Electrical hot melting waterproof cover and method for achieving waterproof sealing of cable waterproof cover

A waterproof sealing and waterproof cover technology, which is applied to bridge parts, bridge materials, cable-stayed bridges, etc., can solve the problems of reduced waterproofness, easy corrosion, durability, and insufficient weather resistance, so as to improve sealing durability and sealing Good performance and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A two-half type electrothermal fusion waterproof cover:

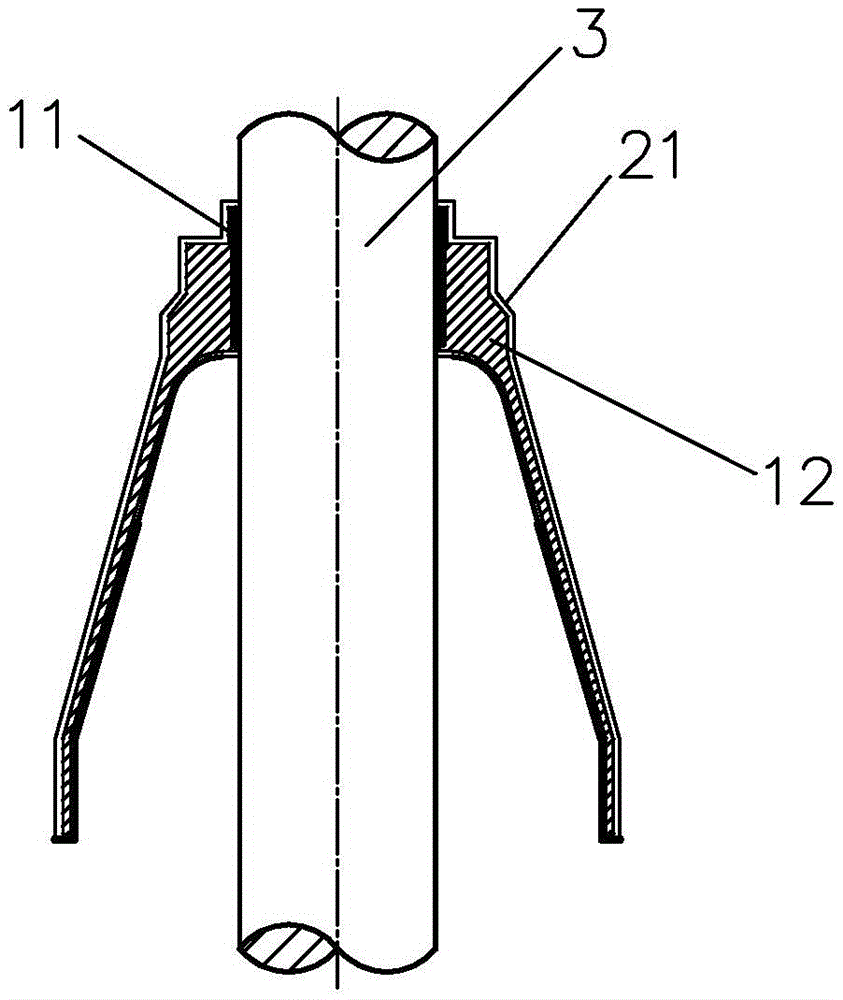

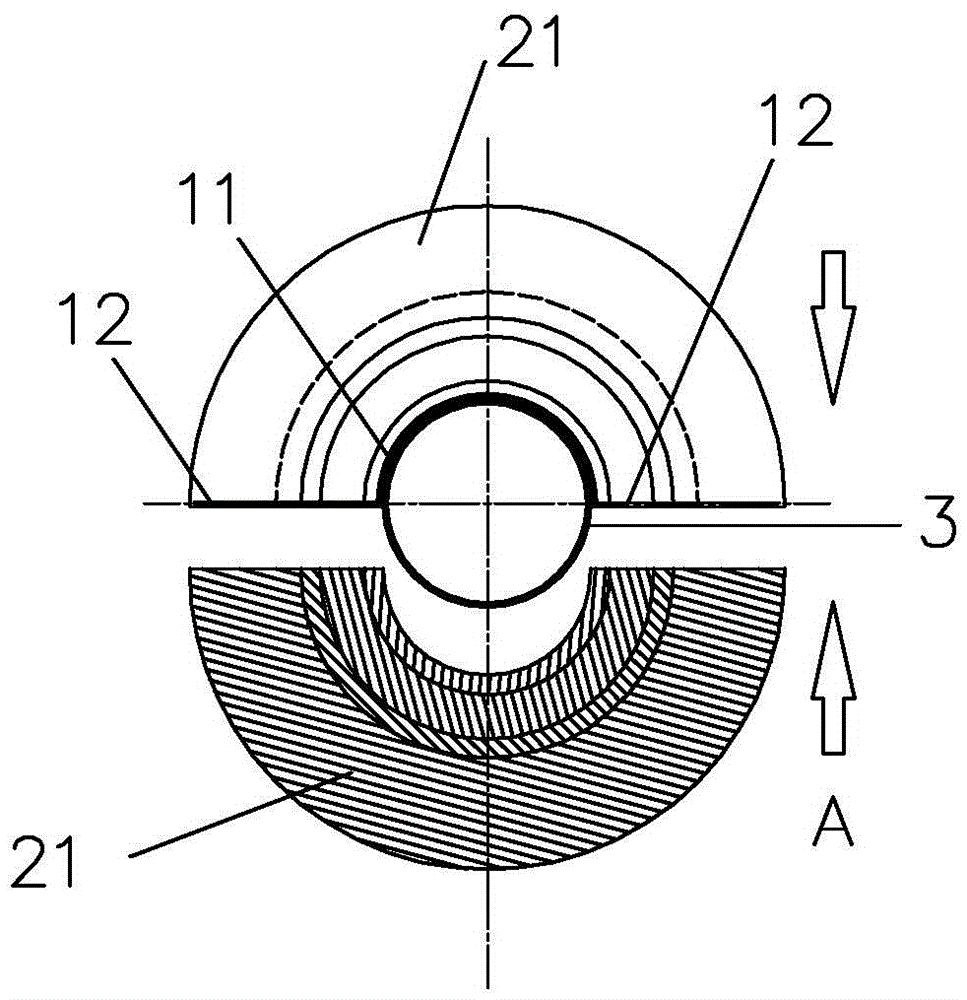

[0050] like Figure 1-Figure 2 As shown, the waterproof cover is a two-half waterproof cover sheet 21 composed of two identical waterproof cover sheets, and the heating element 1 includes a nozzle for being located at a two-half waterproof cover sheet 21, a The heat-generating element I11 is used to fuse the two halves of the waterproof cover sheet 21 and the sheath tube 3 into one body, and the longitudinal section of one of the two halves of the waterproof cover sheet 21 is used to heat the two halves of the waterproof cover sheet. The heating element II12 fused together, in the assembled state, after the heating element I11 is heated, the two halves of the waterproof cover sheet 21 and the sheath tube 3 are thermally melted and connected into one body, and the heating element II12 heats the two halves of the waterproof cover sheet 21 Fused together to form two halves of the electrothermal fusion waterproof co...

Embodiment 2

[0053] An integral one-piece electrothermal fusion waterproof cover:

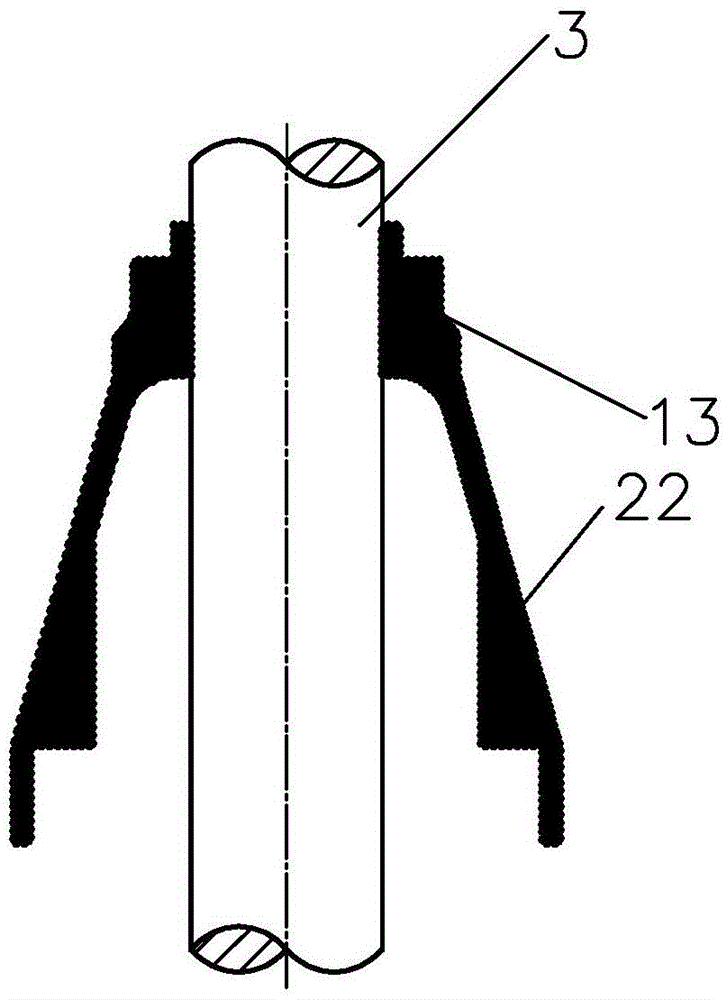

[0054] like Figure 3-Figure 4 As shown, the waterproof cover is an integral waterproof cover 22, at the mouth of the integral waterproof cover 22, there is a heating element III13 for thermally melting the integral waterproof cover 22 and the sheath pipe 3 into one, So as to form a whole one-piece electrothermal fusion waterproof cover (see image 3 , Figure 4 ).

Embodiment 3

[0056] An integral detachable electric thermal fusion waterproof cover:

[0057] like Figure 5 , Figure 7 As shown: the waterproof cover is an integral detachable waterproof cover 23, and the integral detachable waterproof cover 23 has a welding block 4 with a separate structure inside. Block 4 and the sheath tube 3 are thermally melted and integrated into a heating element IV14 (see Image 6 ), in use state, heating element Ⅳ14 thermally melts the welding block 4 and the sheath pipe 3 into one body, and the integral detachable waterproof cover 23 is coated with sealing material and is threaded into one body with the welding block 4, thus forming Integral detachable electric melting waterproof cover.

[0058] In Embodiment 1, Embodiment 2 and Embodiment 3, the two half-type waterproof cover pieces 21, the integral one-piece waterproof cover 22, the integral detachable waterproof cover 23 or the welding block 4 are all used with the cable body outermost The hot-melt mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com