Production technology of anti-corrosion prefabricated reinforced concrete inspection well

A technology of corrosion-resistant concrete and reinforced concrete, which is applied to water supply devices, waterway systems, drainage structures, etc., and can solve problems such as poor impermeability, poor durability, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

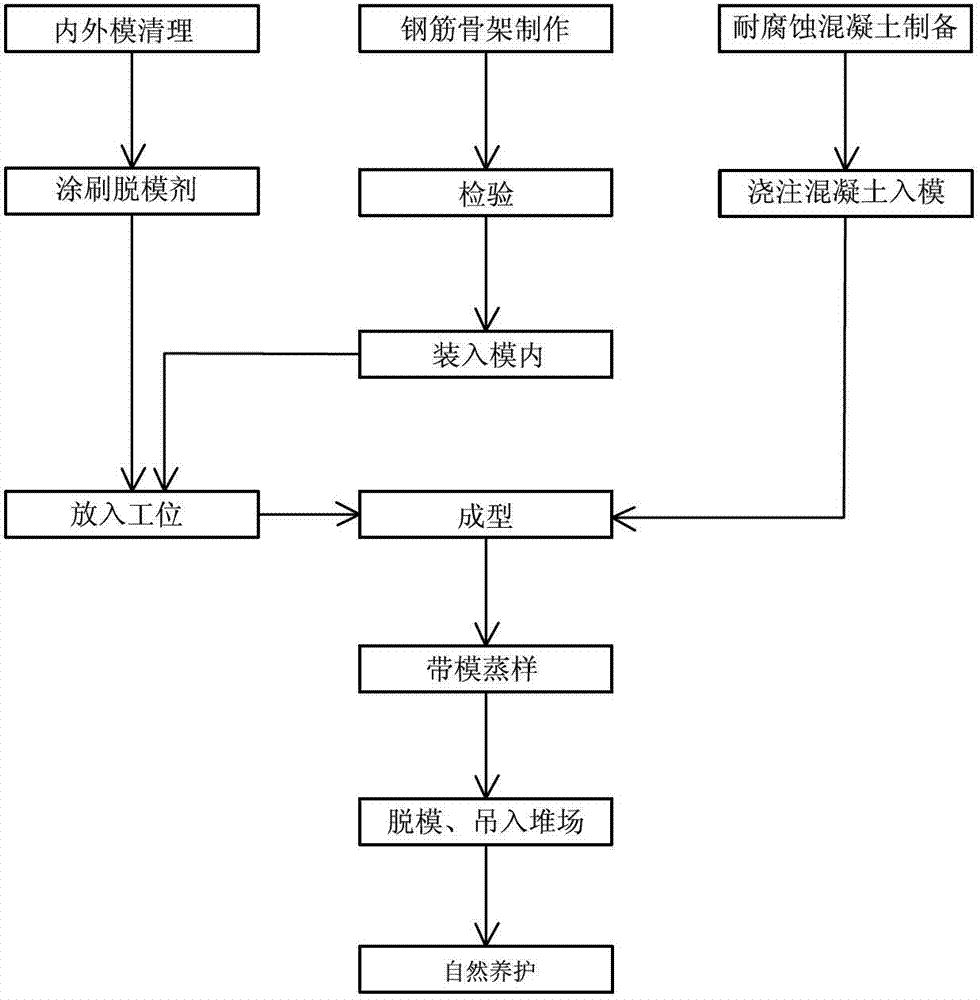

[0029] Such as figure 1 As shown, a production process of a corrosion-resistant prefabricated reinforced concrete inspection well, by using the corrosion-resistant material "alkali-activated slag fly ash concrete" to produce a prefabricated assembled reinforced concrete inspection well product with good corrosion resistance, high strength , good impermeability, factory prefabrication, short pipeline construction period, no pollution, energy saving and environmental protection, its manufacturing cost is similar to that of ordinary concrete inspection wells, but its service life is much higher than that of ordinary concrete inspection wells.

[0030] The invention provides a production process of a corrosion-resistant prefabricated reinforced concrete inspection well, which is further described in detail below, and its process flow includes the following steps:

[0031] A1. Clean the internal and external molds of the prefabricated corrosion-resistant concrete inspection well; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com