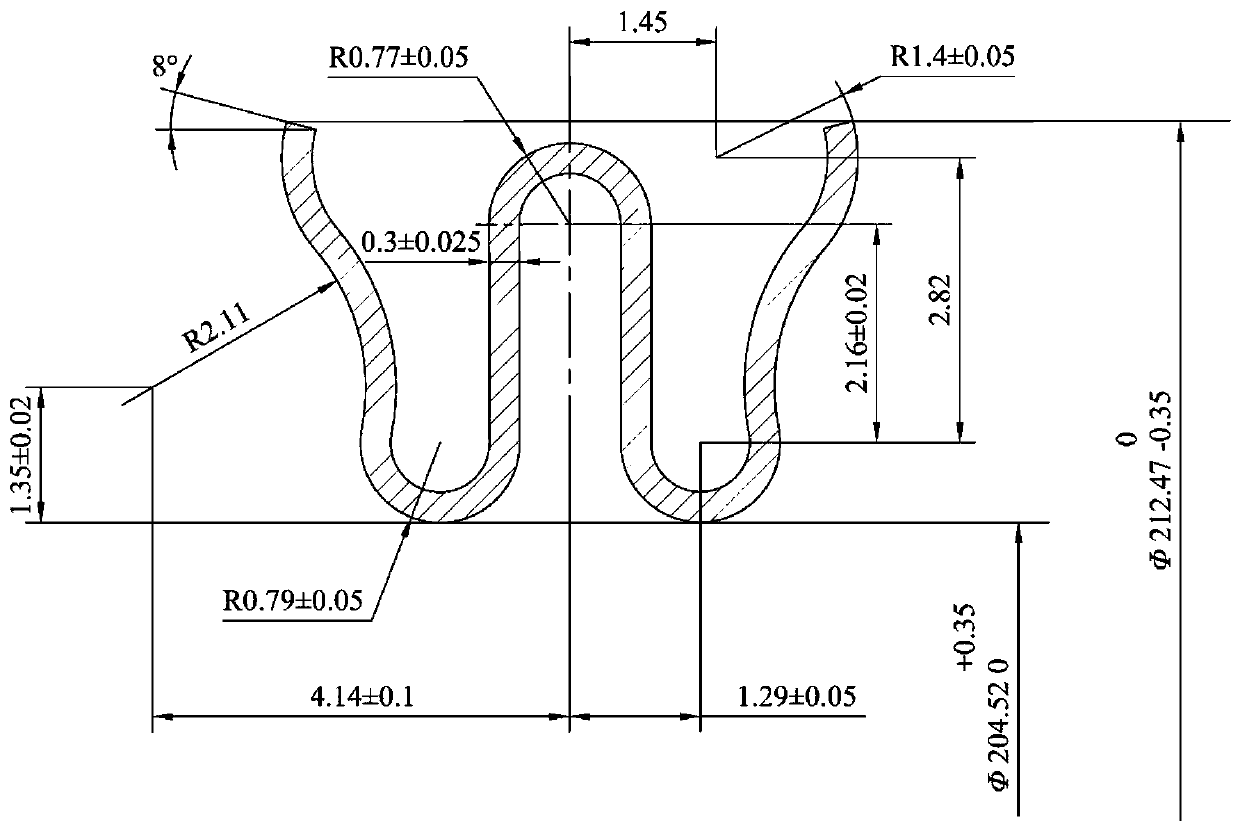

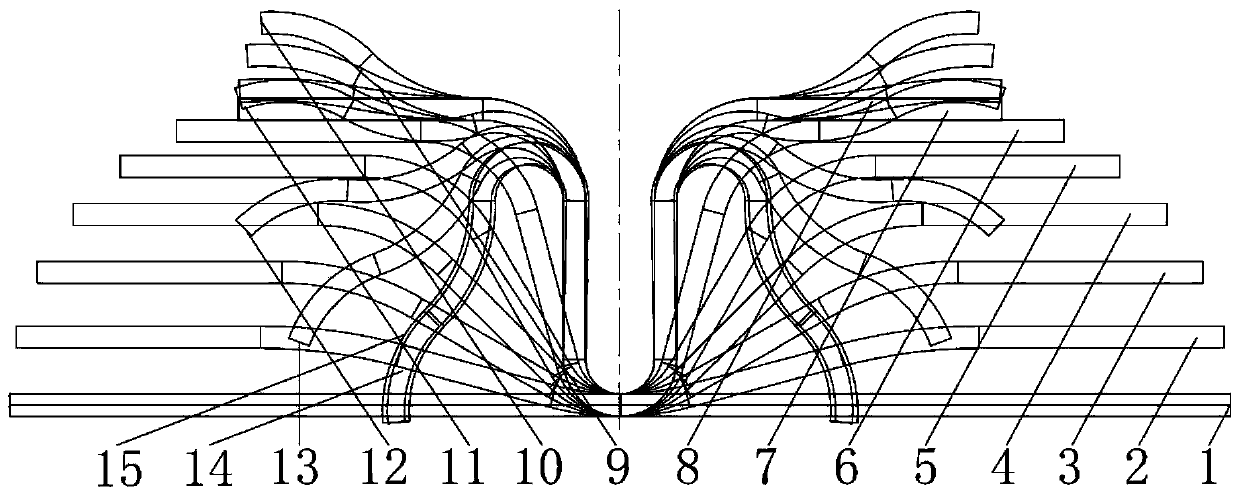

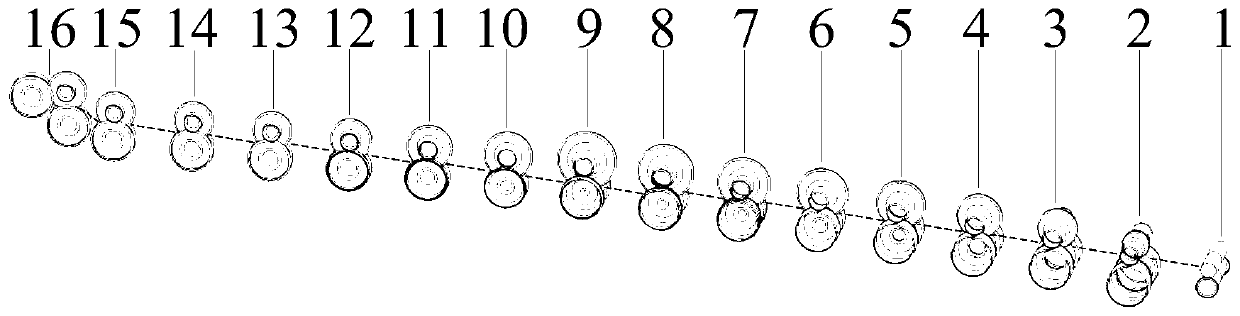

[0022] The W-shaped sealing ring part targeted by the present invention has horizontal flanges on both sides of the "W", which did not participate in the deformation during the actual forming process. The main deformation area is the middle "W", so only the middle "W" part of the analysis. The material used is age-hardening nickel-based deformed superalloy GH4169. The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0023] A kind of aero-engine W-shaped sealing ring manufacturing method of the present invention, concrete steps are as follows:

[0024] Step 1. According to the structural form of the W-shaped sealing ring that needs to be formed, such as figure 1 As shown, calculate the number of passes required for forming;

[0025] (1), calculate the board width

[0026] The part section consists of straight line entities and arc entities. Sheet width = length of all straight line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com