A New Embedded Anti-Blow-by Oil Piston Structure

An oil-piston, anti-channeling technology, applied in the direction of pistons, variable-capacity pump components, liquid-variable-capacity machinery, etc., can solve the problem of increased cost, unfavorable normal use of air compressors or internal combustion engines, and increased friction between the piston and the inner wall of the cylinder liner. Loss and other problems to achieve the effect of solving oil channeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

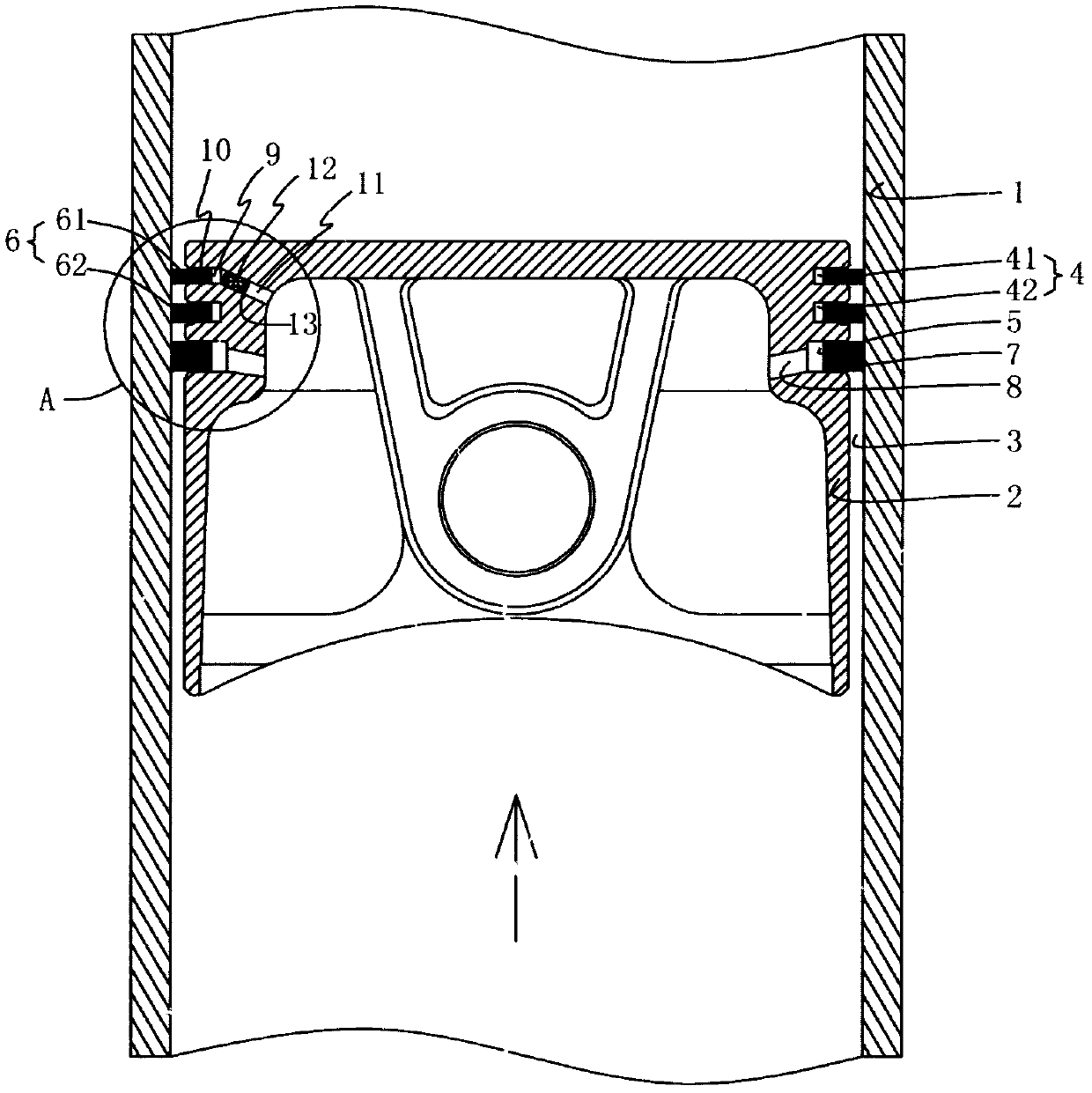

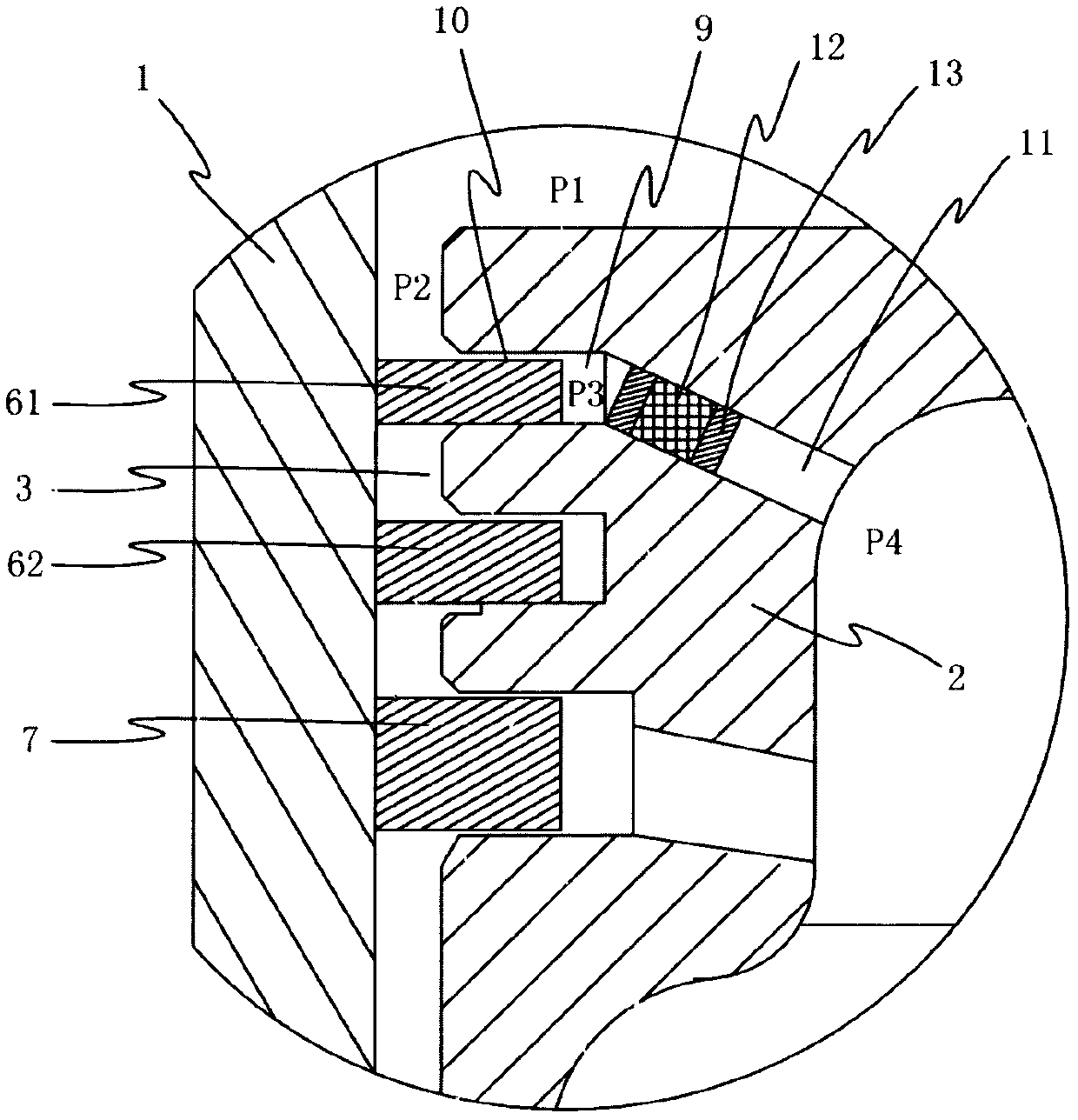

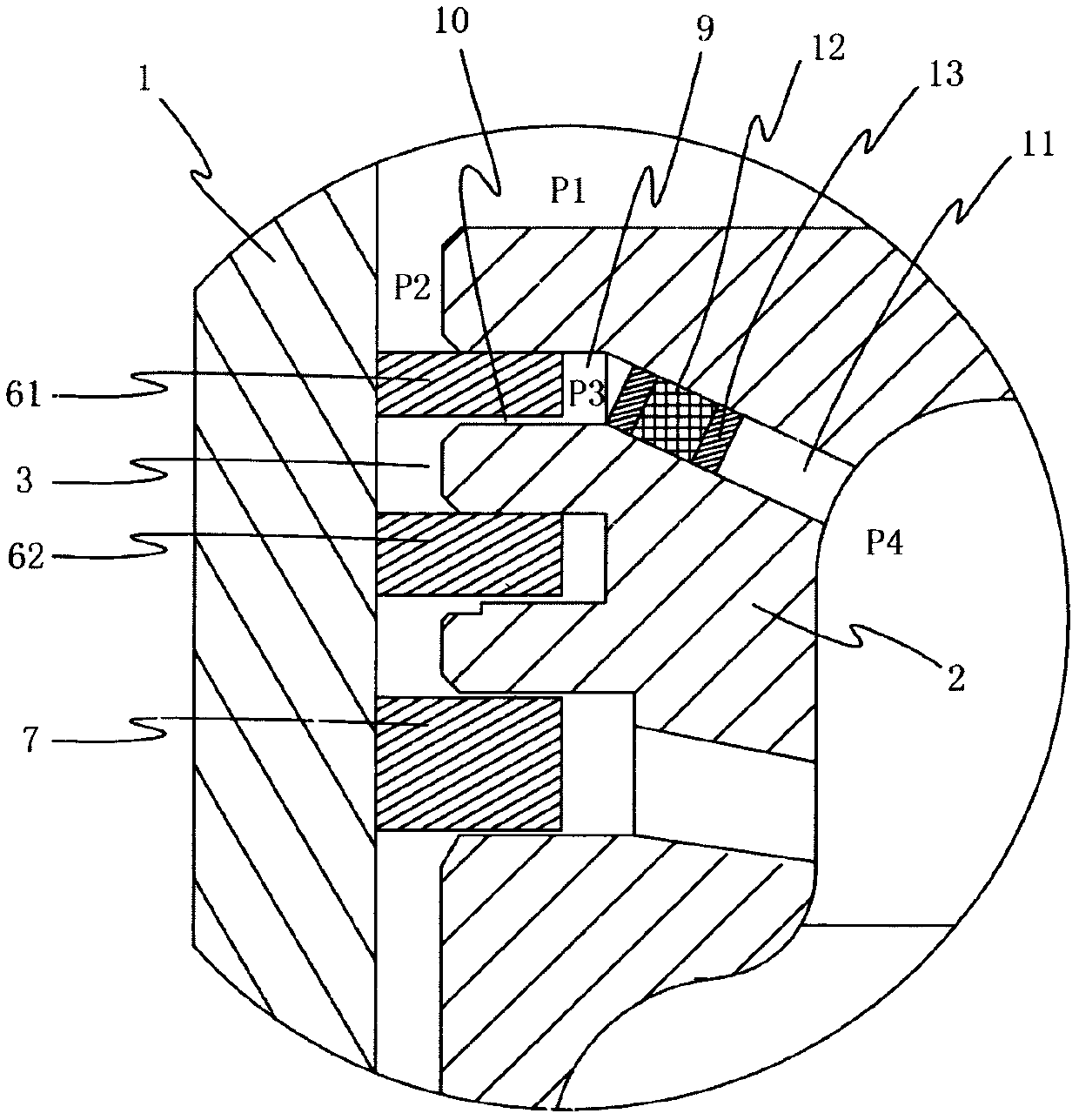

[0020] see Figure 1-Figure 4 , an embedded anti-bleeding piston structure, including a piston 2 arranged in the cylinder liner 1, a gap cavity 3 is provided between the outer wall of the piston 2 and the inner wall of the cylinder liner 1, and an air ring groove is arranged on the outer wall of the piston 2 from top to bottom 4 and the oil ring groove 5, the gas ring groove 4 is equipped with a gas ring 6 that is sealingly matched with the inner wall of the cylinder liner 1, wherein there are two gas ring grooves 4, which are respectively the first gas ring groove 41 and the second gas ring groove The ring groove 42, the first gas ring groove 41 is arranged above the second gas ring groove 42, the first gas ring groove 41 and the second gas ring groove 42 are respectively equipped with a first gas ring 61 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com