Oil cooling motor with integrated electric drive system

A system oil and electric drive technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of difficult to ensure the uniformity of the air gap, low integration, poor cooling effect of the motor stator and rotor, etc., to achieve compact structure, Improved power density and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

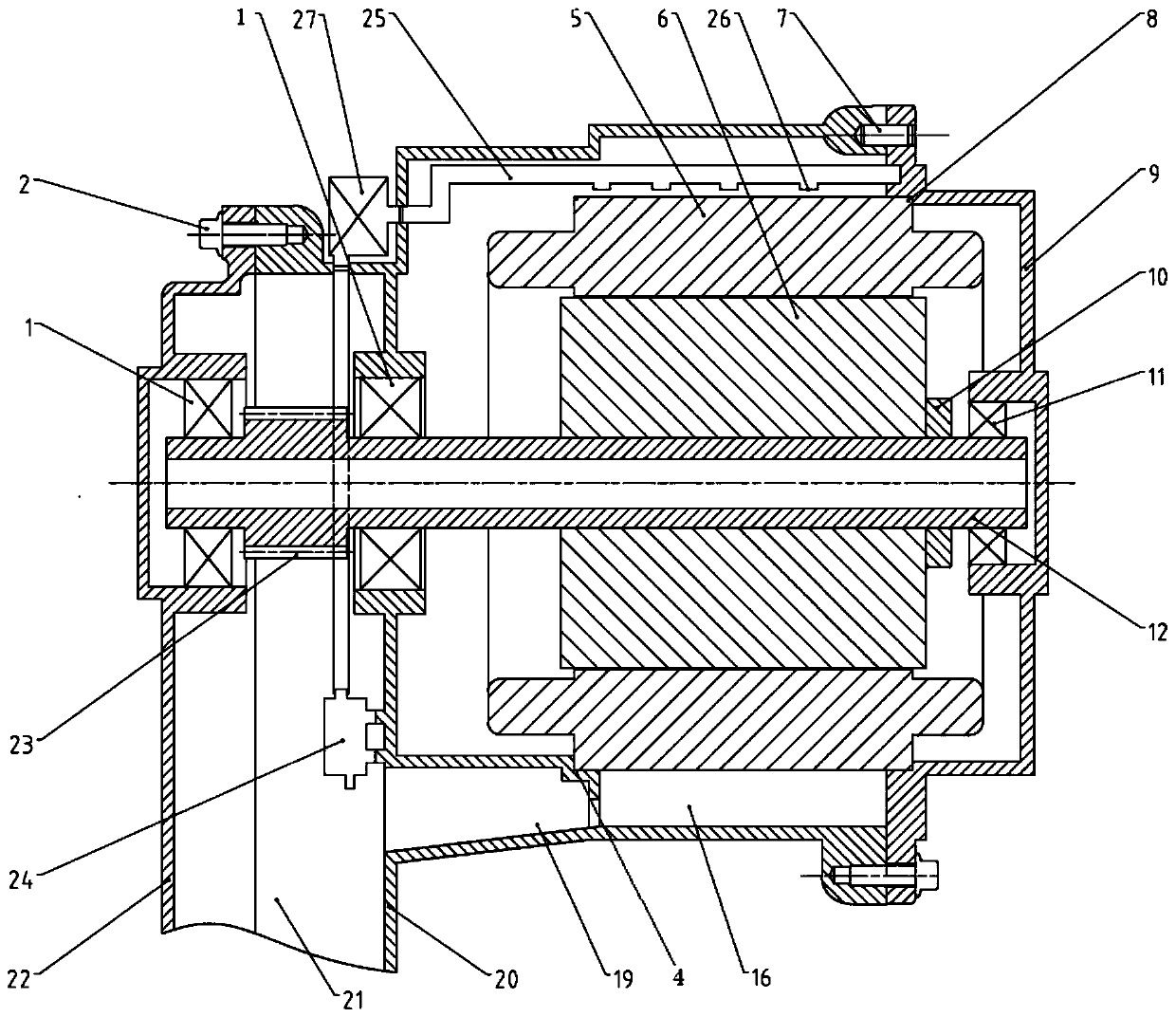

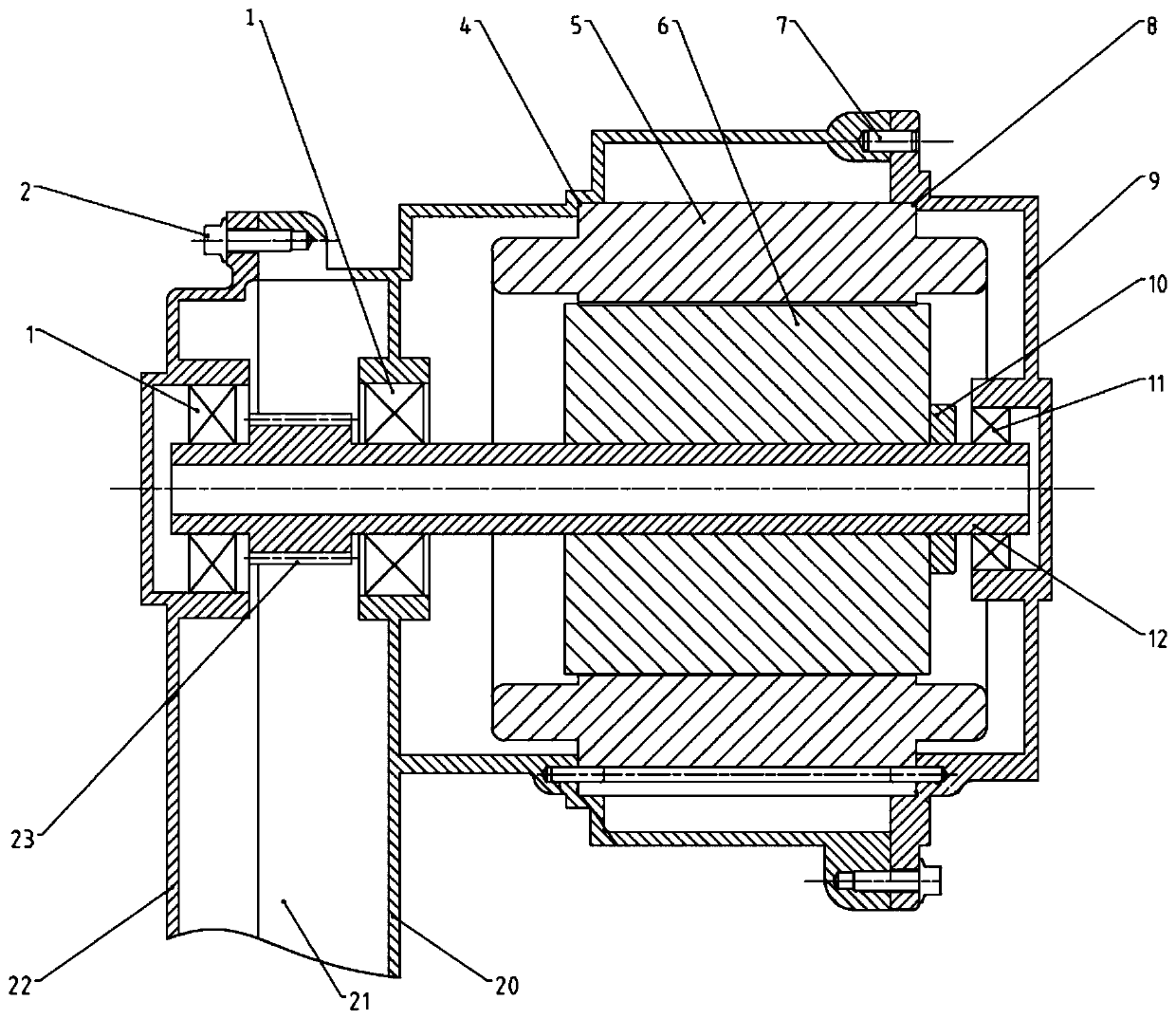

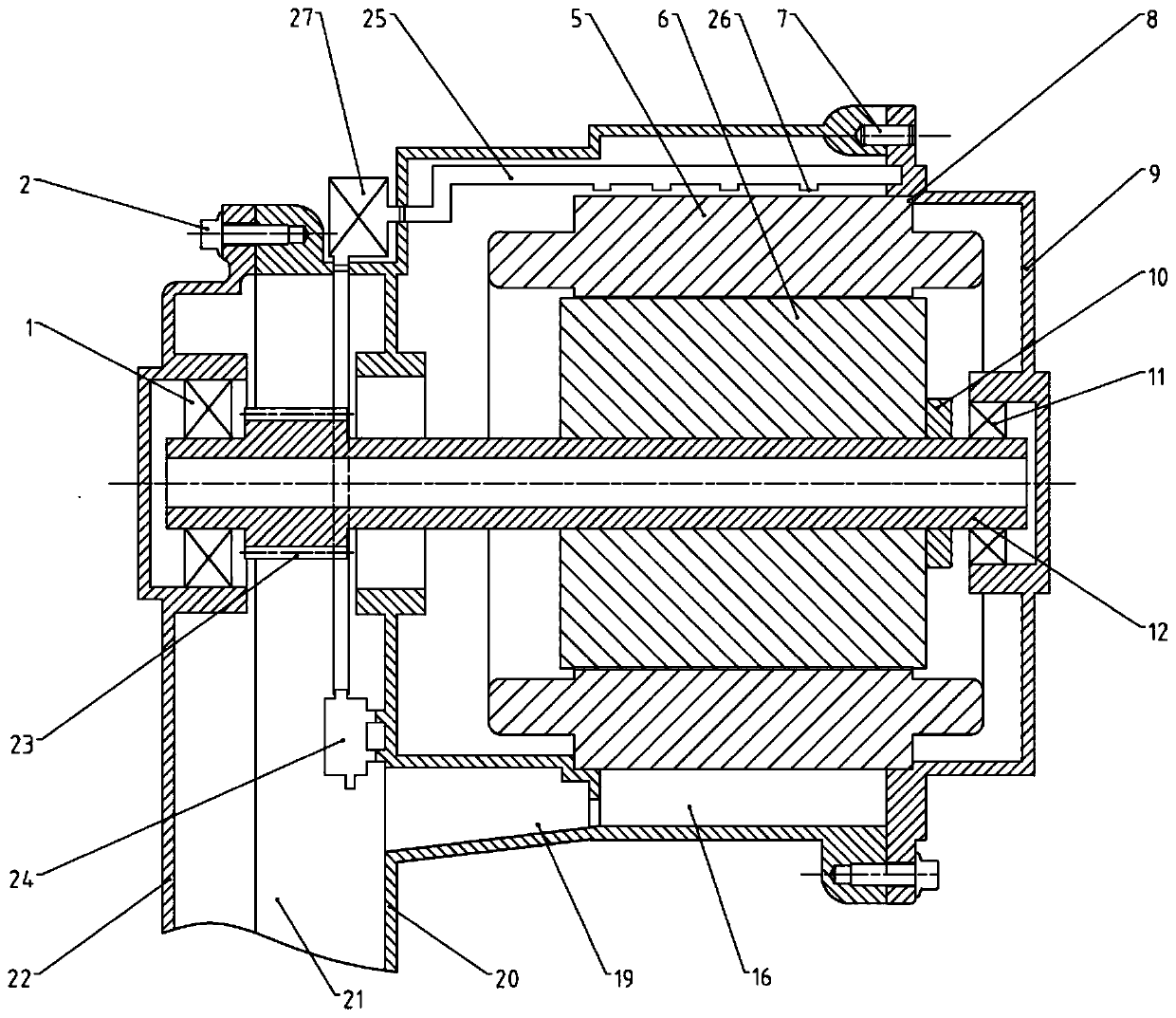

[0027] Below in conjunction with accompanying drawing and specific embodiment content of the present invention is described in further detail:

[0028] Such as figure 1 , figure 2 As shown, an oil-cooled motor for an integrated electric drive system includes a motor rotor 6, a motor stator 5, a transmission shaft 12, a cooling assembly and a housing;

[0029] The casing includes the left casing 22 of the reducer, the right casing 20 of the reducer and the motor end cover 9 connected in sequence; the left casing 22 of the reducer is connected with the right casing 20 of the reducer through bolts 2 and a plurality of positioning pins 7; The right housing 20 of the device is connected with the motor end cover 9 through bolts 2 and a plurality of positioning pins 7 . Among them, the reducer left housing 22 and the reducer right housing 20 form the reducer working chamber 21, and the reducer right housing 20 and the motor end cover 9 form the motor working chamber 16;

[0030] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com