Tobacco tar thickener, electronic cigarette tobacco tar and preparation method thereof

A thickener and electronic cigarette technology, applied in the field of electronic cigarettes, can solve the problems of low viscosity of e-liquid, low viscosity of e-cigarette oil, oil leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

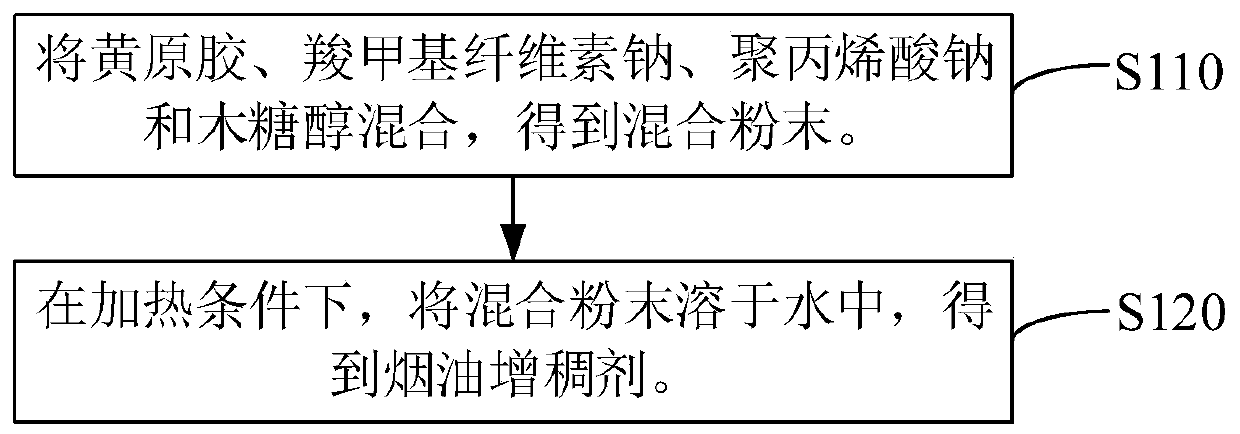

[0032] see figure 1 , a preparation method of an e-liquid thickener in one embodiment, comprising the following steps: mixing xanthan gum, sodium carboxymethyl cellulose, sodium polyacrylate, xylitol and water to obtain the e-liquid thickener.

[0033] Specifically, in the step of mixing xanthan gum, sodium carboxymethyl cellulose, sodium polyacrylate, xylitol and water, according to the e-liquid thickener, the mass percentage of xanthan gum is 0.56% to 0.63%, carboxy The mass percentage of sodium methylcellulose is 1.25% to 1.50%, the mass percentage of sodium polyacrylate is 0.18% to 0.20%, the mass percentage of xylitol is 2.82% to 5.00%, and the mass percentage of water is 92.93% to 94.94% %, the substances were mixed. Specifically, in this embodiment, xanthan gum, sodium carboxymethylcellulose, sodium polyacrylate and xylitol are all food grade.

[0034] In one embodiment, in the e-liquid thickener, the mass percentage of xanthan gum is 0.56%, 0.58%, 0.60%, 0.62% or 0.6...

Embodiment 1-1

[0077] The preparation process of the e-liquid thickener of this embodiment is as follows:

[0078] (1) Accurately weigh 2.25 g of xanthan gum, 6.0 g of sodium carboxymethyl cellulose, 0.75 g of sodium polyacrylate, and 11.25 g of xylitol, and mix them uniformly to obtain a mixed powder.

[0079] (2) Slowly add the mixed powder into a stirred beaker filled with 350g of 70°C distilled water, and continue stirring until the mixed powder is completely dissolved. Then add 29.75 g of distilled water and continue to stir evenly. Finally, the temperature was lowered to room temperature to obtain 400 g of e-liquid thickener.

Embodiment 1-2

[0081] The preparation process of the e-liquid thickener of this embodiment is as follows:

[0082] (1) Accurately weigh 2.50 g of xanthan gum, 6.0 g of sodium carboxymethyl cellulose, 0.75 g of sodium polyacrylate, and 15.0 g of xylitol, and mix them uniformly to obtain a mixed powder.

[0083] (2) Slowly add the mixed powder into a stirred beaker filled with 300g of 70°C distilled water, and continue stirring until the mixed powder is completely dissolved. Then add 75.75 g of distilled water and continue to stir evenly. Finally, the temperature was lowered to room temperature to obtain 400 g of e-liquid thickener.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com