Sealing device for hollow oil cooling tail end seat of machining center screw

A technology for machining centers and sealing devices, which is applied to feeding devices, metal processing equipment, metal processing machinery parts, etc., can solve problems such as oil leakage and poor sealing performance, and achieve the goals of reducing heat, low production costs, and improving precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

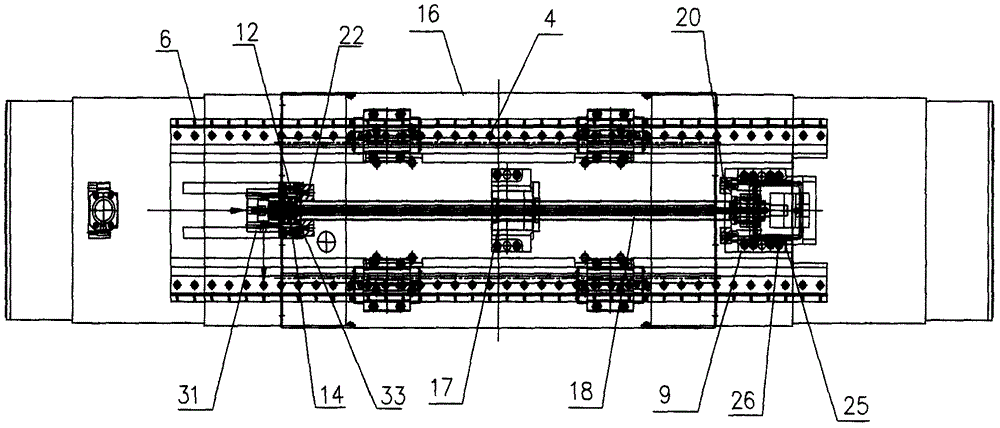

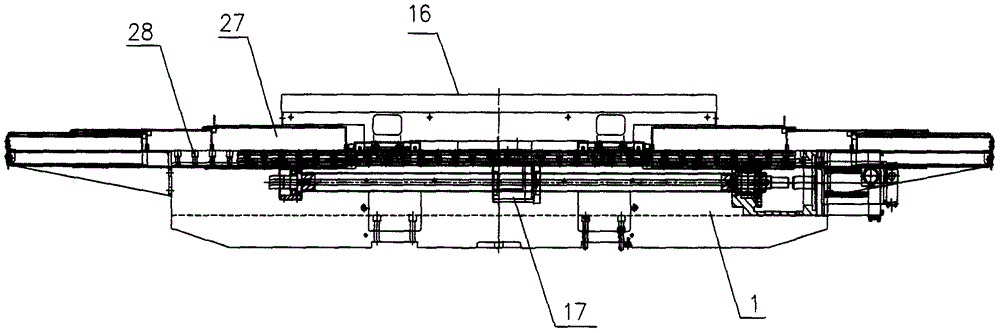

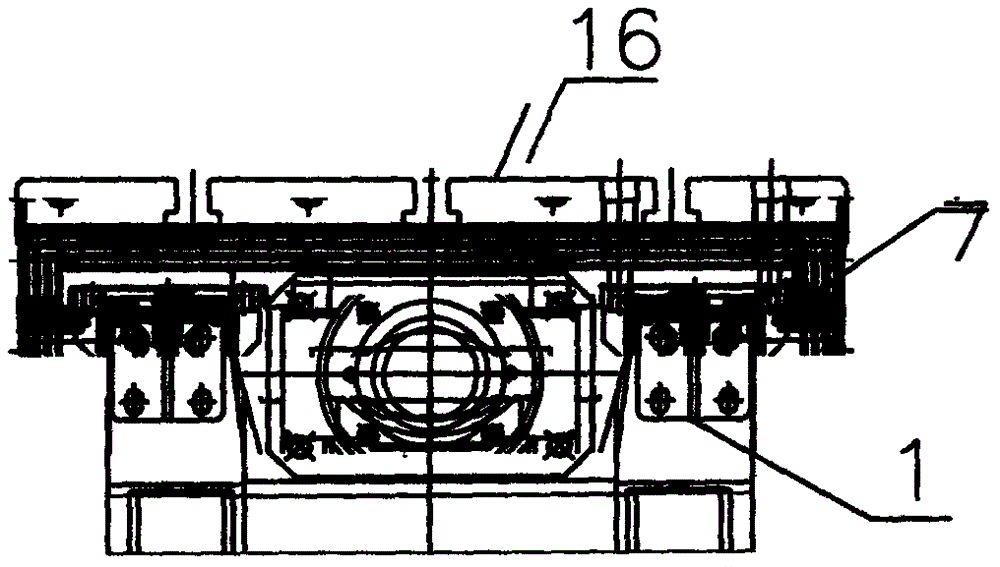

[0018] A sealing device for a hollow oil-cooled end seat of a screw rod in a machining center, including a workbench 16 and a saddle 1, the workbench 16 is installed on the upper part of the saddle 1 through a headed hexagon socket head screw and a slider on the roller rail 4, Both ends of the side of the workbench 16 are equipped with an X-axis telescopic shield group 27 through round head screws and flat washers, and a group of rollers are installed on both sides of the upper part of the saddle 1 through a headed hexagon socket head screw and a stop hexagon socket head screw 6. Column line rail 4, one end of the upper part of the saddle 1 is equipped with a tail end support seat 12 through a headed hexagon socket head screw, and the other end is installed with a headed hexagon socket head angle screw and an oblique pin. The X-axis transmission seat group 9 is installed, and the tail end support seat 12 A deep groove ball bearing 14 is installed inside through a C-shaped buckl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com