Super-hydrophilic anti-fogging oxidized graphene coating, preparation method and application thereof

An anti-fogging and super-hydrophilic technology, which can be used in coatings, devices for coating liquids on surfaces, pre-treatment surfaces, etc. It can promote the application and development, solve the problems of poor durability and long durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

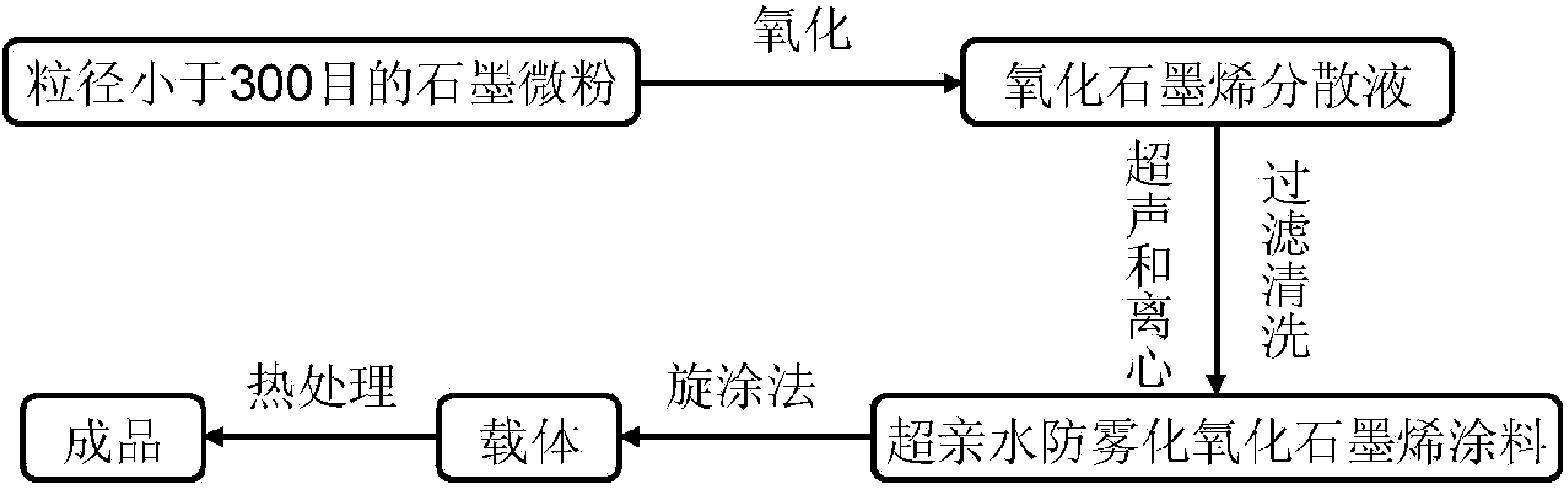

[0024] 1, the preparation method of a kind of superhydrophilic anti-atomization graphene oxide coating of the present embodiment, such as figure 1 As shown, the steps are as follows:

[0025] (1) be 325 purpose graphite micropowders with particle diameter as raw material, adopt Hummers method to prepare graphite oxide dispersion;

[0026] (2) Take 100ml of the above-mentioned graphite oxide dispersion, first add 100ml of deionized water to dilute, then filter and wash to neutrality, then ultrasonicate at 300W for 2 hours, and finally centrifuge at 15000 rpm for 2 hours, retain the upper layer liquid, Obtaining concentration is the superhydrophilic antifogging graphene oxide coating of 0.1mg / ml.

[0027] 2. If figure 1 As shown, the method for preparing the super-hydrophilic anti-fogging graphene oxide coating in the present embodiment is as follows: at 300 rpm and 3500 rpm, process for 20 seconds respectively by using the spin coating method. The above-mentioned graphene ox...

Embodiment 2

[0030] 1, the preparation method of a kind of superhydrophilic anti-atomization graphene oxide coating of the present embodiment, such as figure 1 As shown, the steps are as follows:

[0031] (1) be that 400 order graphite micropowders are raw material with particle diameter, adopt Staudenmaier method to prepare graphite oxide dispersion liquid;

[0032] (2) Take 200ml of the above-mentioned graphite oxide dispersion, first add 100ml of deionized water to dilute, then filter and wash to neutrality, then ultrasonicate at 600W for 1 hour, and finally centrifuge at 10000 rpm for 3 hours, retain the upper layer liquid, The super-hydrophilic anti-fogging graphene oxide coating with a concentration of 0.2 mg / ml was obtained.

[0033] 2. If figure 1 As shown, the method for preparing the super-hydrophilic anti-fogging graphene oxide coating in the present embodiment is as follows: at 350 rev / min and 4000 rev / min, process for 30 seconds respectively, The above-mentioned graphene ox...

Embodiment 3

[0036] 1, the preparation method of a kind of superhydrophilic anti-atomization graphene oxide coating of the present embodiment, such as figure 1 As shown, the steps are as follows:

[0037] (1) be 400 purpose graphite micropowders with particle diameter as raw material, adopt Brodie method to prepare graphite oxide dispersion;

[0038] (2) Take 50ml of the above-mentioned graphite oxide dispersion, first add 100ml of deionized water to dilute, then filter and wash to neutrality, then ultrasonicate at 300W for 2 hours, and finally centrifuge at 15000 rpm for 2 hours, retain the upper layer liquid, Obtaining concentration is the superhydrophilic antifogging graphene oxide coating of 0.1mg / ml.

[0039] 2. If figure 1 As shown, the method for preparing the super-hydrophilic anti-fogging graphene oxide coating in the present embodiment is as follows: at 250 rev / min and 3000 rev / min, process for 20 seconds respectively, The above-mentioned graphene oxide coating is coated on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com