Patents

Literature

43results about How to "Solve oil leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

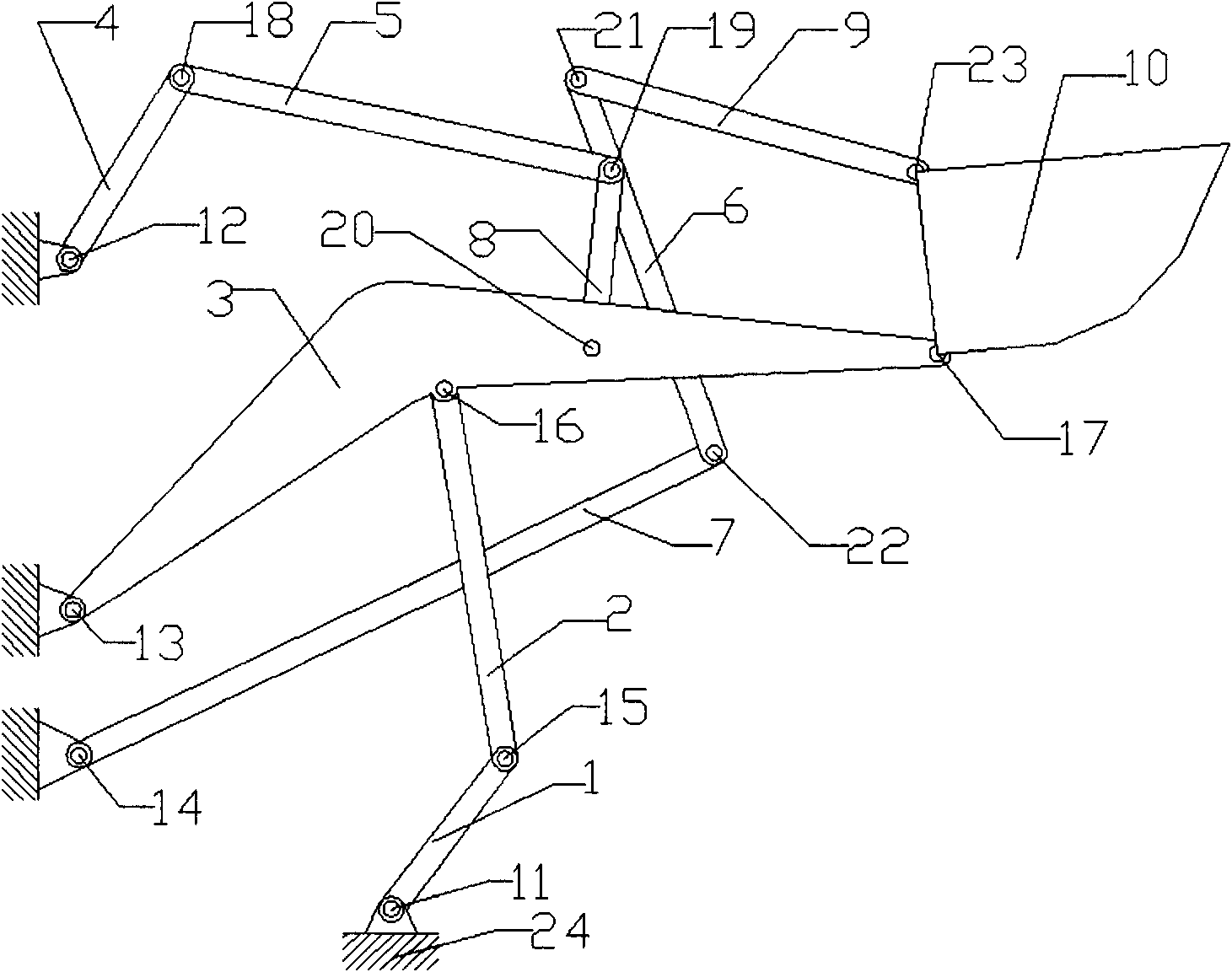

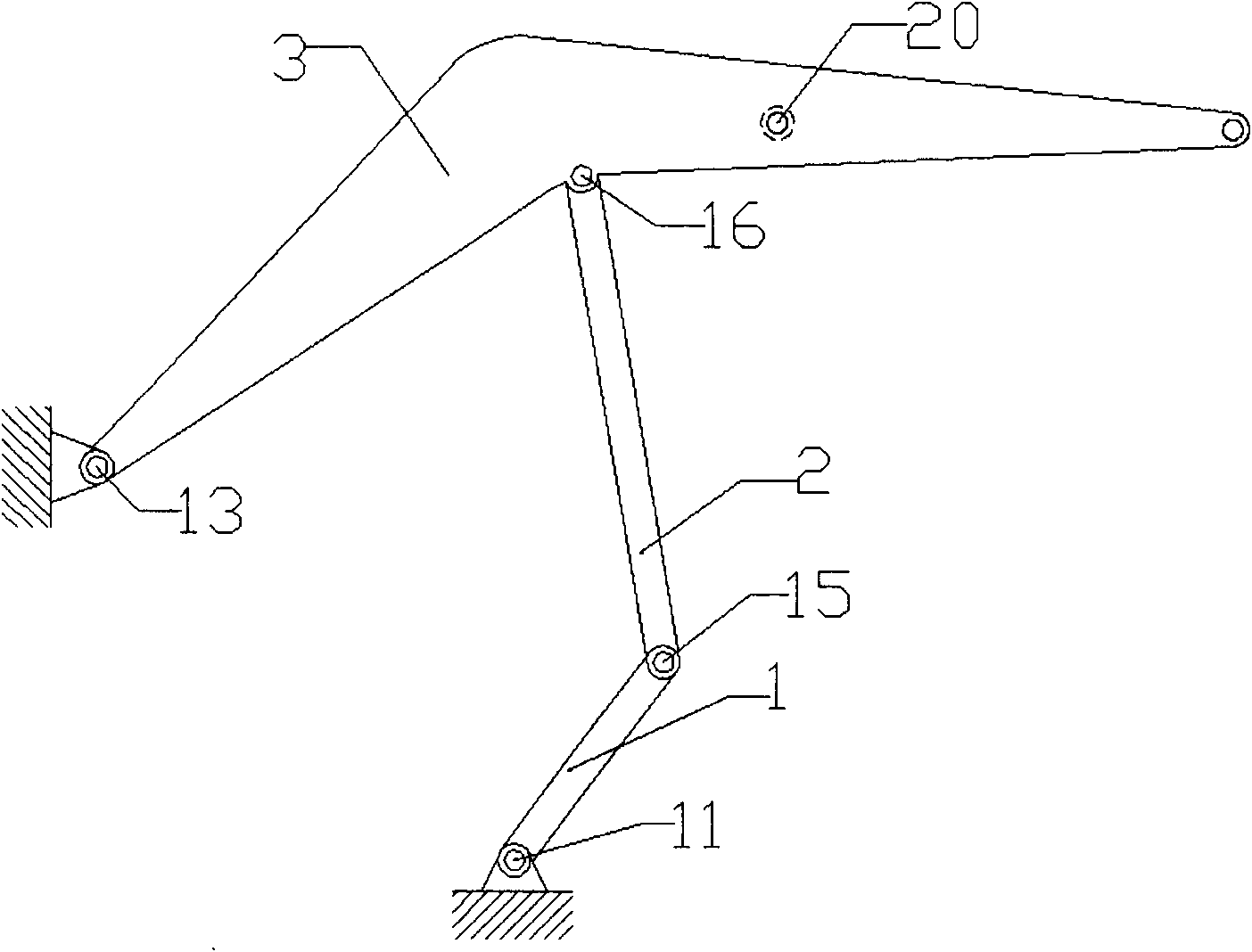

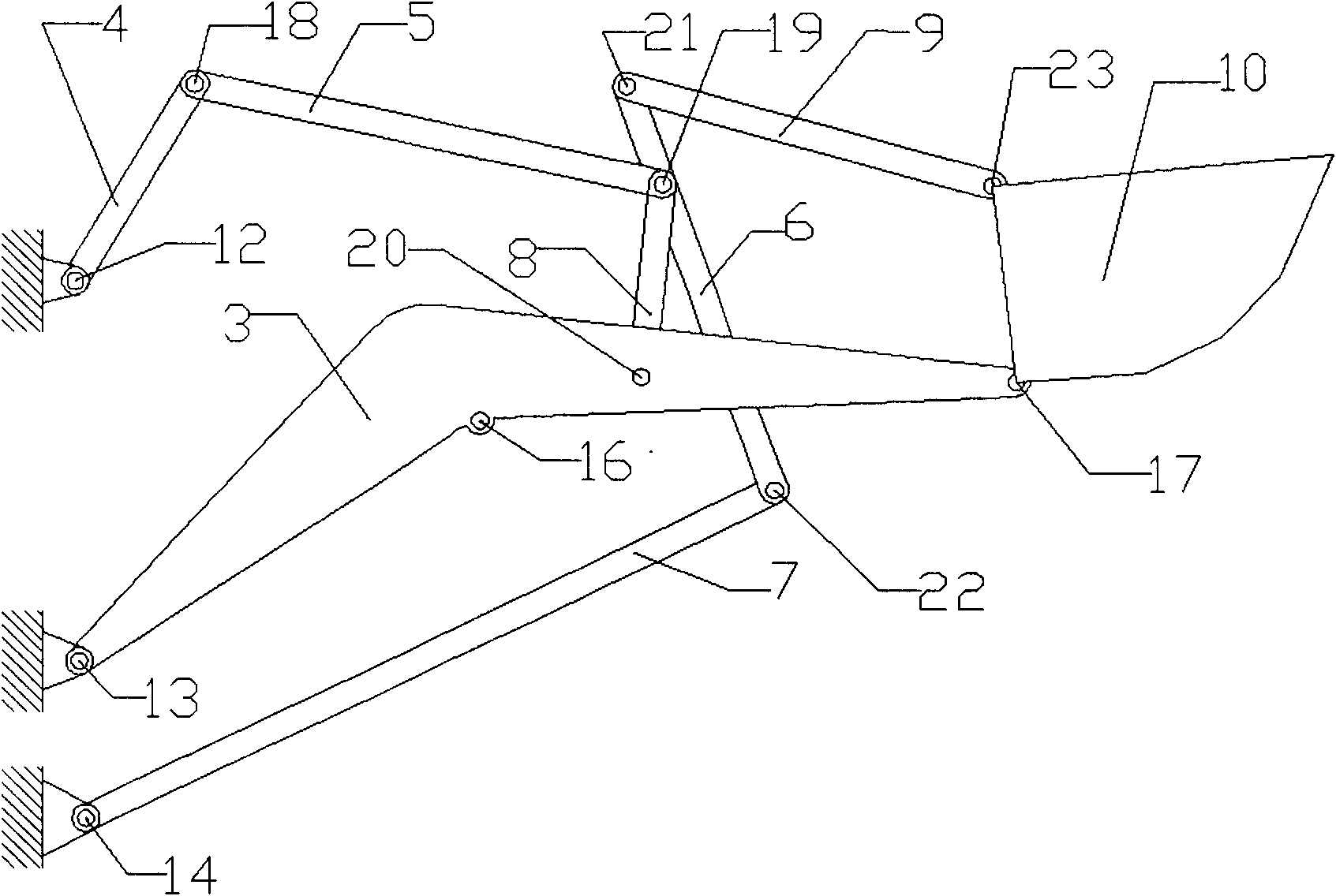

Planer multiple degree of freedom controllable loading mechanism

InactiveCN101899846AGuaranteed levelPrevent crossingMechanical machines/dredgersRolloverSingle degree of freedom

The invention relates to a planer multiple degree of freedom controllable loading mechanism. The raise-rise arm of the loading mechanism is a planer single degree of freedom controllable mechanism, wherein one end of the raise-rise arm is hinged on the chassis, and the other end is hinged a bucket; and a bucket rollover mechanism is linked between the bucket and the chassis. By using the invention, the problem that the hydraulic system of the traditional hydraulic loading machine has high demand on parts and short service life and leaks oil, etc can be solved.

Owner:GUANGXI UNIV

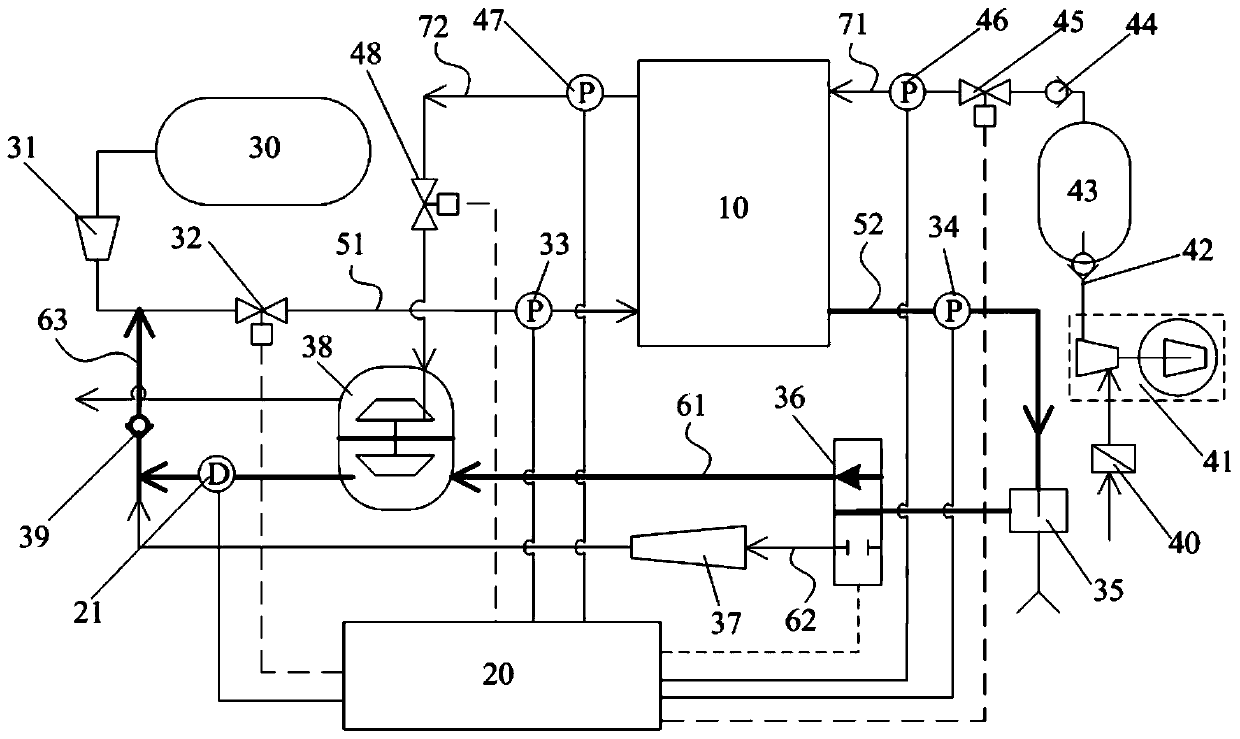

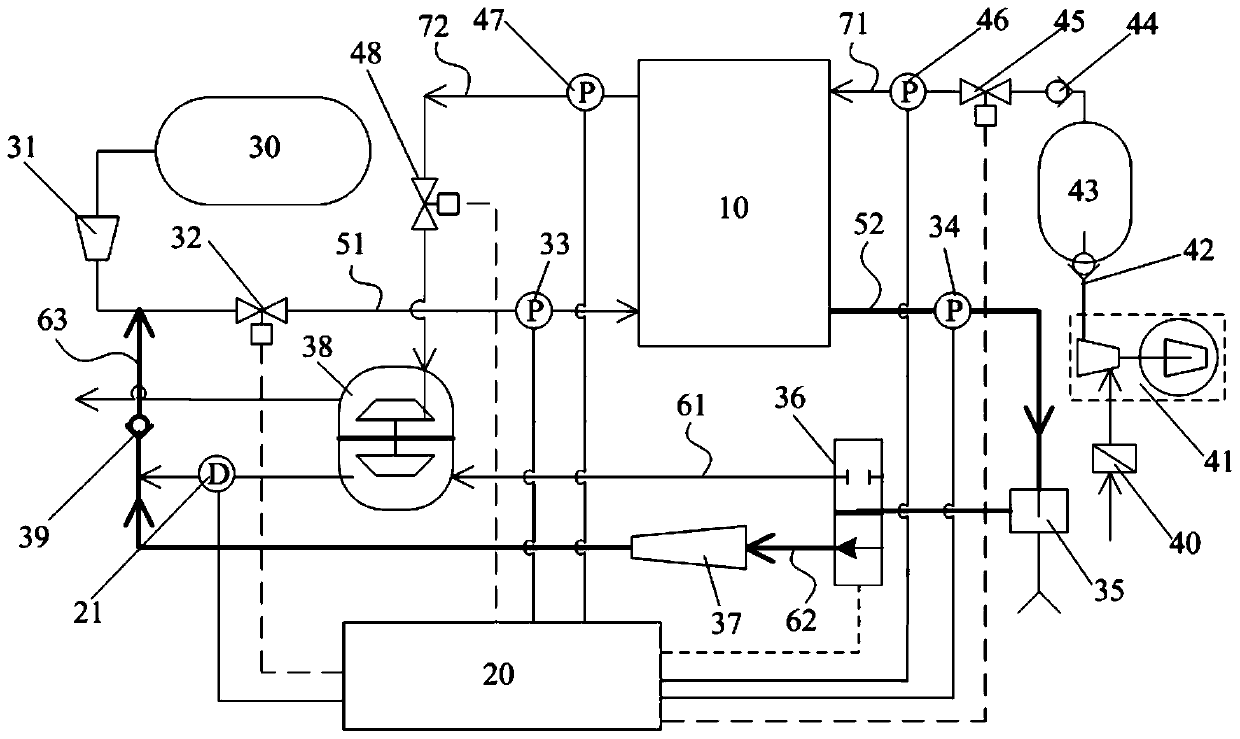

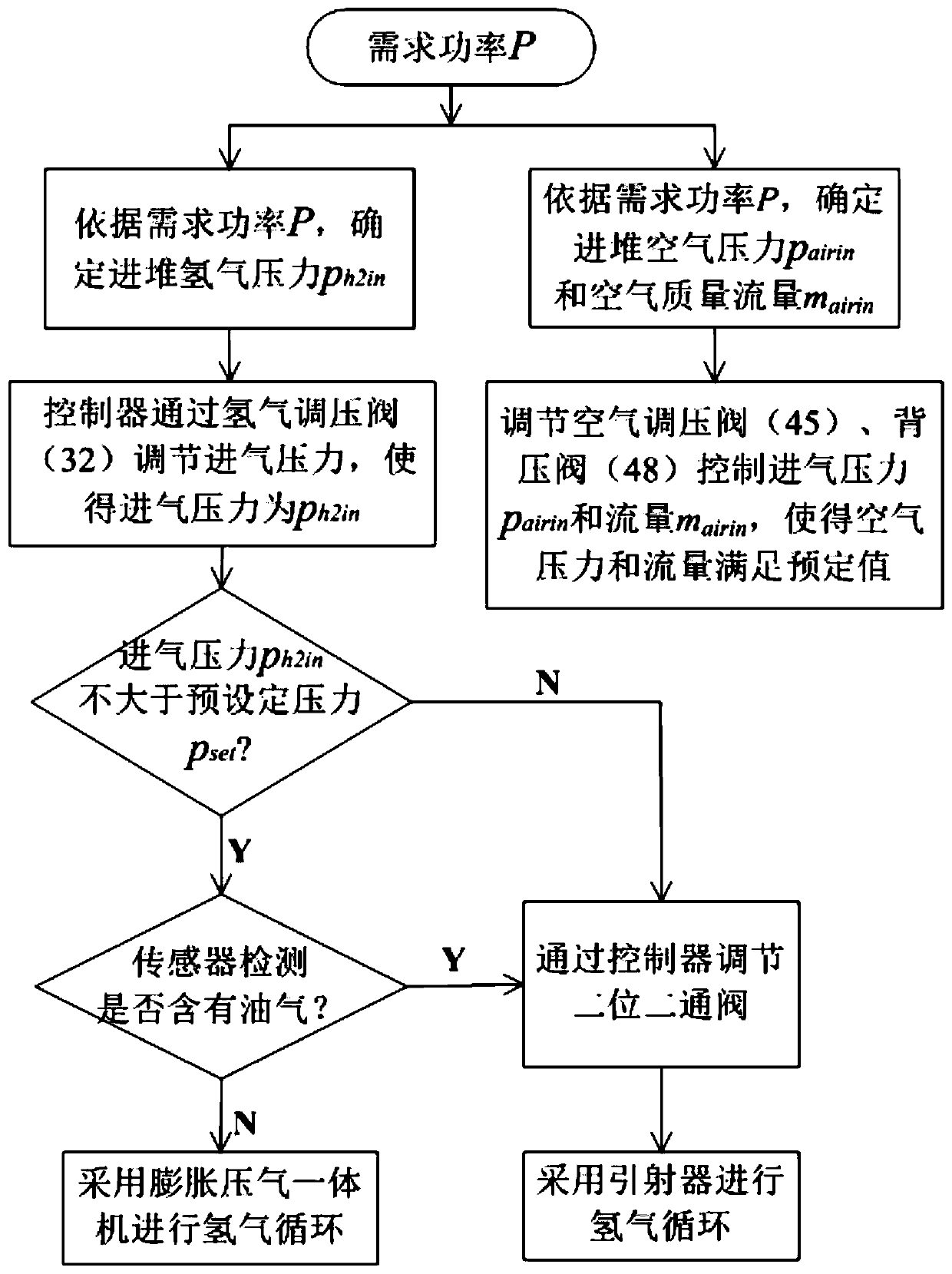

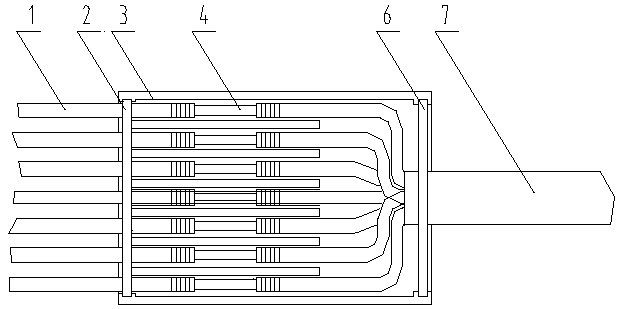

Fuel cell engine system and air supply system thereof, and control method

ActiveCN110649287AReduce parasitic loadIncrease net output powerReactant parameters controlGas compressorHydrogen pressure

The invention discloses a fuel cell engine system and an air supply system thereof, and a control method. The air supply system comprises a hydrogen supply system and an air supply system; a hydrogenoutlet pipeline is connected with a two-position two-way valve; the two-position two-way valve is connected with a first hydrogen circulating pipeline and a second hydrogen circulating pipeline in parallel; the first hydrogen circulating pipeline is connected to an inlet of a gas compressor of an expansion and gas compression all-in-one machine; and the outlet of the gas compressor is connected toa hydrogen circulation main pipeline, the hydrogen circulation main pipeline is connected to a hydrogen inlet pipeline, a second hydrogen circulation pipeline is connected to the hydrogen circulationmain pipeline through a hydrogen ejector, an inlet hydrogen pressure detection device is arranged on the hydrogen inlet pipeline, and an air outlet pipeline is connected to an expansion machine of the expansion and gas compression all-in-one machine. High-pressure tail gas exhausted by the air supply system is effectively used for driving the expansion and gas compression all-in-one machine to achieve hydrogen cyclic utilization, parasitic loads of the auxiliary system are reduced, and the net output power of the stack is improved.

Owner:WEICHAI POWER CO LTD

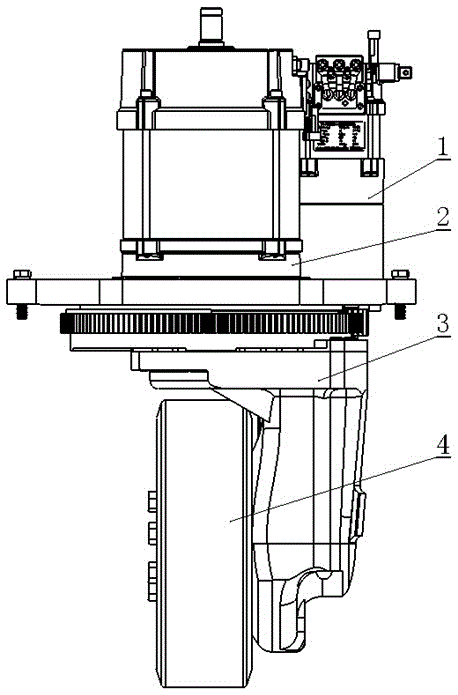

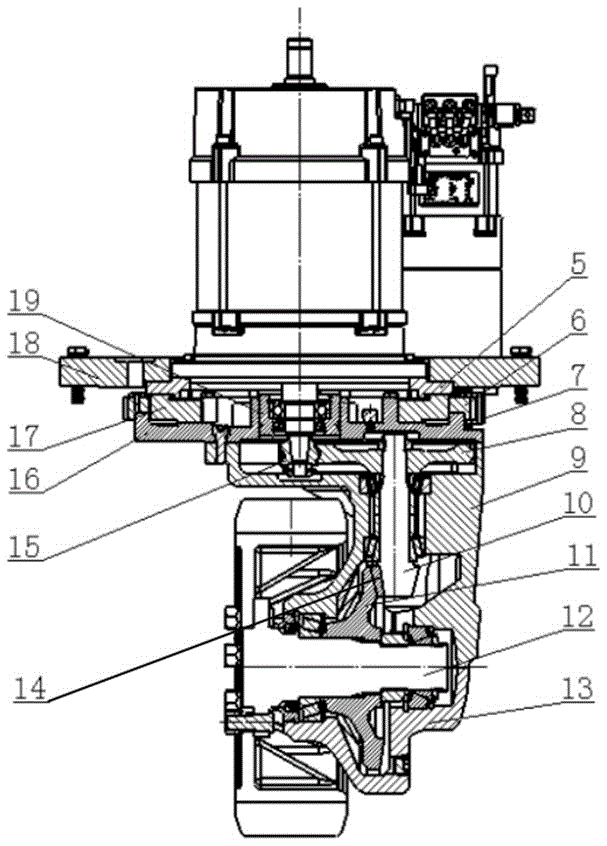

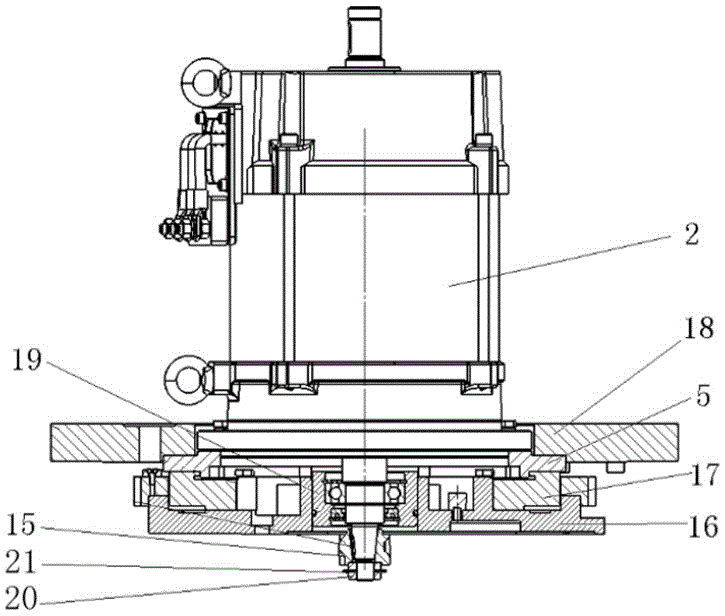

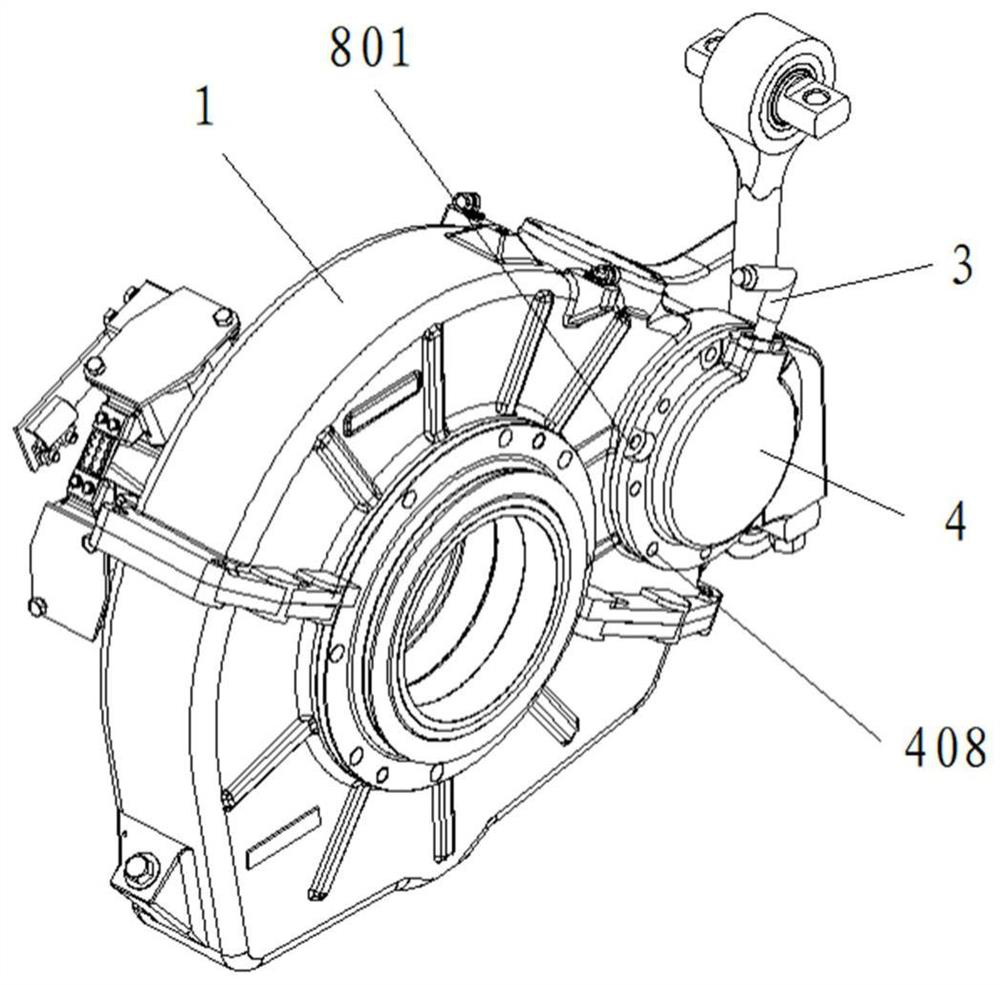

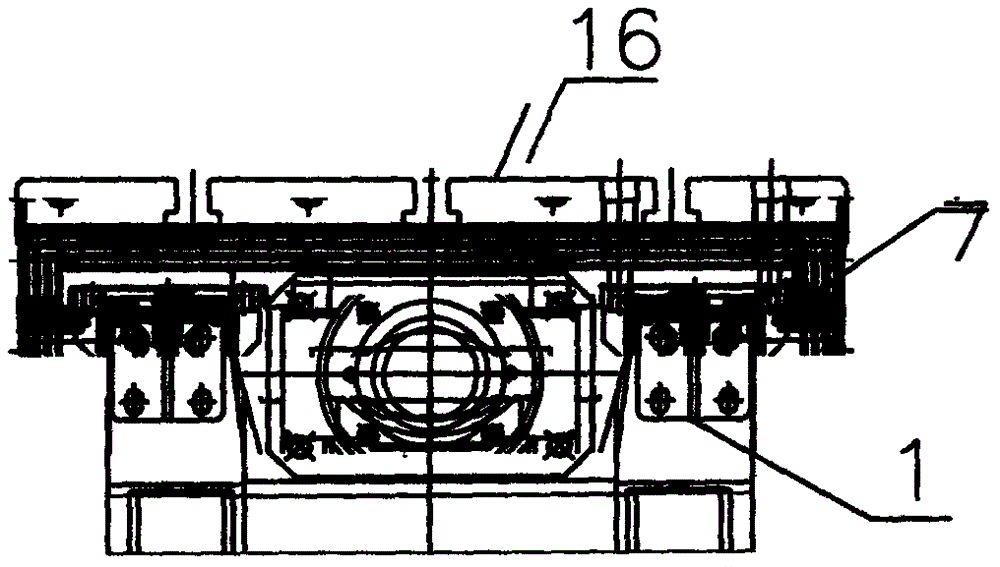

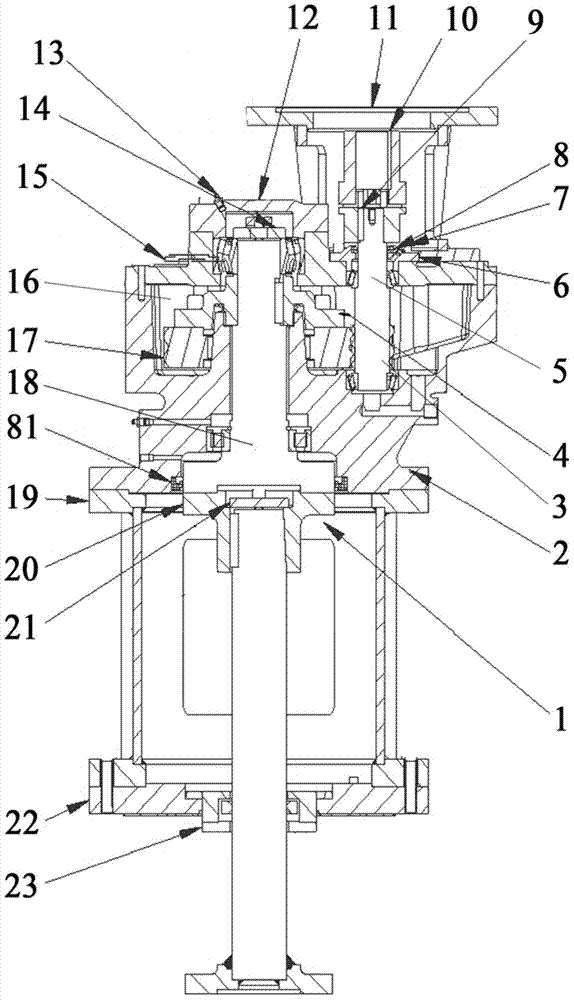

Electrified steering vertical driving device

InactiveCN106043416AReduce the requirement of high installation accuracyGuaranteed flexibilityElectrical steeringDrive motorSlewing bearing

The invention relates to an electrified steering vertical driving device. The electrified steering vertical driving device comprises a power assembly, a reducing mechanism and a steering mechanism. The power assembly comprises a driving motor and a steering motor, the driving motor is arranged on a connection disc, and the steering motor is arranged on a connection plate fixedly connected with the connection disc. The reducing mechanism comprises a shell body, an input end and an output end; the shell body is formed by connecting an upper shell body and a lower shell body; and the top surface of the upper shell body is horizontally provided with a slewing bearing, and the connection disc is fixedly connected to the slewing bearing. A motor shaft of the driving motor stretches into the upper shell body and is connected with the input end, and the output end is transversely located at the bottom end of the shell body. The steering mechanism comprises a driven steering gear and a driving steering gear; the driven steering gear is arranged on the outer circle of the slewing bearing and fixedly connected to the upper shell body; and the driving steering gear is arranged on the motor shaft of the steering motor and in correspondence engagement with the driven steering gear. According to the electrified steering vertical driving device, the installing precision requirement is low, steering is flexible, and a side gap of a spiral bevel gear is convenient to adjust.

Owner:ANHUI HELI CO LTD

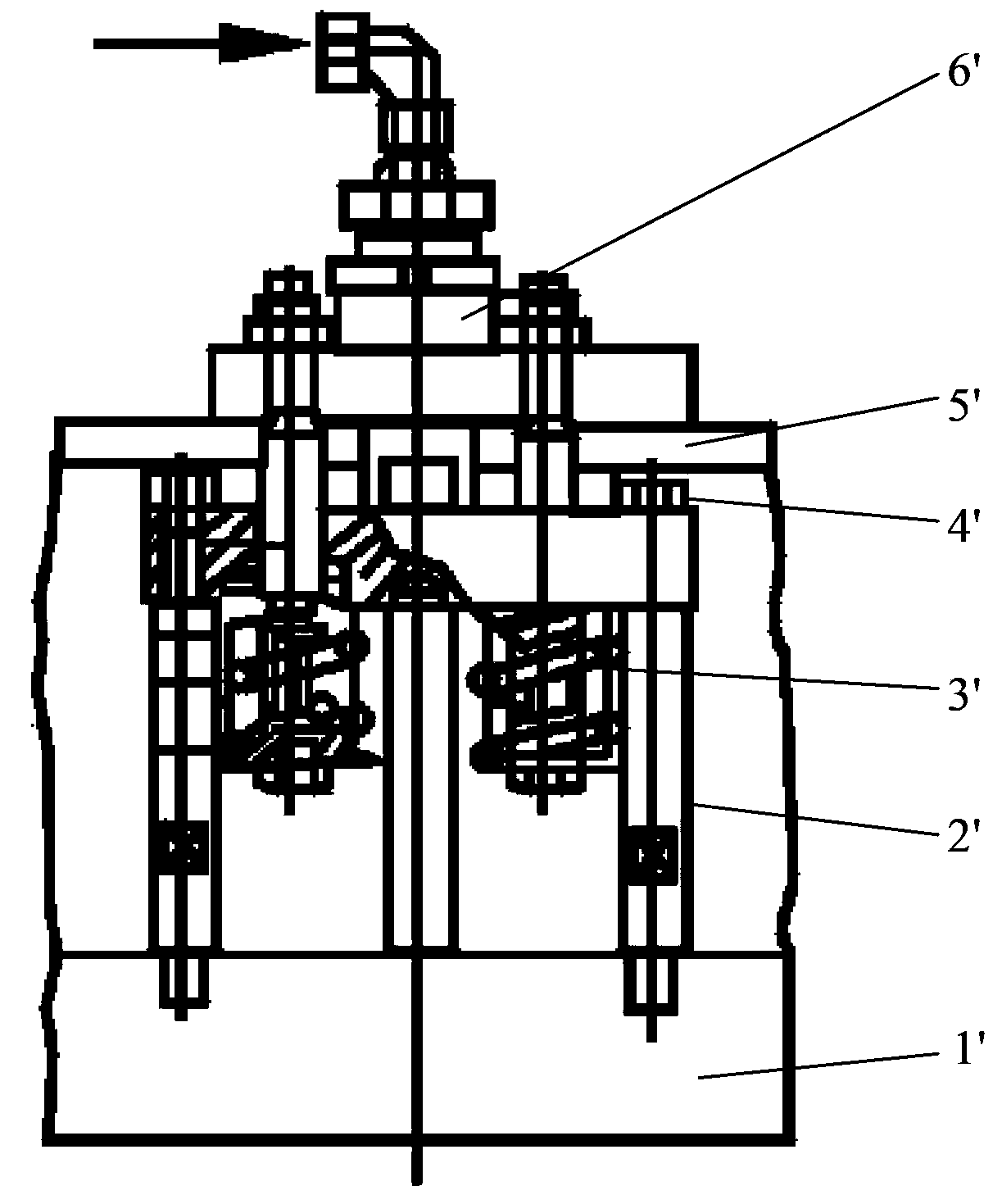

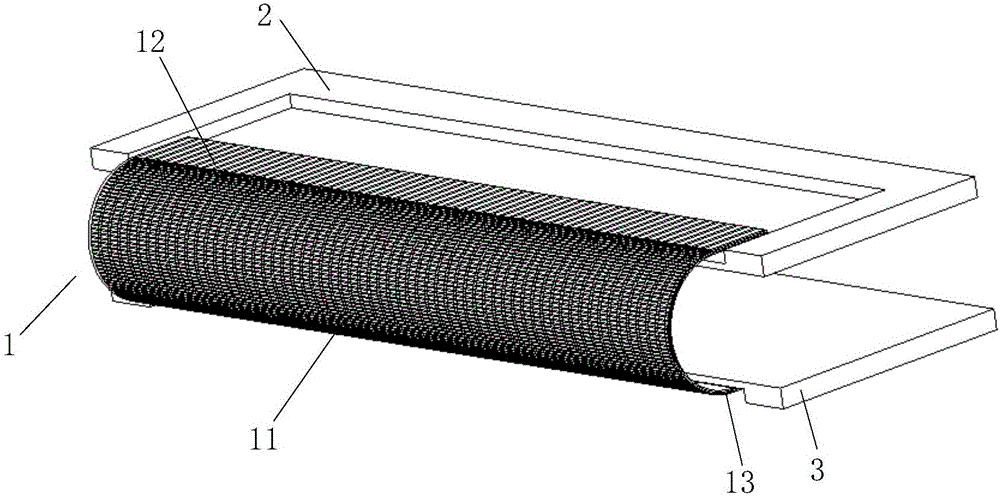

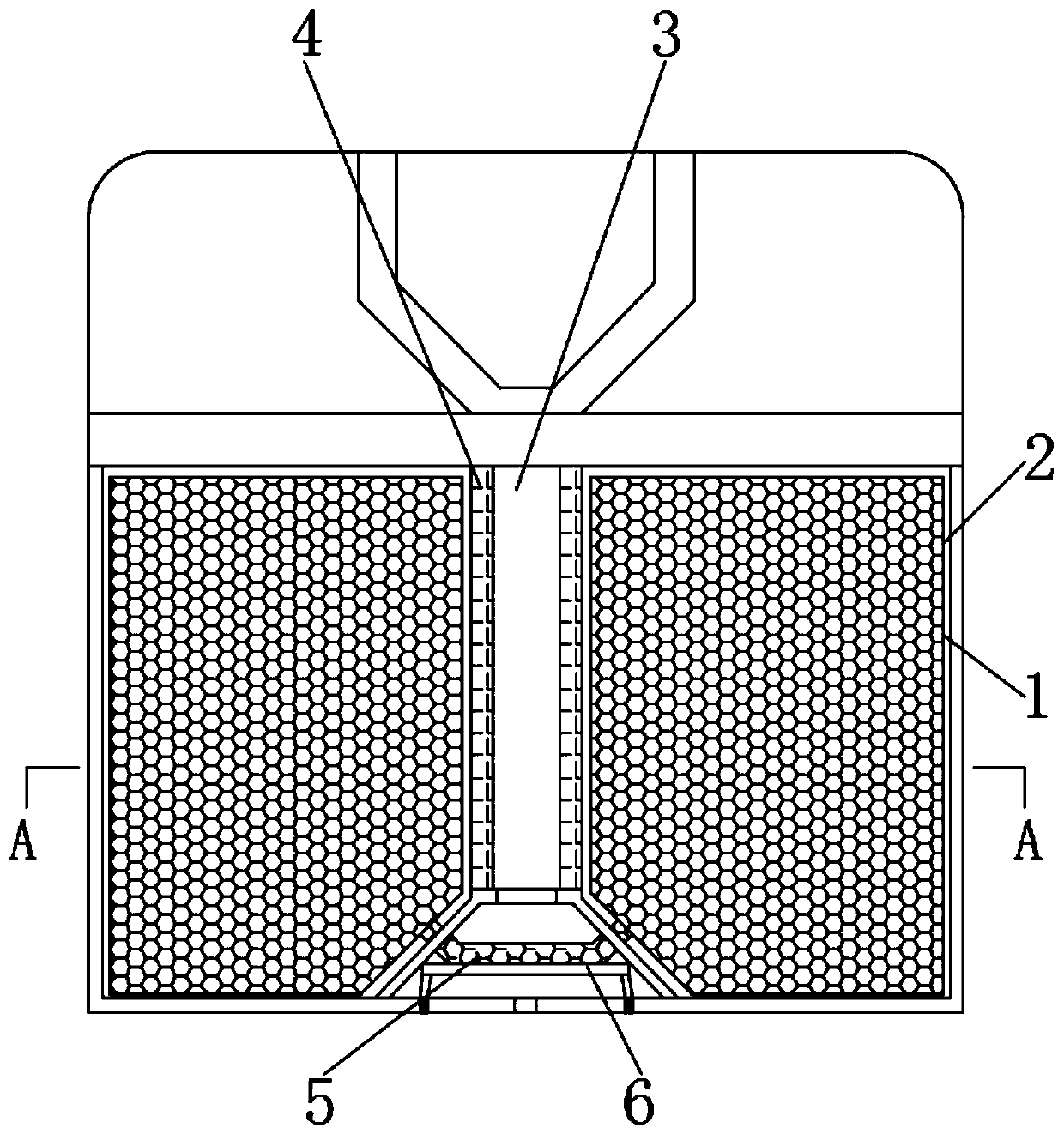

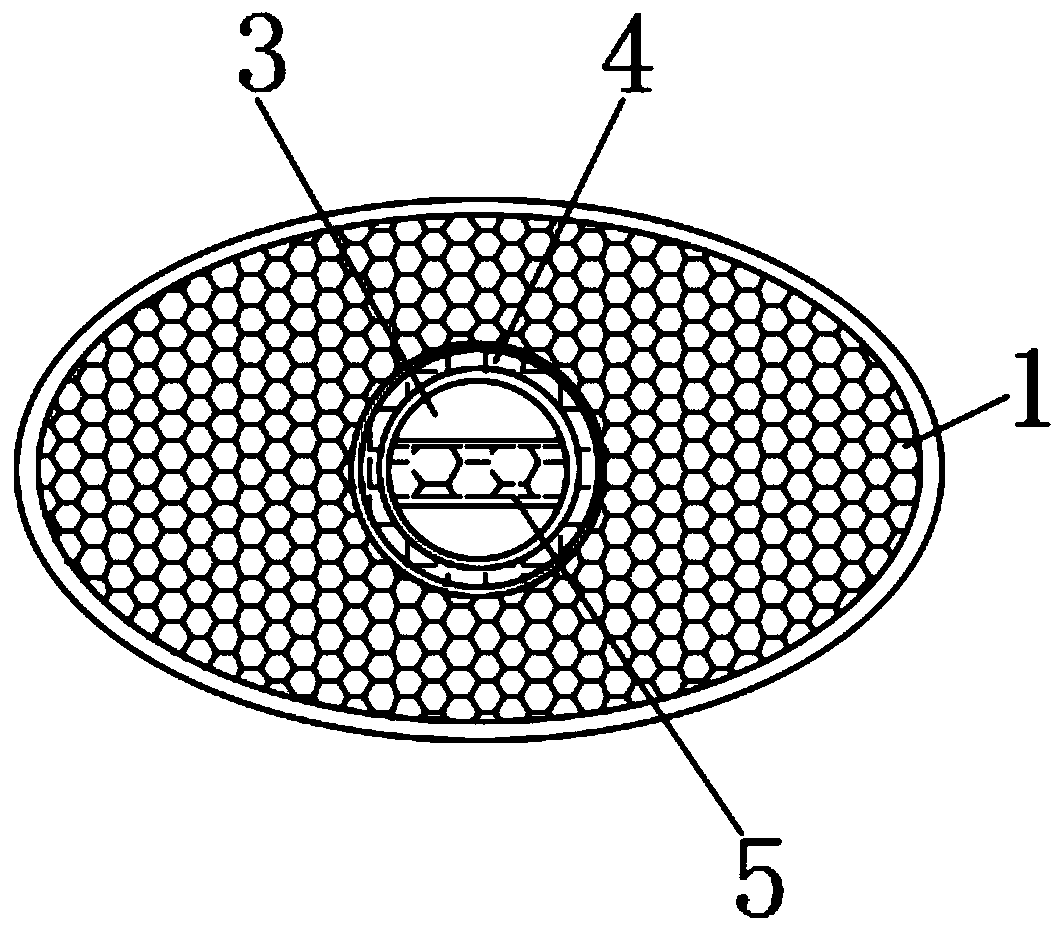

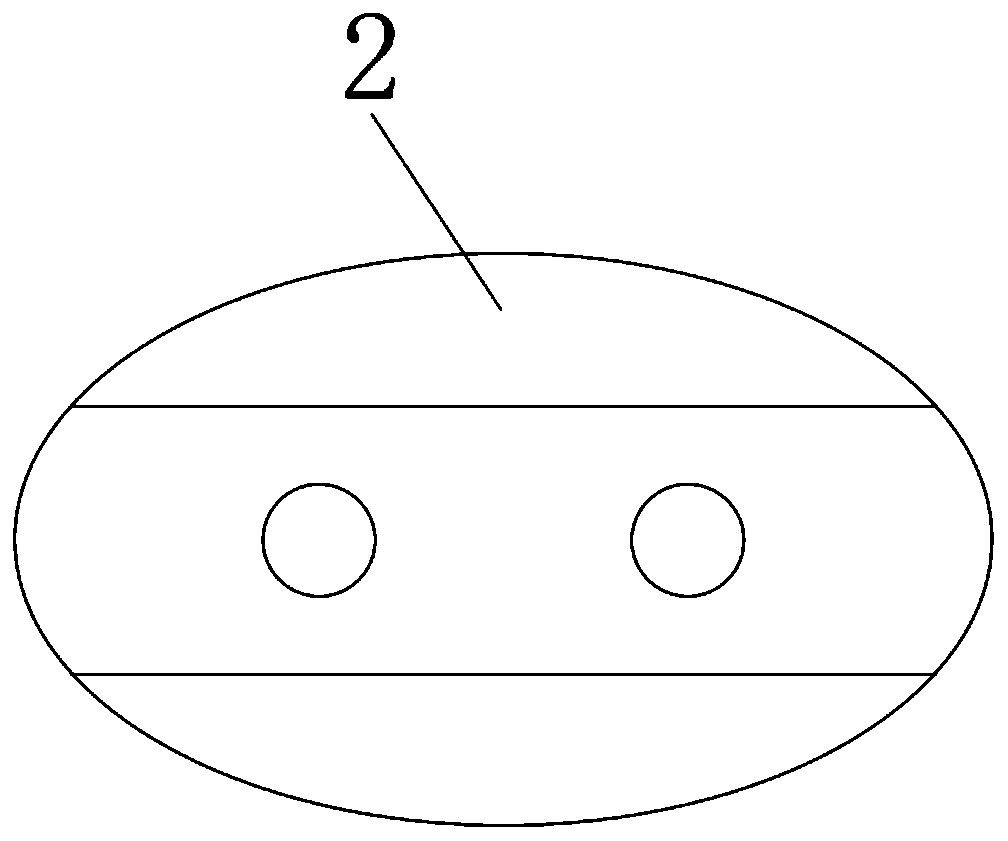

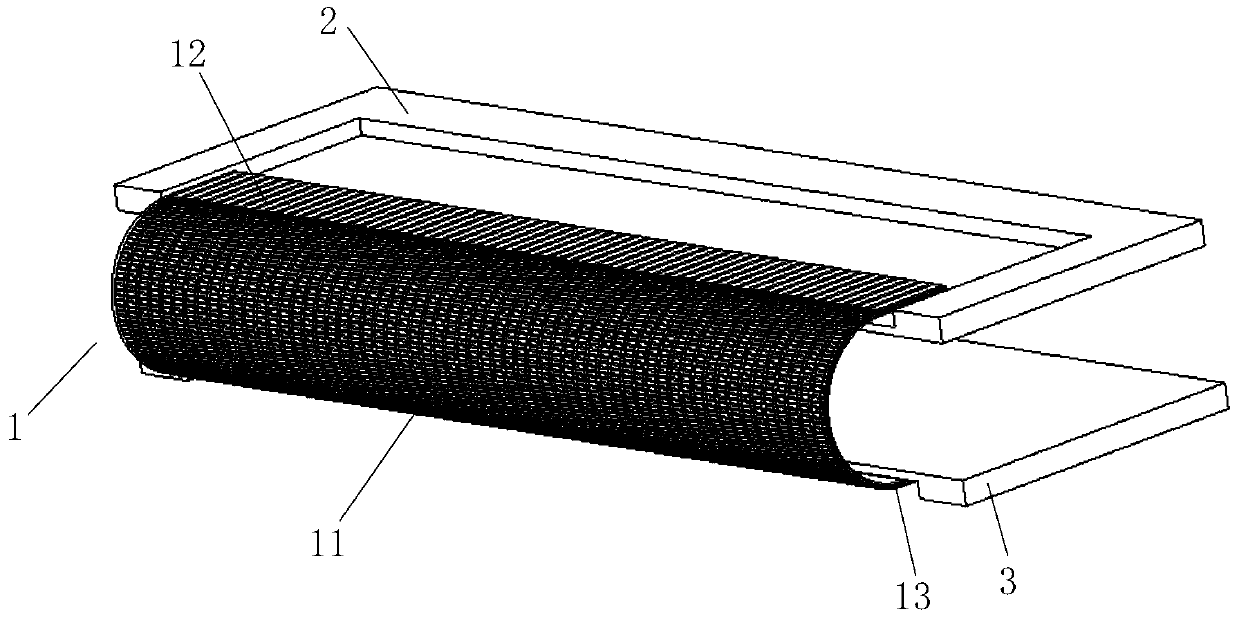

Compaction device and paver

The invention provides a compaction device for road surface compaction. The compaction device comprises a compaction beam and a vibration mechanism disposed on the compaction beam. The vibration mechanism includes a magnetic component and an elastic component arranged on one side of the magnetic component. The magnetic component and the elastic component can drive the compaction beam to move up and down. The compaction device makes use of an electromagnetic mechanism, namely the suction of an electromagnet and the elastic force of a spring, to realize compaction of a road surface mixture. Characterized by simpler structure and more reliable work, the compaction device effectively solves the problems of easy oil leakage and poor work reliability in compaction mechanisms. On the other hand, the invention also provides a paver, which includes a screed and the compaction device in the screed. The compaction device is as described above.

Owner:HUNAN SANY ROAD MACHINERY

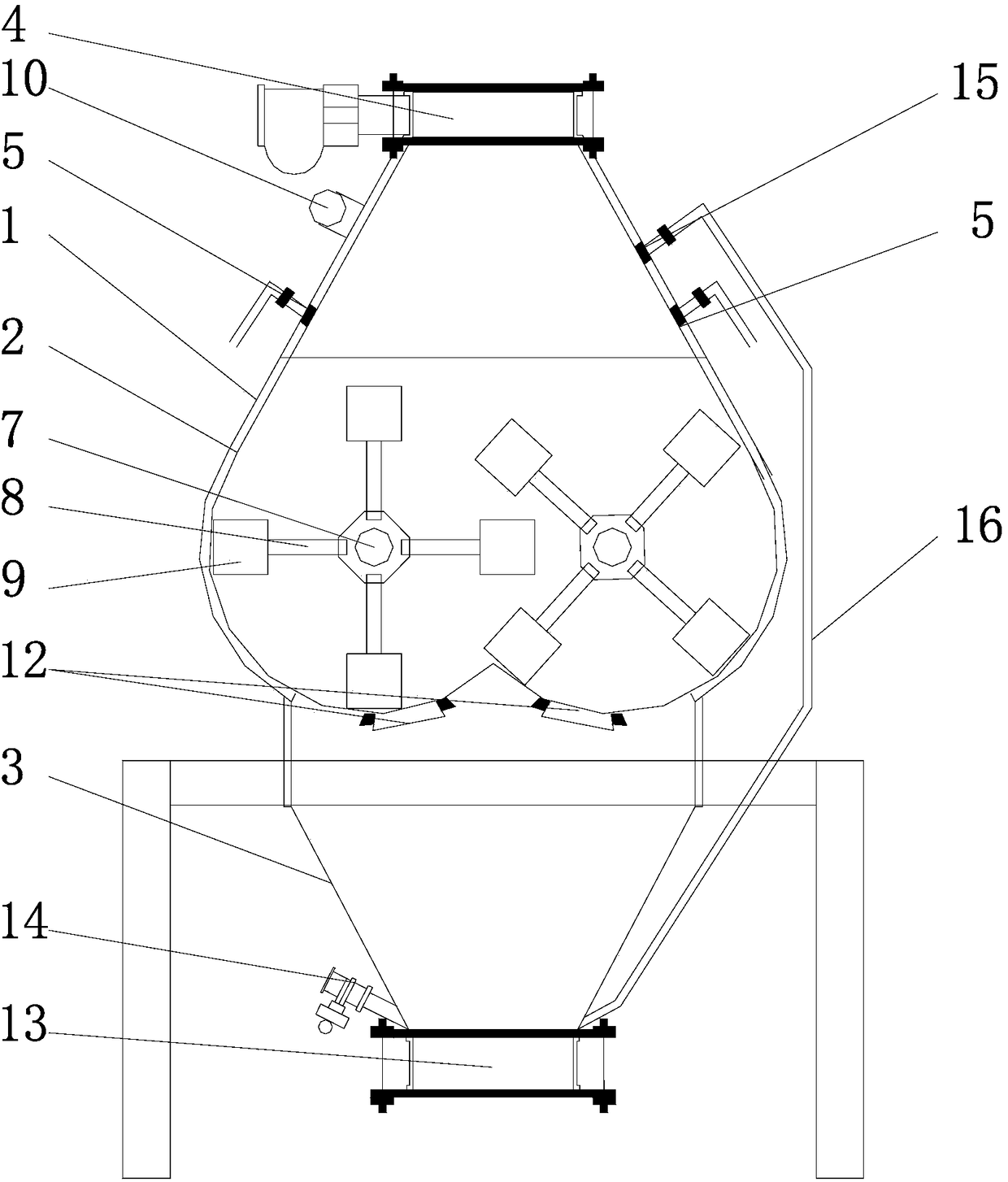

Horizontal vacuum spraying machine

InactiveCN108465397AMeet capacity needsIncrease production capacityRotary stirring mixersTransportation and packagingSpray nozzlePulp and paper industry

The invention relates to a horizontal vacuum spraying machine. A horizontal structure is adopted, and compared with a spraying machine of a vertical structure, the production capacity is improved greatly, so that the production capacity requirement of an existing large-sized extruder is met, wherein the stirring and mixing effect is good so as to ensure the product quality; compared with an existing horizontal machine, the horizontal vacuum spraying machine adopts arrangement of two-shaft stirring so as to further improve the mixing effect; furthermore, since two stages of gates, a recovery nozzle and an oil recovery pipe are arranged, the pressure difference between a stirring chamber and a recovery chamber is utilized to send leaked oil to the stirring chamber through the oil recovery pipe for recovery so as to conduct spraying, so that the problem of oil leakage is solved.

Owner:佛山市金柏机械制造有限公司

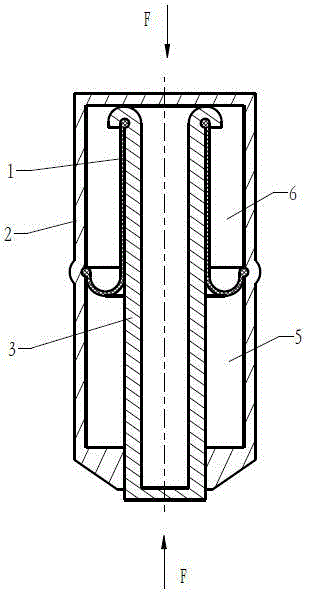

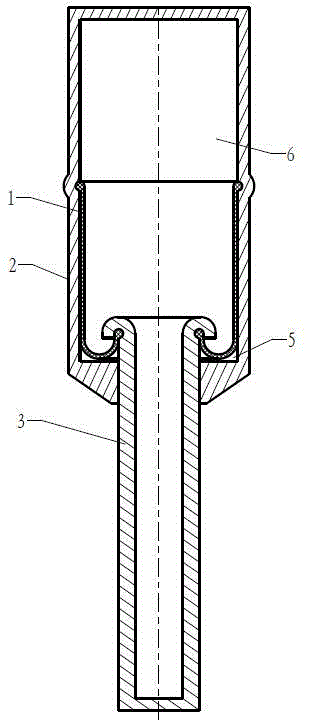

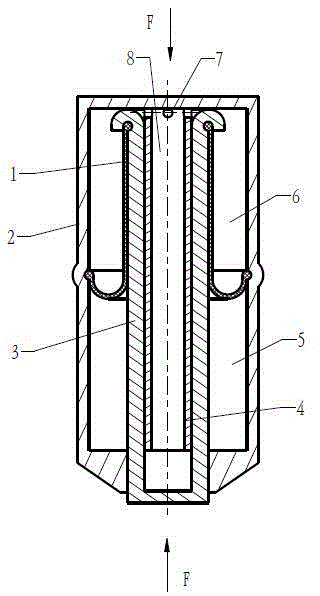

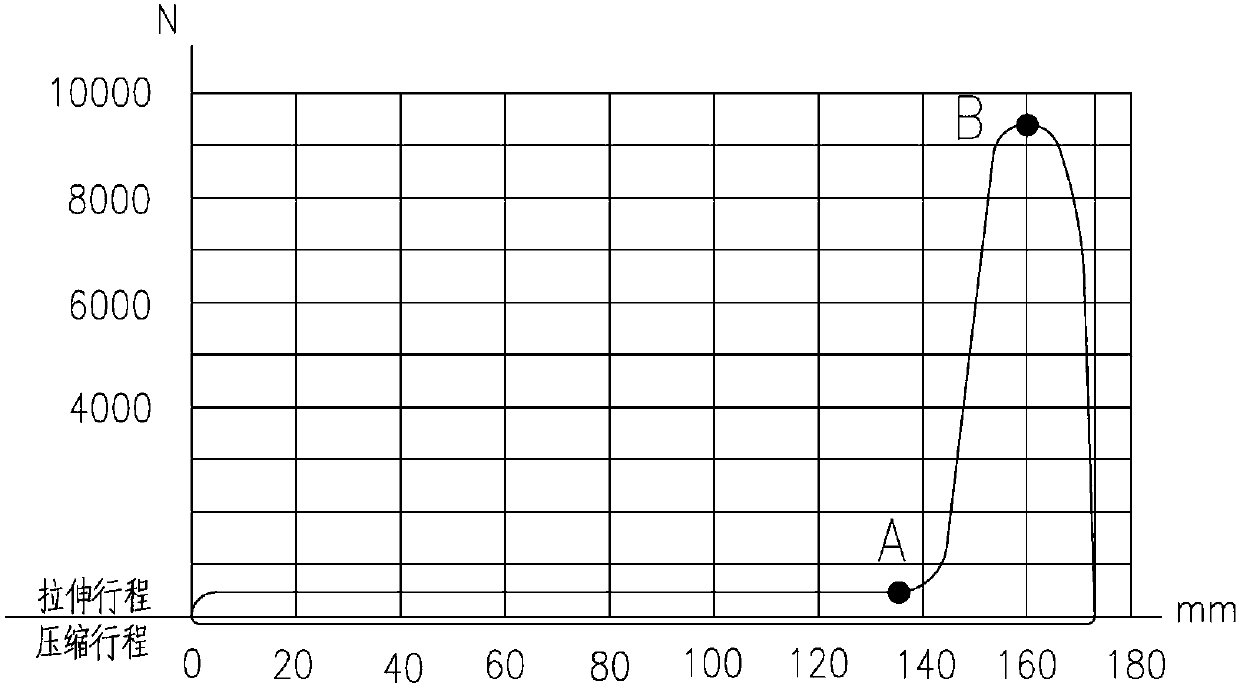

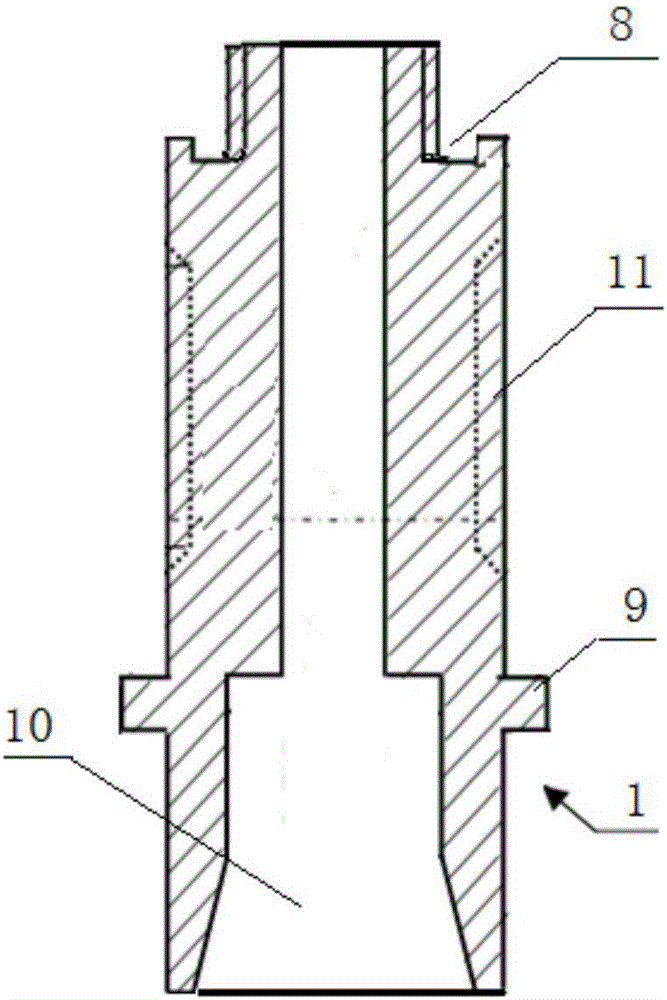

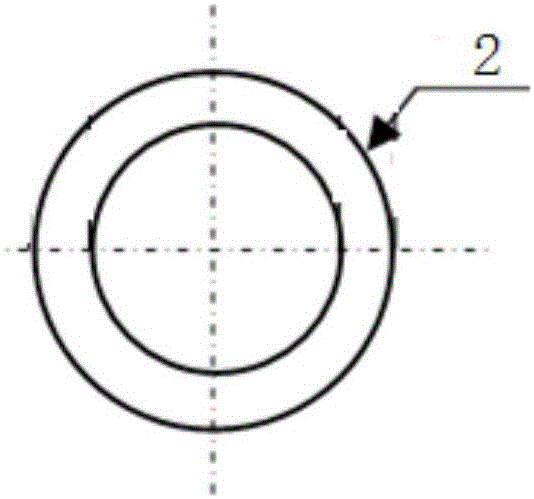

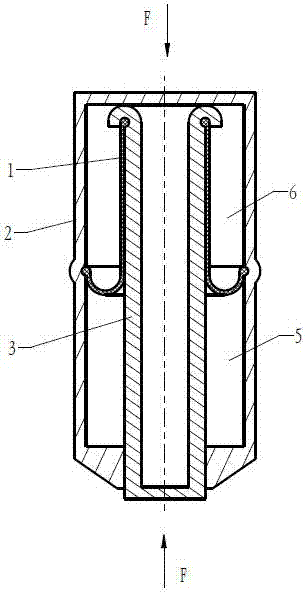

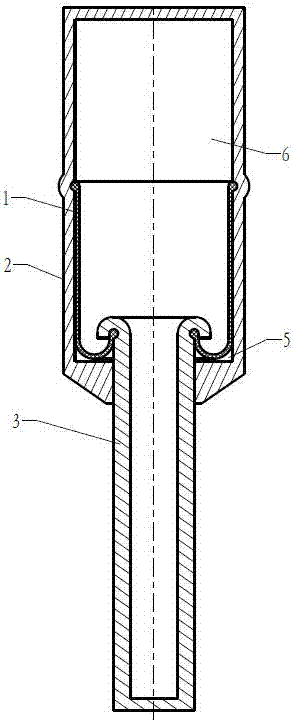

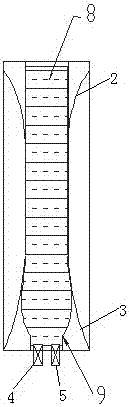

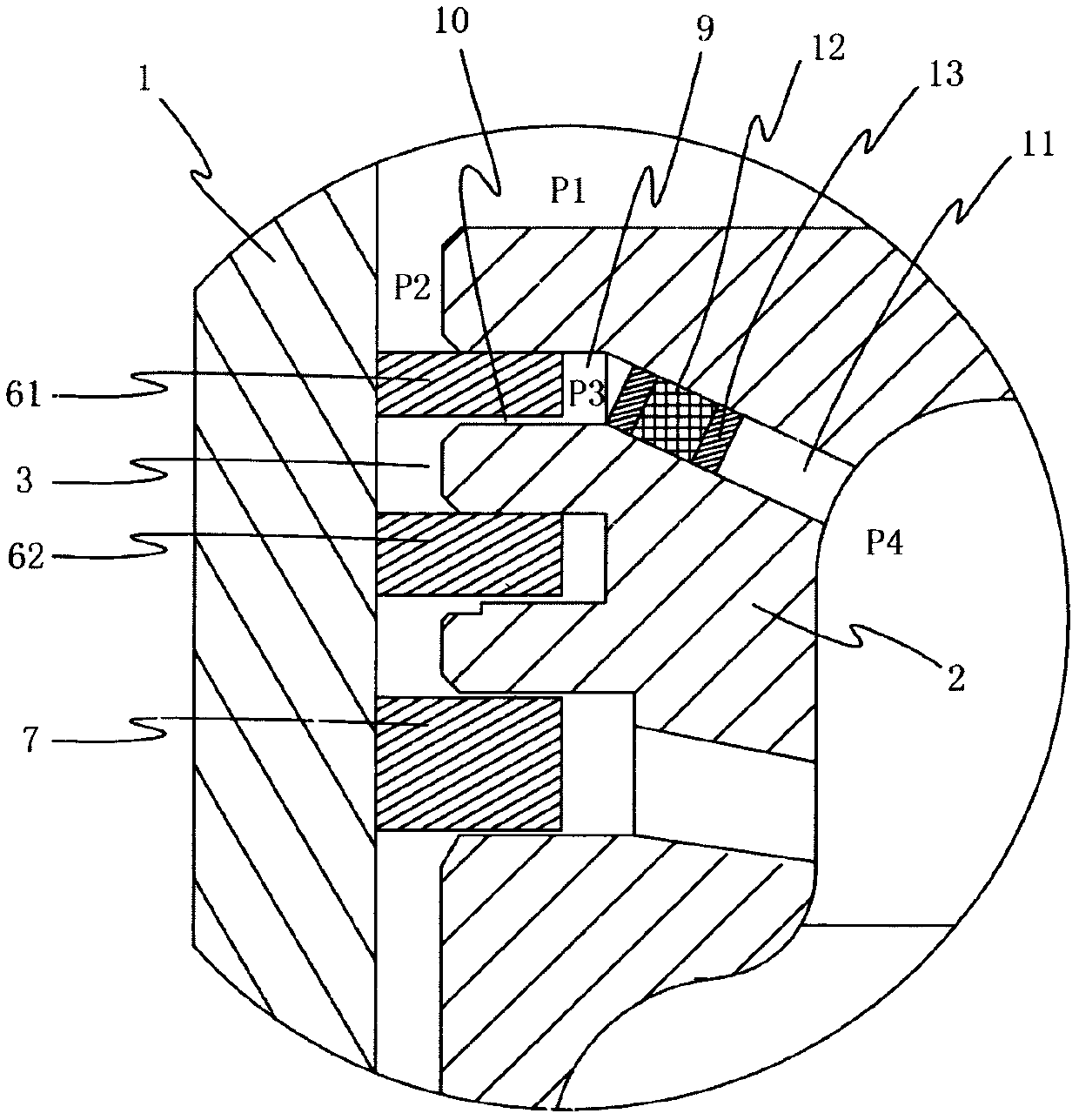

Static sealing oil cylinder with rodless cavity

ActiveCN105587708ALarge bearing pressureLight weightFluid-pressure actuatorsInternal pressureEngineering

The invention relates to a static sealing oil cylinder with a rodless cavity. According to the invention, a capsule (1) is partitioned to form a rod cavity (5) and the rodless cavity (6) of the oil cylinder disclosed by the invention, wherein the rod cavity (5) is a dynamic sealing cavity; the rodless cavity (6) is a static sealing cavity; during stretching and compression processes of the oil cylinder, the capsule (1) only fits with with the inner wall of a cylinder barrel (2) and the outer wall of a piston rod (3) in a rolling manner; when the rodless cavity (6) is charged with high-pressure oil or high-pressure gas, the rod cavity (5) of the oil cylinder discharges outwards the oil or the gas, and the oil cylinder is stretched; and when an external force F on each of the two ends of the oil cylinder is greater than the inner pressure of the rodless cavity (6), the oil cylinder is compressed.

Owner:重庆戴文能源科技有限公司

Rotating shaft device and electronic device

Owner:LENOVO (BEIJING) LTD

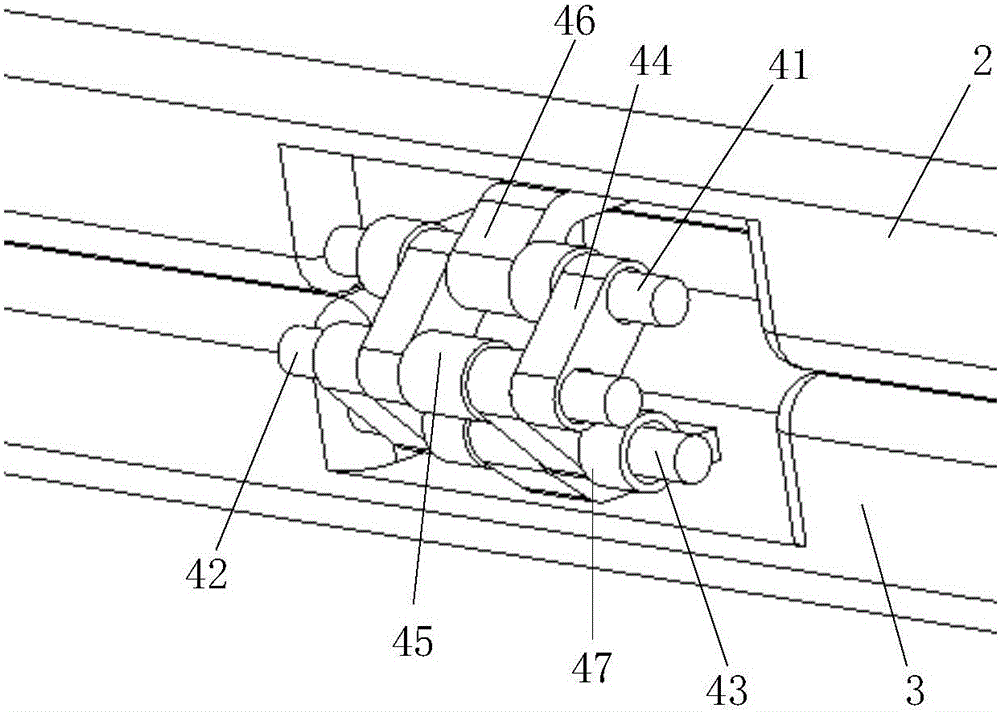

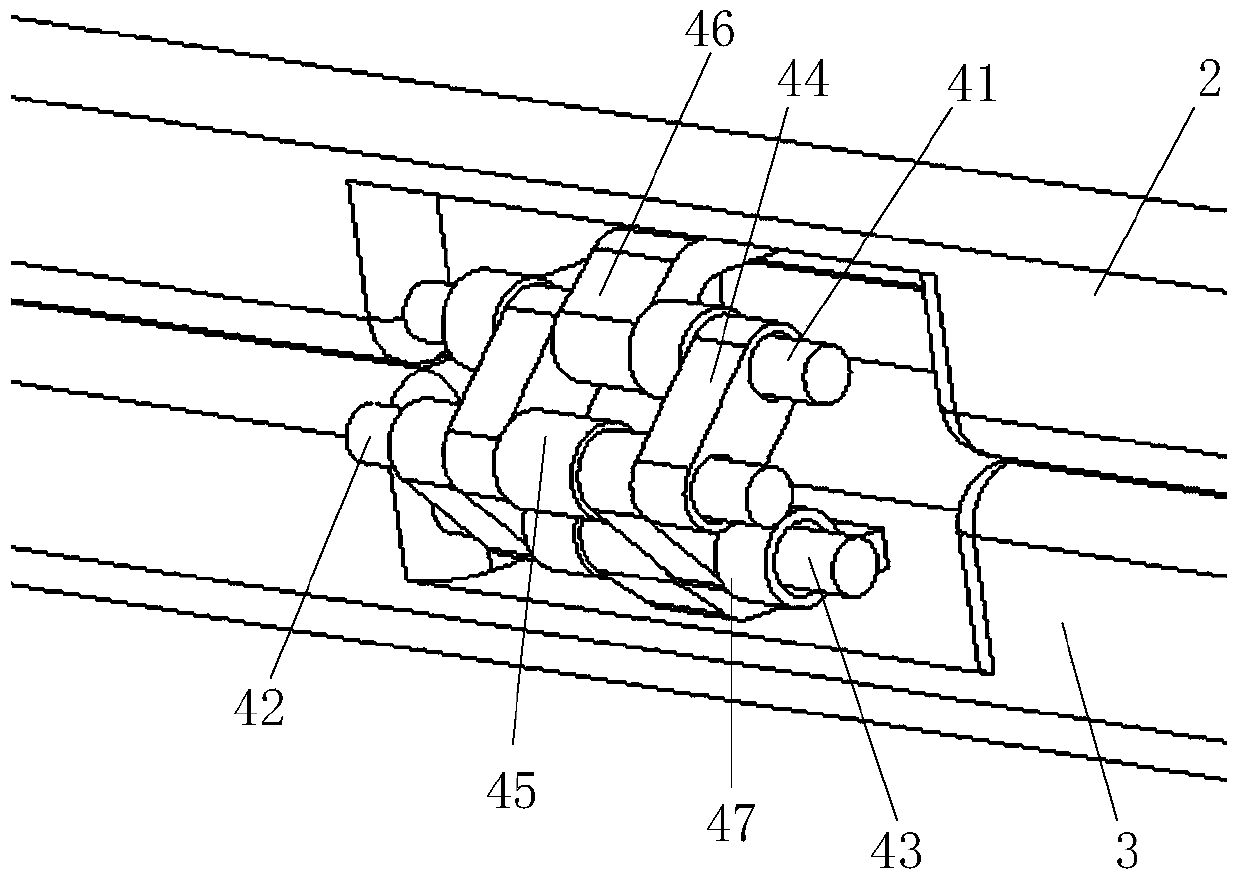

Pantograph

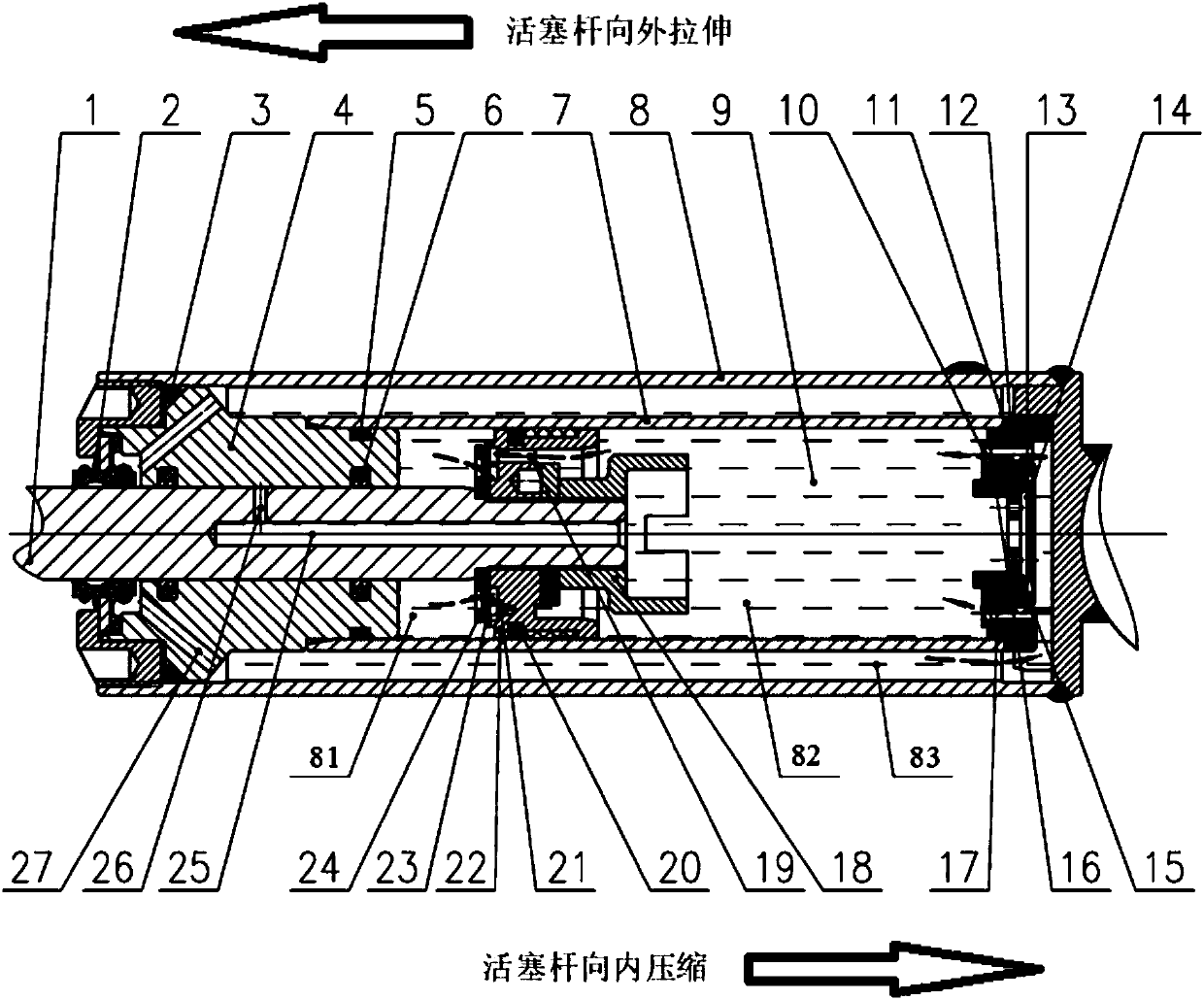

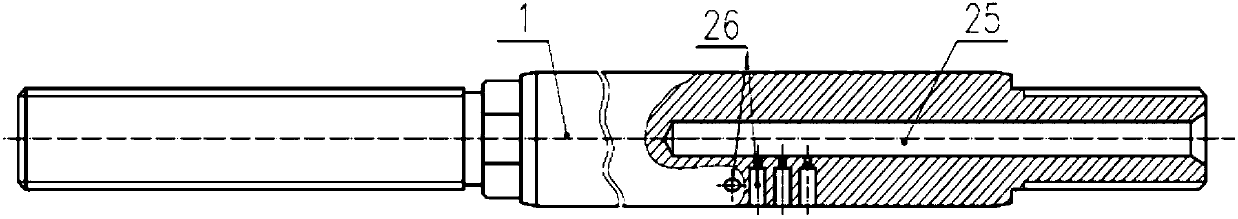

ActiveCN107839489AEasy maintenanceAchieving tightnessSpringsElectric vehicle charging technologyEngineeringPiston rod

The invention provides a pantograph which comprises a damper, a bottom frame, a pantograph lifting device and the like. The damper comprises an oil storage cylinder, an oil cylinder, a guide, a pistonrod, a piston, hydraulic oil and a bottom valve seat, a plurality of throttling holes are formed in the piston rod, one end of each throttling hole is connected with an oil through hole, the other end of each throttling hole is an opening facing outside the piston rod, openings of the throttling holes can be exposed in an I cavity and / or covered by the guide, at least two throttling holes are distributed at different axial positions of the piston rod, and spacers are arranged between an inner axial end of the oil cylinder and the bottom valve seat and used for adjusting stretching maximum damping force in the outward stretching stroke of the piston rod. The pantograph cancels the mode that the stretching maximum damping force is adjusted by a nut, a spring and a valve plate in the prior art, and the stretching maximum damping force is adjusted by additionally mounting the spacers with different depths. The pantograph can effectively meet requirements of use conditions of the pantograph and is simple, easy and convenient to maintain.

Owner:ZHUZHOU LINCE GRP +1

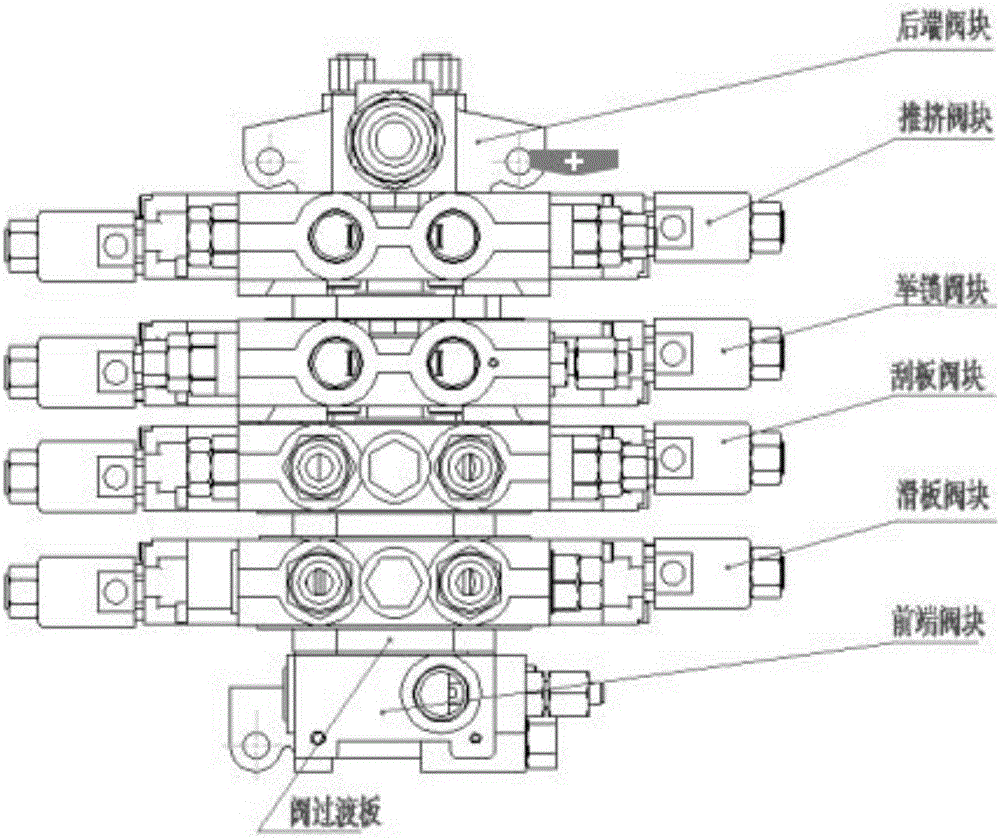

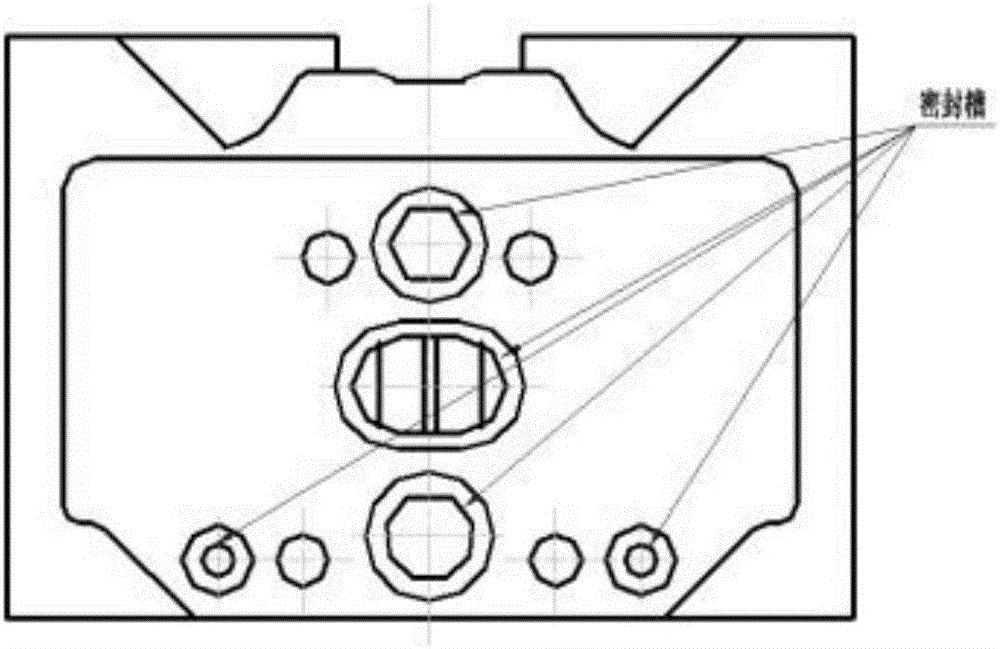

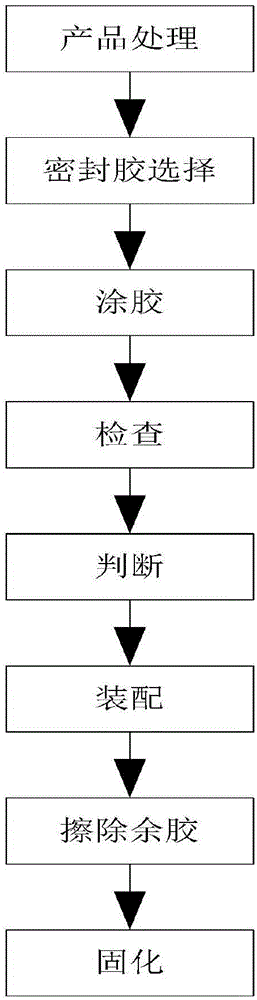

Inter-sheet sealing method for valve sheets of sheet type multi-way directional valve

InactiveCN106122537ASolve oil leakageReduce scrapMultiple way valvesContinuous/uninterruptedRoom temperature

The invention provides an inter-sheet sealing method for valve sheets of a sheet type multi-way directional valve. The sealing method comprises the following steps: S1, cleaning and drying the surface of a valve sheet, which is to be coated with a sealant; S2, assembling sealing elements into sealing grooves, and uniformly coating the flat surface around the sealing elements with a layer of sealant with a brush; S3, selecting a white transparent hard plastic plate which is matched with the sealing surface in size to cover the sealing surface coated with the sealant, and pressing the white transparent hard plastic plate hard against the sealing surface again and again, and observing the condition of the sealant through the white transparent hard plastic plate when the sealant fluid is squeezed by the white transparent hard plastic plate; S4, judging the sealant coating amount, and if the sealant can form a circle of uninterrupted thin film on the periphery of an entire seal ring and does not flow into an oil hole and an oil channel under the pressure of the white transparent hard plastic plate, determining that the sealant coating amount meets a requirement; S5, taking the white transparent hard plastic plate away, and performing assembly according to the requirements of product assembly; S6, cleaning waste sealant with cotton cloth; and S7, placing a finished product in a room temperature environment to cure the finished product.

Owner:NANJING CHENGUANG GRP

Gear box, bogie and railway vehicle

The invention provides a gear box, a bogie and a railway vehicle. The gear box comprises a box body, an input gear shaft and a speed measuring device; a first end of the input gear shaft penetrates through the box body and is suitable for being connected with a driving mechanism, and a second end of the input gear shaft extends to the outer side of the box body; and the speed measuring device is installed at the second end of the input gear shaft and located on the outer side of the box body. According to the gear box provided by the invention, a series of work such as vehicle lifting, wheel falling and wheel withdrawing does not need to be carried out during decomposition inspection, the box body of the gear box does not need to be disassembled, and the speed measuring device can be disassembled on the outer side of the box body of the gear box, so that the gear box is convenient and rapid, and the decomposition inspection cost is lower.

Owner:CRRC QINGDAO SIFANG CO LTD

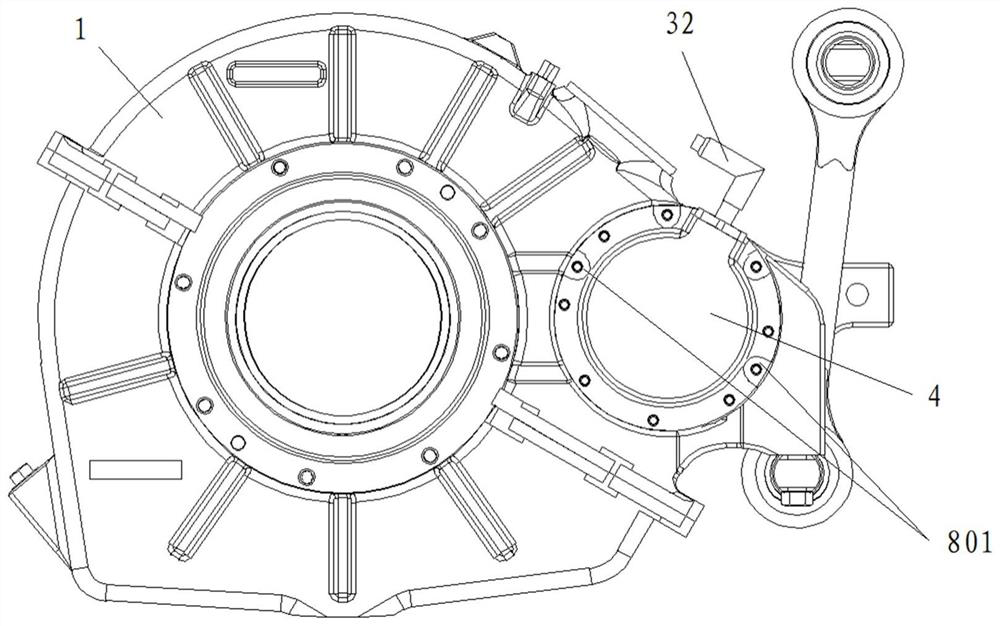

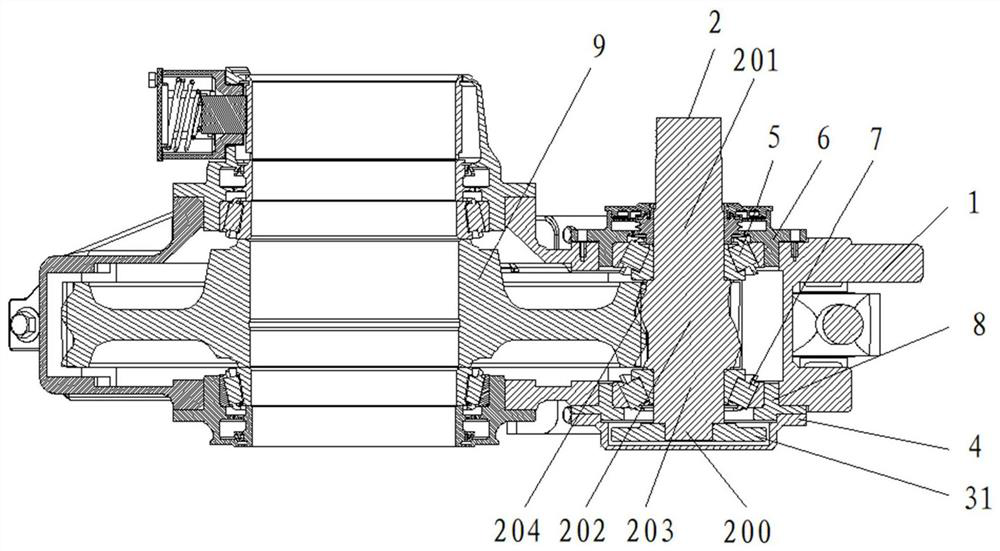

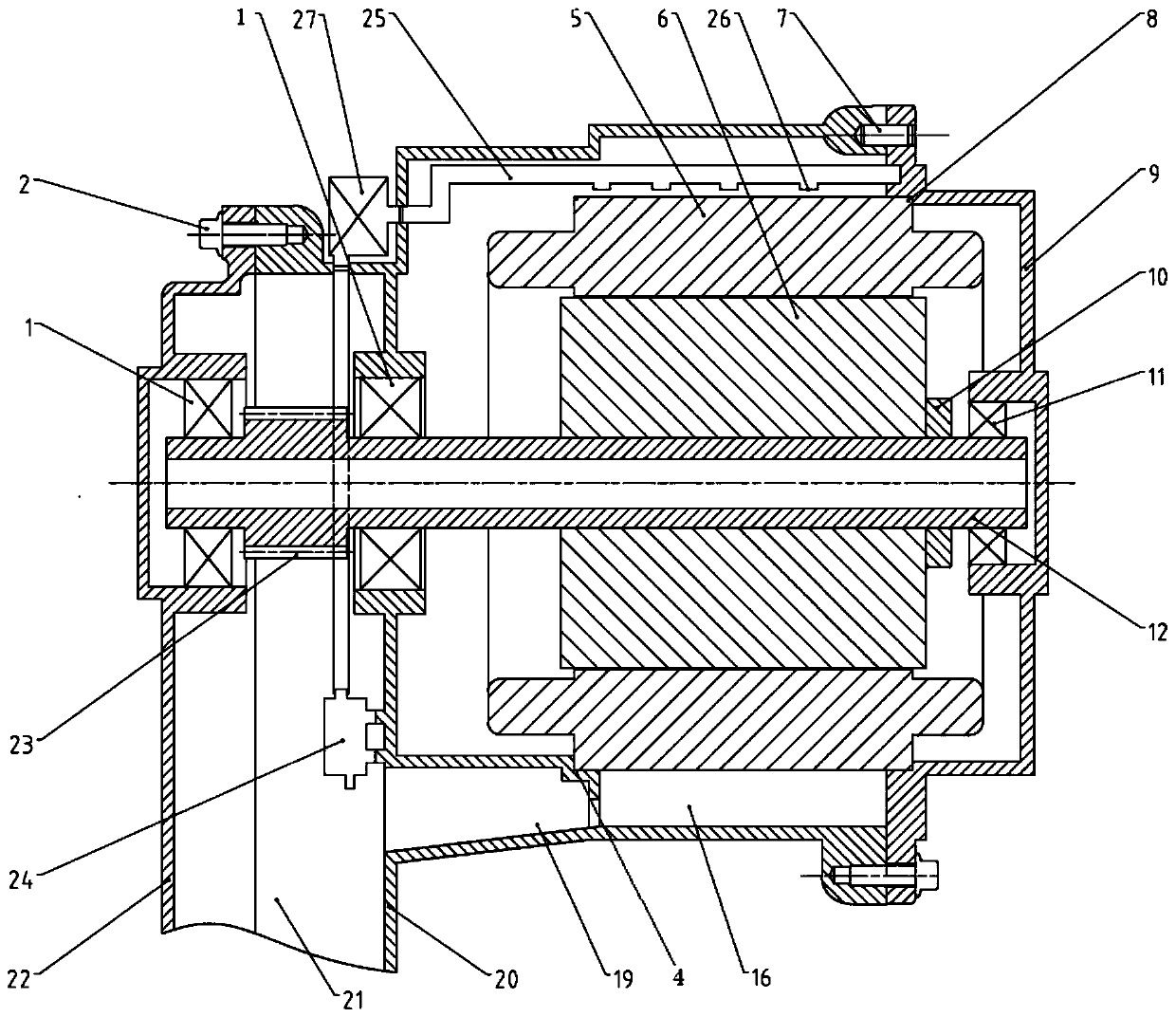

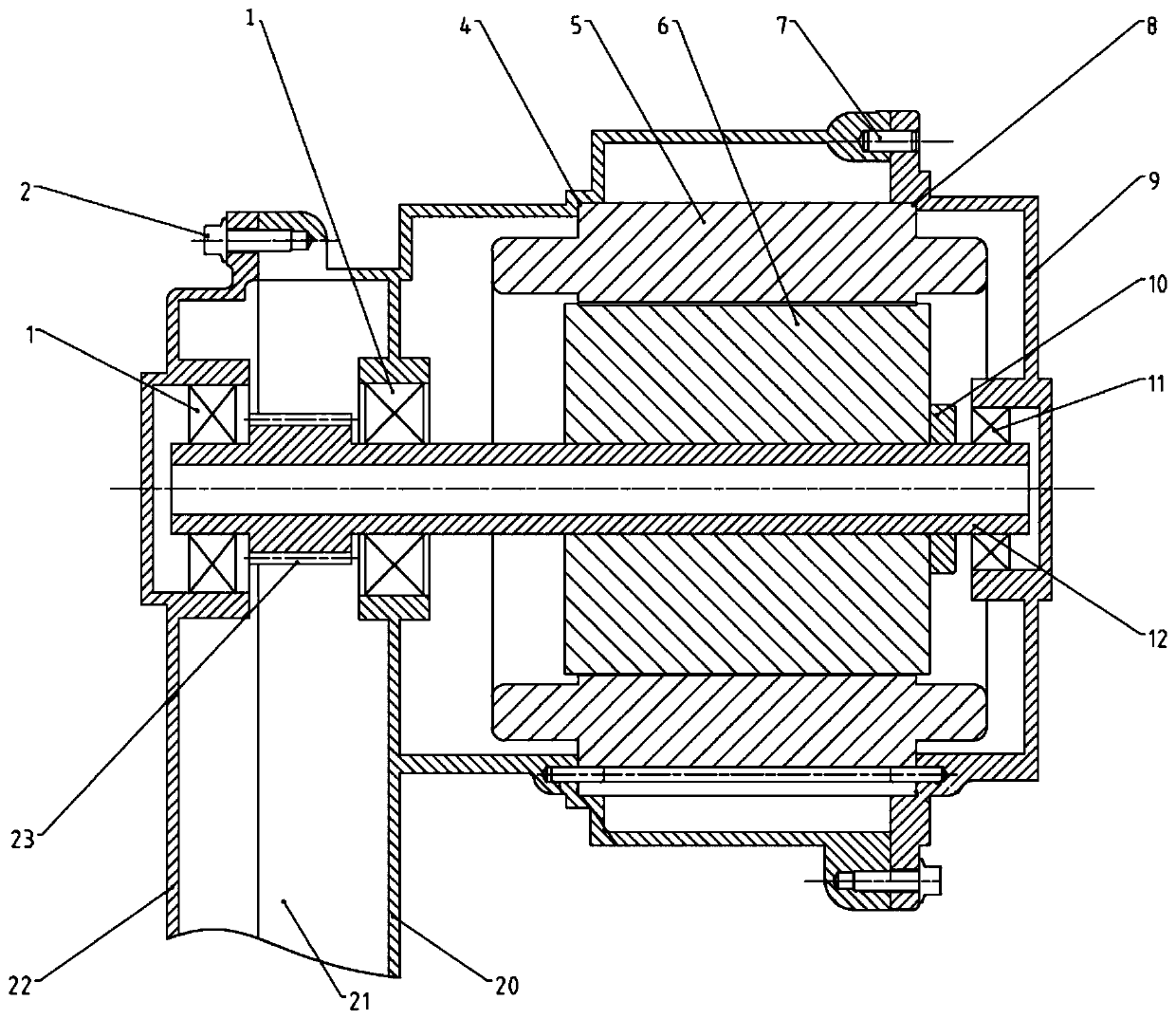

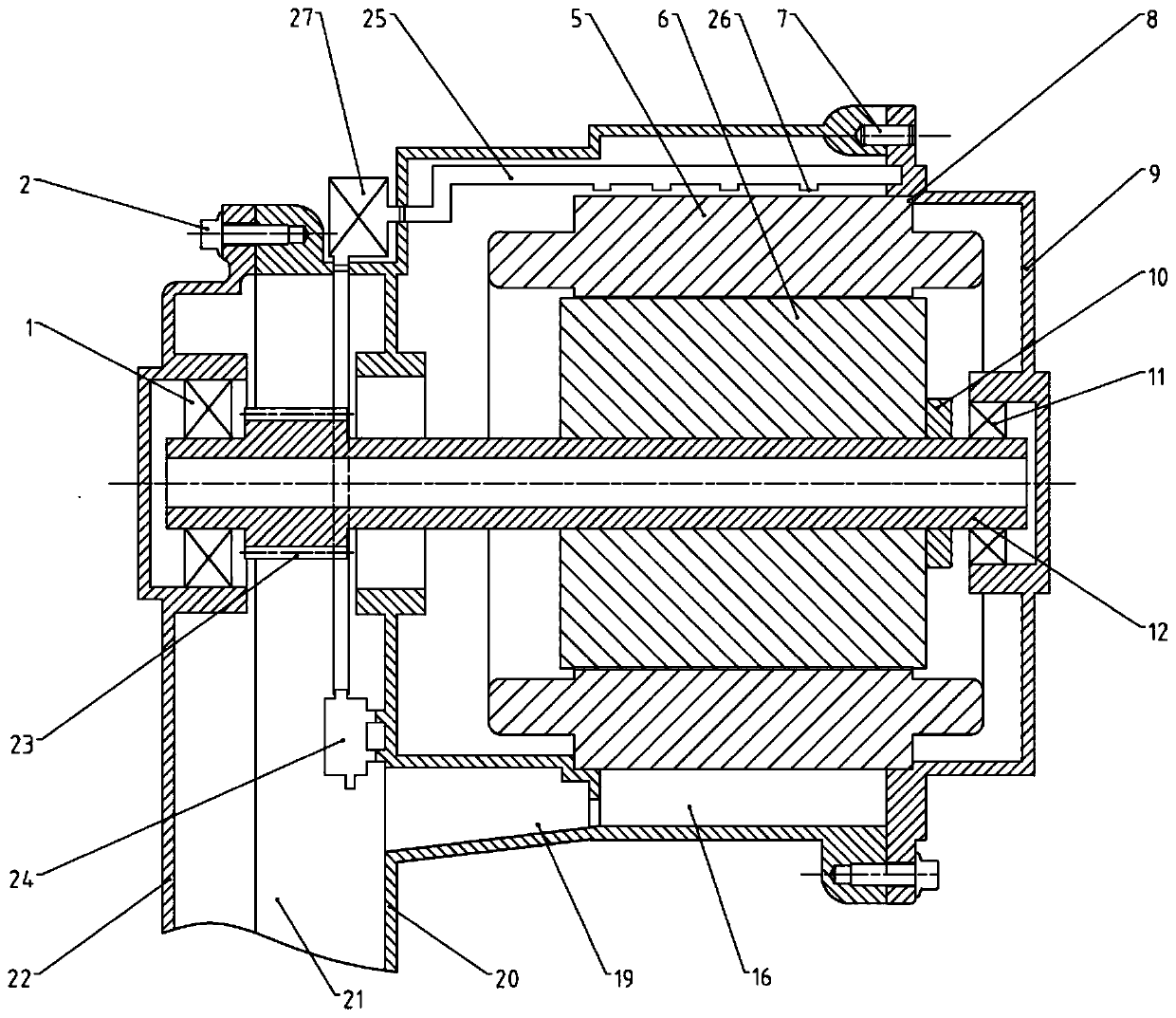

Oil cooling motor with integrated electric drive system

ActiveCN110071602AIncrease torqueIncrease powerCooling/ventillation arrangementSupports/enclosures/casingsElectricityElectric machine

The invention provides an oil cooling motor with an integrated electric drive system, and solves the problems of low integration, poor cooling effect of the stator and rotor of the motor and difficulty in ensuring uniformity of the air gap in the prior art. The oil cooling motor comprises a motor rotor, a motor stator, a transmission shaft, a cooling component and a casing, wherein the casing is divided into two chambers of a reducer working chamber and a motor working chamber; the transmission shaft passes through the motor rotor, one end of the transmission shaft is installed on the end cover of the motor through a first bearing, and the other end is mounted on the left housing or the right housing of the reducer through a second bearing; a reducer gear is also disposed on the transmission shaft; the motor stator is fixed between the right housing of the reducer and the end cover of the motor; the cooling component comprises an oil pump, an oil pipe and a heat exchanger; the heat exchanger is located outside the casing, the oil pump pumps the lubricating oil of the working chamber of the reducer through the oil pipe to the heat exchanger for cooling, then pumps into the working chamber of the motor and sprays on the motor stator and the motor rotor; and the two chambers are connected through an oil return hole.

Owner:SHAANXI FAST GEAR CO

Disposable cartridge

The invention discloses a disposable cartridge and relates to the field of atomized e-cigarettes. A to-be-atomized liquid storage cavity of the cartridge is filled with an absorption medium which restricts liquid fluidity. The cartridge further includes an air flow channel, the to-be-atomized liquid storage cavity, a heating atomization device and a liquid guide module of to-be-atomized liquid, and the absorption medium makes contact with the liquid guide module of the heating atomization device. The absorption medium is adopted and stores a large number of to-be-atomized liquid, meanwhile theabsorption medium makes contact with the liquid guide module, the to-be-atomized liquid penetrates into the liquid guide module through the absorption medium and is heated by the heating atomizationdevice to form smoke, and then the smoke is inhaled into the mouth cavity of a user. As the absorption medium limits flowing of tobacco tar, no flowing liquid exists in the to-be-atomized liquid storage cavity, the problem is solved that tobacco tar is easily leaked from a to-be-atomized liquid storage cavity of a traditional cartridge, leakage pollution is avoided, and the use experience is improved.

Owner:栗明

Whitening and skin-care cream and preparation method thereof

InactiveCN107174537AEvenly dispersedImprove stabilityCosmetic preparationsToilet preparationsSide effectIrritation

The invention relates to "a whitening skin care cream and its preparation method", and relates to the field of cosmetics. A whitening skin cream, which is mainly prepared from mirabilis seed oil, stearic acid, acetylated lanolin, glycerin, stearyl alcohol, methylparaben, triethanolamine, and mirabilis seed oil and glycerine Alcohol weight ratio is 1:1. The invention solves the problem that the mirabilis seed oil is easy to leak oil in the skin cream through the unique formula ratio and preparation process. The skin cream of the present invention can be used as a cosmetic for a long time. This product has no adverse side effects on the skin of the face or various parts of the body, is non-irritating, has obvious therapeutic effects on acne, ringworm, warts, acne and other symptoms, and also has antipruritic and antibacterial properties It is a skin care product integrating beauty, curative effect, function and naturalness.

Owner:刘从双

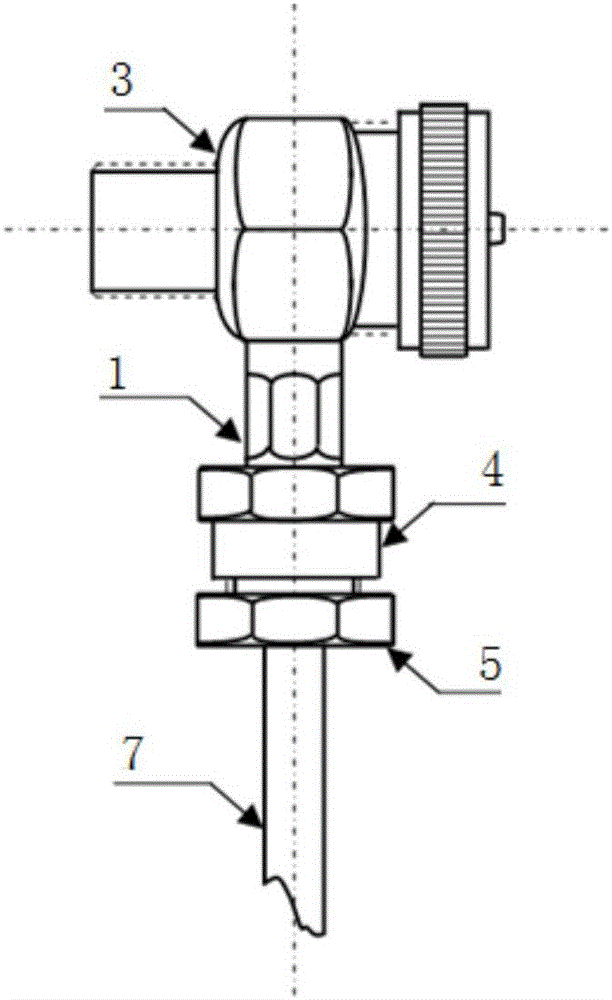

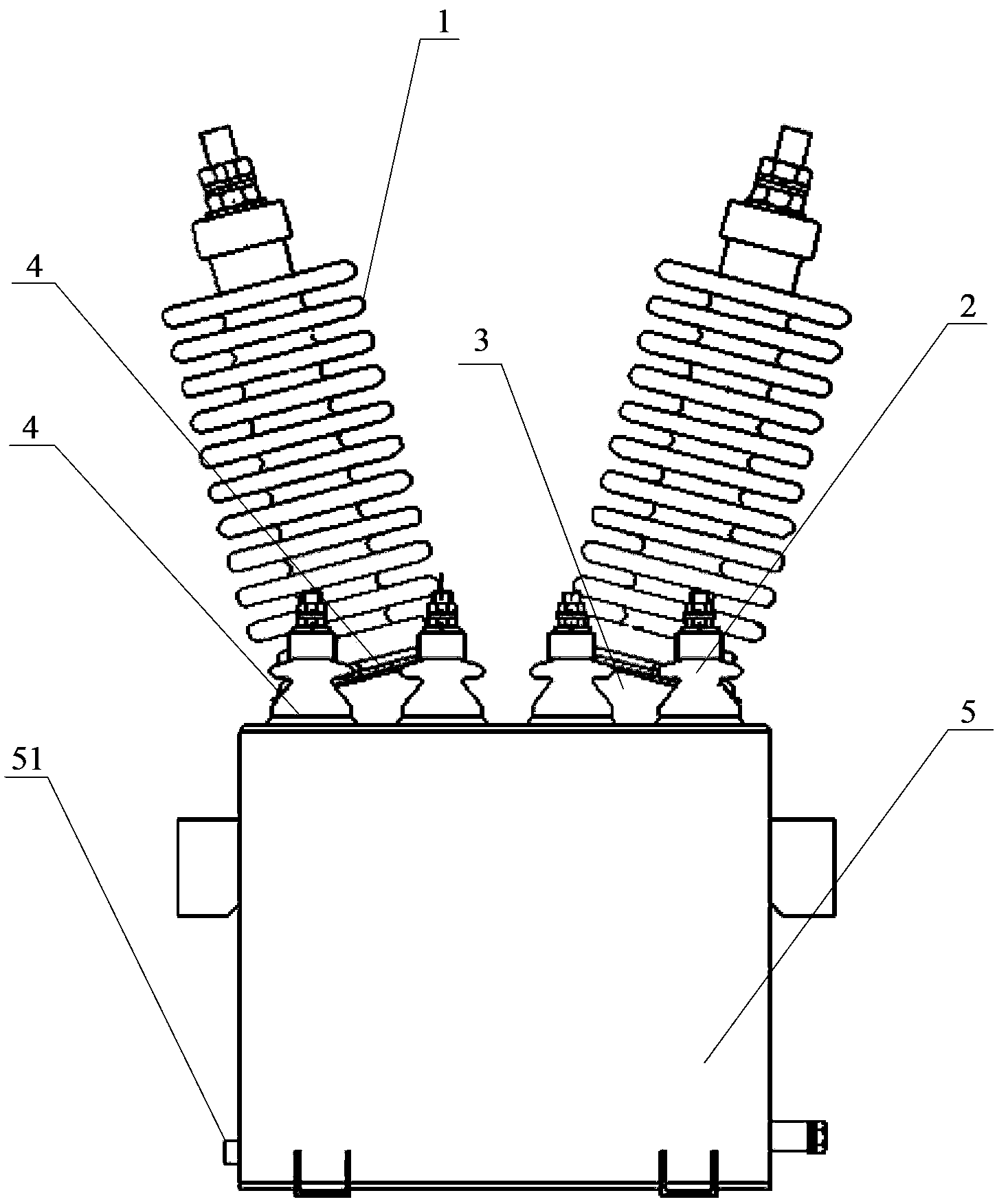

Oil drain valve and oil pipe loop sealing device assembly for transformer oil chromatography online monitoring device

ActiveCN106090474AImprove safe and stable operationRun fastJoints with sealing surfacesPower usageTower

The invention discloses an oil drain valve and oil pipe loop sealing device assembly for a transformer oil chromatography online monitoring device. The oil drain valve and oil pipe loop sealing device assembly comprises a connection arm, a sealing flat ring, an oil drain valve, a locking sealing oil pipe nut, a locking sealing oil pipe hollow bolt, a hollow tower-shaped sealing ring and an oil pipe. Through the oil drain valve and oil pipe loop sealing device assembly for the transformer oil chromatography online monitoring device, the problem of oil leakage in the joint of the oil drain valve and the oil pipe of the high-voltage high-capacity transformer oil chromatography online monitoring device is solved, the defects of the transformer oil chromatography online monitoring device are overcome, a great facilitation function on deep development of transformer oil chromatography online monitoring work with high heat degree in China at present is achieved, a positive boosting effect is achieved for installing oil chromatography online monitoring devices on high-voltage high-capacity transformers in China energetically, and effective safety measures and technical support are provided for further improving safe and stable operation of the transformers and reliability of safe power usage.

Owner:STATE GRID TIANJIN ELECTRIC POWER +1

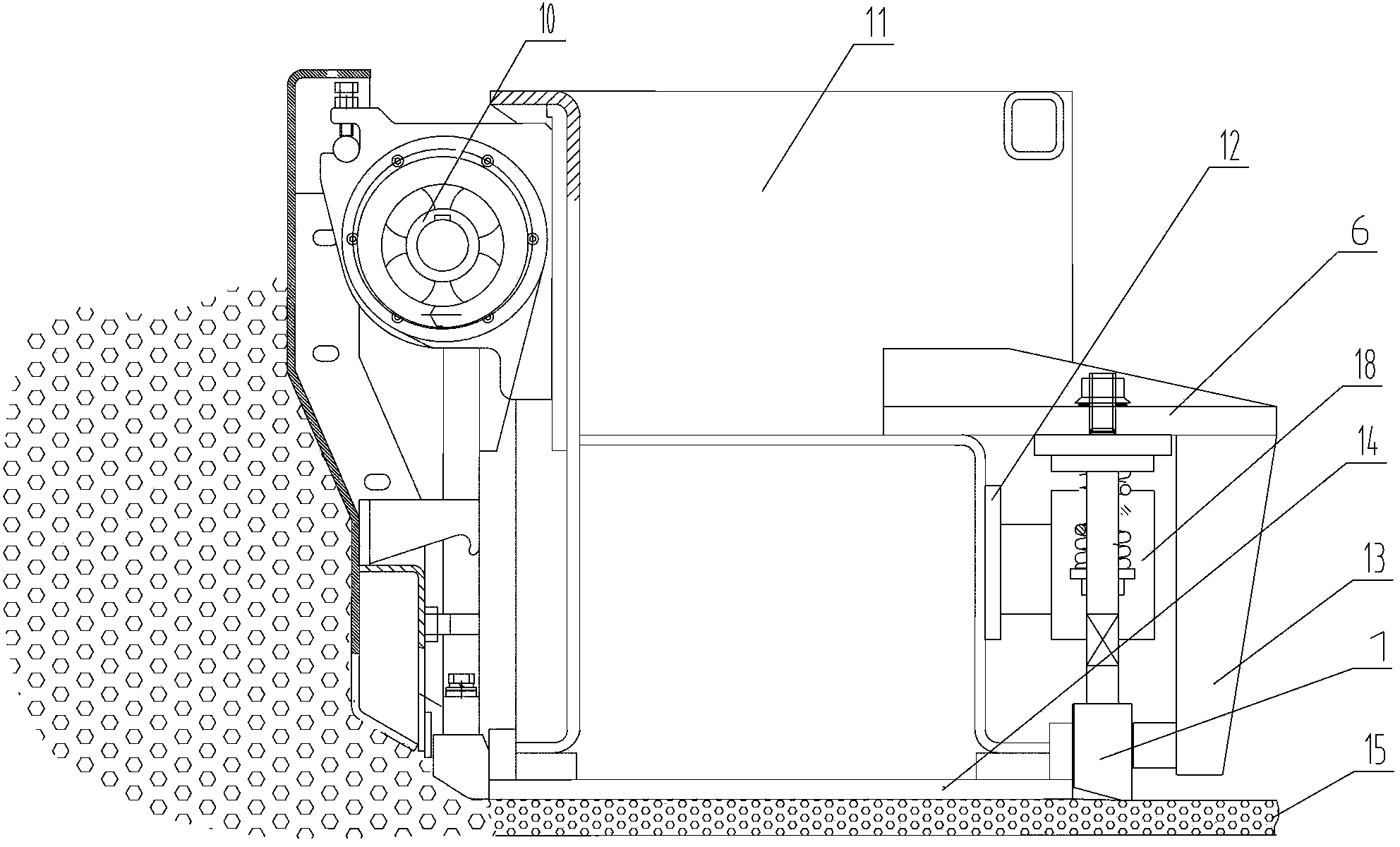

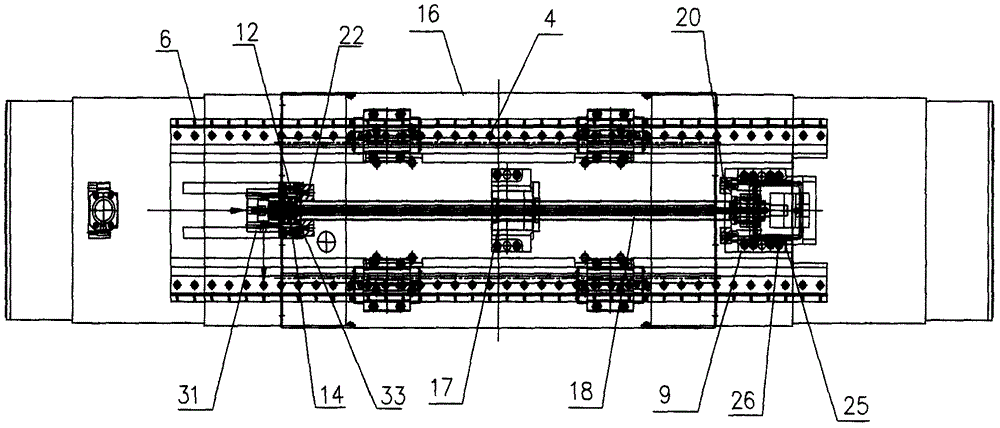

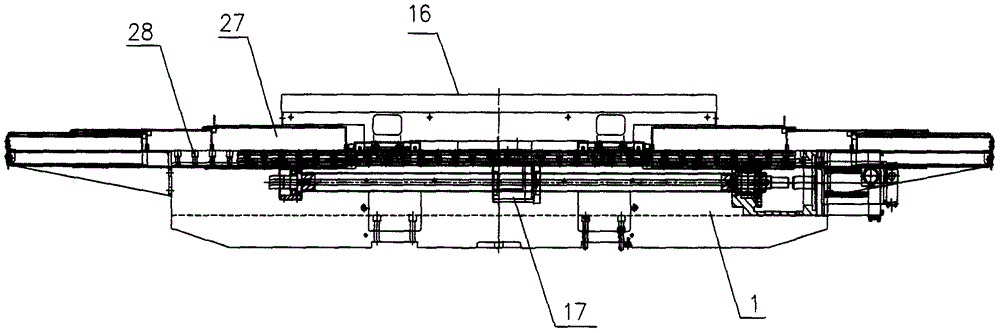

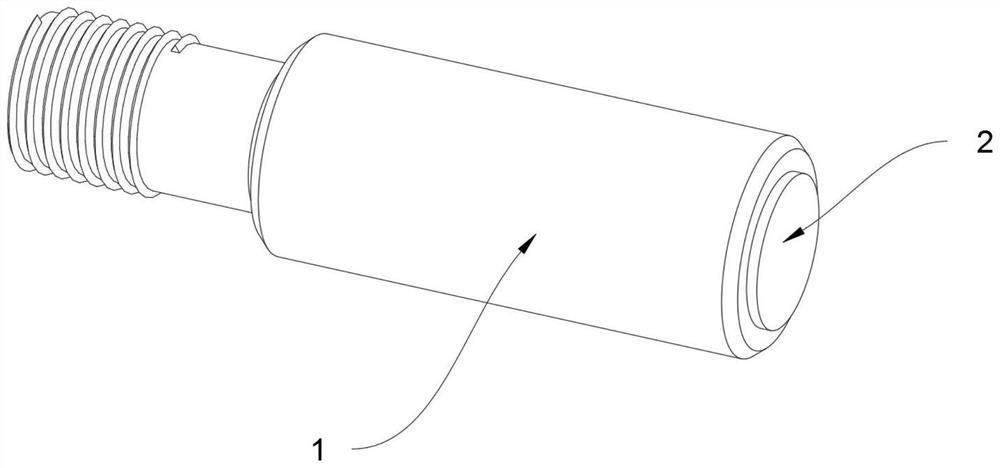

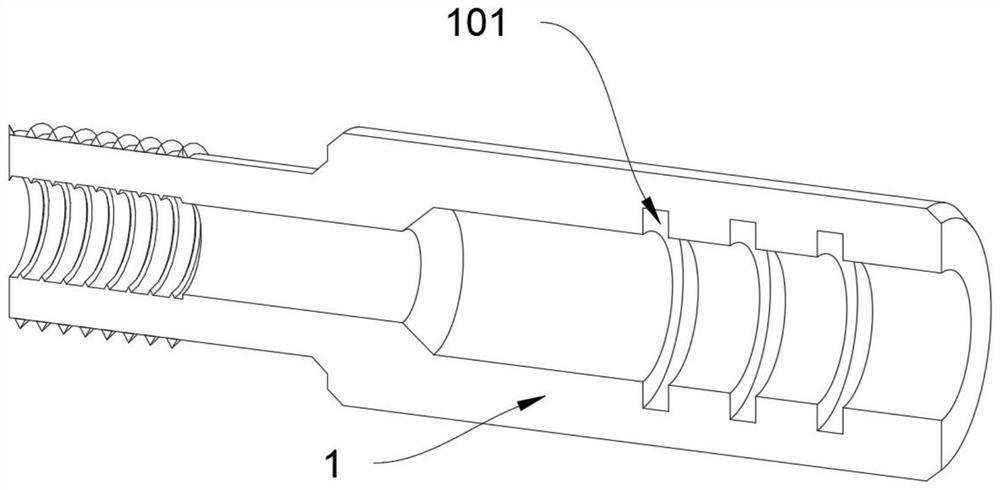

Sealing device for hollow oil cooling tail end seat of machining center screw

PendingCN106541299AReduce heatReduce generationFeeding apparatusMaintainance and safety accessoriesBall bearingBall screw

The invention discloses a sealing device for a hollow oil cooling tail end seat of a machining center screw. The sealing device comprises a worktable and a saddle. The worktable is mounted on the upper part of the saddle through hexagon socket head cap screws with heads and slide blocks on pin roller wire rails, X-axis extensible cover units are mounted at two ends of the lateral side of the worktable through round head screws and flat washers, a group of the pin roller wire rails is mounted on two sides of the upper part of the saddle through hexagon socket head cap screws with heads and set hexagon socket head cap screws, a tail end supporting seat is mounted at one end of the upper part of the saddle through hexagon socket head cap screws with heads and an X-axis driving seat unit is mounted at the other end through hexagon socket head cap screws with heads and angle pins, a deep groove ball bearing is mounted in the tail end supporting seat through a C-shaped retaining ring, a deep groove ball bearing is mounted in the X-axis driving seat unit, a hollow ball screw is connected between the deep groove ball bearing in the tail end supporting seat and the deep groove ball bearing in the X-axis driving seat unit, and an oil seal is arranged in the tail end seat at the tail end of the ball screw. The sealing device has the beneficial effect of solving the problem that oil is likely to leak in a using process.

Owner:NINGBO MACO MECHATRONIC

Spot welding method for reinforcing rib of corrugated sheet of corrugated oil tank

InactiveCN104759748ASolve oil leakageSolve the mechanical strengthTransformers/inductances coolingInductances/transformers/magnets manufactureFuel tankAtmospheric pressure

The invention discloses a spot welding method for a reinforcing rib of a corrugated sheet of a corrugated oil tank. The spot welding method specifically comprises the steps that a long arm welding machine is adopted, after voltage and air pressure are adjusted, spot welding is conducted at the reinforcing rib, formed through pressing, of the corrugated sheet in the length direction of the reinforcing rib at the interval of 40-50 mm, and then the spot welding of the reinforcing rib of the corrugated sheet of the corrugated oil tank is completed. By the adoption of the spot welding method, a corrugated wing will not deform and can bear the mechanical strength of 50 kPa which is far larger than a nationally regulated value, the oil injection amount can be reduced, and the problem that the oil tank leaks oil can be solved.

Owner:JIANGSU ZHONGRONG ENVIRONMENTAL PROTECTION

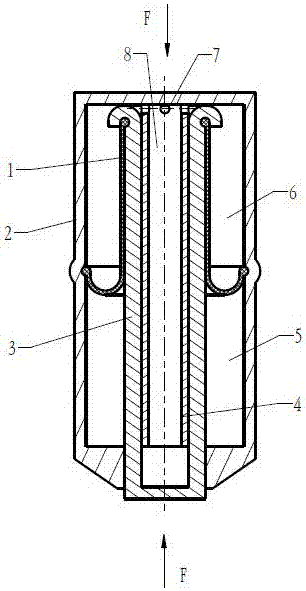

Rodless Cavity Static Seal Cylinder

ActiveCN105587708BLarge bearing pressureLight weightFluid-pressure actuatorsInternal pressureHigh pressure

The present invention relates to a rodless cavity static seal oil cylinder. The capsule (1) separates and forms the rod cavity (5) and the rodless cavity (6) of the cylinder in this case, wherein the rod cavity (5) is a dynamic sealing cavity, and the rodless cavity The cavity (6) is a static sealing cavity. During the stretching and compression process of the oil cylinder, the capsule (1) is only rolled up and attached to the inner wall of the cylinder (2) and the outer wall of the piston rod (3). When the rodless chamber (6) is fed with high-pressure oil or high-pressure gas, the rod chamber (5) of the oil cylinder discharges oil or gas, and the oil cylinder stretches. When the external force F at both ends of the oil cylinder is greater than the internal pressure of the rodless cavity (6), the oil cylinder compresses.

Owner:重庆戴文能源科技有限公司

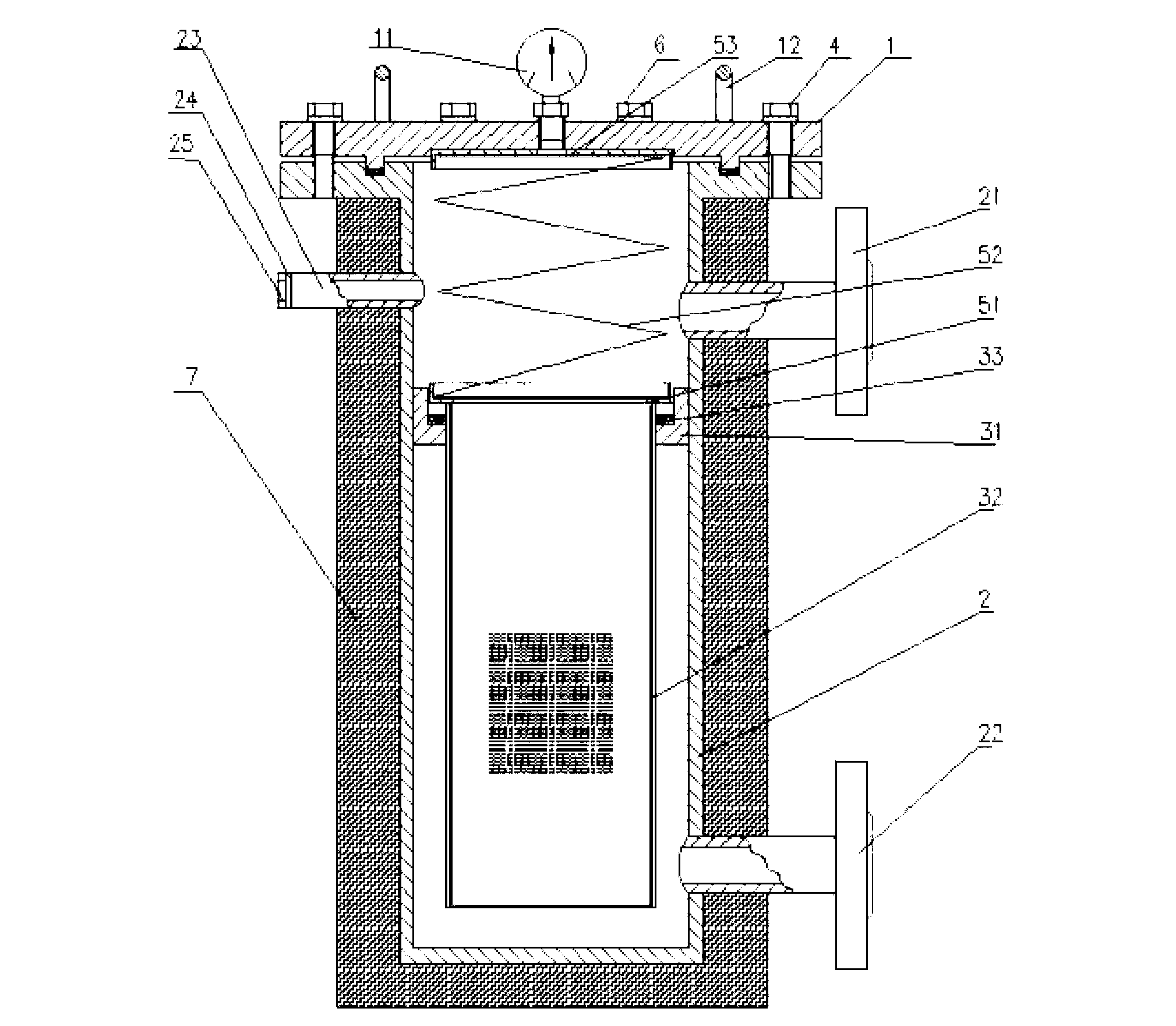

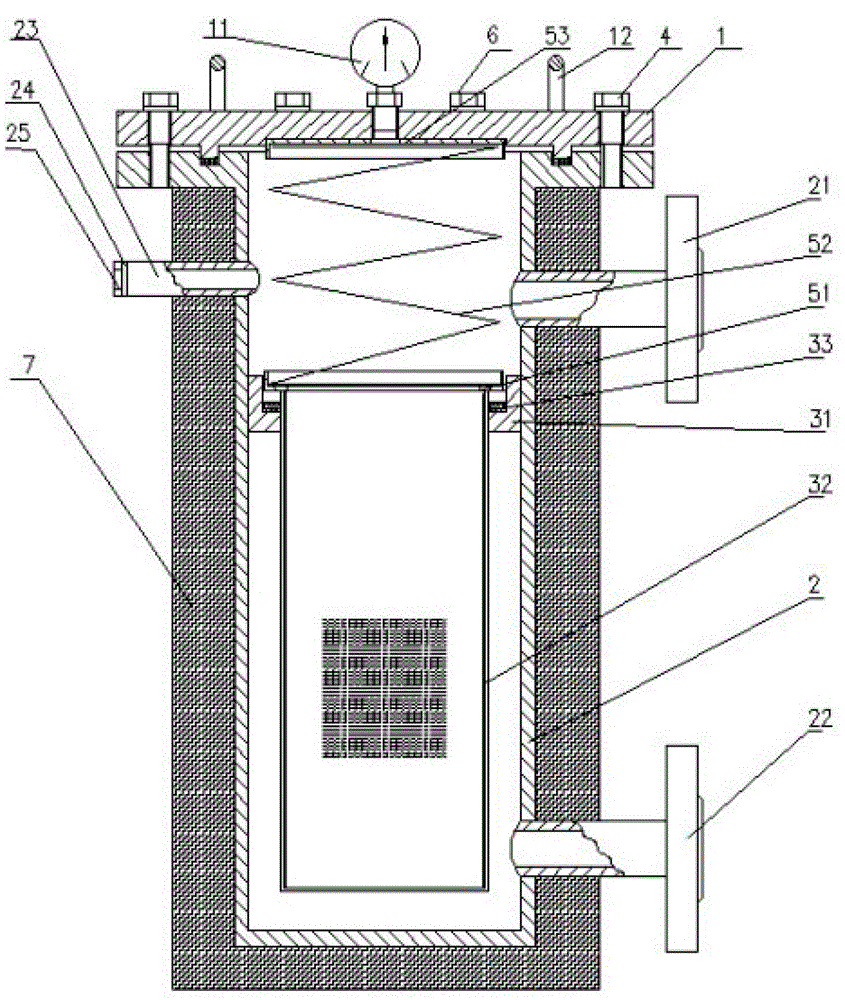

Anti-liquid-channeling high-temperature-resisting filtering device

ActiveCN103007605ASolve oil leakageImprove securityStationary filtering element filtersCarbon steelMetal

The invention discloses an anti-liquid-channeling high-temperature-resisting filtering device. The filtering device is formed by a barrel cover, a barrel body, an oil inlet pipe opening at the upper part of one side of the barrel body, an oil outlet pipe opening at the lower part of one side of the barrel body, a filtering net tray and a metal filtering net assembly, wherein the filtering net tray and the metal filtering net assembly are placed inside the barrel body; a high-temperature sealing gasket is mounted between the convex edges of the filtering net tray and the metal filtering net assembly; a force application device formed by a lower bowl-shaped sleeve of a compressed spring, the compressed spring and an upper bowl-shaped sleeve of the compressed spring vertically acts on the convex edge of the metal filtering net assembly, so that an upper cavity and a lower cavity of the barrel body are in sealed separation; a maintenance oil discharging opening is formed in the upper part of the barrel body; and all the components of the filtering device are prepared from stainless steel or carbon steel metal materials. The anti-liquid-channeling high-temperature-resisting filtering device disclosed by the invention can be ensure no liquid channeling in a filtering process and can resist a high temperature of 400 DEG C, and has the advantages of safety and convenience in a maintenance process, convenience for popularization and application, and the like.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

An oil storage device for an electronic atomizer

Owner:CHINA TOBACCO HUNAN INDAL CORP

Intermediate conjunction box body for oil-immersed electric roller motor leading-out wire

Owner:天津斯巴克斯机电有限公司

A kind of rotating shaft device and electronic equipment

ActiveCN105134753BSolve oil leakageSmooth rotationPivotal connectionsEngineeringElectronic equipment

Owner:LENOVO (BEIJING) LTD

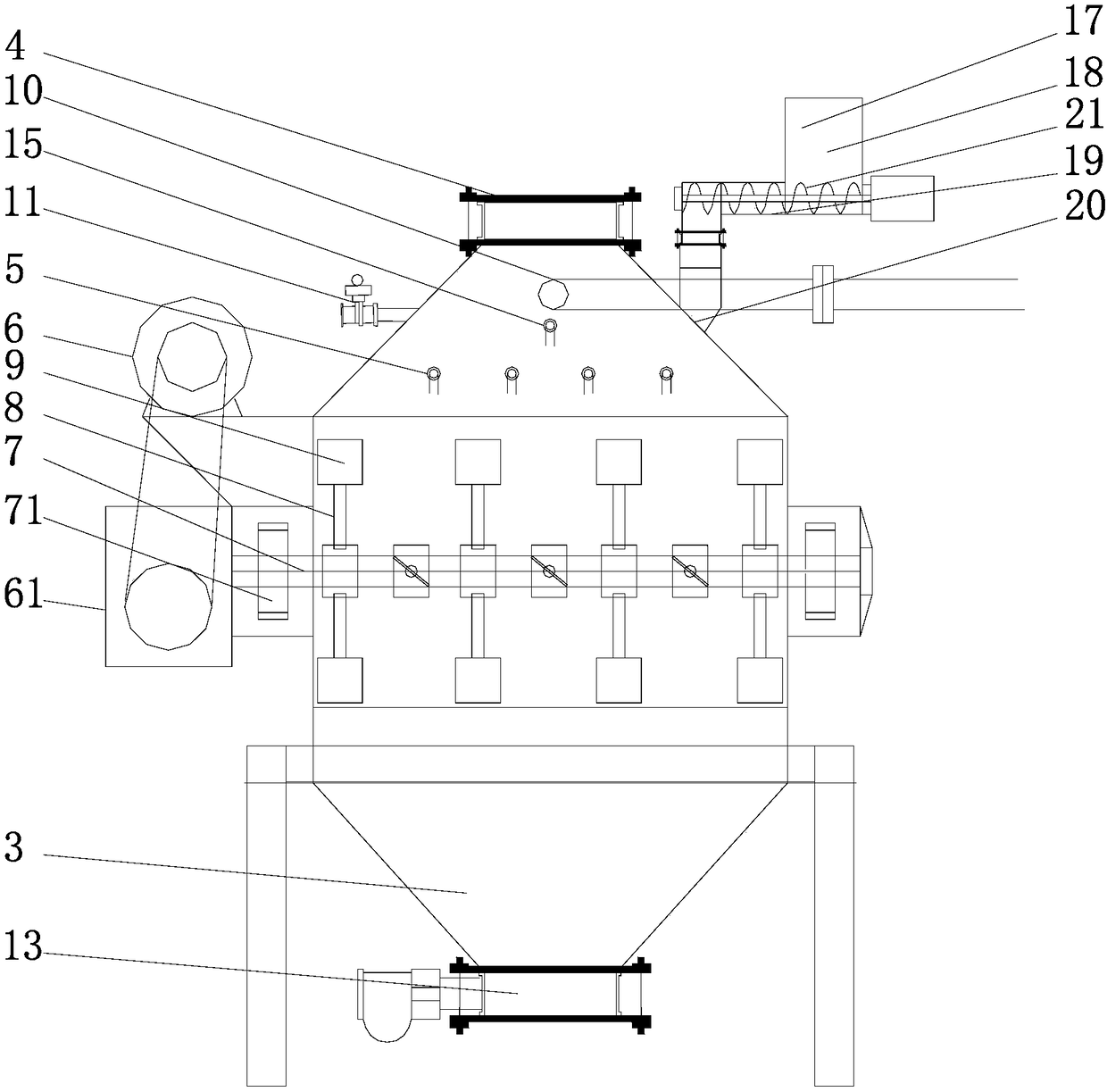

Supporting-point-free universal type blender transmission mechanism

Owner:DALIAN CLEAN ENERGY HEAVY IND +1

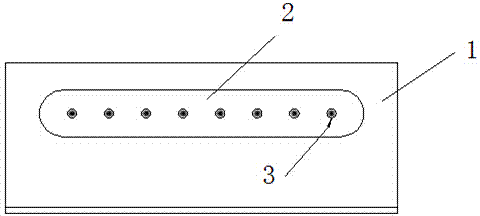

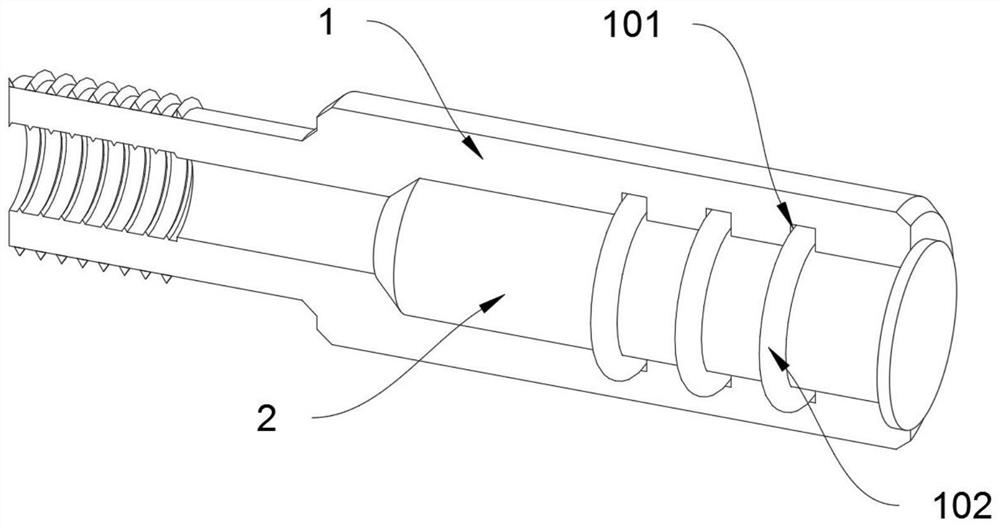

Micro hydraulic cylinder structure

InactiveCN111810487ASolve oil leakageClosely connectedFluid-pressure actuatorsHydraulic ramMaterials science

The invention discloses a micro hydraulic cylinder structure, relates to the technical field of hydraulic cylinders, and solves the problem of hydraulic oil leakage caused by unreasonable cylinder barrel size design and seal ring size design of an existing suspension hydraulic lock. The micro hydraulic cylinder structure comprises a cylinder barrel; and a cylinder rod is inserted into the cylinderbarrel. According to the micro hydraulic cylinder structure provided by the invention, three seal rings are arranged inside the device, thus the existing hydraulic oil leakage phenomenon can be effectively solved; the depth and width of a sealing groove and the outer diameter of the cross sections of the seal rings are the same, and the inner diameter of the seal rings is the same as the outer diameter of the cylinder rod, so that the seal rings are more closely connected with the cylinder barrel and the cylinder rod, the oil leakage phenomenon caused by the unreasonable cylinder barrel sizedesign and the seal ring size design can be effectively solved, and the practicability of the device is improved.

Owner:湖北豪凯汽车零部件有限公司

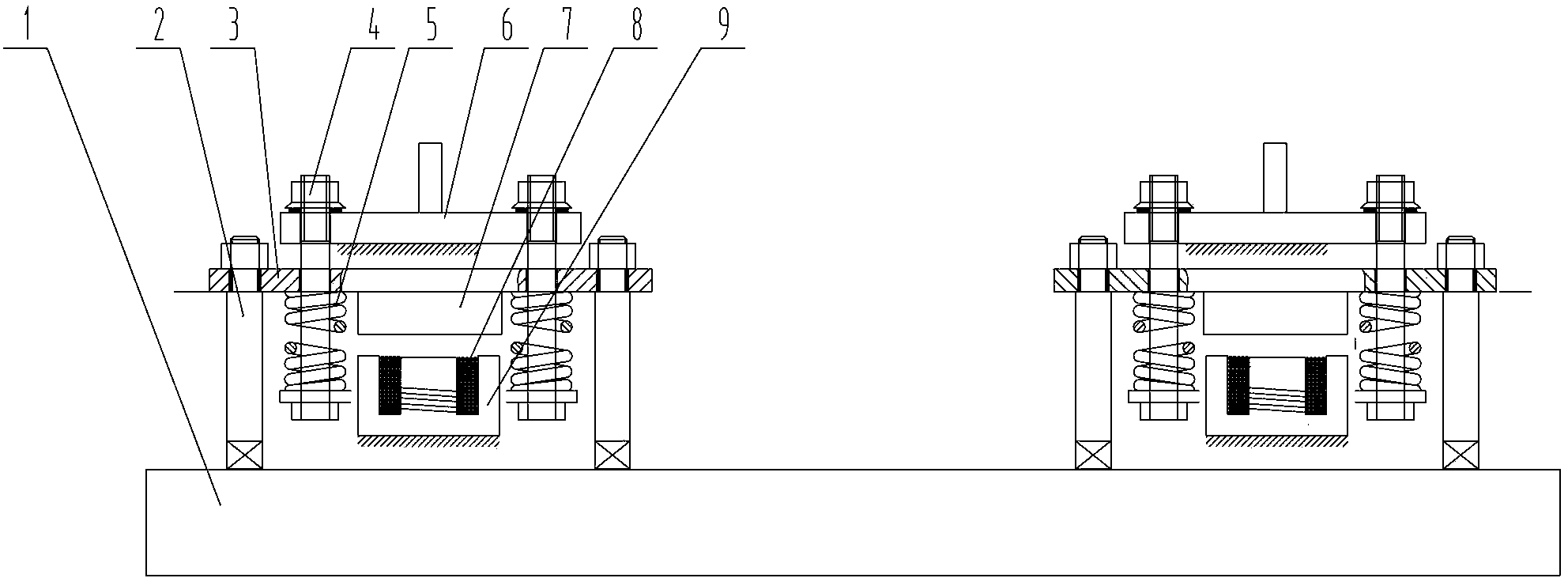

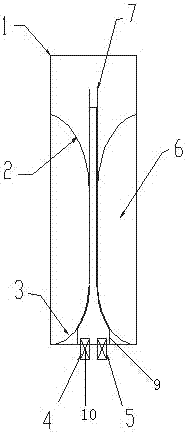

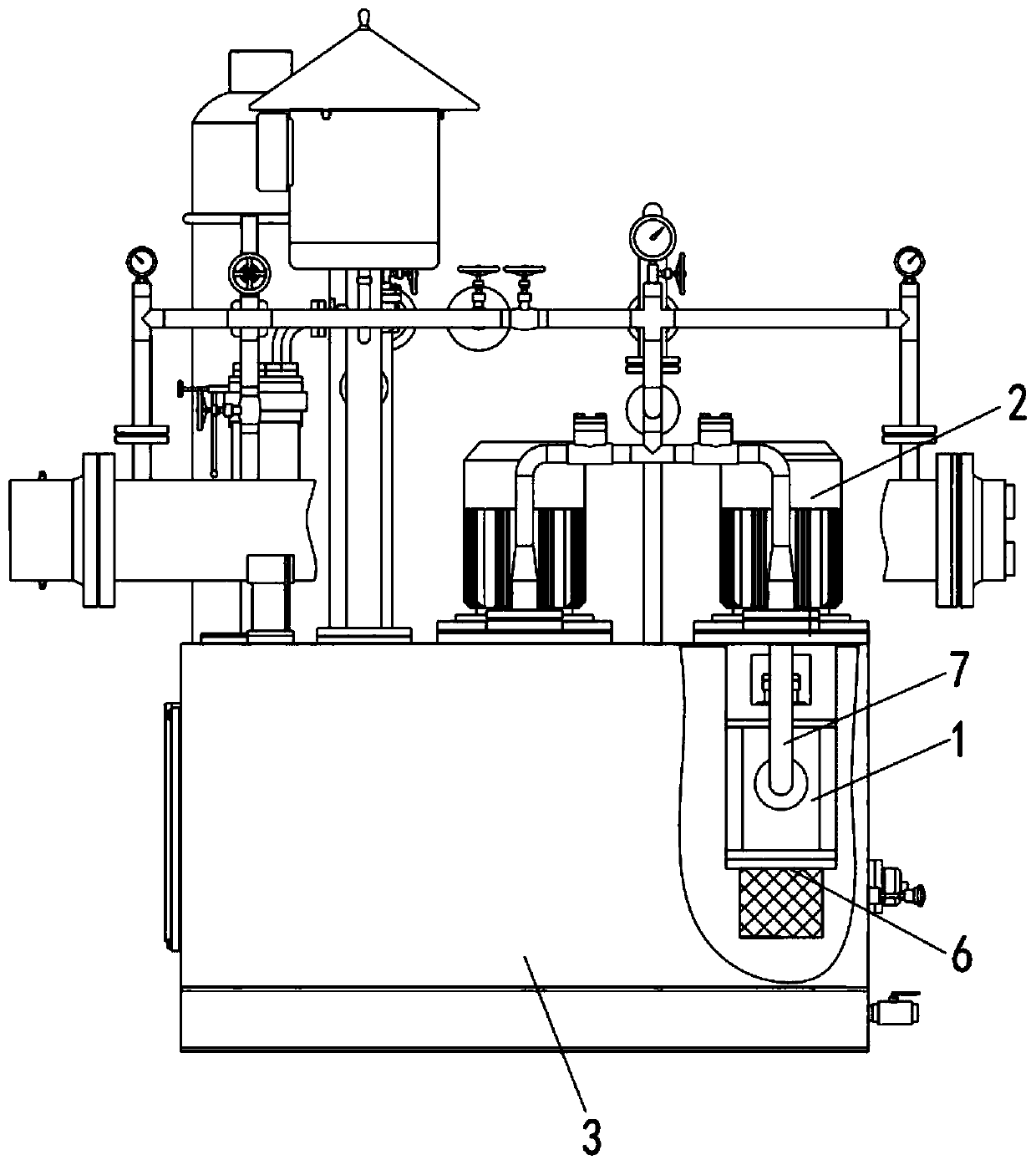

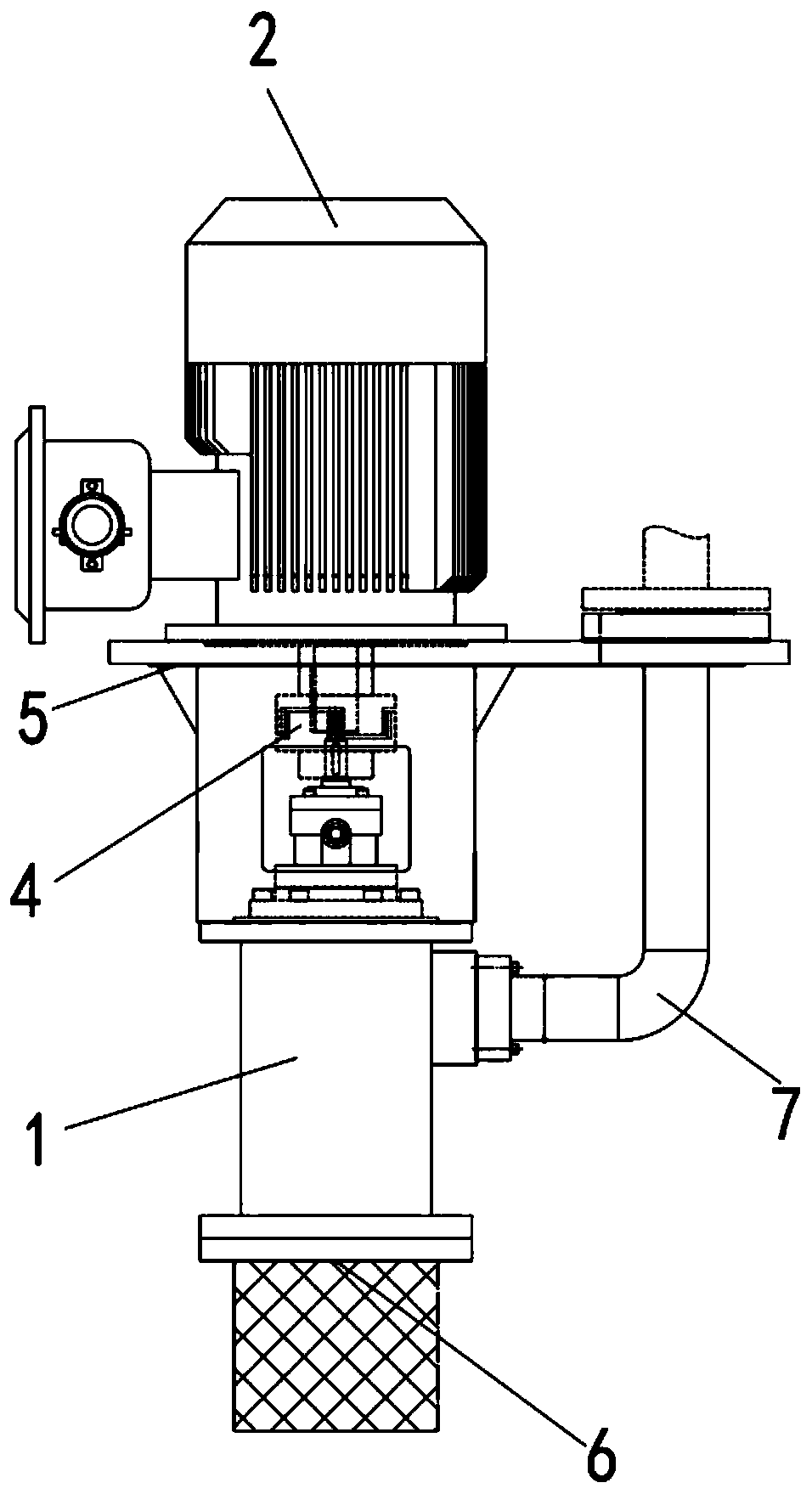

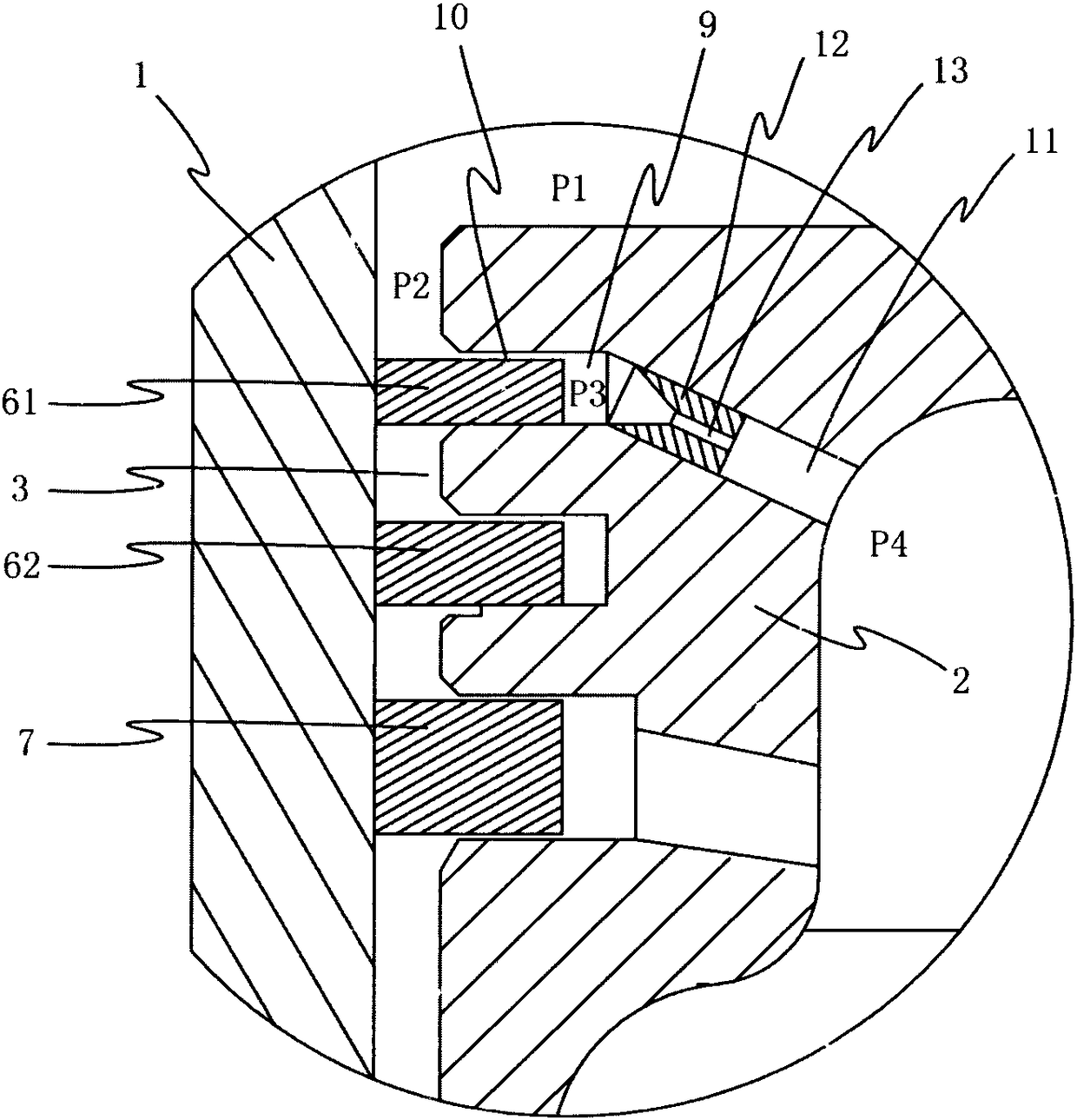

Oil supply device without oil pump oil leakage for turbo expander

PendingCN111485960ASolve oil leakageHigh oil absorptionMachines/enginesEngine componentsElectric machineryPollution

The invention discloses an oil supply device without oil pump oil leakage for a turbo expander. The oil supply device comprises an oil pump and an oil tank, wherein the oil pump is connected with a motor through a coupler, and the oil pump and the coupler are arranged in the oil tank. According to the oil supply device without oil pump oil leakage for the turbo expander, the oil pump and the coupler are arranged in the oil tank together, so that the oil suction effect of the oil pump is better, the phenomenon that the oil pump leaks oil outwards is thoroughly avoided, pollution to the environment is eliminated, the purposes of energy conservation, emission reduction and environmental protection are achieved, and meanwhile the use cost is saved.

Owner:苏州制氧机股份有限公司

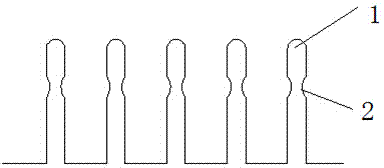

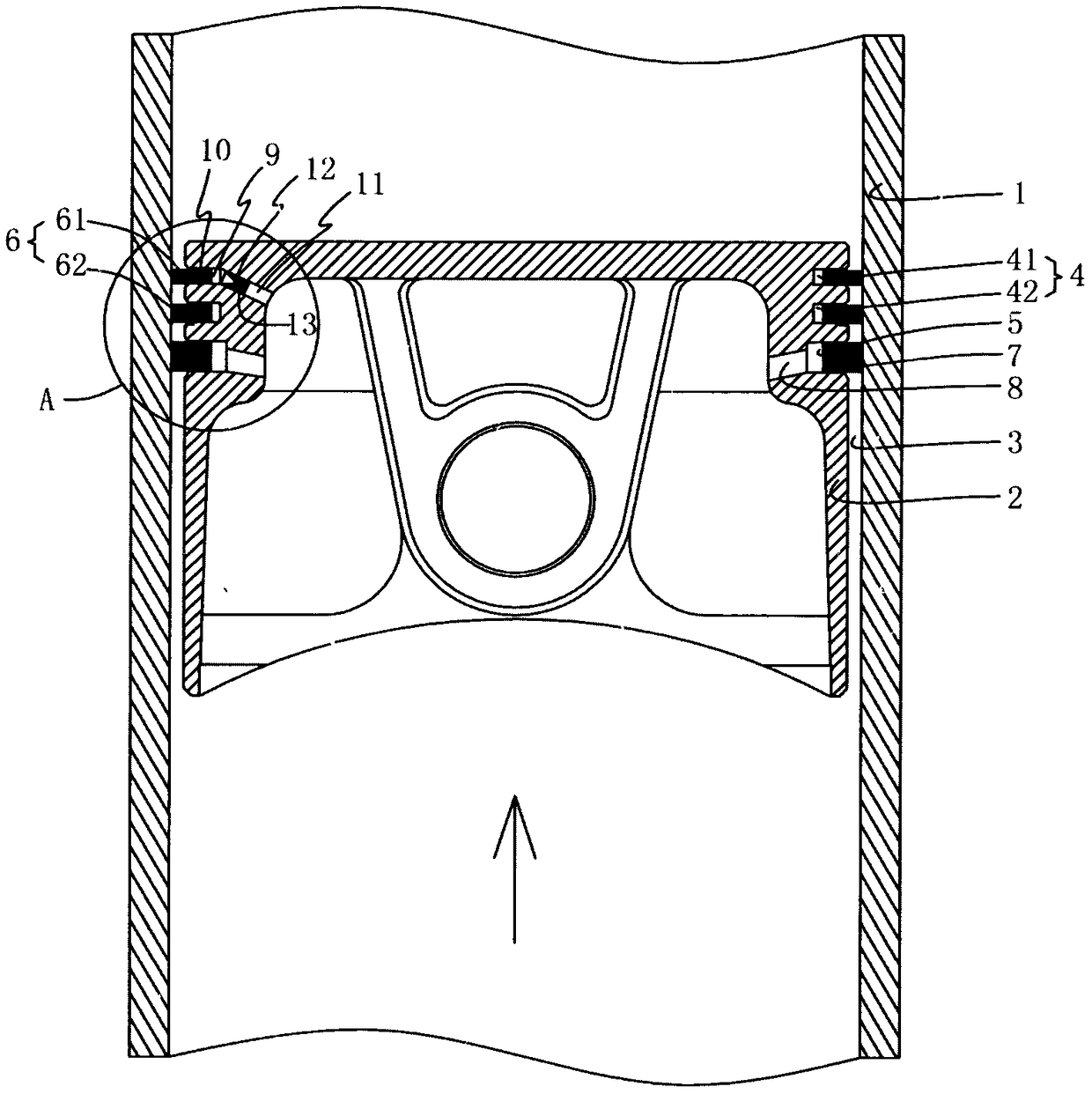

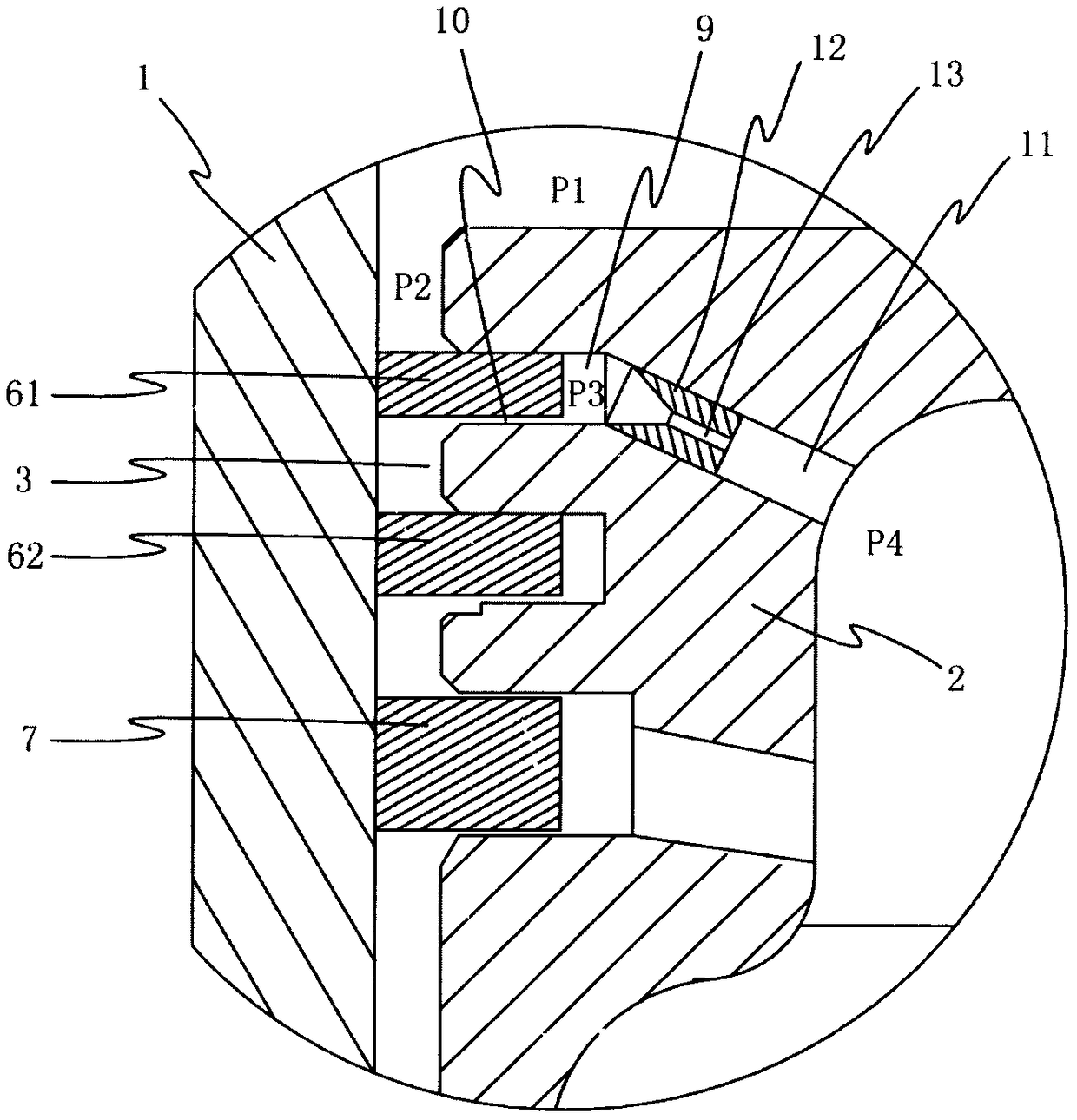

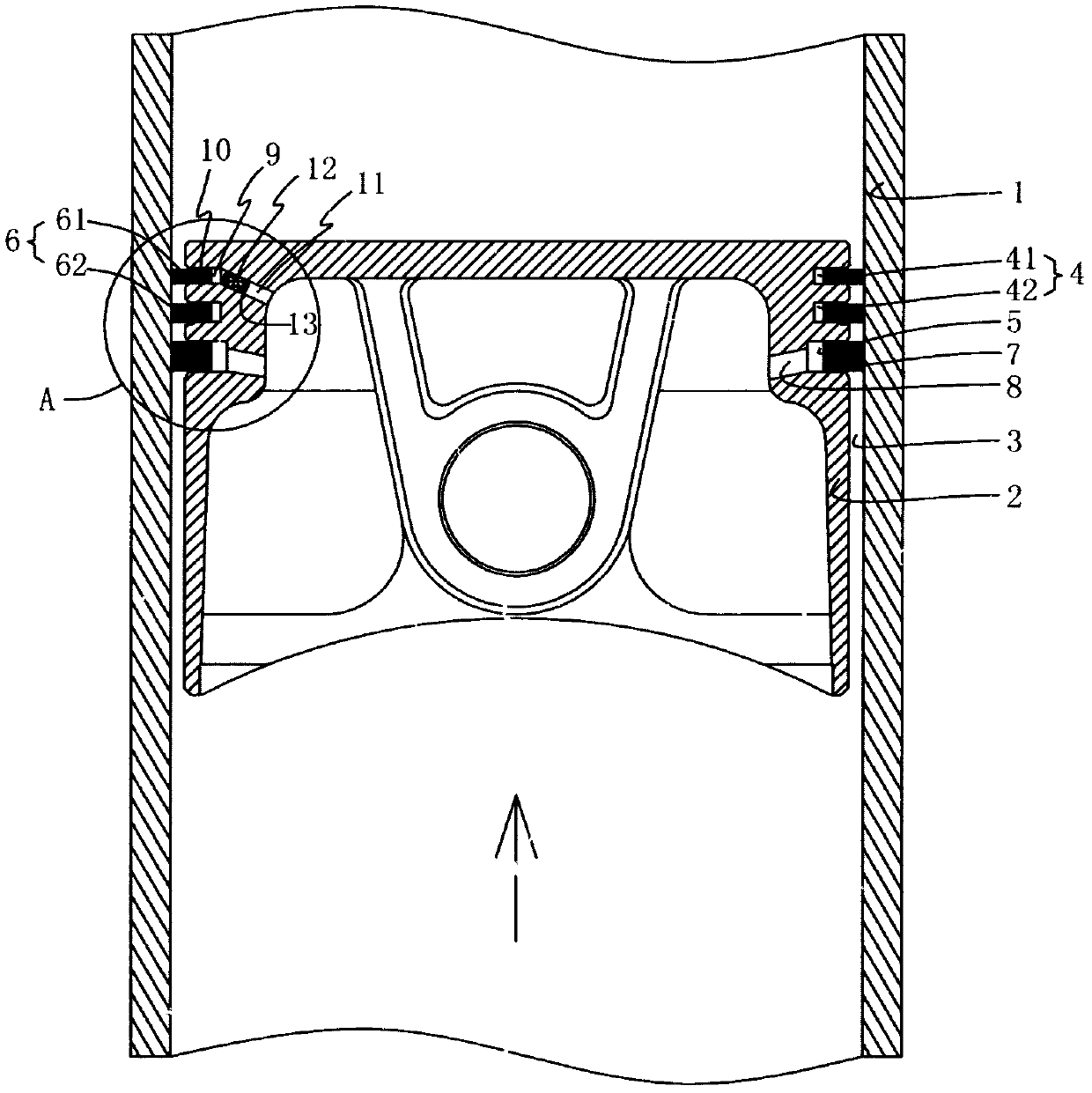

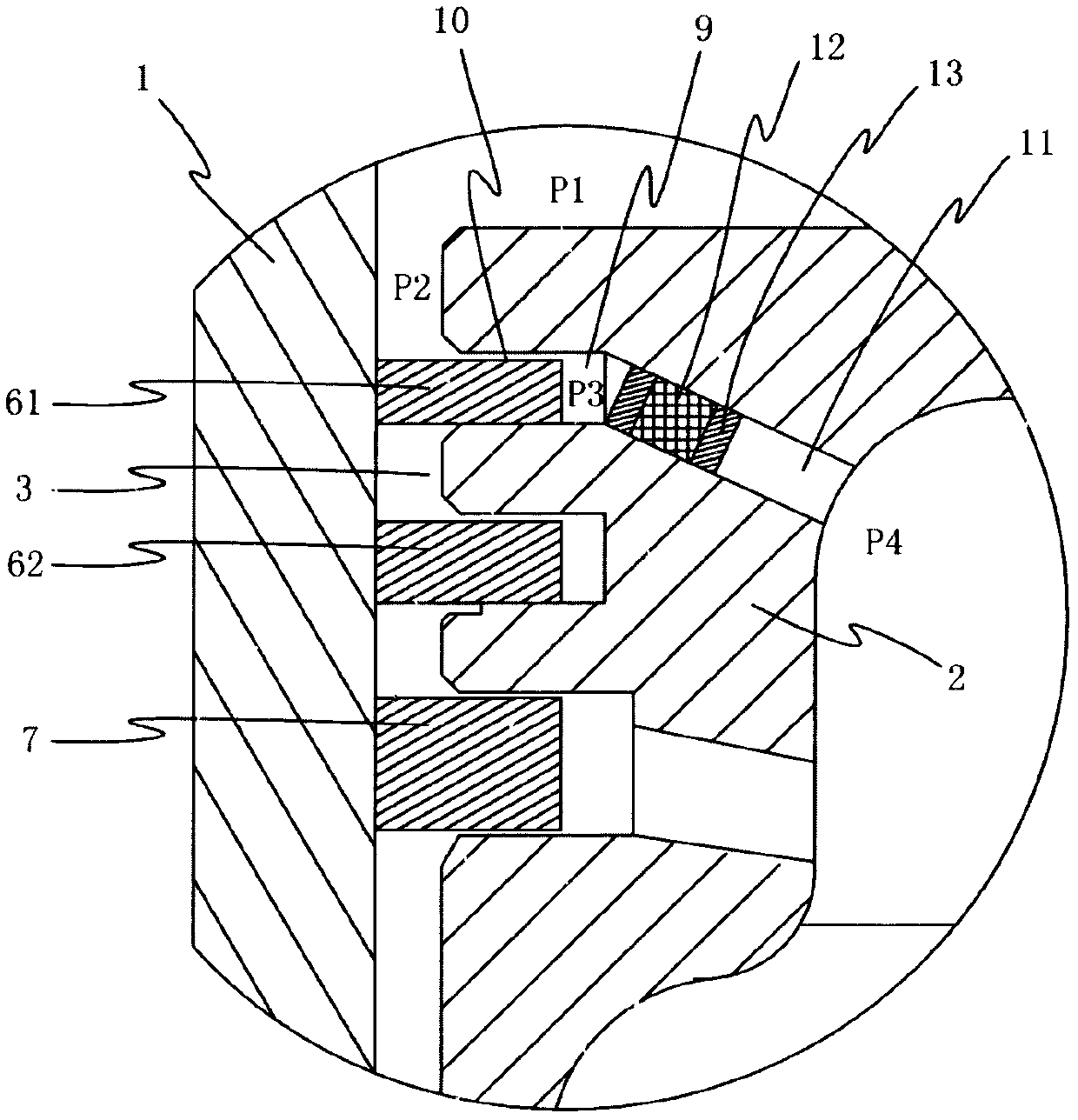

A built-in anti-channeling oil piston structure

ActiveCN105736317BPlay a lubricating roleSolve oil leakagePositive displacement pump componentsPistonsDifferential pressureInternal combustion engine

The invention discloses an embedded oil pumping prevention piston structure. The embedded oil pumping prevention piston structure comprises a piston arranged in a cylinder jacket; a gap cavity is formed between the outer wall of the piston and the inner wall of the cylinder jacket; a gas ring groove and an oil ring groove are formed in the outer wall of the piston; a gas ring is mounted in the gas ring groove; an oil ring is mounted in the oil ring groove; the gas ring is movably arranged in the gas ring groove; a back gap cavity is formed between the gas ring and the side wall of the gas ring groove; a gap channel for conducting the back gap cavity with the gap cavity is formed between the gas ring and the upper wall and / or the lower wall of the gas ring groove; an assembly hole is formed in the piston body; an embedded part matched with the assembly hole is embedded in the assembly hole; and the embedded part is provided with a dredging channel with two conducted ends. The embedded oil pumping prevention piston structure uses a pressure difference generated in the pressurization process of an air compressor or an internal combustion engine, and uses the dredging channel for removing pumped oil in the back gap cavity of the piston, so that the service life of the air compressor or the internal combustion engine is longer, and the operation is more stable; and for manufacturing, the precision requirement is lower, the cost can be reduced, and the manufacturing is facilitated.

Owner:FENGHUA DINGLIAN AUTO AIR COMPRESSOR FACTORY

A New Embedded Anti-Blow-by Oil Piston Structure

ActiveCN105697338BPlay a lubricating roleSolve oil leakagePositive displacement pump componentsPistonsEngineeringPressure difference

The invention discloses a novel built-in oil expelling prevention piston structure which comprises a piston arranged in a cylinder sleeve. An interval cavity is formed between the outer wall of the piston and the inner wall of the cylinder sleeve. The outer wall of the piston is provided with a gas ring slot and an oil ring slot. A gas ring is installed in the gas ring slot movably. An oil ring is installed in the oil ring slot. A back clearance cavity is formed between the gas ring and the side wall of the gas ring slot. An interval channel is formed between the gas ring and the upper wall of the gas ring slot and / or the lower wall of the gas ring slot and used for enabling the back clearance cavity and the interval cavity to communicate. A piston body is further provided with an assembly hole. An insert made of powder metallurgy materials is mounted in the assembly hole, and a drainage channel is formed inside the insert. Expelled oil in the back clearance cavity of the piston is removed through the drainage channel and the pressure difference generated during compression of an air compressor or an internal combustion engine, so that the air compressor or the internal combustion engine has a longer service life and operates more stably; and for processing and manufacturing, the demand for precision is low, cost can be reduced, and the novel built-in oil expelling prevention piston structure is beneficial to production, processing and manufacturing.

Owner:FENGHUA DINGLIAN AUTO AIR COMPRESSOR FACTORY

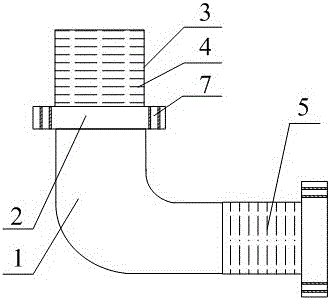

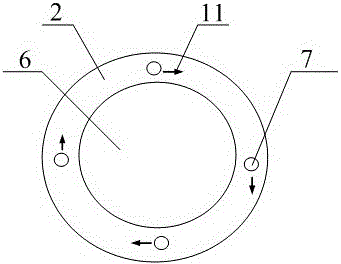

Sealing leakage-proof device for automobile fluid bend

InactiveCN106704038ASolve oil leakageClosely connectedElectrical controlInternal combustion piston enginesEngineeringMechanical engineering

The invention discloses a sealing leakage-proof device for an automobile fluid bend. Cylindrical sealing plates are arranged at the two ends of the bend. A cylindrical hollow connector is arranged at one end of the bend, and an outer thread is arranged on the hollow connector. The corresponding cylindrical sealing plate is located between the bend and the hollow connector. An inner thread is arranged at the other end of the bend, and the inner thread is located between the bend and the corresponding cylindrical sealing plate. A through hole is formed in the center of each cylindrical sealing plate, and the through holes communicate with the bend. Four insertion connecting holes are evenly formed in the periphery of each through hole, and threads are arranged on the inner walls of the insertion connecting holes. By means of the above manner, the problem that an automobile fuel bend in the prior art is prone to oil leakage is solved.

Owner:CHENGDU LINGCHUAN SPECIAL IND

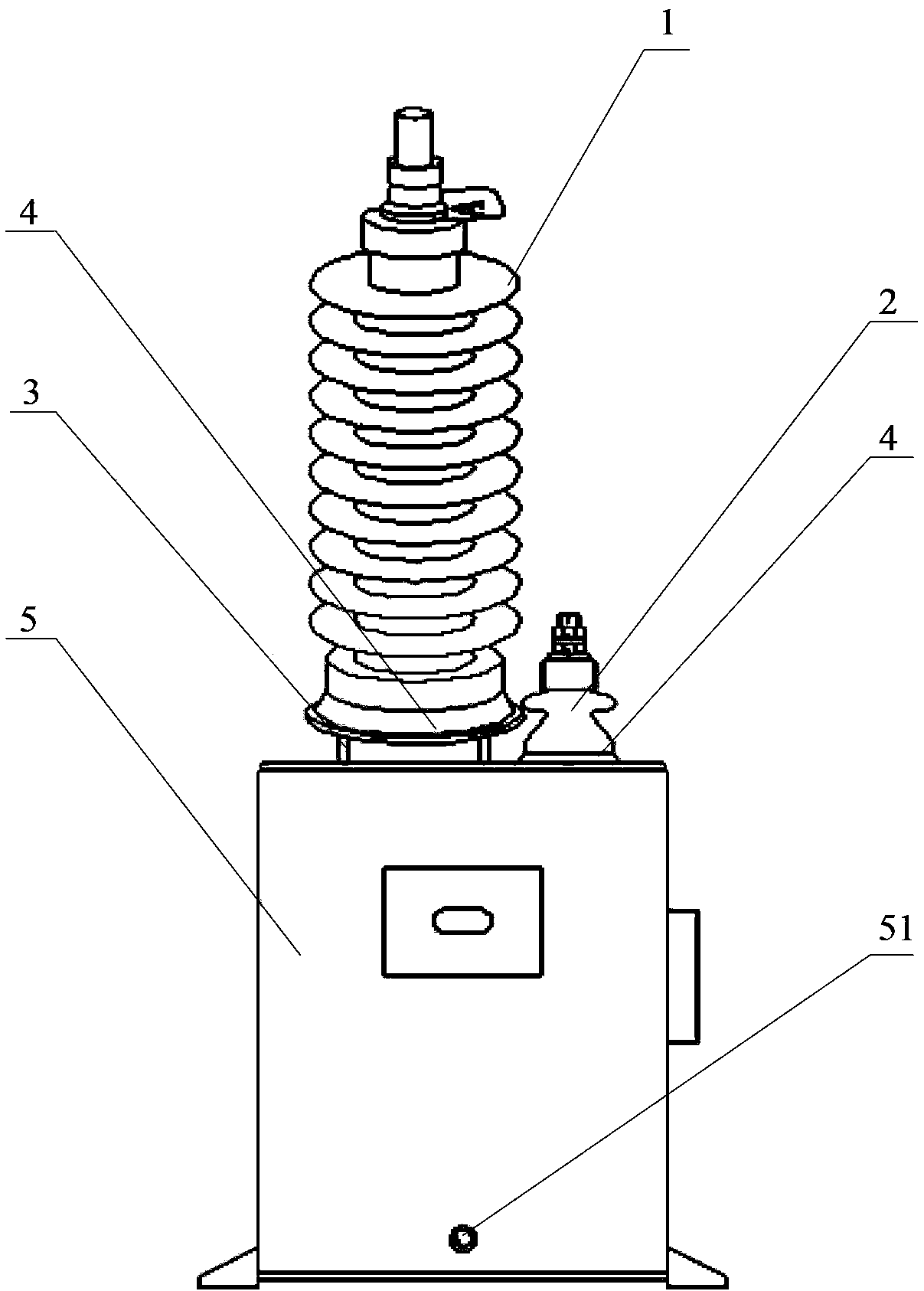

Oil immersed discharge coil

InactiveCN102637501BMeet the sealing performanceSolve oil leakageCoils manufactureCoilsLow voltageFuel tank

The invention discloses an oil immersed discharge coil which comprises a high-voltage rolling crimp ferrule, a low-voltage rolling crimp ferrule, an oil tank, an ascending seat and a flange, wherein the materials of the ascending seat and the flange are the same as that of the oil tank; the oil tank is provided with an expansion box, whose air vent uses the same material with that of the oil tank; and the connection parts of the components with the same material of the oil immersed discharge coil are connected in a fusion welding manner. With the adoption of the oil immersed discharge coil disclosed by the embodiment of the invention, as the components of the oil immersed discharge coil are connected by adopting a seamless fusion welding process, the oil immersed discharge coil is fully sealed, and the problem of oil leakage of the oil immersed discharge coil is solved; and meanwhile, the oil immersed discharge coil is free from maintenance due to no leakage, so that a large amount of maintenance cost can be saved.

Owner:QINGDAO ZHONGZI ZHONGCHENG GROUP CO LTD

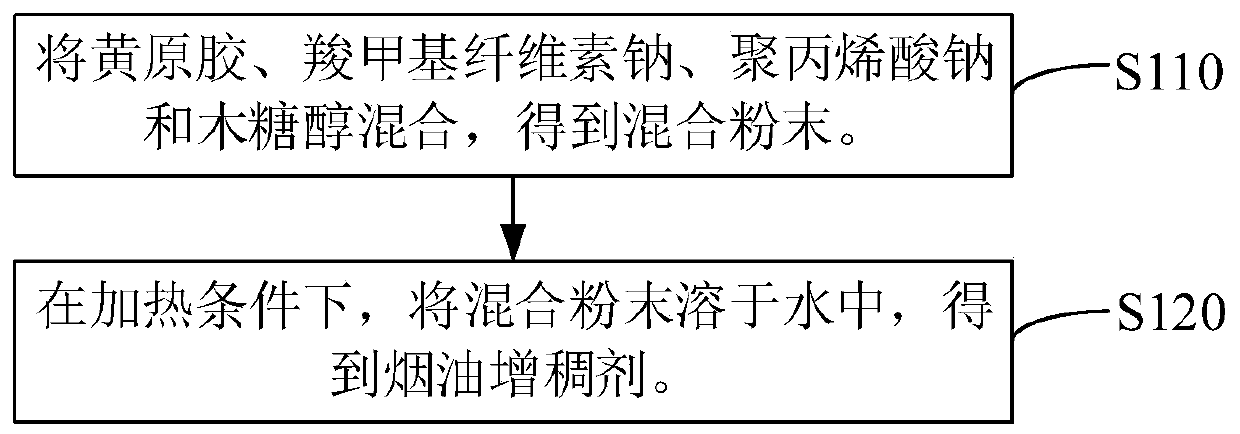

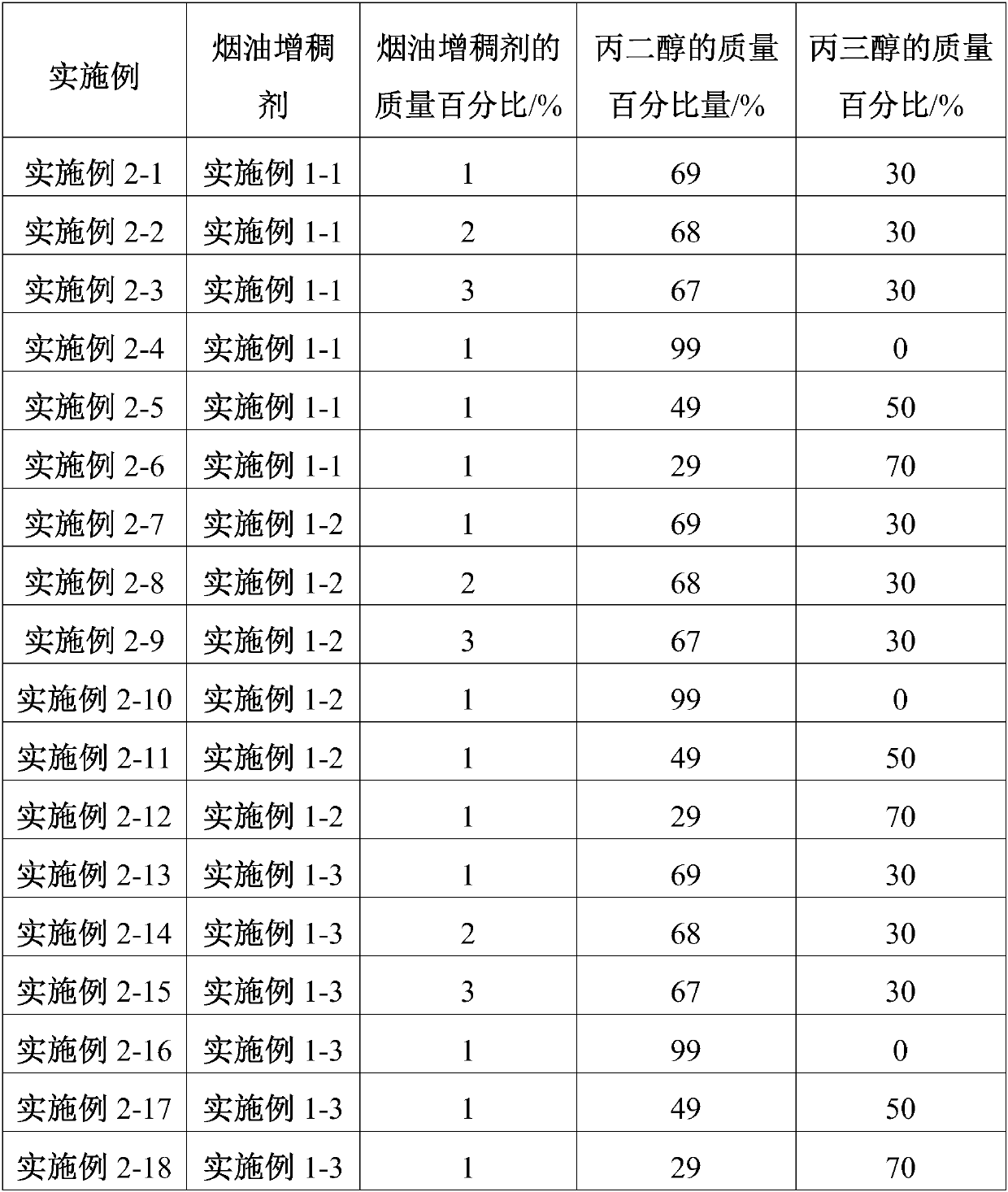

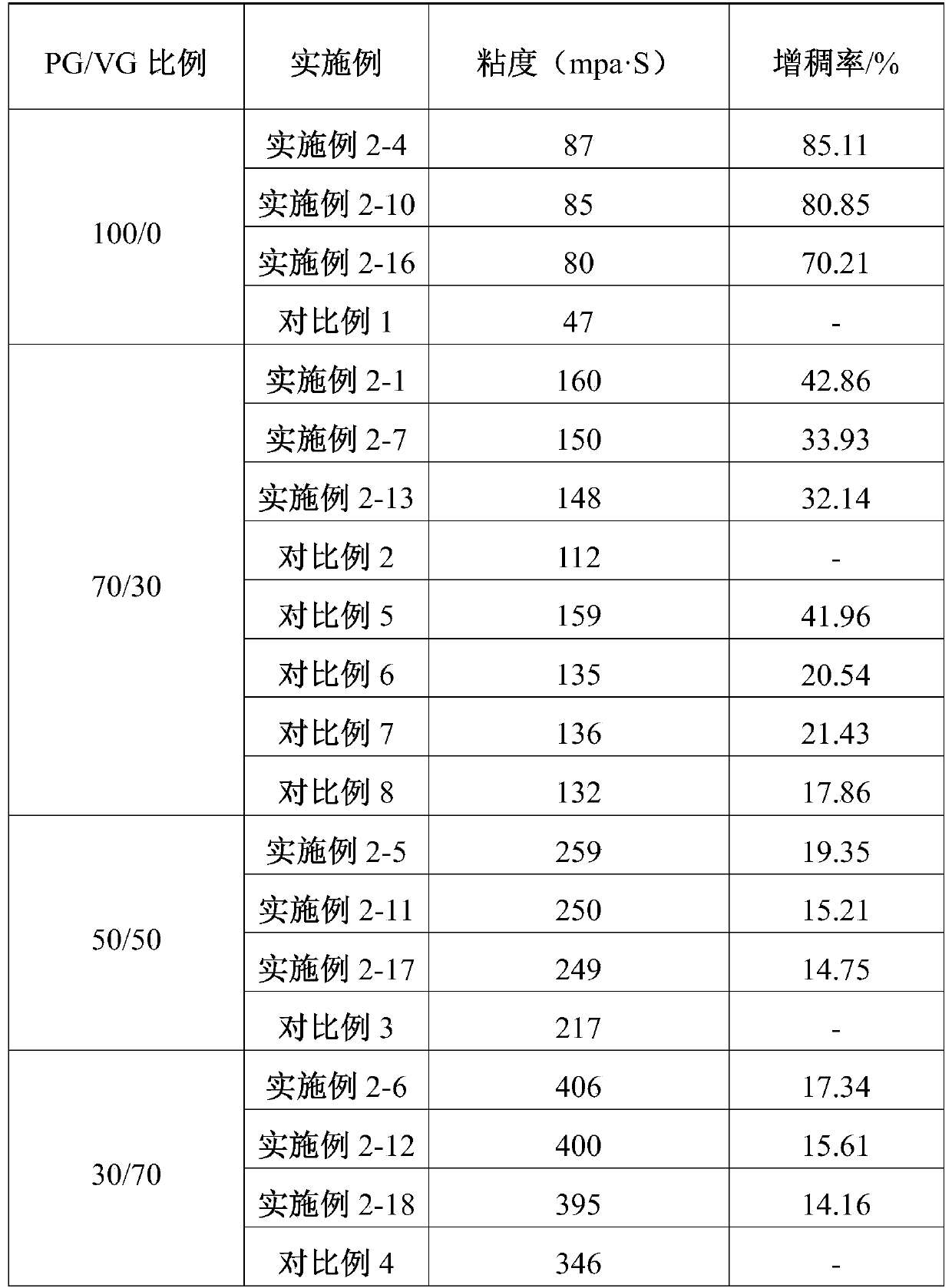

Tobacco tar thickener, electronic cigarette tobacco tar and preparation method thereof

The invention relates to a tobacco tar thickener, electronic cigarette tobacco tar and a preparation method thereof. The tobacco tar thickener comprises xanthan gum, sodium carboxymethyl cellulose, sodium polyacrylate, xylitol and water. The tobacco tar thickener is compounded by taking water as a solvent, xanthan gum, sodium carboxymethyl cellulose and sodium polyacrylate as main materials and xylitol as an auxiliary material. The xanthan gum, the sodium carboxymethyl cellulose and the sodium polyacrylate play a role in thickening, the xylitol plays a role in increasing body fluid and preserving moisture, and the substances are matched with one another, so that the viscosity of the tobacco tar can be obviously improved when the tobacco tar thickener is added into the tobacco tar, and peculiar smell is not brought to the fragrance of the tobacco tar.

Owner:SHENZHEN HANGSEN STAR TECH

Anti-liquid-channeling high-temperature-resisting filtering device

ActiveCN103007605BSolve oil leakageImprove securityStationary filtering element filtersDevice formCarbon steel

The invention discloses an anti-liquid-channeling high-temperature-resisting filtering device. The filtering device is formed by a barrel cover, a barrel body, an oil inlet pipe opening at the upper part of one side of the barrel body, an oil outlet pipe opening at the lower part of one side of the barrel body, a filtering net tray and a metal filtering net assembly, wherein the filtering net tray and the metal filtering net assembly are placed inside the barrel body; a high-temperature sealing gasket is mounted between the convex edges of the filtering net tray and the metal filtering net assembly; a force application device formed by a lower bowl-shaped sleeve of a compressed spring, the compressed spring and an upper bowl-shaped sleeve of the compressed spring vertically acts on the convex edge of the metal filtering net assembly, so that an upper cavity and a lower cavity of the barrel body are in sealed separation; a maintenance oil discharging opening is formed in the upper part of the barrel body; and all the components of the filtering device are prepared from stainless steel or carbon steel metal materials. The anti-liquid-channeling high-temperature-resisting filtering device disclosed by the invention can be ensure no liquid channeling in a filtering process and can resist a high temperature of 400 DEG C, and has the advantages of safety and convenience in a maintenance process, convenience for popularization and application, and the like.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com