Oil supply device without oil pump oil leakage for turbo expander

A technology of a turboexpander and an oil supply device, which is applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of polluting the site environment, large flow pulsation, and high noise, and can solve the oil leakage of the oil pump and save the use of cost, the effect of improving competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

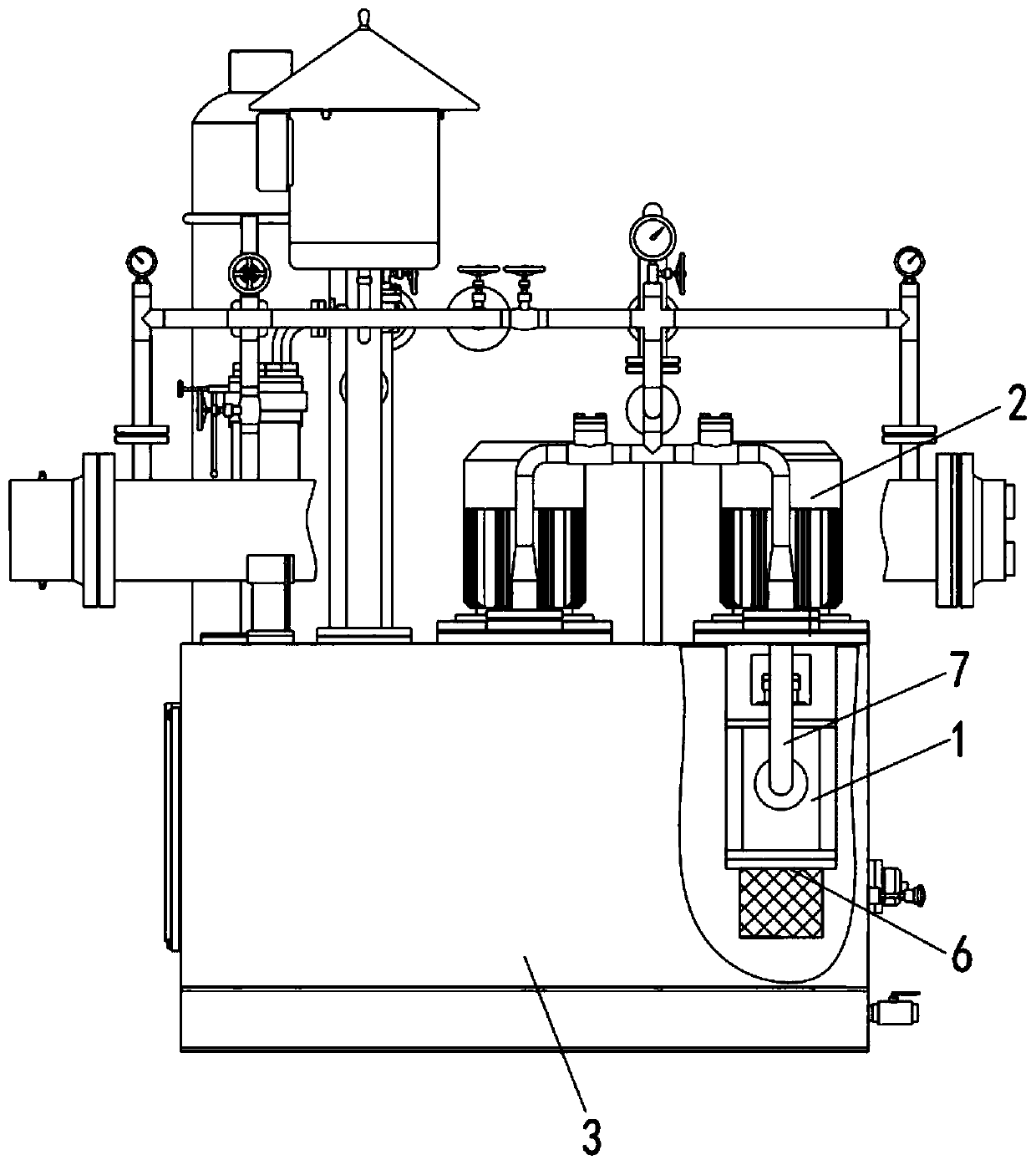

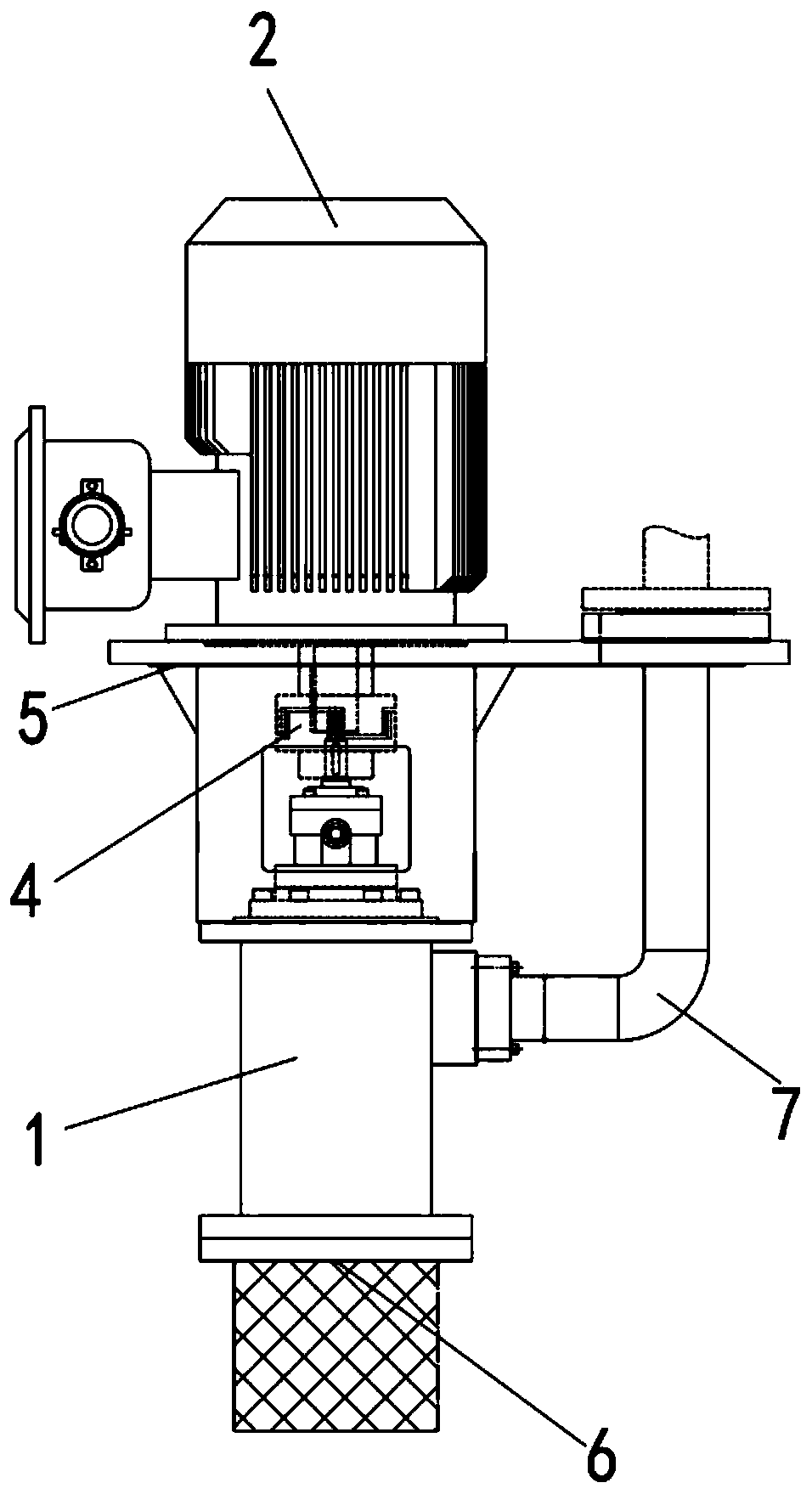

[0016] see Figure 1-2 , the oil supply device of the turbo expander oil pump without oil leakage according to the present invention comprises a vertical three-screw pump 1, a motor 2, an oil tank 3, an oil inlet filter, a one-way valve, a safety valve, an oil-water cooler, Duplex oil filter, accumulator, oil return observer, oil-gas separator, electric heater, valves and other components; the vertical three-screw pump 1 is connected to the motor 2 through a coupling 4; wherein the vertical The three-screw pump 1 and the shaft coupling 4 are arranged in the oil tank 3, and the motor 2 is vertically arranged on the upper end of the oil tank 3. The specific method is to arrange a connecting plate 5 above the junction of the shaft coupling 4 and the motor 2, and pass The connecting plate 5 is connected with the panel of the oil tank 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com