Micro hydraulic cylinder structure

A hydraulic cylinder, miniature technology, applied in the field of hydraulic cylinders, can solve the problems of low practicality, high after-sales compensation rate of suspension hydraulic locks, hydraulic oil leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

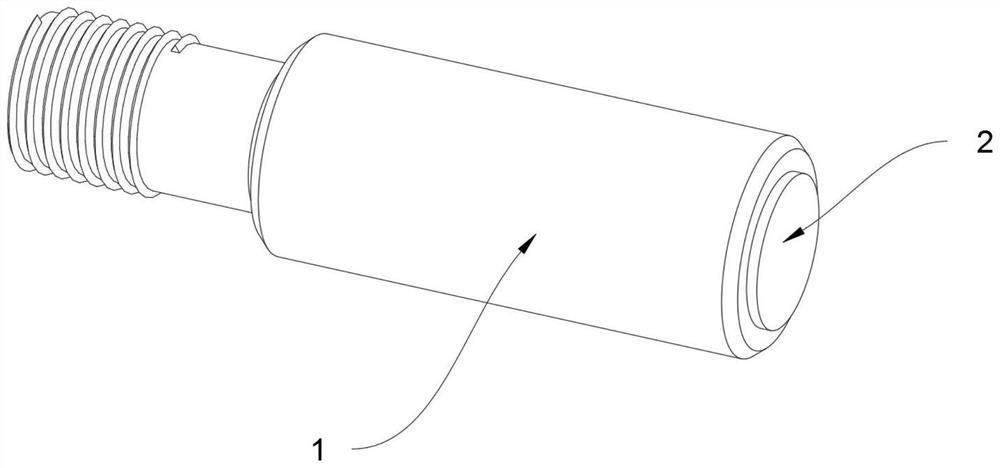

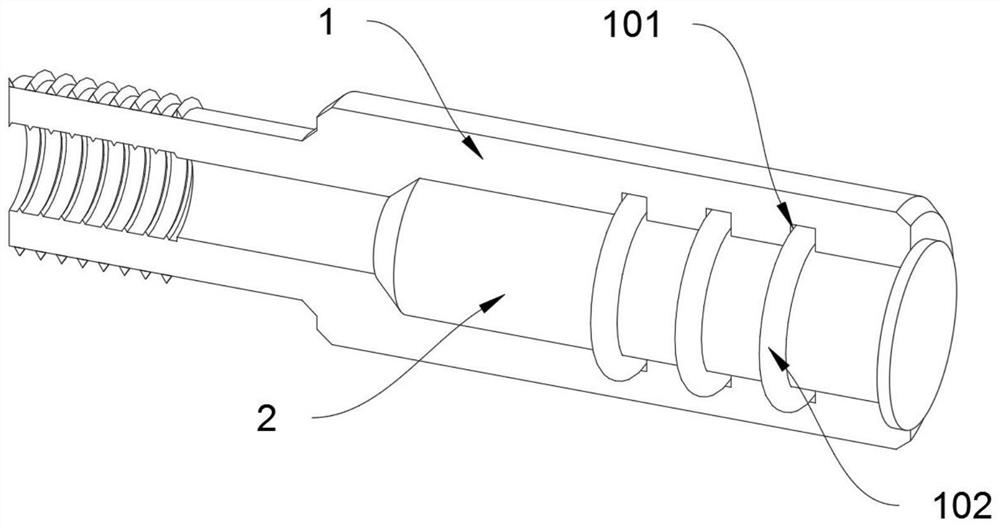

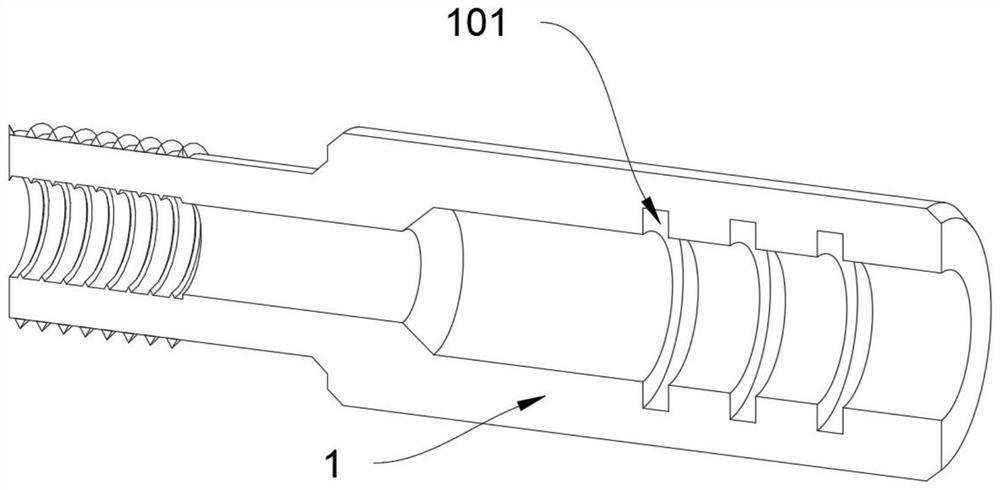

[0023] as attached figure 1 to attach image 3 Shown:

[0024] The invention provides a micro hydraulic cylinder structure, which includes a cylinder barrel 1; a cylinder rod 2 is plugged inside the cylinder barrel 1.

[0025] Wherein, the inside of cylinder 1 is provided with sealing groove 101, and sealing groove 101 is provided with three, as attached figure 2 And attached image 3 As shown, the multi-channel sealing groove 101 and the sealing ring 102 can effectively prevent oil leakage during the operation of the device and improve the stability of the device.

[0026] Wherein, a sealing ring 102 is arranged inside the sealing groove 101, and the sealing ring 102 is designed as a circular ring body, as attached figure 2 And attached image 3 As shown, this design enables the sealing ring 102 to surround the outside of the cylinder rod 2 .

[0027] Wherein, the inner diameter of the sealing ring 102 is the same as the outer diameter of the cylinder rod 2, as attach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com