Electrified steering vertical driving device

A vertical drive and drive motor technology, applied in the direction of electric steering mechanism, steering mechanism, power steering mechanism, etc., can solve the problems of inconvenient adjustment of the backlash of the spiral bevel gear, easy to get stuck in the steering, high installation accuracy requirements, etc., and achieve good reliability. Detachability, avoiding understeer or stuck, ensuring coordination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

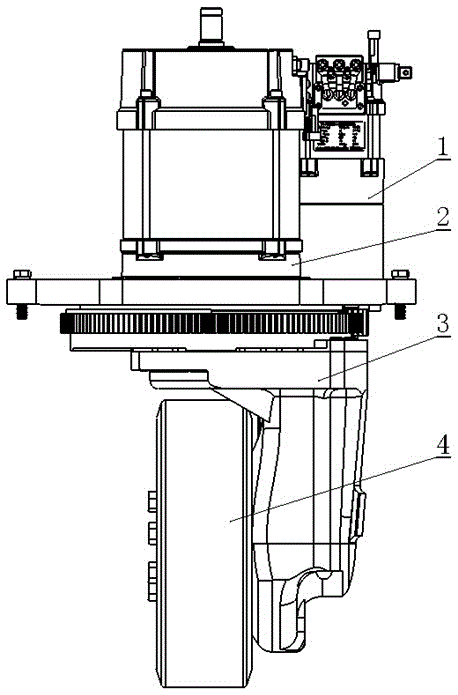

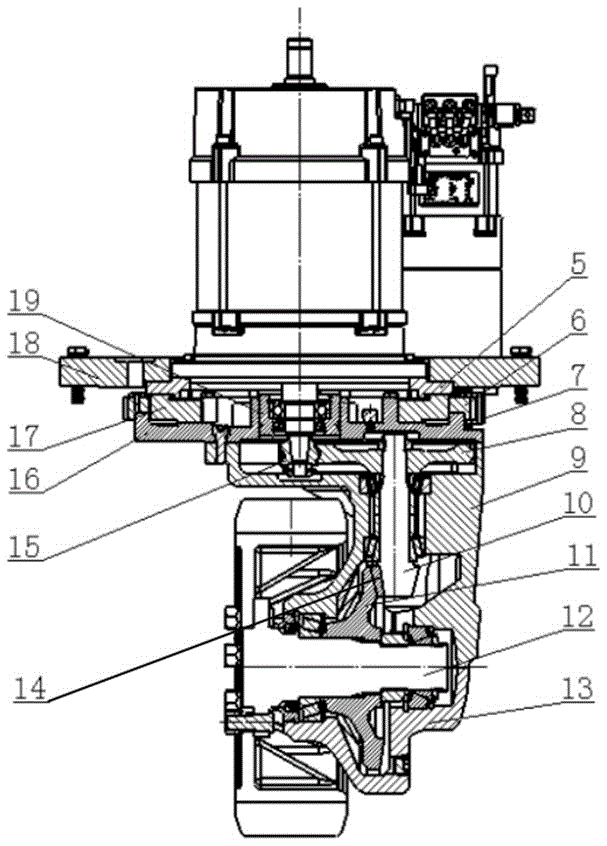

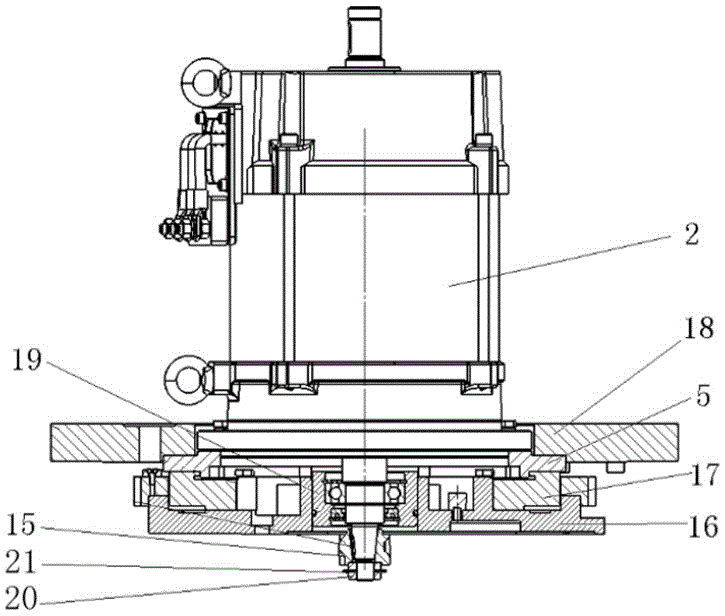

[0027] see figure 1 , a vertical driving device with electric steering, including a power assembly, a speed reduction mechanism 3 and a steering mechanism; On the connecting plate 18, the connecting plate 18 is sleeved on the bottom end of the driving motor 2, and is fixedly connected with the connecting plate 5, and the motor shafts of the driving motor 2 and the steering motor 1 all extend vertically downward;

[0028] see figure 2 , Figure 5 , the deceleration mechanism 3 includes a housing, an input end and an output half end, and the deceleration mechanism 3 is located below the power assembly; see Figure 4 , the housing is formed by connecting the upper housing 9 and the lower housing 13; see image 3 , the middle part of the cover plate 16 of the upper housing 9 is provided with a shaft hole, and a bearing seat 19 is coaxially provided at the shaft hole, and an "O"-shaped sealing ring is provided between the outer circular surface of the bearing seat 19 and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com