Grease hydrostatic lubrication system for heavy numerical control roll grinder center frame bearing shoe

A roll grinder and lubricating system technology, applied in the field of auxiliary systems, can solve the problems of increased friction, increased friction between the support shoe and the roll neck, and fast wear of the support shoe, so as to ensure the sealing performance, reduce the number of changes of the shoe, and reduce the wear of the shoe. Wear reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

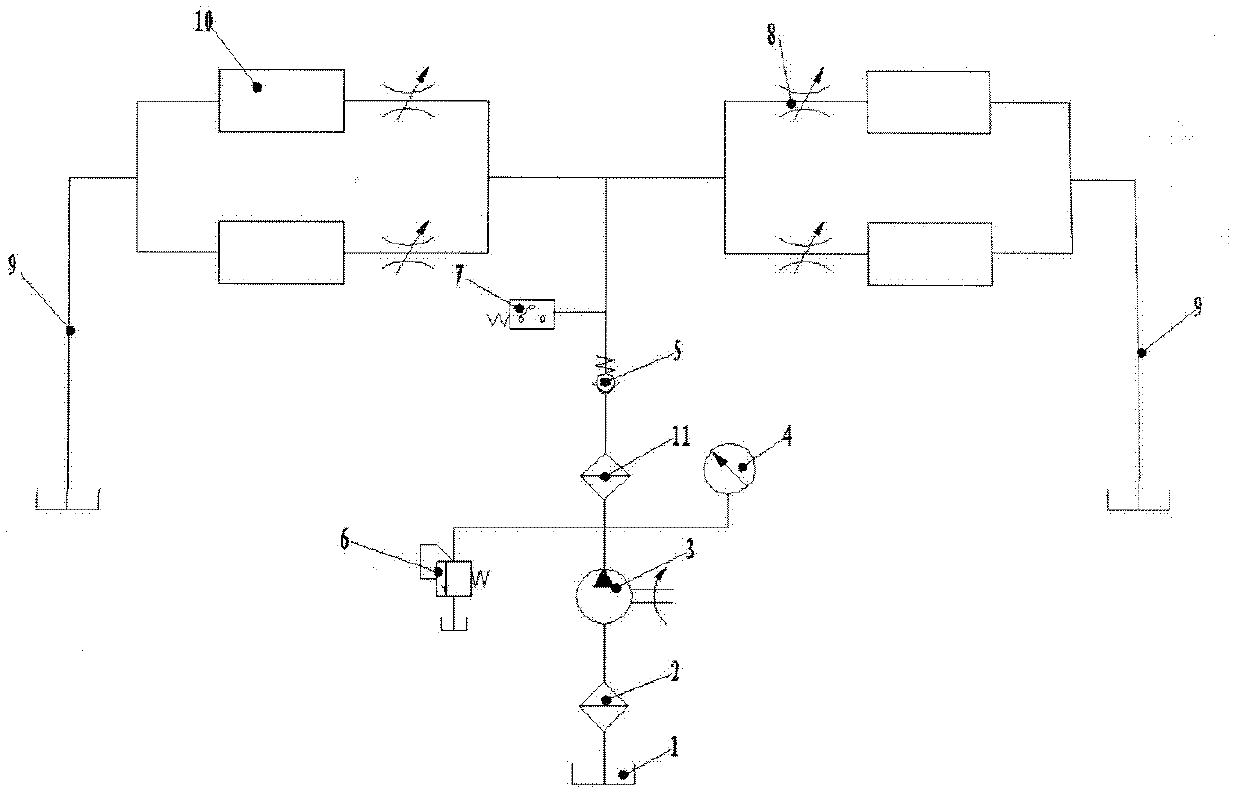

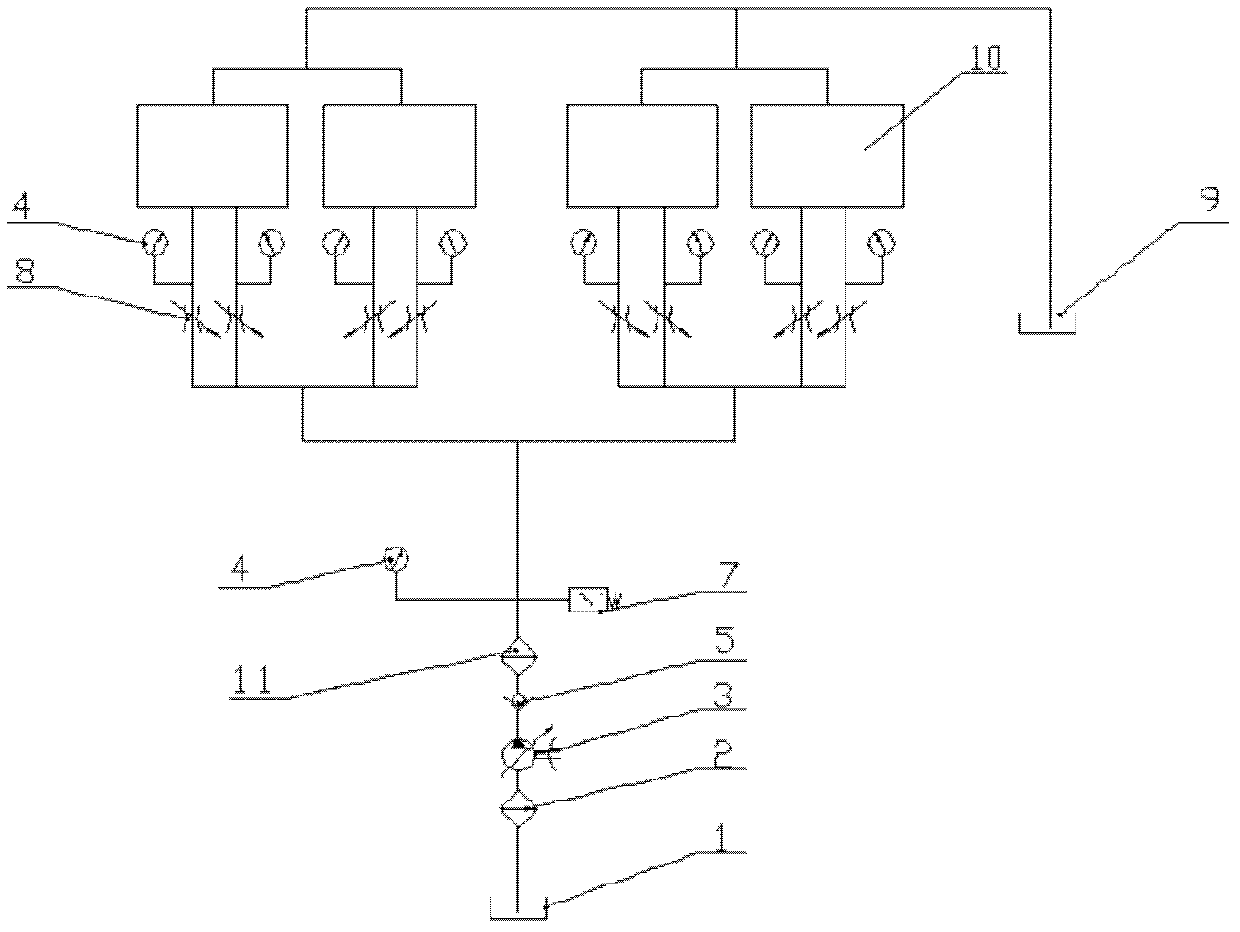

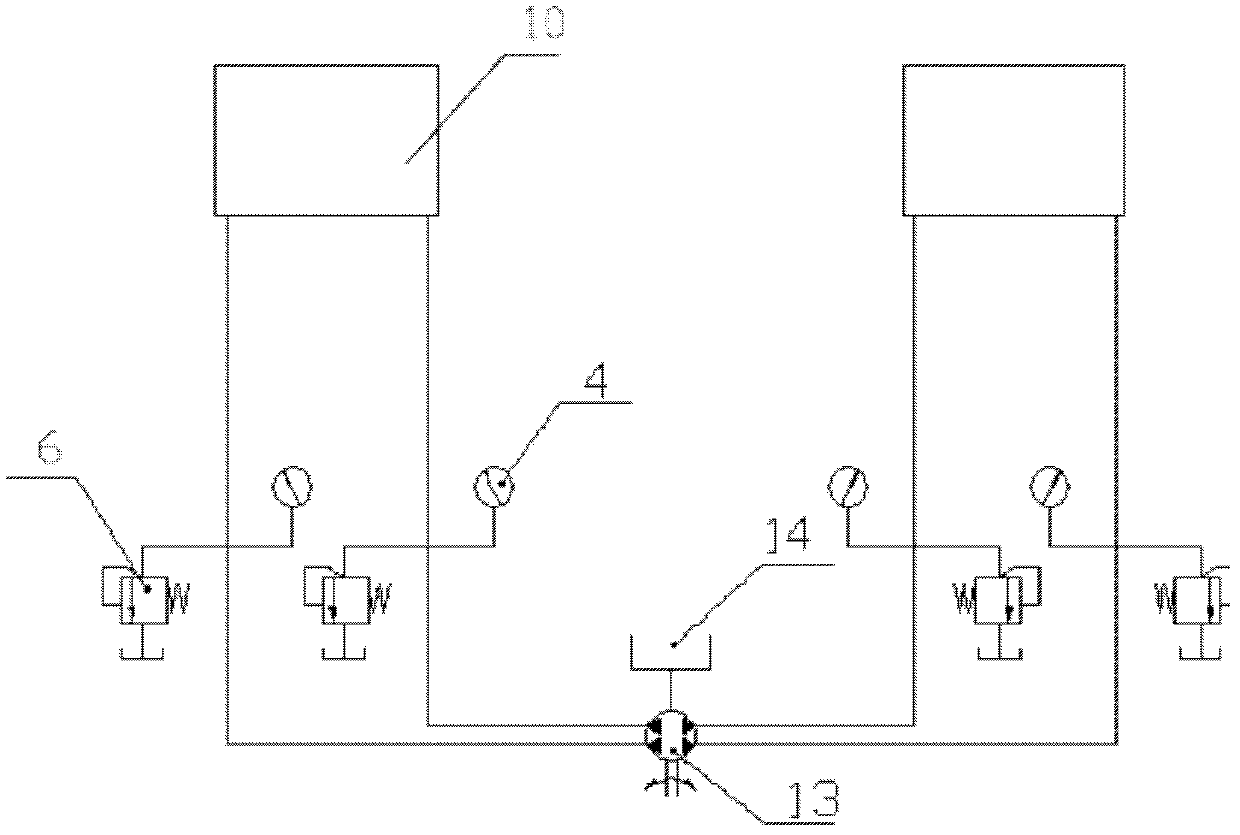

[0031] Embodiment: A dry oil hydrostatic lubrication system for the center frame bracket of a heavy-duty CNC roll grinder. A groove-shaped lubricating oil bag 12 is provided on the side of the bracket as a supporting surface, and a lubricating oil bag 12 is also provided on the bracket. The connected oil inlet channel 10 is also provided with an oil supply circuit, a grease hydrostatic pressure pump 13 and an oil tank 14 filled with grease. The oil port is connected to the oil tank 14, the oil outlet of the grease hydrostatic pressure pump 13 is connected to the oil inlet of the overflow valve 6 through a pipeline, and the oil outlet of the overflow valve 6 is connected to the oil inlet passage 10 on the support shoe through a pipeline , the viscous grease can form a flowing oil film between the two friction surfaces between the bracket and the neck, and use the pressure of the oil film to support the external load, and the oil film itself plays a role in lubricating the fricti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com