Pantograph

A pantograph and bow head technology, applied in the field of pantographs, can solve the problems of unreliable maximum damping force and easy loosening of the structure, so as to solve the problem of easy oil leakage, eliminate the precision and consistency of dimensional processing, reduce the The effect of small processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

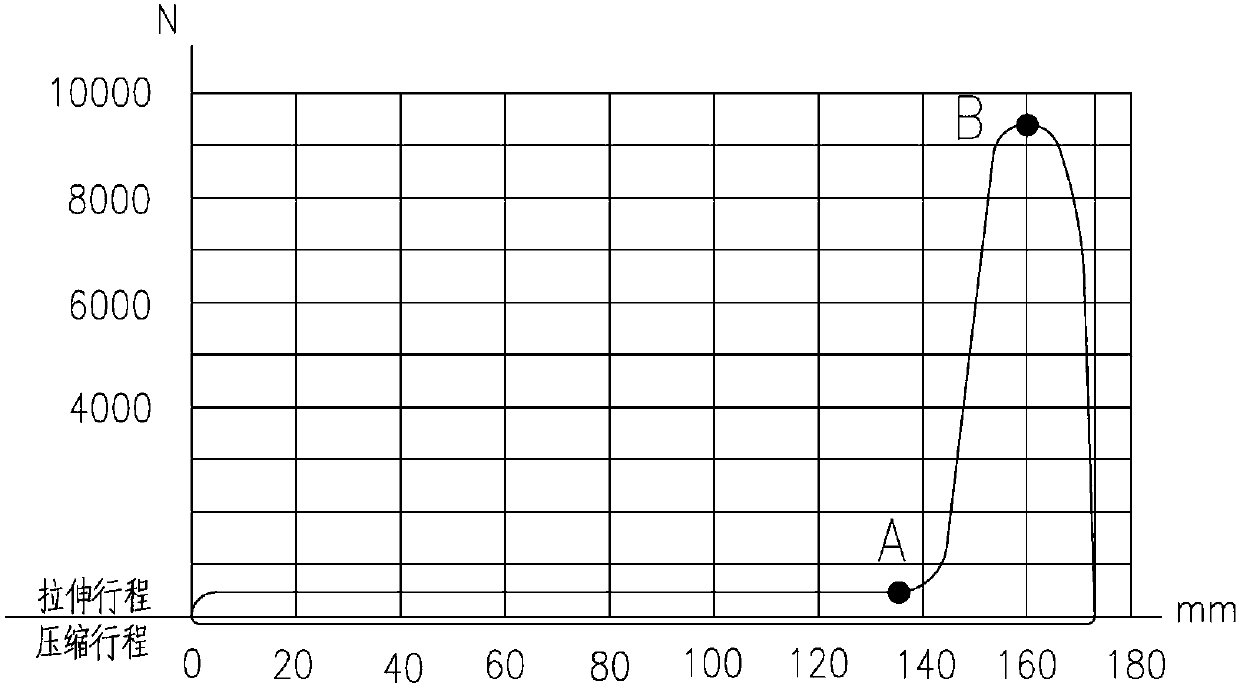

[0034] as attached figure 1 As shown, the tensile damping force and the compressive damping force of the pantograph damper involved in the present invention are very asymmetrical, and the damping force is required to maintain a relatively stable small damping force during the entire compression process, while the preceding Most of the stroke damping force needs to be kept at a relatively stable small damping force, and the damping force needs to increase rapidly in the following small part of the stroke, and a peak value appears.

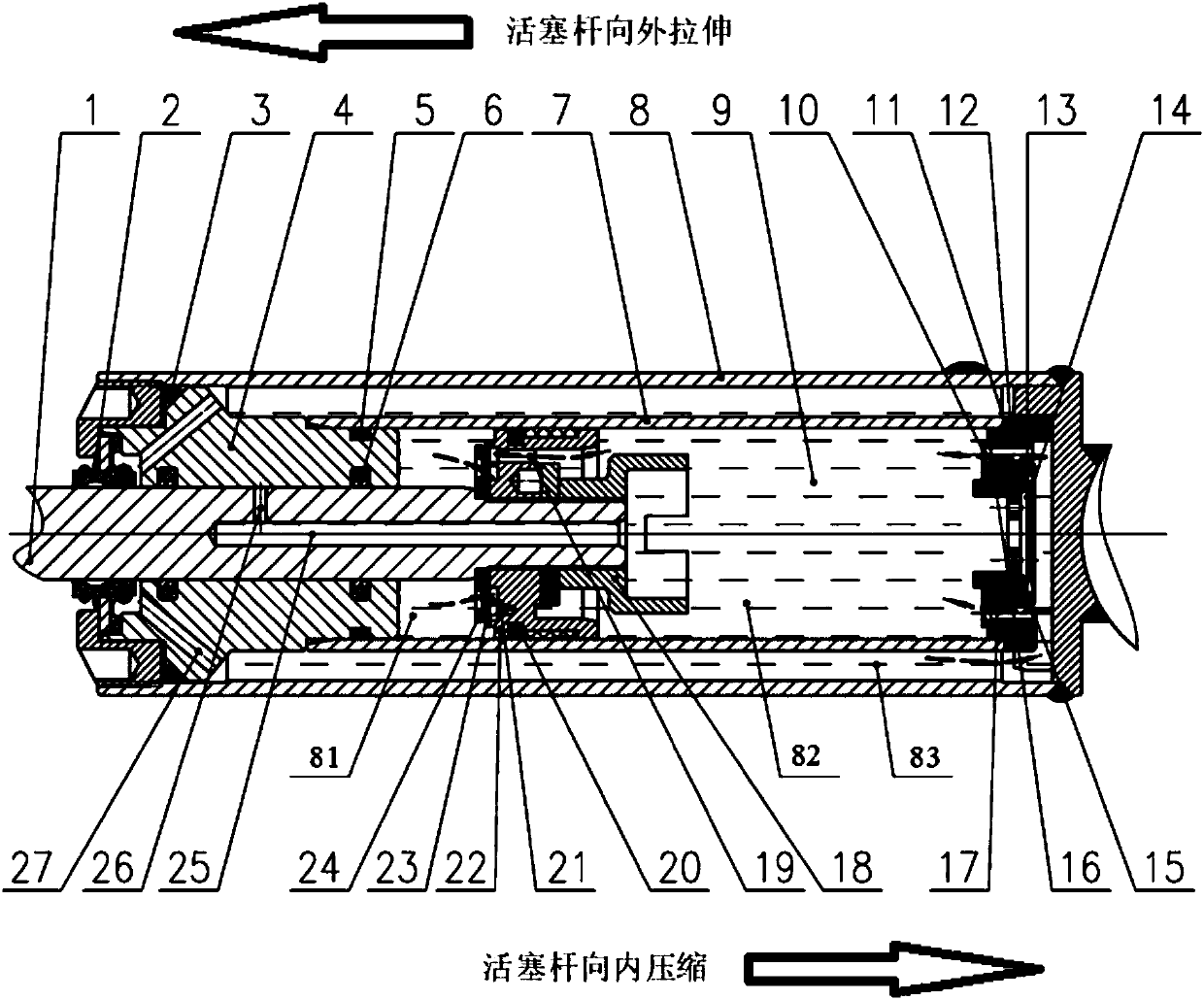

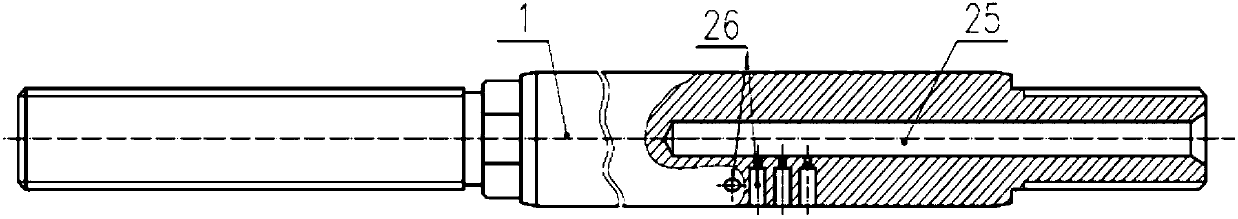

[0035] as attached Figure 2-5 As shown, a pantograph damper of this embodiment includes: oil storage cylinder 8, oil cylinder 7, guide assembly, piston rod assembly, hydraulic oil 9 and bottom valve assembly; guide assembly includes guide 4 and its Sealing structure, the sealing structure includes two static seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com