Anti-liquid-channeling high-temperature-resisting filtering device

A filter device and high-temperature-resistant technology, which is applied in the direction of filtration and separation, fixed filter elements, chemical instruments and methods, etc., can solve problems such as liquid channeling, no good solution, and high-temperature-resistant filter devices have not been developed simultaneously , to achieve accurate monitoring, improve safety and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

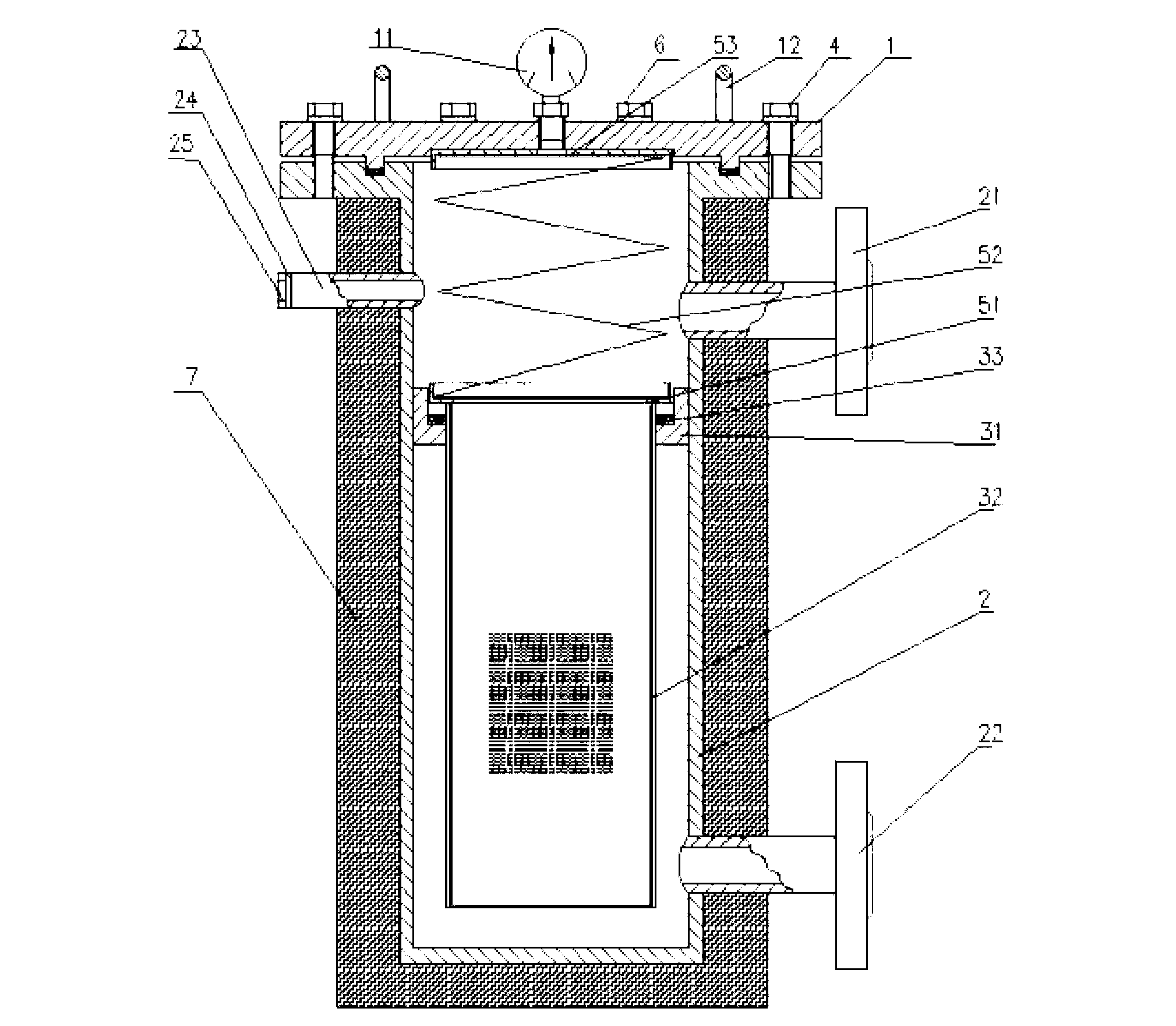

[0023] figure 1 The anti-channeling liquid high-temperature resistant filtering device shown is composed of a barrel cover 1, a barrel body 2, an oil inlet pipe opening 21 located at the upper part of the barrel body 2, an oil outlet pipe opening 22 at the lower part, and a filter tray 31 placed inside the barrel body 2 and The metal screen assembly 32 is composed, and the bucket cover 1 and the bucket body 2 are tightly connected by bolts 4 . A high-temperature sealing gasket 33 is installed between the filter tray and the convex edge of the metal filter assembly, and the force-applying device composed of the lower bowl-shaped sleeve 51 of the compression spring, the compression spring 52, and the upper bowl-shaped sleeve 53 acts on the metal filter vertically. The convex edge of the mesh assembly 32 thus seals and isolates the upper cavity and the lower cavity of the barrel, so that all the heat transfer oil entering the barrel from the oil inlet pipe is filtered. The bowl-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com