Rodless Cavity Static Seal Cylinder

A rodless cavity and oil cylinder technology, applied in the direction of fluid pressure actuation device, etc., can solve the problems of oil cylinder leakage and other problems, achieve the effect of strong bearing pressure, avoid leakage oil pollution, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

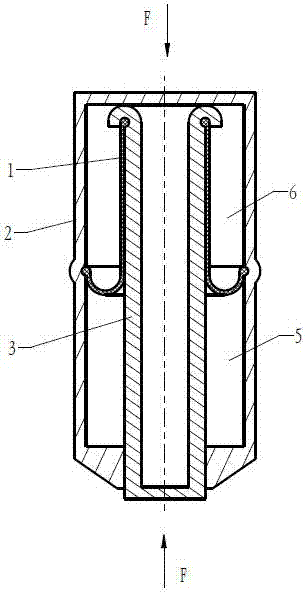

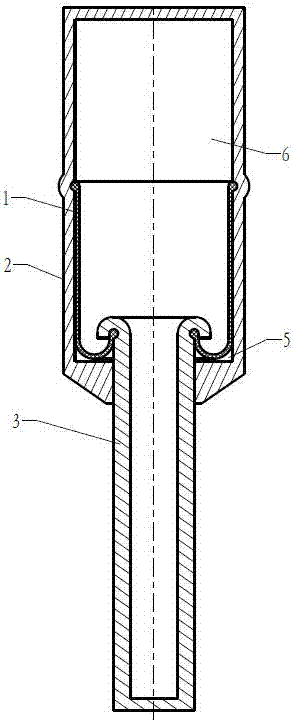

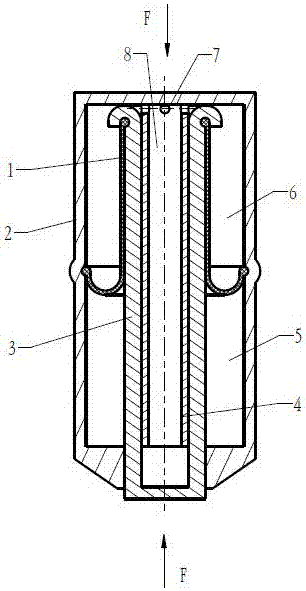

[0028] exist figure 1 In the first embodiment, the piston rod (3) is coaxially assembled with the cylinder (2), the piston rod (3) slides axially along the port of the cylinder (2), and the capsule (1) is clamped on the cylinder ( 2) Between the piston rod (3), the two ports of the capsule (1) are connected to the cylinder (2) and the piston rod (3) respectively, and the capsule (1) separates to form the rod cavity of the cylinder in this case ( 5) With the rodless cavity (6), the rod cavity (5) is a dynamic sealing cavity, the rodless cavity (6) is a static sealing cavity, and the capsule (1) is only in contact with the cylinder during stretching and compression. The inner wall of the barrel (2) and the outer wall of the piston rod (3) are folded and bonded together. When the rodless chamber (6) is fed with high-pressure oil or high-pressure gas, the rod chamber (5) discharges oil or gas, and the oil cylinder stretches. figure 2 Is the first embodiment stretched state. Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com