Polyphenyl plate thinly plastered external insulation system of outer wall

A technology of external wall insulation and polystyrene board, which is applied in thermal insulation, building components, sustainable waste treatment, etc., and can solve problems such as cracks and easy aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

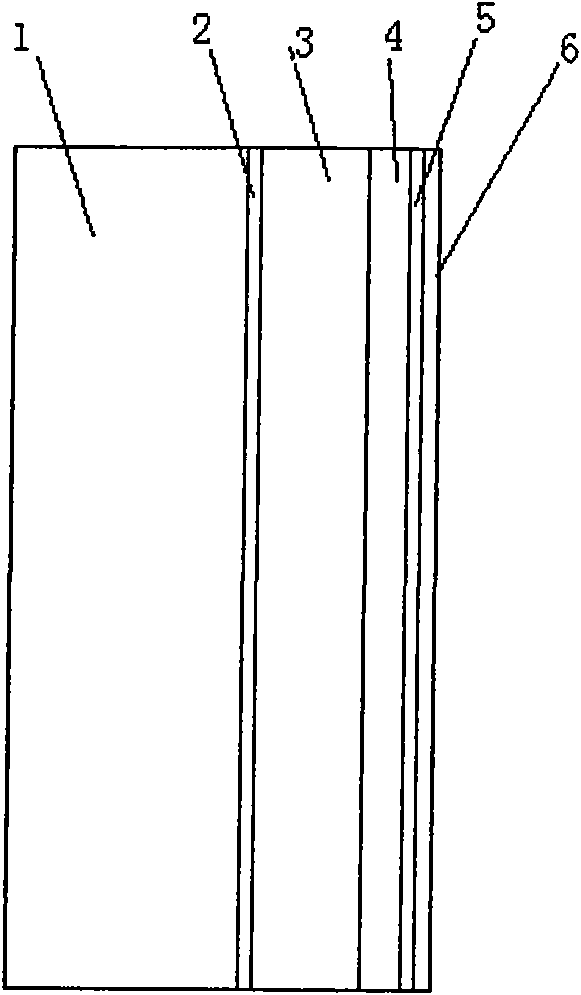

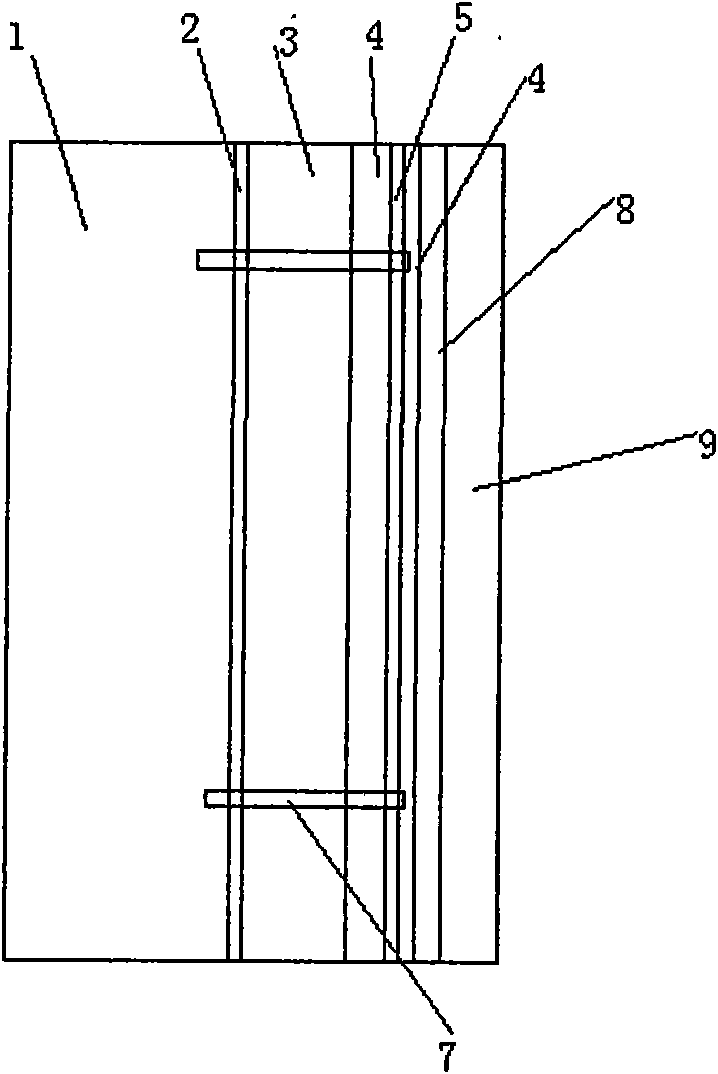

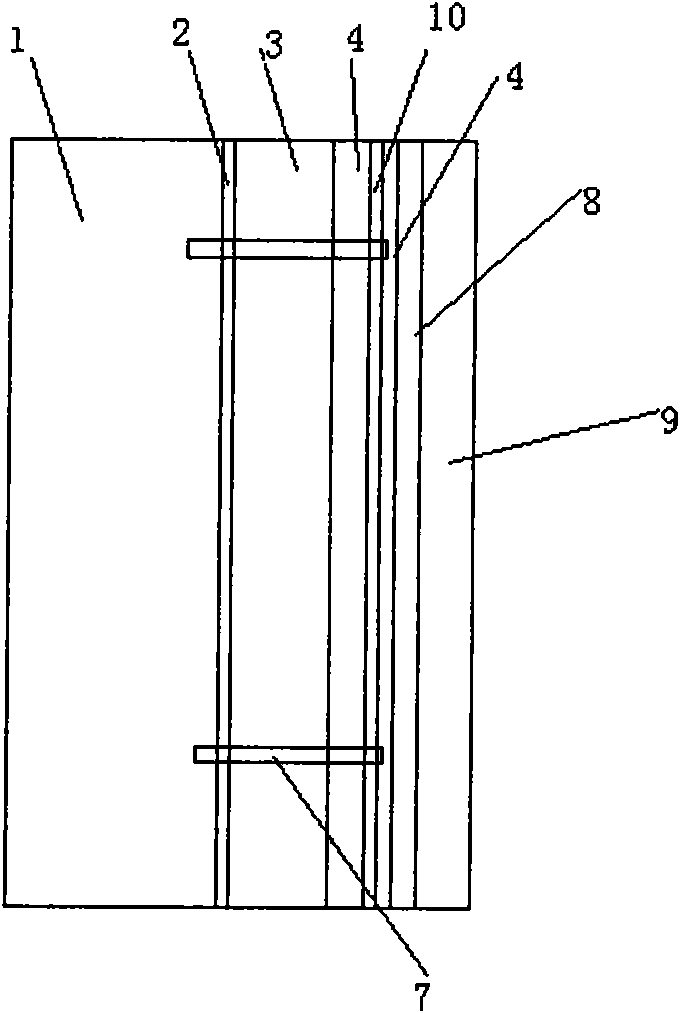

[0008] figure 1 The shown embodiment 1 includes a wall structure layer 1, which is characterized in that: outside the wall structure layer 1 there are thermal insulation layer, anti-crack protection layer and finish layer. The insulation layer is composed of adhesive mortar 2 and flame-retardant expanded polystyrene board 3 , the anti-crack protective layer is composed of anti-crack mortar 4 and glass fiber alkali-resistant grid cloth 5 , and the finishing layer is flexible putty 6 for external walls. figure 2 In the shown example 2, the insulation layer is composed of bonding glue 2, flame-retardant expanded polystyrene board 3, and the anti-crack protection layer is composed of anti-crack mortar 4 and glass fiber alkali-resistant grid cloth 5. There are pallet anchors 7 on the alkali grid cloth 5 to connect the wall structure layer 1, and the facing layer is composed of anti-crack mortar 4, flexible tile adhesive 8 and tiles 9. image 3 In Example 3 shown, the insulation l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com