Intermediate conjunction box body for oil-immersed electric roller motor leading-out wire

A technology for connecting electric drums and motors, which is applied in the direction of electric components, electrical components, electromechanical devices, etc., and can solve problems such as environmental pollution, wire cores and junction boxes, oil leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

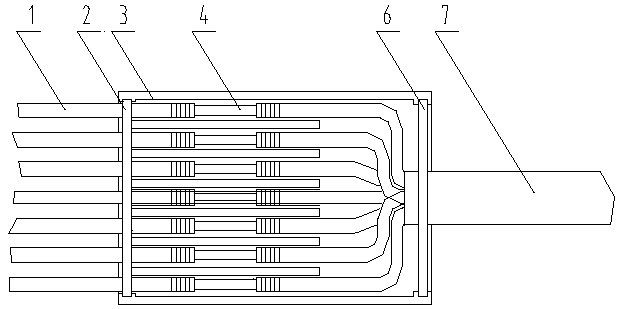

[0007] The present invention is realized in this way: firstly, the cable support blocking plate 6 is penetrated into the motor cable 7; the cable sheath is removed according to the specified length to expose the electric wires connected with the lead wires of the motor, and each wire that passes through is inserted into the motor cable according to the specified length. Strip off the exposed copper wires of the wires, insert the exposed copper wires into the wire holes at the end of the middle terminal 4, and press them firmly with a crimping machine; then pass the motor lead wire 1 through the motor lead wire In each hole of the supporting block board, the lead wires passing through shall be stripped off the wire sheath of each lead wire end according to the specified length, and the exposed copper wire shall pass into the wire nose wire hole at the end of the middle terminal 4 and ensure that it has been crimped. The lead wires at the other end are the corresponding relations...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com