Super-hydrophobic high-transmittance SiO2 anti-reflecting thin film and preparation method thereof

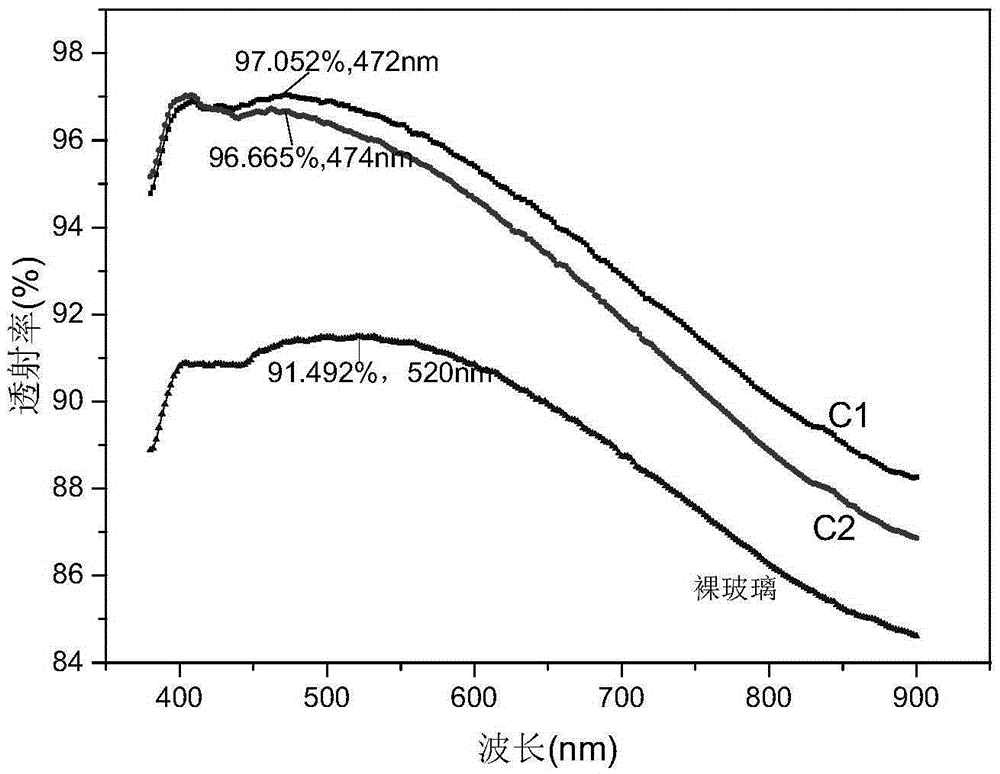

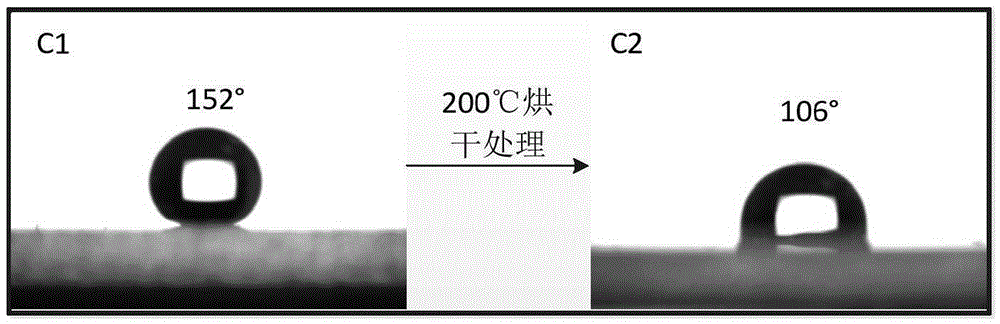

An anti-reflection and high-transmission technology, which is applied in the field of superhydrophobic high-transmission SiO2 anti-reflection film and its preparation, can solve the problems of low transmittance and high refractive index of the film, and achieve obvious anti-reflection effect, small transmittance attenuation, The effect of lowering the refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Superhydrophobic high transmittance SiO 2 The preparation method of anti-reflection film, the whole preparation process can be subdivided into three steps: preparation of sol, treatment of substrate and preparation of film (dipping and pulling, drying treatment).

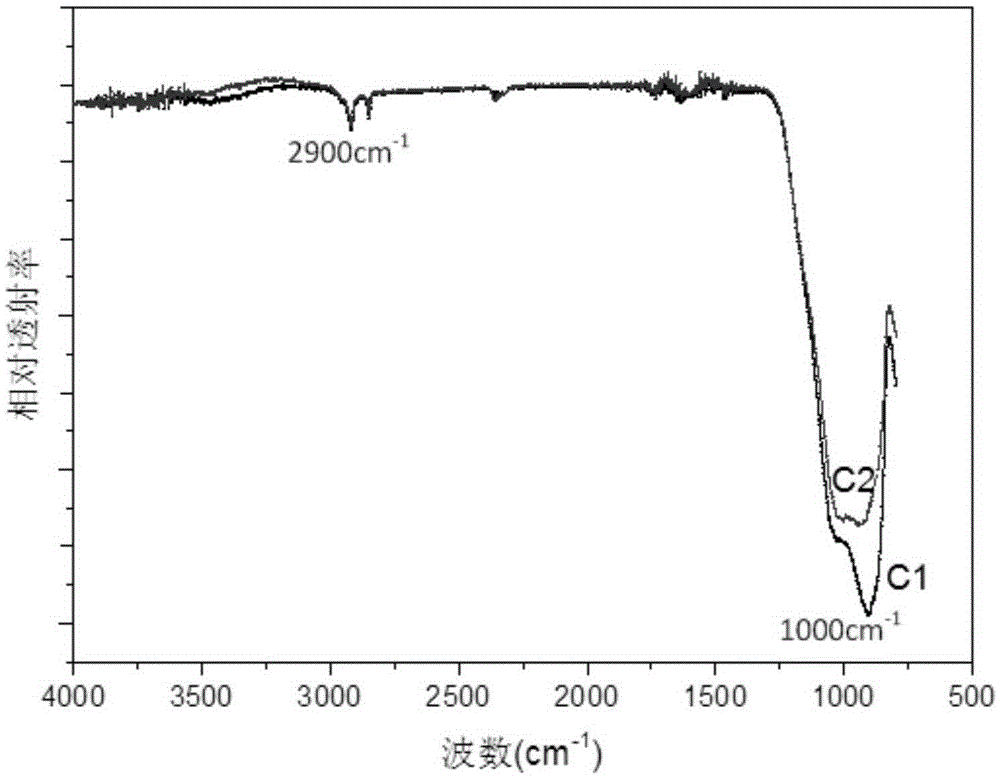

[0034]Preparation of sol: A TMES-doped hybrid sol was prepared by a sol-gel one-step method, and the hybrid sol was labeled SolC. Before the experiment, the beaker, measuring cylinder, dropper and other equipment were acid-washed, then ultrasonically cleaned for 30 minutes, finally rinsed with deionized water, and dried in an oven for later use. Preparation steps: in the first step, 1.3ml of ammonia water is added to 40ml of absolute ethanol, and the mixed solution is magnetically stirred at a constant temperature of 50°C for 10 minutes. In the second step, 1 ml of tetraethyl orthosilicate (TEOS) and 0.8 ml of trimethylethoxysilane (TMES) were mixed, and then added dropwise to the mixed solution of the first...

Embodiment 2

[0044] A superhydrophobic and highly transparent SiO 2 The preparation method of the anti-reflection film adopts the following steps:

[0045] (1) The hybrid sol doped with trimethylchlorosilane is prepared by the sol-gel method, and the following steps are specifically adopted:

[0046] (1-1) Add ammonia water to absolute ethanol, the volume ratio of ammonia water to absolute ethanol is 1:30, stir magnetically at a constant temperature of 40°C for 20 minutes to obtain a mixed solution;

[0047] (1-2) Mix ethyl orthosilicate and trimethylethoxysilane, the volume ratio of ethyl orthosilicate and trimethylethoxysilane is 1:0.5, and then add it dropwise to (1-1 ) to form a reaction solution in the mixed solution, the volume concentration of ethyl orthosilicate in the solution is 3.08%. ;

[0048] (1-3) The reaction solution was magnetically stirred at 30° C. for 30 h, and then aged at room temperature for 4 days to prepare a hybrid sol;

[0049] (2) Clean the surface of the g...

Embodiment 3

[0056] A superhydrophobic and highly transparent SiO 2 The preparation method of the anti-reflection film adopts the following steps:

[0057] (1) The hybrid sol doped with trimethylchlorosilane is prepared by the sol-gel method, and the following steps are specifically adopted:

[0058] (1-1) Add ammonia water to absolute ethanol, the volume ratio of ammonia water to absolute ethanol is 1:50, stir magnetically at a constant temperature of 60°C for 5 minutes to obtain a mixed solution;

[0059] (1-2) Mix ethyl orthosilicate and trimethylethoxysilane, the volume ratio of ethyl orthosilicate and trimethylethoxysilane is 1:1, then add dropwise to (1- 1) A reaction solution is formed in the mixed solution, and the volume concentration of ethyl orthosilicate in the solution is 1.89%. ;

[0060] (1-3) The reaction solution was magnetically stirred at 40°C for 15 hours, and then aged at room temperature for 6 days to prepare a hybrid sol;

[0061] (2) Clean the surface of the gla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com