Metal soft solder for vacuum glass

A technology of vacuum glass and solder, which is applied in the field of brazing materials and can solve problems affecting the mechanical strength of vacuum glass, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

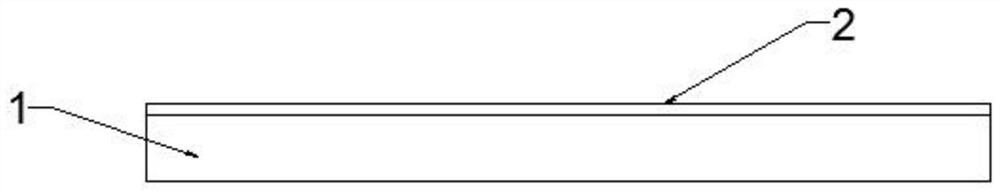

[0017] Example 1, such as figure 1 Shown is: a metal solder for vacuum glass, comprising a solid strip-shaped body 1, the body 1 is an indium-tin alloy with a thickness of 0.3-0.6 mm and a width of 0.6-1.5 mm. The surface of the body 1 is coated with a nano-light-absorbing material 2, the nano-light-absorbing material 2 is an organic solution of nano-silver, nano-gold or nano-graphene, and the solvent of the organic solution is ethanol. The concentration of nano silver in the organic solution is 0.1%-2%. The body 1 is vacuum plasma cleaned before coating the nano light-absorbing material 2, and the surface contact angle of the body 1 after vacuum plasma cleaning is less than 15°.

[0018] The specific implementation process is as follows: In the production of vacuum glass, metal solder is used for sealing, the metal solder is sandwiched between two pieces of glass, a metallized layer is set on the glass for welding with metal solder, and laser welding is used The method adop...

Embodiment 2

[0019] Embodiment 2. In this embodiment, the nano light-absorbing material is an organic solution of nano gold.

Embodiment 3

[0020] Embodiment 3, in this embodiment, the nano light-absorbing material is an organic solution of nano-graphene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com