Horizontal vacuum spraying machine

A vacuum spraying, horizontal technology, applied in the direction of mixers, mixer accessories, mixers with rotating stirring devices, etc., can solve the problems of production process influence, liquid leakage, and the outlet can not be sealed, etc., to solve the problem of seepage Oil leakage, increased production capacity, good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In the following, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments, so as to understand more clearly the technical idea claimed in the present invention.

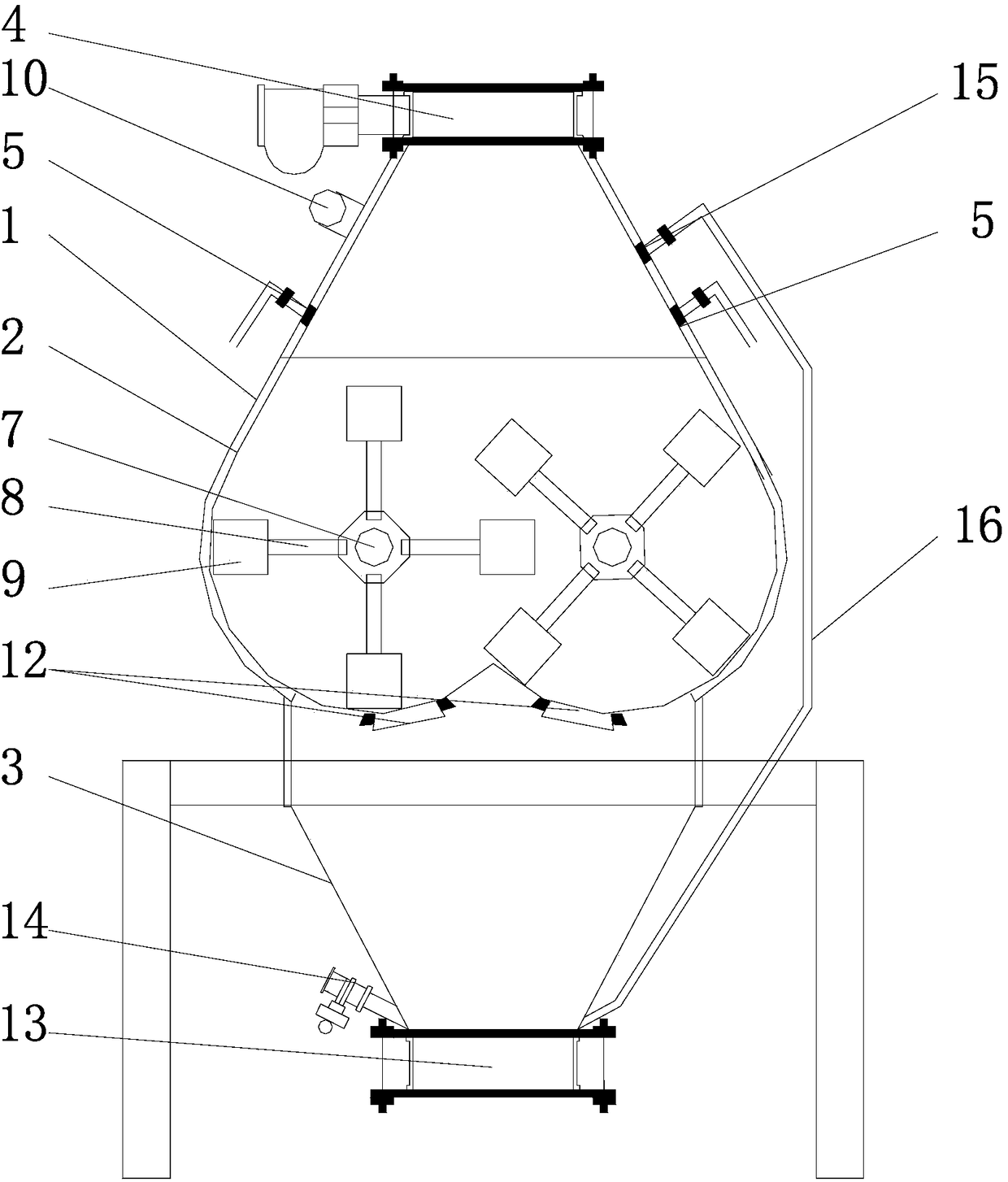

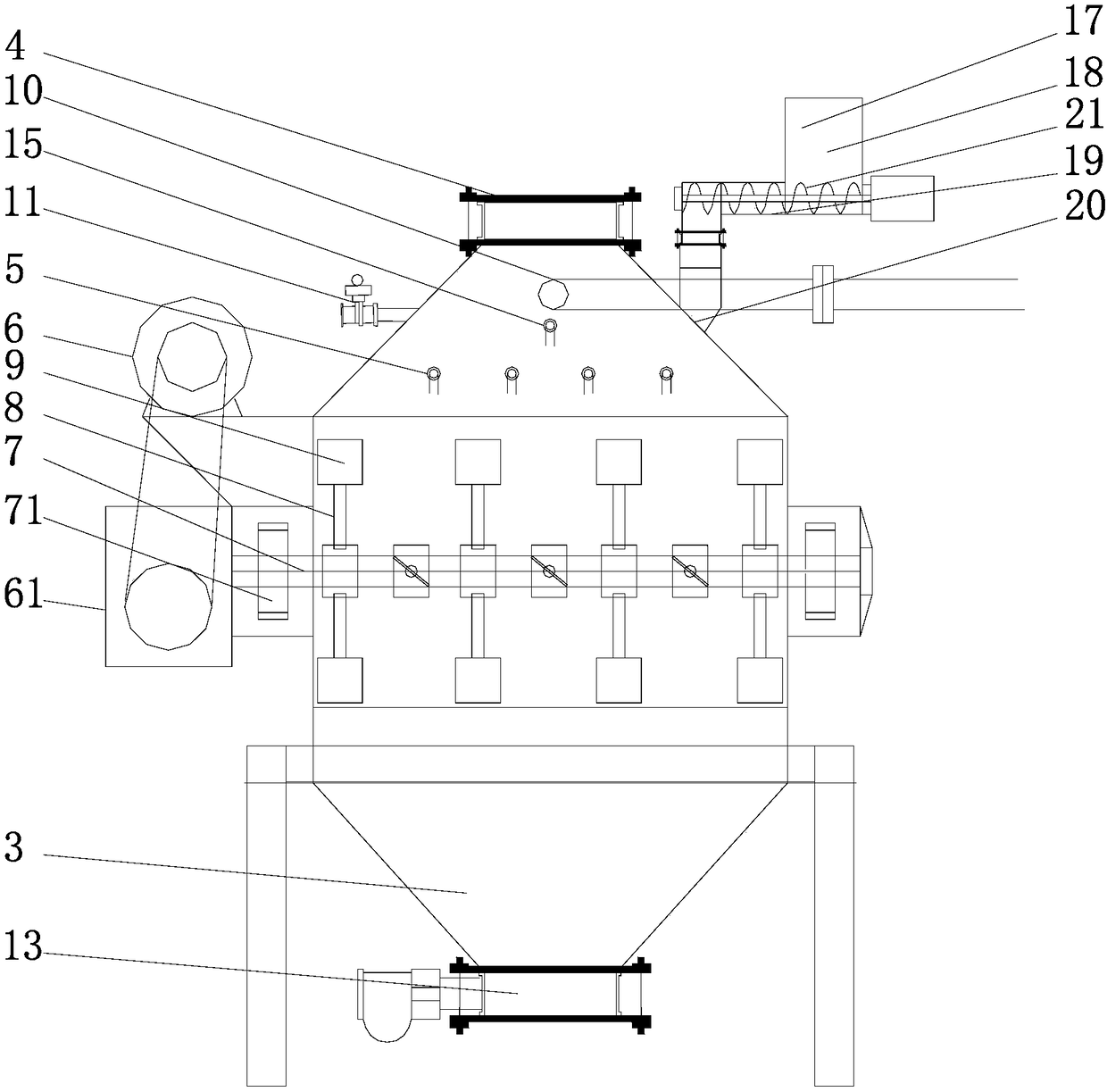

[0020] A horizontal vacuum spraying machine disclosed in the embodiment of the present invention includes a horizontal cylinder 1, the horizontal cylinder 1 includes a mixing chamber 2 above and a recovery chamber 3 below, and the top of the mixing chamber 2 is provided with a feed gate 4. A plurality of conventional nozzles 5 are arranged on both sides. The stirring chamber 2 is provided with a stirring shaft 7 extending along the axis of the stirring chamber 2 and driven by a motor 6 for stirring. The stirring shaft 7 is evenly arranged with a plurality of paddles radially The paddle shaft 8 and the paddle shaft 8 are evenly distributed along the length direction of the stirring shaft 7. The end of each paddle shaft 8 is also provided with a paddl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com