Spot welding method for reinforcing rib of corrugated sheet of corrugated oil tank

A corrugated fuel tank and reinforcing rib technology, applied in welding equipment, resistance welding equipment, metal processing equipment, etc., can solve problems such as increasing oil consumption, deformation and expansion of wave fins, and increasing costs, reducing oil injection and solving seepage. The effect of oil spills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

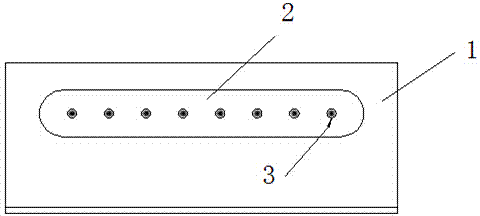

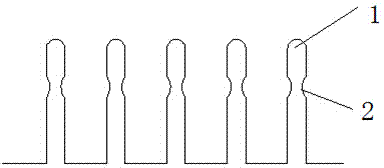

[0012] A method for spot welding corrugated sheet stiffeners of a corrugated fuel tank, the specific requirements are: using a long-arm welding machine, after adjusting the voltage and air pressure, the corrugated sheet 1 and the 2 stiffeners are pressed and formed, every 40-50mm along the length of the stiffeners. Carry out spot welding, spot welding position 3 such as figure 1 As shown, complete the spot welding of the corrugated sheet stiffeners of the corrugated fuel tank.

[0013] A single-point long-arm welding machine can be used to perform spot welding at intervals of 40-50 mm. A multi-point automatic welding machine can also be used to perform spot welding every 40-50 mm.

[0014] The invention uses the multi-spot welding process at the reinforcing rib to solve the problem of mechanical strength. After using the method, the wave fins are not deformed, and can withstand the mechanical strength of 50kPa, which is far greater than the national requirements; at the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com