Hard alloy impact fatigue testing method

An impact fatigue and cemented carbide technology, which is used in the application of repetitive force/pulsation force to test the strength of materials, etc., can solve the problems of no impact fatigue detection method for cemented carbide products, hindering the development speed of new products, and increasing research and development costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

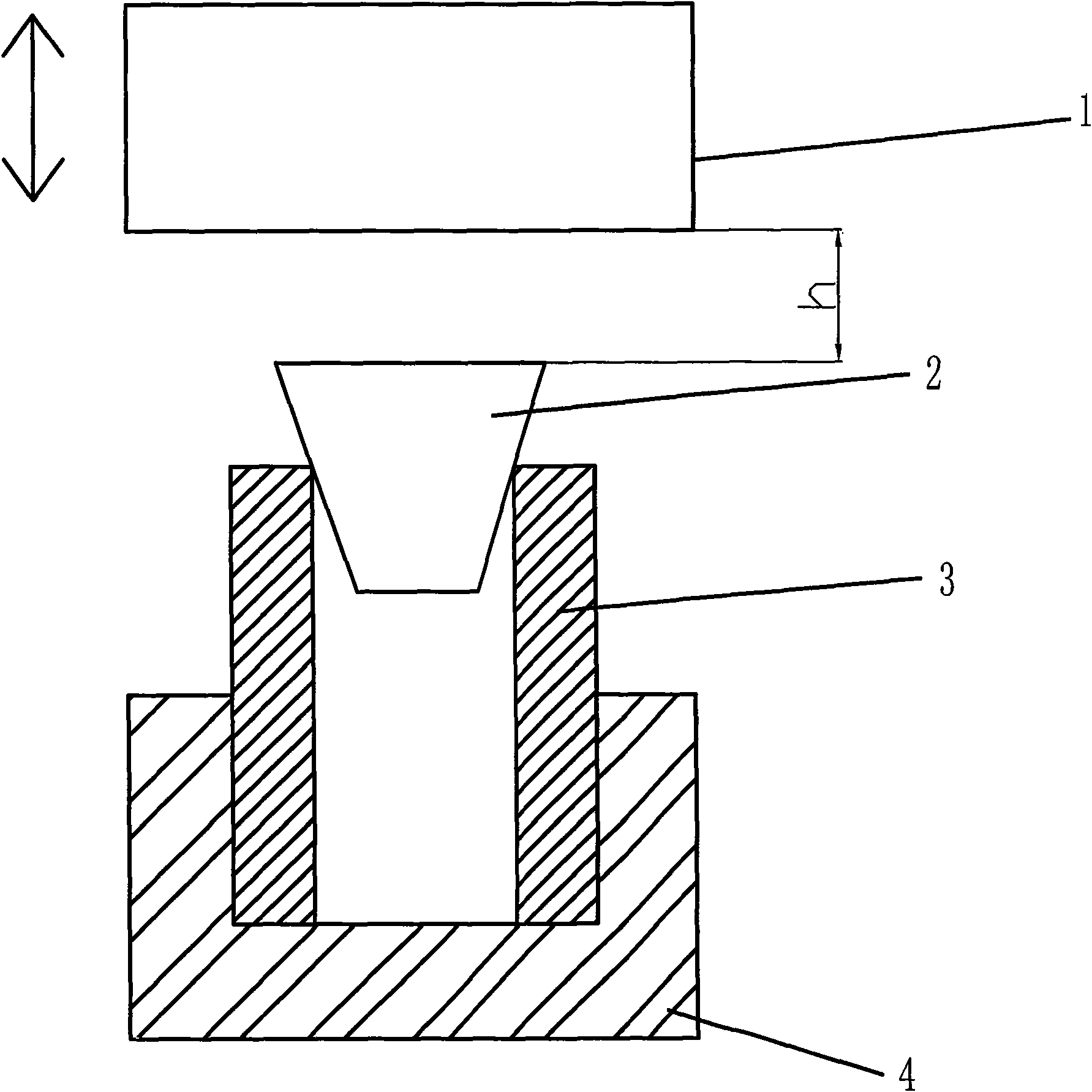

[0016] Attached below figure 1 , the detection method, standard sample, indenter and specific detection process of the cemented carbide impact fatigue performance of the present invention are described in detail.

[0017] The sample material adopts three typical cemented carbide grades YG6, YG15 and YG20.

[0018] The sample is made by typical cemented carbide production process. That is, Co powder and WC powder with a certain composition are firstly wet-ground, mixed with molding agent after drying, and pressed into a thin-walled cylindrical blank. The sintering temperature is 1410-1450°C. The thin-walled cylindrical sample 3 preferably has an outer diameter of Φ16 mm, a wall thickness of 3.5 mm, and a height of 20 mm. The properties of the three grades are shown in Table 1.

[0019] A round table or conical indenter 2 made of hard alloy is prepared by the same process, the hardness is greater than HRA90, and the diameter of the bottom surface of the round table or cone ty...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com