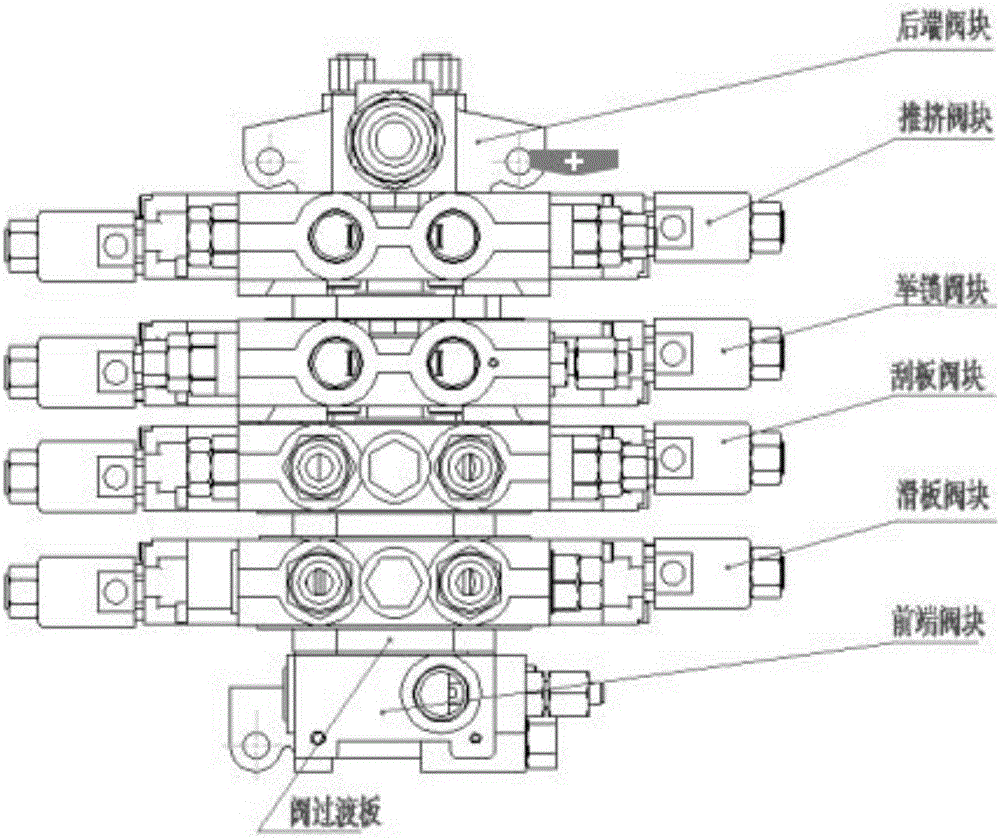

Inter-sheet sealing method for valve sheets of sheet type multi-way directional valve

A technology of multi-way reversing valves and valve plates, which is applied in the direction of multi-way valves, valve devices, engine components, etc., can solve the problems of increasing production costs and affecting production progress, and achieve the effect of simple operation, reduction of scrap and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

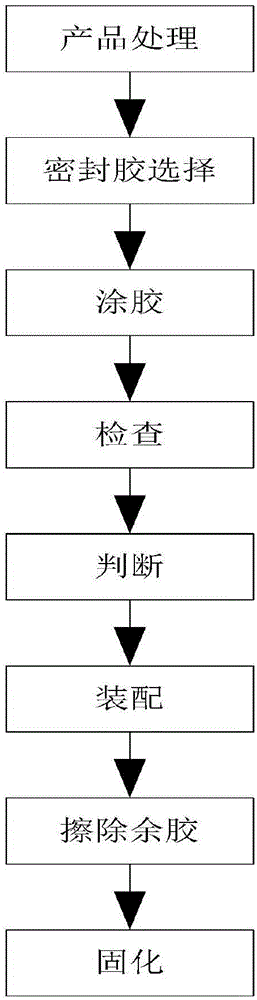

[0016] combine image 3 , a method for sealing between valve plates of a multi-way reversing valve, comprising the following steps:

[0017] Step 1, product treatment: clean the glued surface with aviation washing gasoline (or acetone and other types of solvents), make sure that the glued surface is free of oil stains, and dry it;

[0018] Step 2, sealant selection: the type of auxiliary sealant should be anaerobic flat sealant, and at the same time, according to the use conditions of the sealing part, the material of the sealing pair, the state of the joint surface of the sealing pair, the type and performance of the sealed medium and Select the appropriate model according to comprehensive conditions such as curing conditions;

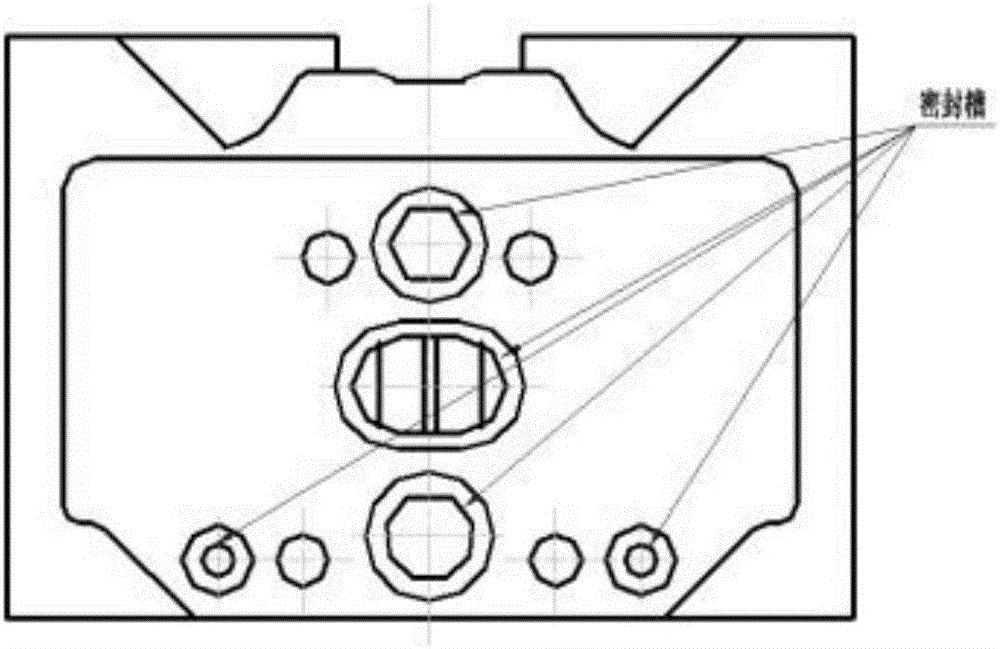

[0019] Step 3, glue application: first assemble the rubber seal in the sealing groove, and use a brush to evenly brush a layer of sealant on the surface around the seal;

[0020] Step 4, inspection: choose a white transparent hard plastic plate with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com