Preparation method of high strength antibacterial non-woven fabric

A non-woven, antibacterial technology, applied in the field of preparation of high-strength antibacterial non-woven fabrics, can solve the problems of easy weathering, unsolved aging resistance, poor mechanical properties, affecting strength properties, etc., and achieves excellent oxygen barrier. and oil resistance, excellent mechanical properties, and the effect of enhancing strength properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

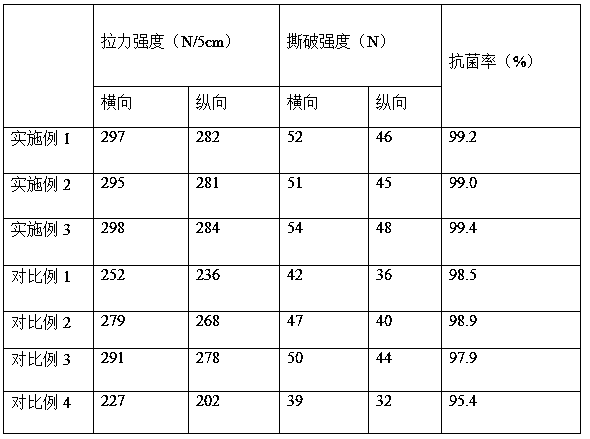

Examples

Embodiment 1

[0025] A kind of preparation method of high-strength antibacterial non-woven fabric of the present embodiment, comprises the following steps:

[0026] Step 1: Add 50 parts of polypropylene into the calciner, raise the temperature to 220°C until the polypropylene is completely melted, then add 10 parts of modified liquid, increase the stirring speed to 200r / min, stir for 10min, and then add 5 1 part of rice husk powder, 1 part of polytriazole resin, continue to stir for 20 minutes, and then add 2 parts of lignin;

[0027] Step 2: adding the melted raw materials in step 1 into a twin-screw extruder for extrusion, and then spraying them into filaments, and then spraying the cellulose on the nanofiber meshes, placing them at high temperature for bonding, Then cool it down;

[0028] Step 3: Place the non-woven fabric formed in Step 2 in the treatment solution, react at a temperature of 75°C for 35 minutes, then air-dry it, then wash it twice in deionized water, and then air-dry it...

Embodiment 2

[0037] A kind of preparation method of high-strength antibacterial non-woven fabric of the present embodiment, comprises the following steps:

[0038] Step 1: Add 60 parts of polypropylene into the calciner, raise the temperature to 280°C until the polypropylene is completely melted, then add 20 parts of modified liquid, increase the stirring speed to 300r / min, stir for 20min, and then add 10 Part of rice husk powder, 4 parts of polytriazole resin, continue stirring for 30min, then add 4 parts of lignin;

[0039] Step 2: adding the melted raw materials in step 1 into a twin-screw extruder for extrusion, and then spraying them into filaments, and then spraying the cellulose on the nanofiber meshes, placing them at high temperature for bonding, Then cool it down;

[0040]Step 3: Place the non-woven fabric formed in Step 2 in the treatment liquid, react at 85°C for 35-45 minutes, then air-dry, then wash in deionized water repeatedly for 3 times, and then air-dry for the second t...

Embodiment 3

[0049] A kind of preparation method of high-strength antibacterial non-woven fabric of the present embodiment, comprises the following steps:

[0050] Step 1, add 55 parts of polypropylene into the calciner, raise the temperature to 250°C until the polypropylene is completely melted, then add 15 parts of modified liquid, increase the stirring speed to 250r / min, stir for 15min, and then add 7.5 Part of rice husk powder, 2.5 parts of polytriazole resin, continue stirring for 25min, then add 3 parts of lignin;

[0051] Step 2: adding the melted raw materials in step 1 into a twin-screw extruder for extrusion, and then spraying them into filaments, and then spraying the cellulose on the nanofiber meshes, placing them at high temperature for bonding, Then cool it down;

[0052] Step 3: Place the non-woven fabric formed in step 2 in the treatment solution, react at 80°C for 40 minutes, then air-dry, then place in deionized water for repeated washing 3 times, and then air-dry for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com