Supporting-point-free universal type blender transmission mechanism

A transmission mechanism and general-purpose technology, applied in mixer parts, mixers, dissolving and other directions, can solve the problems of inconvenient disassembly and maintenance of mechanical seals, low universality of the reduction box, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

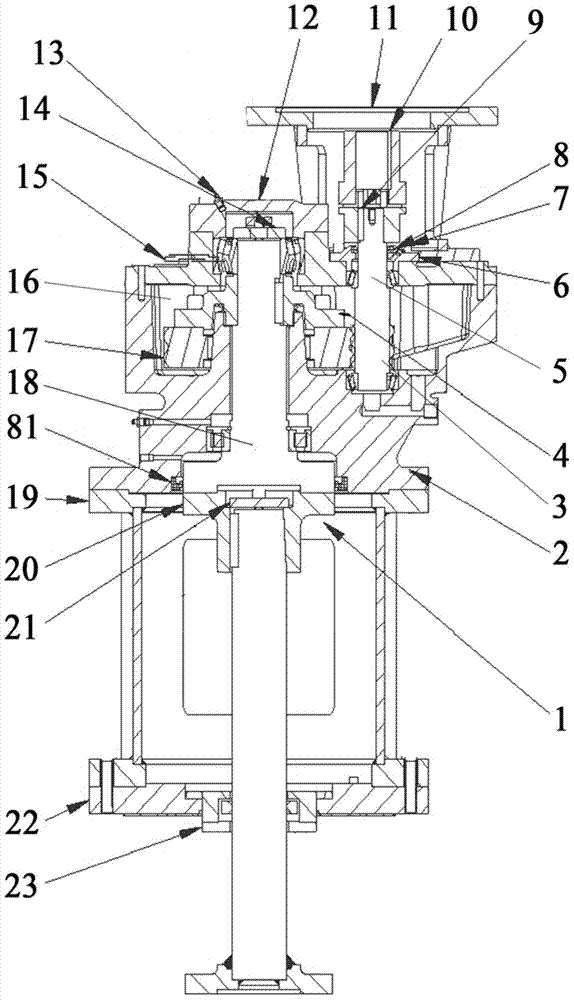

[0014] according to figure 1 The specific structure of the present invention will be described in detail. The fulcrum-free universal mixer transmission mechanism includes a mechanical seal bracket 19, a reduction box 2 installed on the mechanical seal bracket 19, a motor bracket 11 installed on the reduction box 2, and an oil seal cavity is provided between the reduction box 2 and the motor bracket 11. 16 and other parts. Among them, the oil seal cavity 16 has a "W-shaped" structure, which can isolate the lubricating oil inside the reduction box 2 from the output shaft 18 of the reduction box. The output shaft 18 of the reduction gearbox penetrates through the mechanical seal support 19, and the output shaft 18 of the reduction gearbox is respectively limited on the mechanical seal support 19 by the glands located at the upper and lower ends of the mechanical seal support 19 and the spacer ring anti-falling device 24. The bottom of the anti-dropping device 24 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com