Ultrathin anti-skid wearing layer and pavement with wearing layer

A wear layer, ultra-thin technology, applied in the field of cohesive pavement, roads, roads and other directions, can solve the problem of anti-skid performance of the road surface, the reduction of the mechanical strength and durability of thermoplastic asphalt mixture, and improve the anti-skid performance. Sliding ability, faster construction time, and increased contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

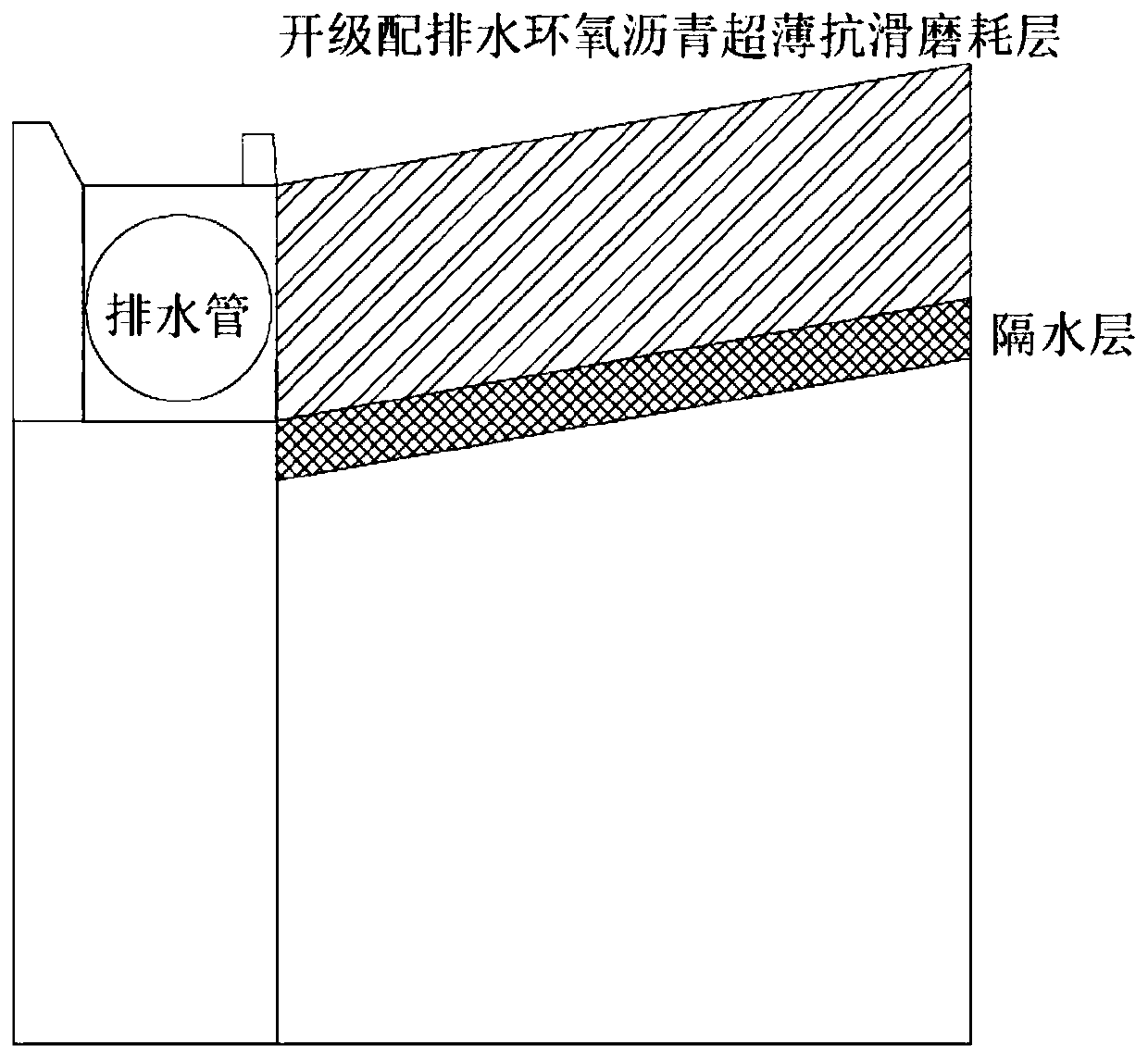

[0027] see figure 1 , the overall structure of the ultra-thin anti-skid wear layer of the open graded drainage type epoxy asphalt of the present invention is shown in the figure. Use open-graded epoxy asphalt mixture with a maximum nominal particle size of 4.75 mm and a porosity between 15% and 20% to pave an open-graded drainage type ultra-thin anti-skid wear layer with a thickness of 1 cm. Solve the problem of the reduction of the mechanical strength and durability of thermoplastic asphalt mixture caused by the combined action of cyclic load, temperature stress and water. Open-graded asphalt mixture with large porosity is good for draining rainwater from the road surface, reducing water drift when the car is running at high speed, increasing the contact area between the tire and the road surface, and improving the anti-skid ability of the asphalt wear layer. The maximum nominal particle size of 4.75mm ensures that the asphalt surface layer is an ultra-thin wear layer of 1c...

Embodiment 2

[0032] The anti-slip ultra-thin wear layer of the present invention also provides an open-graded drainage type epoxy asphalt mixture with a maximum nominal particle size of 4.75 mm. The anti-slip surface layer can not only improve the high temperature performance and fatigue resistance of the surface layer , At the same time, it is beneficial to surface drainage and increases the anti-skid performance of the vehicle when driving at high speed. The following is the specific introduction of the asphalt mixture:

[0033] (1) Mineral material grading

[0034] Aiming at the characteristics of open-graded epoxy asphalt ultra-thin anti-slip wear layer, a kind of open-graded drainage type epoxy asphalt ultra-thin anti-slip wear layer mixture (PEAM-4) of the present invention has a maximum nominal particle size of 4.75mm, which can control the thickness of the surface layer to 1cm, which is conducive to reducing construction costs and speeding up the opening to traffic. It mainly incl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com