Fluorescent glass with low melting point for white light LED and preparation method thereof

A fluorescent glass, low melting point technology, applied in the field of luminescent materials, can solve the problems of reduced luminous efficiency of fluorescent powder, drift of white light tone, easy aging of epoxy resin, etc. The effect of durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

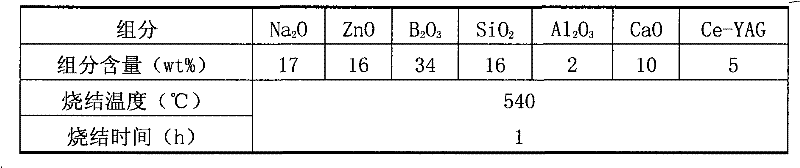

[0030] Fluorescent glass with low melting point for white light LED, which contains Na 2 O, ZnO, B 2 o 3 , SiO 2 , Al 2 o 3 , CaO, MgO, K 2 The raw materials of O and Ce-YAG components were prepared; the mass percentage of each component is shown in Table 1.

[0031] Table 1

[0032]

[0033] Concrete preparation process is as follows: 1) at first according to the formula weighing in table 1 certain weight analysis pure raw material (Na 2 CO 3 , ZnO, H 3 BO 3 , SiO 2 , Al 2 o 3 , CaCO 3 and Ce-YAG raw material);

[0034] 2) Na 2 CO 3 , ZnO, H 3 BO 3 , SiO 2 , Al 2 o 3 , CaCO 3 The raw materials are mixed evenly and melted at a melting temperature of 900°C, and kept for 2 hours to obtain molten glass;

[0035] 3) Pour the glass liquid into cold water, carry out water quenching to cool down, and obtain a transparent matrix glass;

[0036] 4) Grind the glass into powder and mix it evenly with Ce-YAG, place it in the sintering furnace, 2 Sintering under...

Embodiment 2

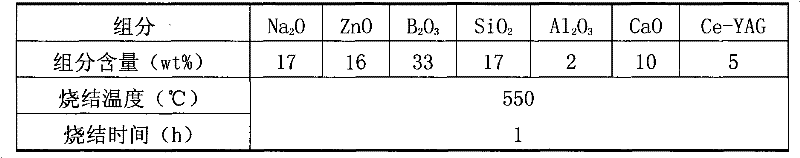

[0040] Fluorescent glass with low melting point for white light LED, which contains Na 2 O, ZnO, B 2 o 3 , SiO 2 , Al 2 o 3 , CaO, MgO, K 2 The raw materials of O and Ce-YAG components are prepared; the mass percentage of each component is shown in Table 2.

[0041] Table 2

[0042]

[0043] Concrete preparation process is as follows: 1) at first according to the formula weighing in table 2 certain weight analysis pure raw material (Na 2 CO 3 , ZnO, H 3 BO 3 , SiO 2 , Al 2 o 3 , CaCO 3 and Ce-YAG raw material);

[0044] 2) Na 2 CO 3 , ZnO, H 3 BO 3 , SiO 2 , Al 2 o 3 , CaCO 3 The raw materials are mixed evenly and melted at a melting temperature of 910°C, and kept for 2 hours to obtain molten glass;

[0045] 3) Pour the glass liquid into cold water, carry out water quenching to cool down, and obtain a transparent matrix glass;

[0046] 4) Grind the glass into powder and mix it evenly with Ce-YAG, place it in the sintering furnace, 2 Sintering under a ...

Embodiment 3

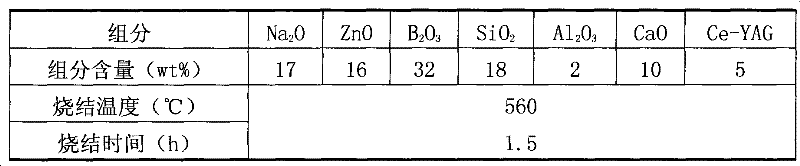

[0049] Fluorescent glass with low melting point for white light LED, which contains Na 2 O, ZnO, B 2 o 3 , SiO 2 , Al 2 o 3 , CaO and Ce-YAG components are prepared from raw materials; the mass percentage of each component is shown in Table 3.

[0050] table 3

[0051]

[0052] Concrete preparation process is as follows:

[0053] 1) First weigh a certain weight analysis pure raw material according to the formula in table 3 (Na 2 CO 3 , ZnO, H 3 BO 3 , SiO 2 , Al 2 o 3 , CaCO 3 and Ce-YAG raw material);

[0054] 2) Na 2 CO 3 , ZnO, H 3 BO 3 , SiO 2 , Al 2 o 3 , CaCO 3 The raw materials are mixed evenly and melted at a melting temperature of 920°C, and kept for 2 hours to obtain molten glass;

[0055] 3) Pour the glass liquid into cold water, carry out water quenching to cool down, and obtain a transparent matrix glass;

[0056] 4) Grind the glass into powder and mix it evenly with Ce-YAG, place it in the sintering furnace, 2 Sintering under a protect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com