Patents

Literature

42 results about "Assimilative capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Assimilative capacity refers to the ability of a body of water to cleanse itself; its capacity to receive waste waters or toxic substances without deleterious effects and without damage to aquatic life or humans who consume the water. It is level to which water body or nature control the toxicity without affecting the aquatic life.

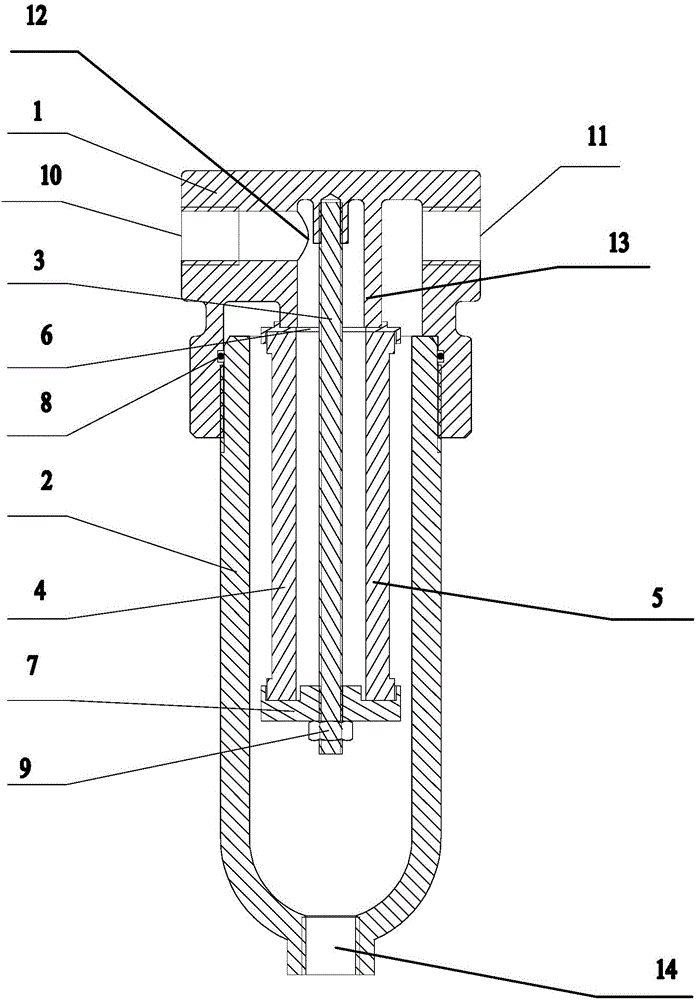

Sintered metal fiber filtering material and preparation method thereof

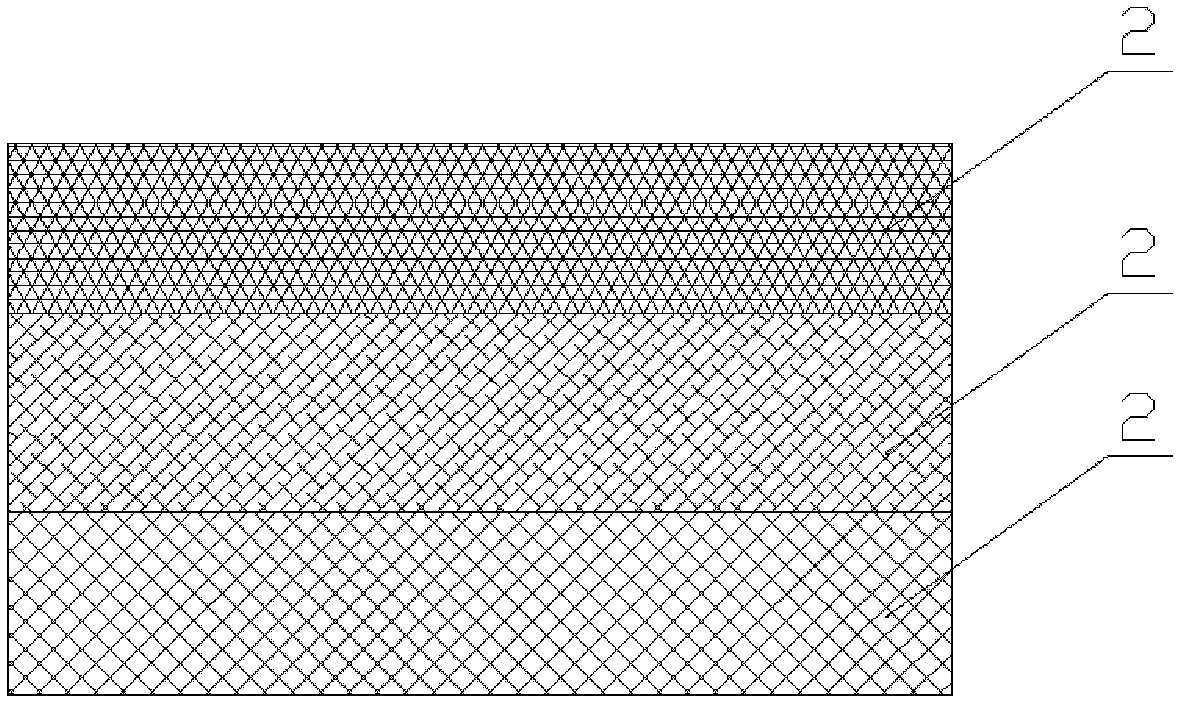

ActiveCN103170186AImprove throughputHigh filtration precisionFiltration separationHigh fluxMetal fibers

The invention discloses a sintered metal fiber filtering material comprising at least two sintered metal fiber felt layers, wherein the pore size of each sintered metal fiber felt layer is decreased layer by layer along the fluid inflowing direction. A preparation method of the sintered metal fiber filtering material includes the steps of shearing into short fibers; feeding the short fibers into a feeding device of a clothing felt machine to produce a soft metal fiber felt by utilizing an airflow depositing principle, and then compacting; overlying two to four metal fiber felt layers with different unit felt weights and filtering precisions according to the filtering precision from small to large so as to form a composite metal fiber felt, then placing the composite metal fiber felt into a vacuum sintering furnace for sintering, and cooling after sintering, wherein a sintering isolation material is arranged between the two adjacent composite metal fiber felts; and finally, flattening the metal fiber felts which are sintered into one body and pressing the metal fiber felts to have certain thickness. The obtained sintered metal fiber filtering material with a multi-layer structure has the characteristics of high filtering precision, strong assimilative capacity and high flux.

Owner:苏州海普过滤分离科技有限公司

Method for calculating assimilative capacity of water functional area in freeze-up period

InactiveCN104615871AWater Quality Safety GuaranteeSpecial data processing applicationsAssimilative capacityWater resource management

The invention provides a method for calculating the assimilative capacity of a water functional area in a freeze-up period, and aims at providing a method for calculating the assimilative capacity of the water functional area suitable for the cold region river freeze-up period. The method is characterized by including the steps of establishing a one-dimensional water quality model of the assimilative capacity of the water functional area and the like. The method has significance in analyzing and regulating the water environment risk of the cold region freeze-up period.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

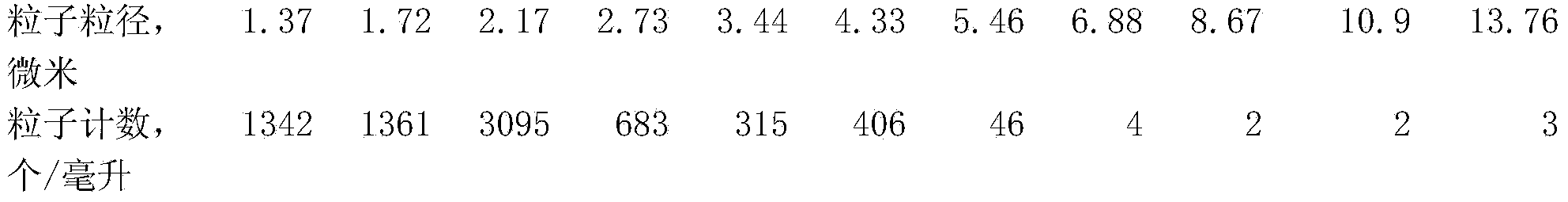

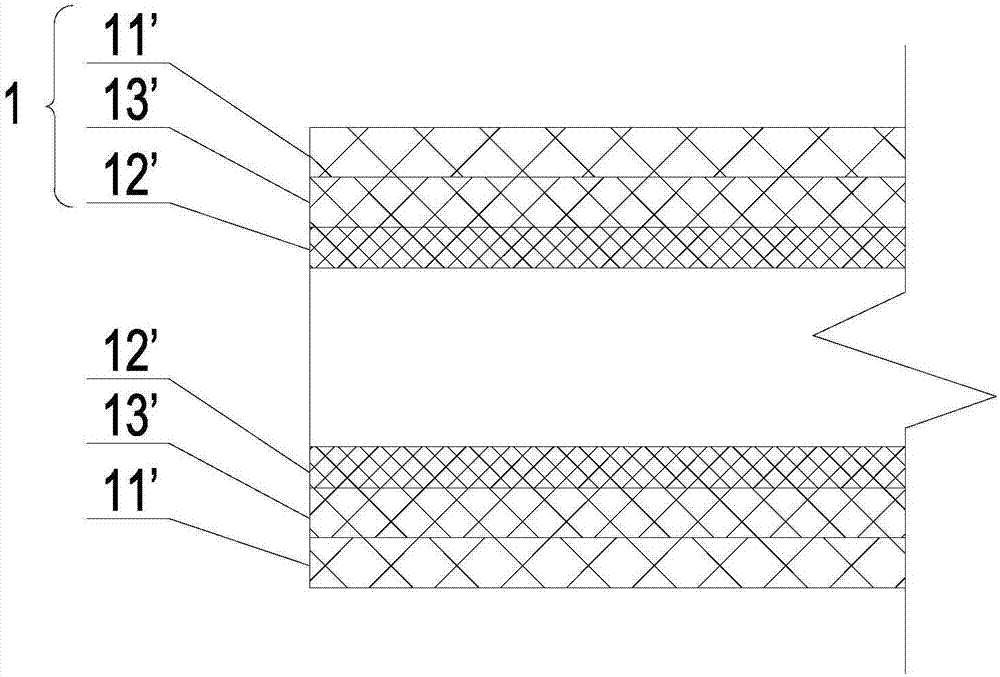

Composite nuclear track membrane and preparation method thereof

ActiveCN104001429AImprove surface hydrophilicityHigh mechanical strengthSemi-permeable membranesPolyesterVolumetric Mass Density

The invention discloses a composite nuclear track membrane and a preparation method thereof. The composite nuclear track membrane comprises a polyester nuclear track membrane or a polycarbonate nuclear track membrane, wherein a porous cellulose acetate membrane is composited on one surface of the polyester nuclear track membrane or the polycarbonate nuclear track membrane so as to form the composite nuclear track membrane of which the thickness is 67-160 microns, the aperture of the polyester nuclear track membrane or the polycarbonate nuclear track membrane is 1-10 microns, the pore density of the polyester nuclear track membrane or the polycarbonate nuclear track membrane is 2*10<5> / cm<2>-2*10<7> / cm<2>, and the thickness of the polyester nuclear track membrane or the polycarbonate nuclear track membrane is 7-25 microns. The composite nuclear track membrane has the advantage that the surface hydrophilicity is good, the mechanical strength is high, the membrane thickness is moderate, the automatic operation can be realized easily, the flux of the filtering liquid is high, and the assimilative capacity is strong; the composite membrane is an integer, is not layered and is suitable for fabricating roll type filter cores; the porous cellulose acetate membrane composited on the nuclear track membrane is taken as a pre-filtering layer or a support layer of the nuclear track membrane, so that the problems about mechanical strength and thickness of the membrane are solved, and meanwhile, the a pre-filtering problem of the membrane is solved.

Owner:天津理源科技有限公司

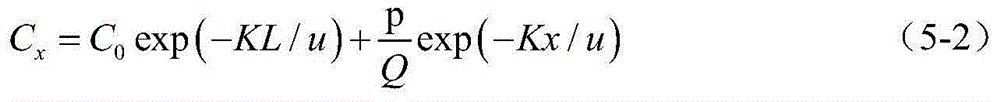

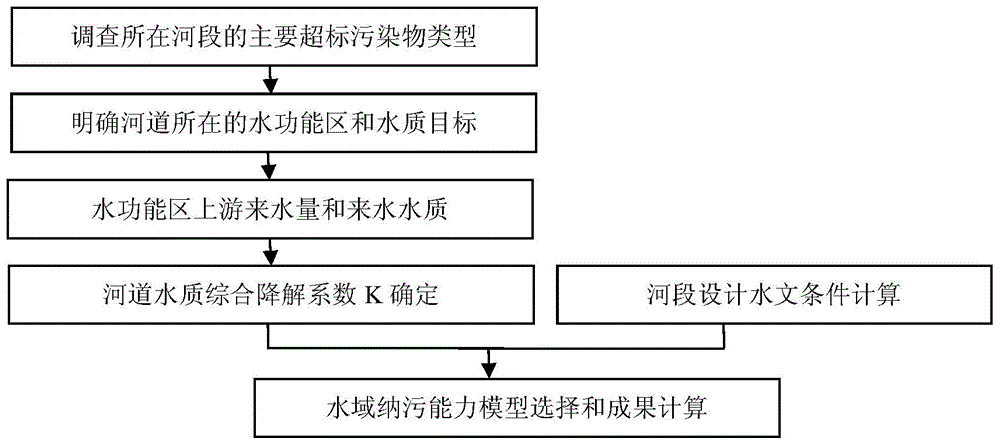

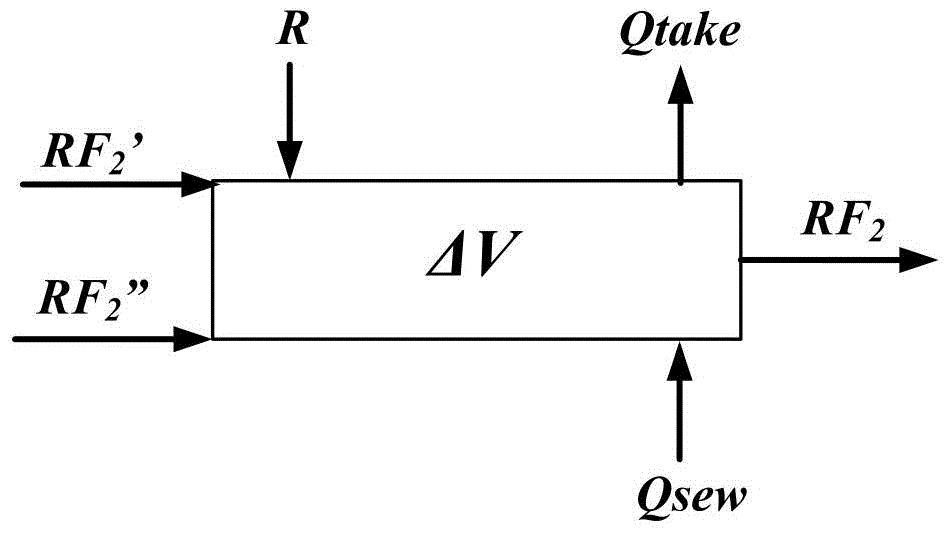

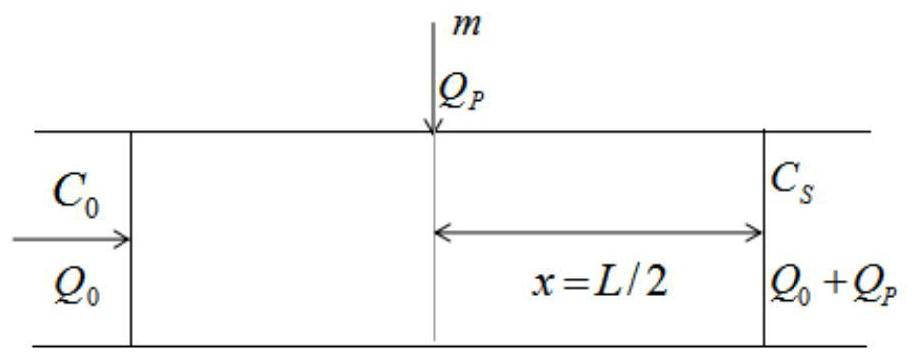

Assimilative capacity calculating method based on binary water circulation

InactiveCN104679993AHealthy water qualityImprove accuracySpecial data processing applicationsWater flowWater circulation

The invention relates to an assimilative capacity calculating method based on binary water circulation. The assimilative capacity calculation method includes steps of 1, determining overproof pollutant types of a watercourse; 2, determining water quality target according to the water function area where the watercourse is; 3, determining upstream coming water flow and quality of the water function area so as to determine boundary conditions of pollutant balance of the watercourse; 4, determining comprehensive degradation coefficient of water quality of the watercourse; 5, determining the design flow of the water function area according to the nature-society binary water circulation flow balance of the watercourse; 6, selecting an assimilative capacity calculation model and calculating assimilative capacity of the water function area according to the water quality target, the upstream coming water flow and quality, the comprehensive degradation coefficient of the water quality and the design flow. The assimilative capacity calculating method can calculate how many pollutants are contained in one river while the water quality of the watercourse can be still kept healthy, and accuracy of calculation results is improved.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

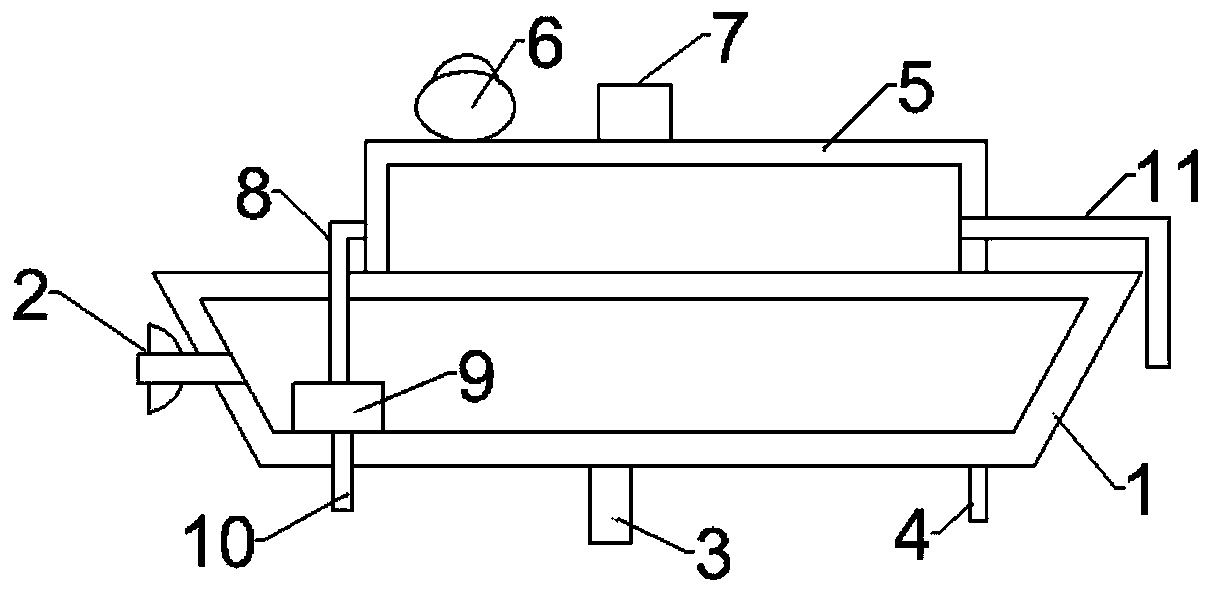

Monitoring and alarming device for water quality pollution control

InactiveCN110156235AEasy to handlePrevent proliferationGeneral water supply conservationTreatment involving filtrationDiffusionTurbidity

The invention discloses a monitoring and alarming device for water quality pollution control. The monitoring and alarming device comprises a ship body; the ship body is provided with a propeller; themiddle of the bottom of the ship body is provided with a water quality detector; one side of the water quality detector is provided with a sensor; the upper part of the ship body is provided with a sewage treatment tank; the top of the sewage treatment tank is provided with an alarm; one side of the alarm is provided with a treater on the sewage treatment tank; and one side of the sewage treatmenttank is provided with a water inlet pipe. The water quality assimilative capacity is compared with a water quality pollutant concentration; when water body pollution is within a water body treatmentcapacity range, the water body pollution is not treated, so that the working efficiency is increased; when the water quality pollutant concentration is higher than the water quality assimilative capacity, sewage is treated, meanwhile, the water quality pollution level is induced and measured by a turbidity sensor and a PH sensor, a water body in a region where the pollution level is high is firstly treated to avoid the diffusion of a pollution source, so that the sewage treatment effect is further improved.

Owner:新沂市新南环保产业技术研究院有限公司

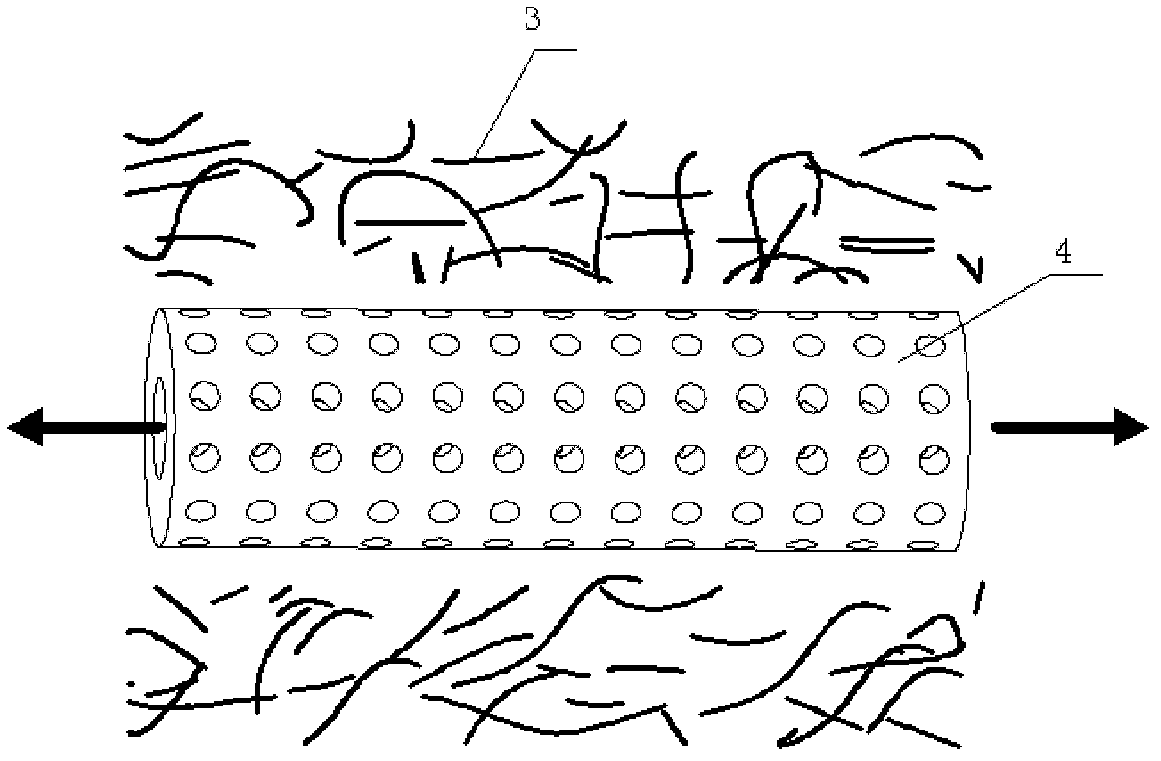

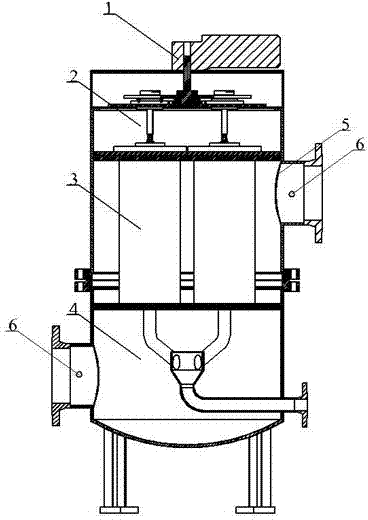

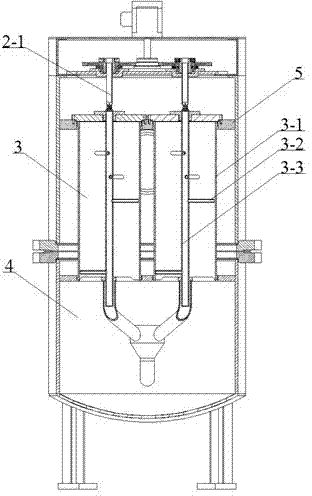

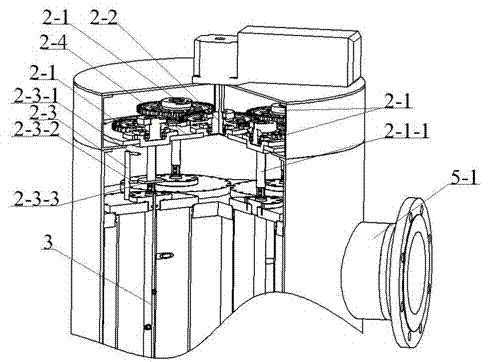

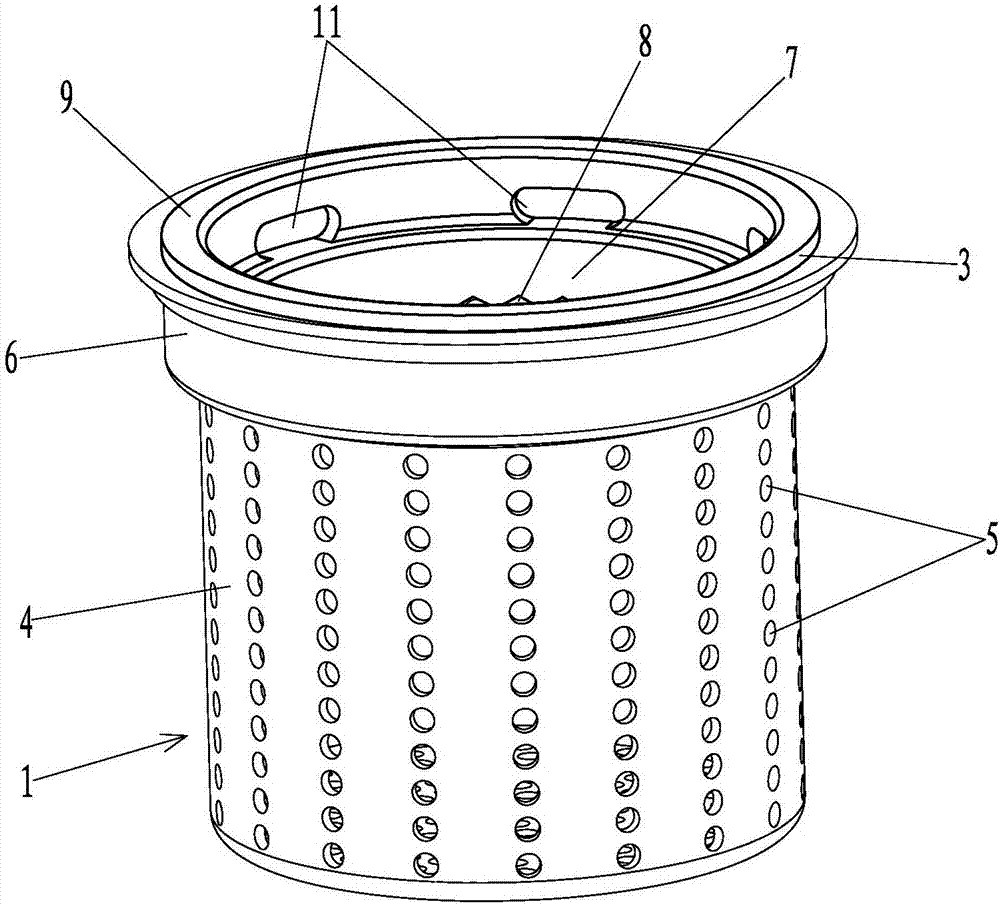

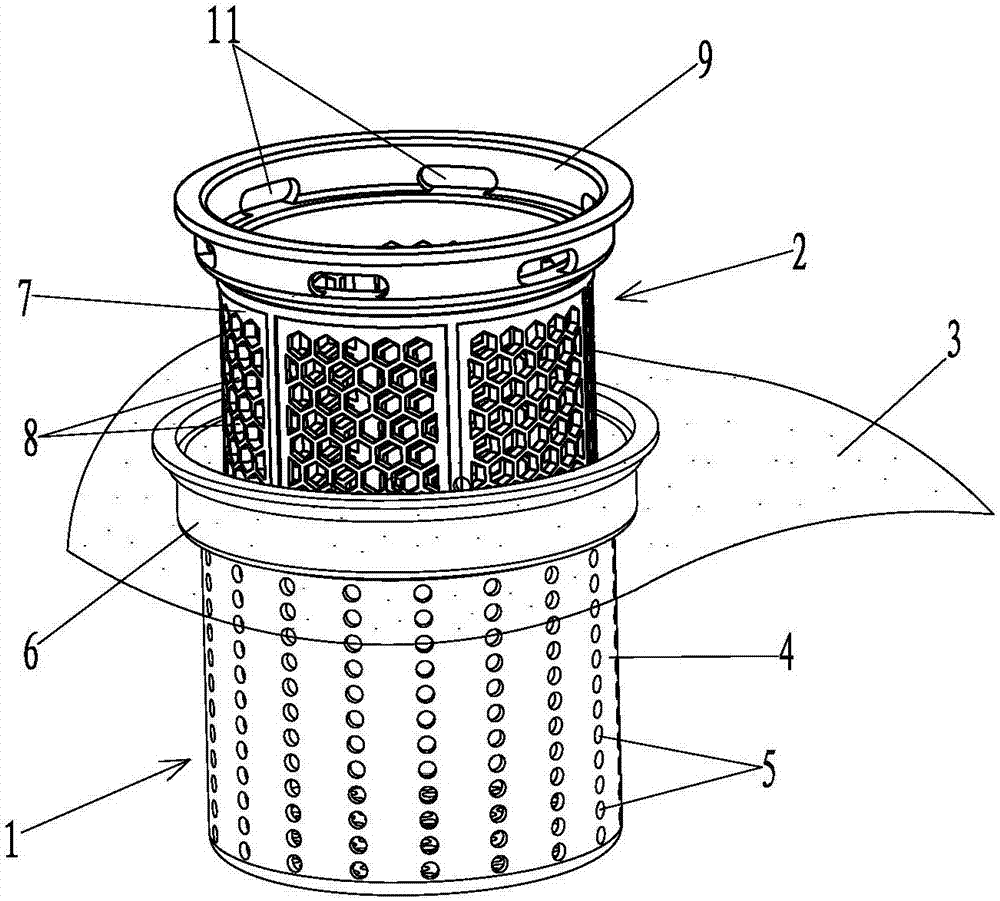

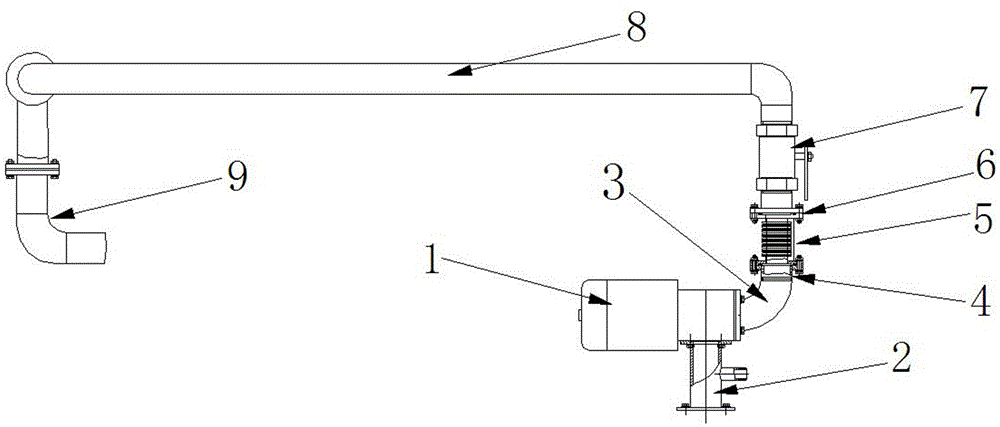

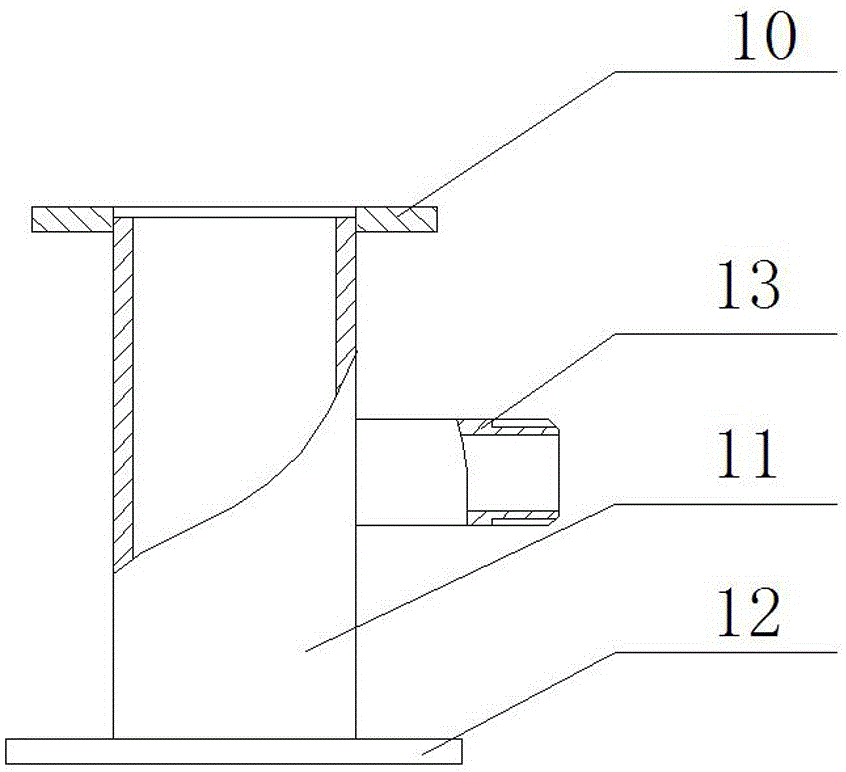

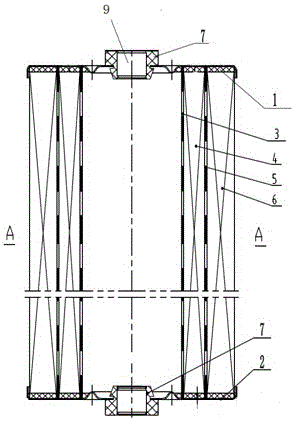

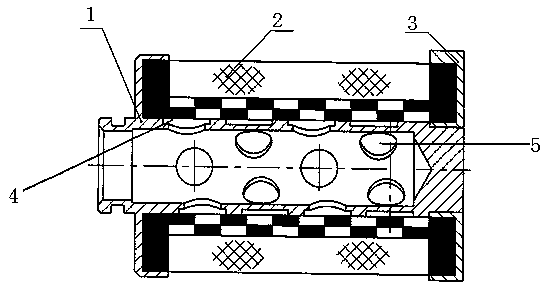

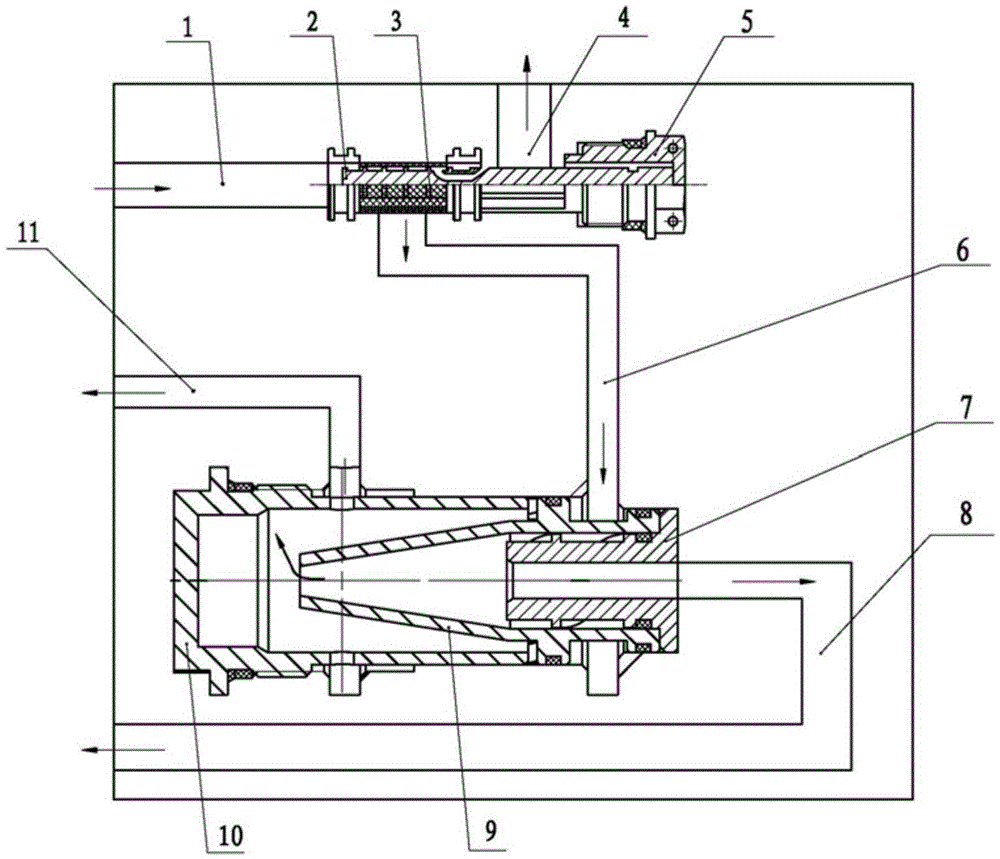

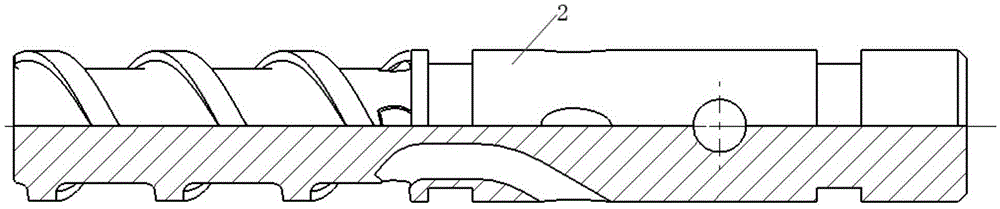

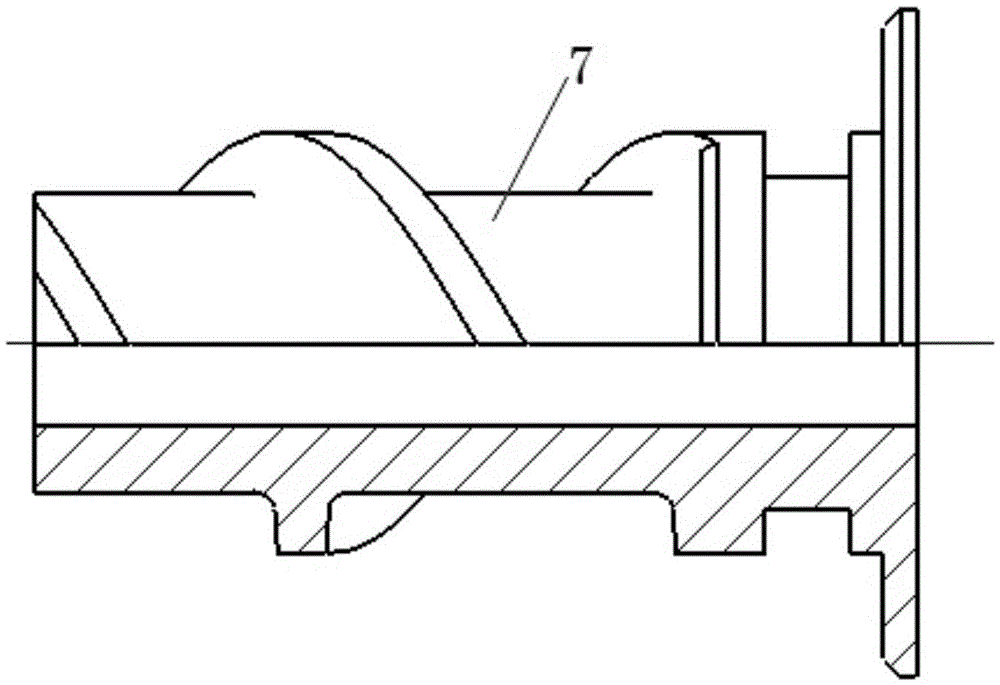

Automatic backwash filter for ballast water management system

InactiveCN103611353ALarge filter areaImprove dirt holding capacityStationary filtering element filtersDrive wheelDifferential pressure

The invention discloses an automatic backwash filter for a ballast water management system. The automatic backwash filter consists of a cleaning motor, a transmission component, a filter component, a lower cylinder component, an upper cylinder component and a differential pressure instrument, wherein the filter component consists of four filter cartridges; filter tips are uniformly distributed on a sewage discharge shaft; the upper end of the sewage discharge shaft is closed, and the lower end of the sewage discharge shaft is provided with an opening; the transmission component consists of a driving wheel train, a limiting mechanism, a fixed plate and four driven wheel trains; threads are formed in a bearing sleeve through hole and are in threaded connection with a screw shaft; a hollow shaft is provided with a key groove and is connected with the screw shaft through a key; threads are formed on the circumferential surface of the screw shaft, and a key groove with a through end is also formed in the circumferential surface of the screw shaft; a water inlet, a drain outlet, a sewage collecting chamber and four sewage discharge bend pipes are arranged on the lower cylinder component. The automatic backwash filter disclosed by the invention has the characteristics of large filtering area, strong assimilative capacity, small pressure loss, small floor area, small amount of backwash water, good installation and maintenance performance and the like, and can greatly meet actual requirements for ship installation.

Owner:JIUJIANG PRECISION MEASURING TECH RES INST

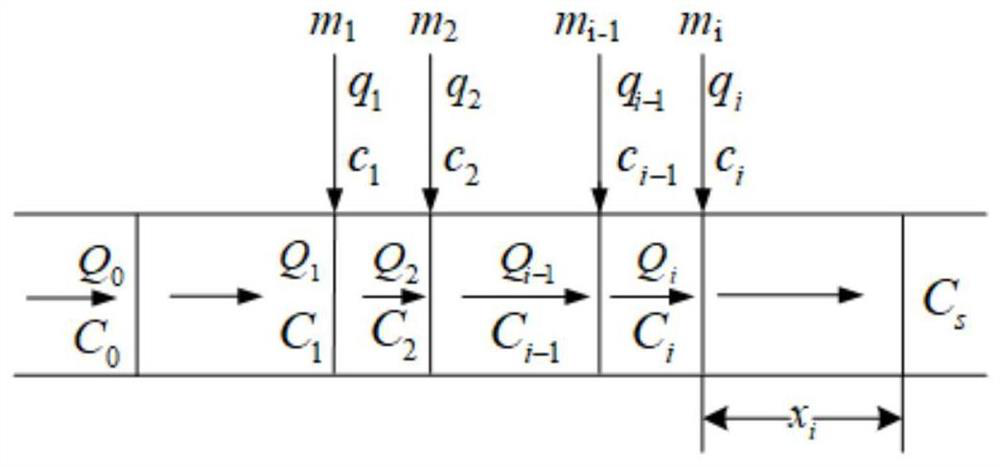

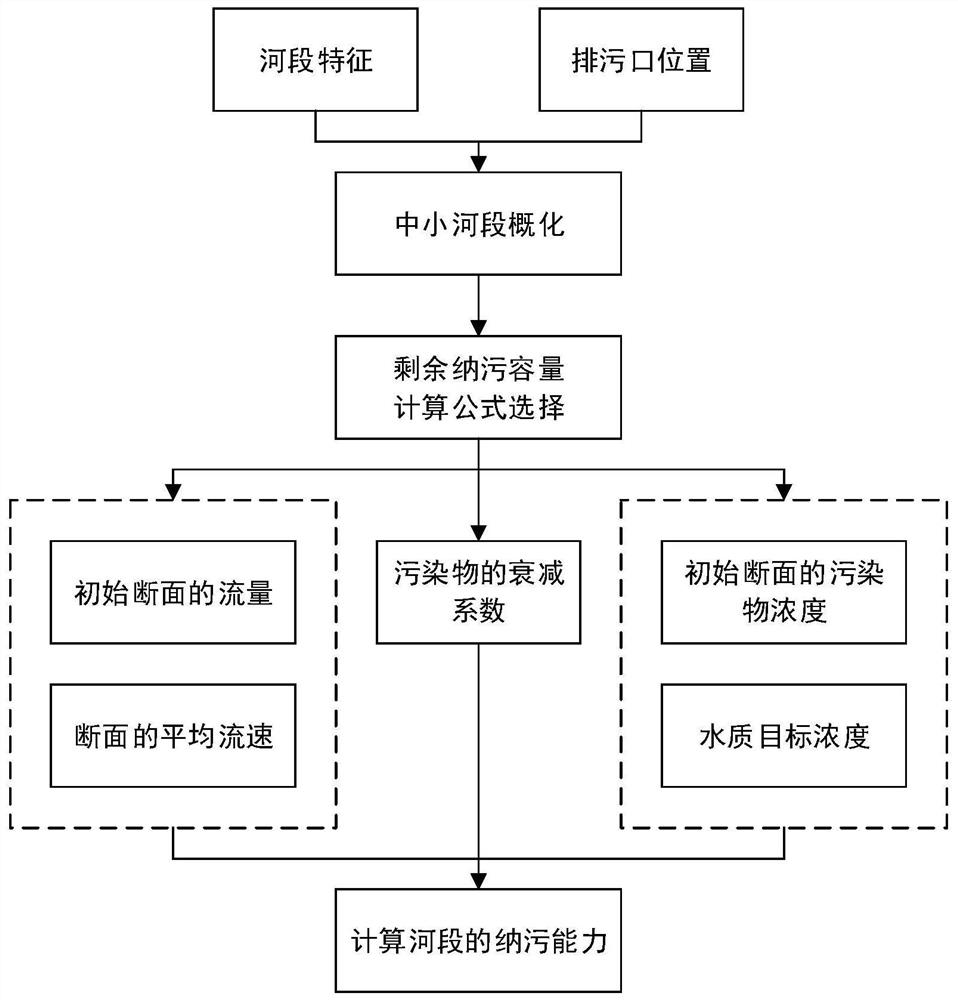

Small and medium-sized river reach assimilative capacity accounting method considering sewage draining exit position influence

ActiveCN112765829AHigh precisionDesign optimisation/simulationSpecial data processing applicationsStream flowSewage outfall

The invention discloses a small and medium-sized river reach assimilative capacity accounting method considering the influence of the position of a sewage draining exit. The method comprises the following steps: carrying out generalized mapping on calculated small and medium-sized river reaches; according to the generalization graph and pollutant discharge data, determining and calculating the length of the river reach, the distance from a drain outlet to the tail end of the river reach, the sewage discharge flow and the pollutant load capacity of the drain outlet; determining the flow and the average flow velocity of the initial section; according to the empirical pollutant degradation coefficient or empirical formula of the river, determining the attenuation coefficient of the pollutant; determining the pollutant concentration and the water quality target concentration of the initial section; selecting a river reach residual pollutant capacity calculation formula according to the actual condition, and calculating the residual pollutant capacity; and calculating the assimilative capacity of the river reach. According to the method, a traditional assimilative capacity calculation model which neglects the sewage discharge flow and does not consider the influence of the sewage discharge outlet position is improved, and the obtained calculation result of the ecological flow and the assimilative capacity for maintaining the river reach water environment quality has higher precision.

Owner:POWERCHINA BEIJING ENG +1

Filter paper with high filtration efficiency and preparation method thereof

InactiveCN103382684AHigh filtration precisionImprove filtration efficiencyPaper/cardboardFiltration separationPhenyl EthersPolyethylene glycol

The invention discloses a filter paper with high filtration efficiency. The filter paper comprises the following raw materials by weight: 50 to 60 parts of hemp pulp, 45 to 50 parts of wood pulp, 20 to 25 parts of a polystyrene fiber, 3 to 5 parts of sodium carboxymethylcellulose, 3 to 4 parts of nanometer carbon dust, 1 to 2 parts of potash feldspar powder, 1 to 2 parts of alum powder, 1 to 2 parts of 4,4'-methyl diphenylene diisocyanate, 2 to 3 parts of diethylenetriamine, 2 to 3 parts of micro polyamide wax powder, 0.8 to 1 part of bis(dioctyloxypyrophosphato)ethylene titanate, 0.4 to 0.6 part of an anti-oxidant DSTP, 0.5 to 0.6 part of water and zinc borate, 2 to 3 parts of glycol, 6 to 7 parts of rosin, 15 to 20 parts of absolute ethyl alcohol, 3 to 4 parts of nanometer alumina, 0.8 to 1 part of polyoxyethylene octyl phenyl ether, 0.3 to 0.4 part of gamma-(2,3-epoxypropanolato)propyl trimethoxy silane and a proper amount of water. The filter paper produced in the invention has high filtration precision, high filtration efficiency, small air resistance and good assimilative capacity and is environment friendly; an impregnation liquid used in the invention overcomes the disadvantages of great brittleness, poor cohesiveness on the surface of fibers in the filter paper and the like of a filter paper adhesive film, exerts the effect of multistage filtration, compensates for the defect of large bore diameters of a part of bores among the fibers in the filter paper, improves uniformity of the bore diameters of bores among the fibers in the filter paper and enhances screening and filtering effects.

Owner:BENGBU PIONEER FILTER

Polyamide filter material and filter element for oil filtration

InactiveCN105688514AMeet filter requirementsAchieve oil and alcohol resistanceMachines/enginesLiquid fuel feedersAlcoholFiltration

The invention discloses a polyamide filter material and a filter element for oil filtration. The filter material is made from a polyamide material and is of a hollow cylindrical structure prepared by mutually gluing and winding superfine fibers ejected by virtue of melt-blowing technical processing; the filter material is of a loose structure which is provided with filter holes different in pore diameters; the pore diameter distribution mode of the filter holes is as follows: the pore diameters are sequentially and gradually decreased from outside to inside along the cylindrical structure. By virtue of controlling the structural parameters of the filter material, filtration of oils such as fuel oil or lubricating oil is realized, the filter material has relatively high filtration precision, assimilative capacity and oil-water separation capability on the premise of ensuring oil resistance and alcohol corrosion resistance; the scheme breaks through the restriction that only hydrophobic materials can be selected as traditional filter materials so as to meet oil-water separation indexes; by virtue of fully using the characteristics such as high corrosion resistance and high reliability of the polyamide material in the oils, the filtration requirements of common oils are met.

Owner:XIAN TIANHOU FILTRATION TECH

Method to improve the success rate of reclosing of cluster wind farm tie line

InactiveCN104362579BImprove absorption capacityImprove efficiencyEmergency protective arrangements for automatic disconnectionElectricityPower grid

Owner:XINJIANG UNIVERSITY +3

High-adsorptivity filter paper and preparation method thereof

InactiveCN103382682AHigh filtration precisionImprove filtration efficiencyPaper/cardboardRosin additionSodium sulfateMaterials science

The invention discloses a high-adsorptivity filter paper. The high-adsorptivity filter paper comprises the following raw materials by weight: 100 to 120 parts of needlebush pulp, 12 to 14 parts of a polytetrafluoroethylene fiber, 2 to 3 parts of chlorinated paraffin, 1 to 3 parts of ceramic powder, 1 to 3 parts of light calcium carbonate, 1 to 2 parts of alum powder, 1 to 2 parts of 1,4-cyclohexanedimethanol, 1 to 2 parts of polypropylene adipate, 0.3 to 0.5 part of ammonium biphosphate, 2 to 3 parts of sodium alginate, 0.8 to 1 part of ethylene bis(stearamide), 0.4 to 0.5 part of cerium oxide, 10 to 12 parts of rosin, 3 to 4 parts of butyl acrylate, 3 to 5 parts of nanometer silica, 20 to 25 parts of absolute ethyl alcohol, 1 to 2 parts of sodium carboxymethylcellulose, 0.2 to 0.4 part of sodium persulfate and a proper amount of water. The filter paper produced in the invention has high filtration precision, high filtration efficiency, small air resistance and good assimilative capacity and is environment friendly; an impregnation liquid used in the invention overcomes the disadvantages of great brittleness, poor cohesiveness on the surface of fibers in the filter paper and the like of a filter paper adhesive film, exerts the effect of multistage filtration, compensates for the defect of large bore diameters of a part of bores among the fibers in the filter paper, improves uniformity of the bore diameters of bores among the fibers in the filter paper and enhances screening and filtering effects.

Owner:BENGBU PIONEER FILTER

Filter paper and preparation method thereof

InactiveCN103334346AHigh filtration precisionImprove filtration efficiencyNon-macromolecular organic additionSynthetic cellulose/non-cellulose material pulp/paperFiberCellulose acetate

The invention relates to filter paper and a preparation method thereof. The filter paper disclosed by the invention is composed of the following raw materials by weight: 90-100 parts of bamboo pulp, 12-15 parts of cellulose acetate, 10-12 parts of mineral wool fibers, 3-4 parts of stearic acid, 2-3 parts of nano silica, 2-3 parts of dolomite powder, 5-6 parts of microwax powder, 1-2 parts of sodium dibutylnaphthalene sulfonate, 1-3 parts of glycerol triacetate, 2-3 parts of oxidized polyethylene wax, 0.8-1 part of dimethyl isooctyl thioglycolate tin, 0.6-1 part of aminopropyl triethoxysilane, 0.1-0.2 part of alumina powder, PAE3-5 parts of a wet strength agent, 6-10 parts of rosin, 15-20 parts of absolute ethyl alcohol, 1-2 parts of lauryl alcohol polyoxyethylene and a proper amount of water. The filter paper produced by the method has high filtration precision, high filtration efficiency, low air resistance, strong assimilative capacity and environmental protection. An impregnation liquid not only overcomes disadvantages of large fragility of filter paper coating, poor cohesive property to fiber surfaces in the filter paper and the like but also plays a multi-filtration effect, thereby making up the defects that partial holes among the filter fibers are relatively large in size, increasing uniformity of the hole size among the filter fibers and enhancing a filtering effect.

Owner:BENGBU PIONEER FILTER

Polypropylene profiled fiber for dust removing and filtering

InactiveCN109056086AHigh yield strengthHigh elongation at breakFilament/thread formingMonocomponent polyolefin artificial filamentYarnMixed materials

The invention discloses polypropylene profiled fiber for dust removing and filtering. The polypropylene profiled fiber is prepared from polypropylene resin, nanometer ceramic powder, nanometer graphene, a silane coupling agent, stearic acid and acetone, the preparation processes of the polypropylene profiled fiber for dust removing and filtering comprise raw material weighing, preparation of modified nanometer ceramic powder, preparation of a mixed material of the stearic acid and the modified nanometer ceramic powder and preparation of the polypropylene profiled fiber. Different profile spinnerets extrude profiled polypropylene fiber yarns out, the section of the fiber is trilobal shape, C-shaped, round and hollow, cruciform, 'mi'-shaped or triangular, the yarns are smooth and round, thesection profile degree of the fiber is 35%-55%, the length of the fiber is 58-100 mm, the fiber fineness is 5.2-13 dtex, the filtering efficiency of the polypropylene profiled fiber is high, the impurity containing and assimilative capacity is high and is 2-3 times that of an ordinary filtering fiber product, the yield strength of the fiber is improved by 3-5 MPa, the elongation at break is improved by 16-25%, and the elasticity modulus is increased by 150-200 MPa.

Owner:ZHEJIANG COLLEGE OF ZHEJIANG UNIV OF TECHOLOGY

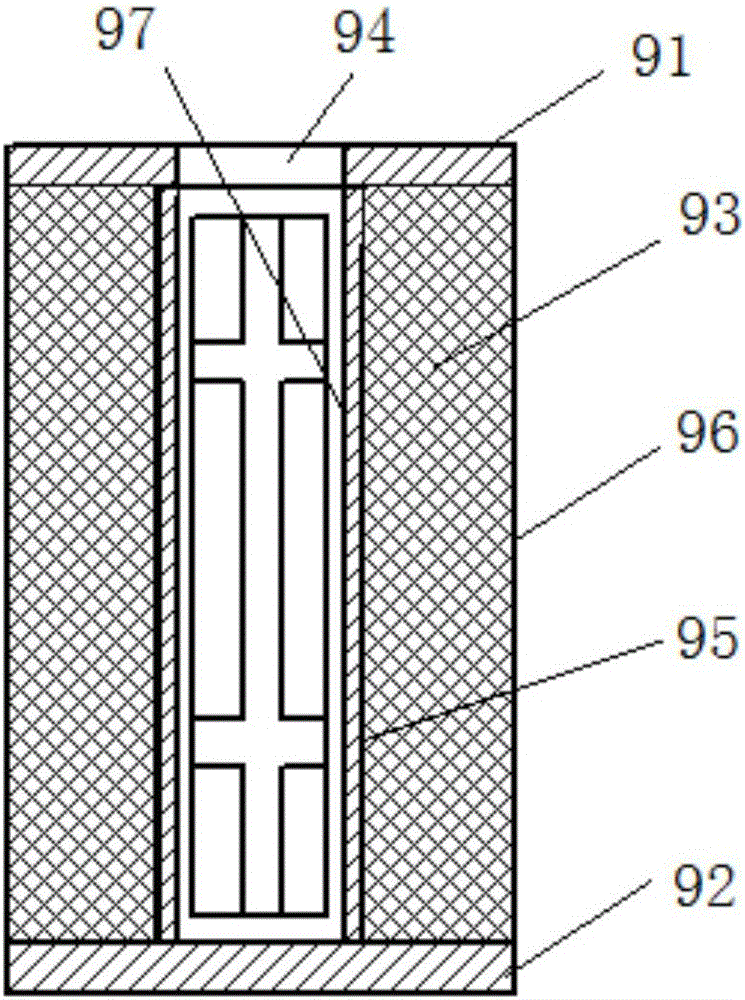

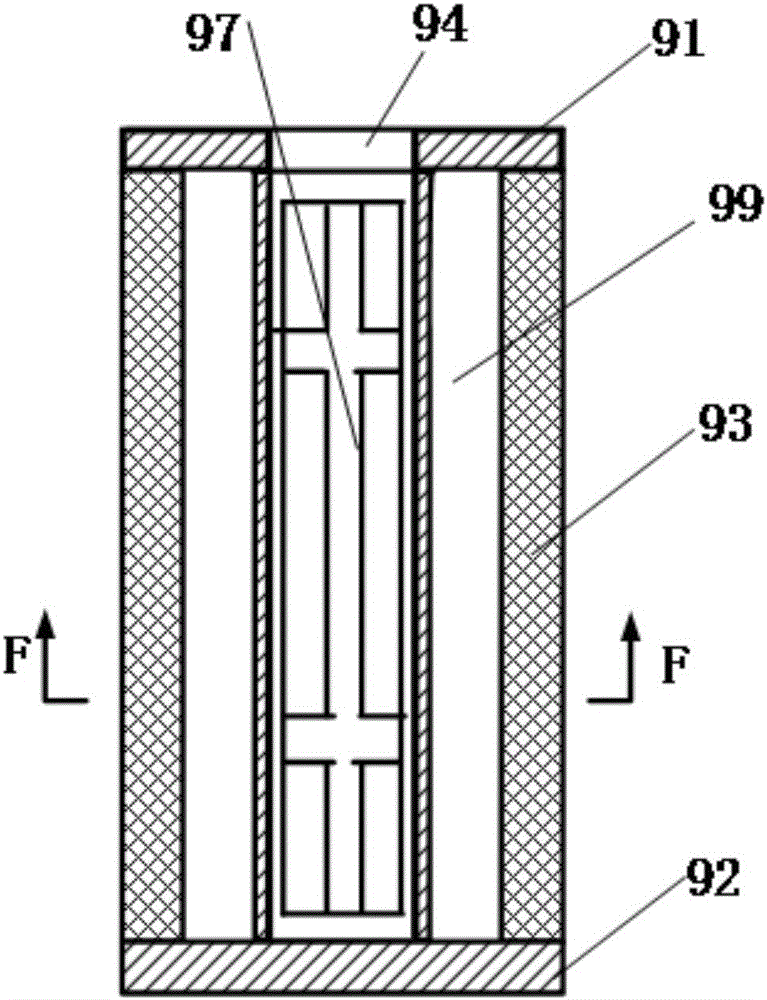

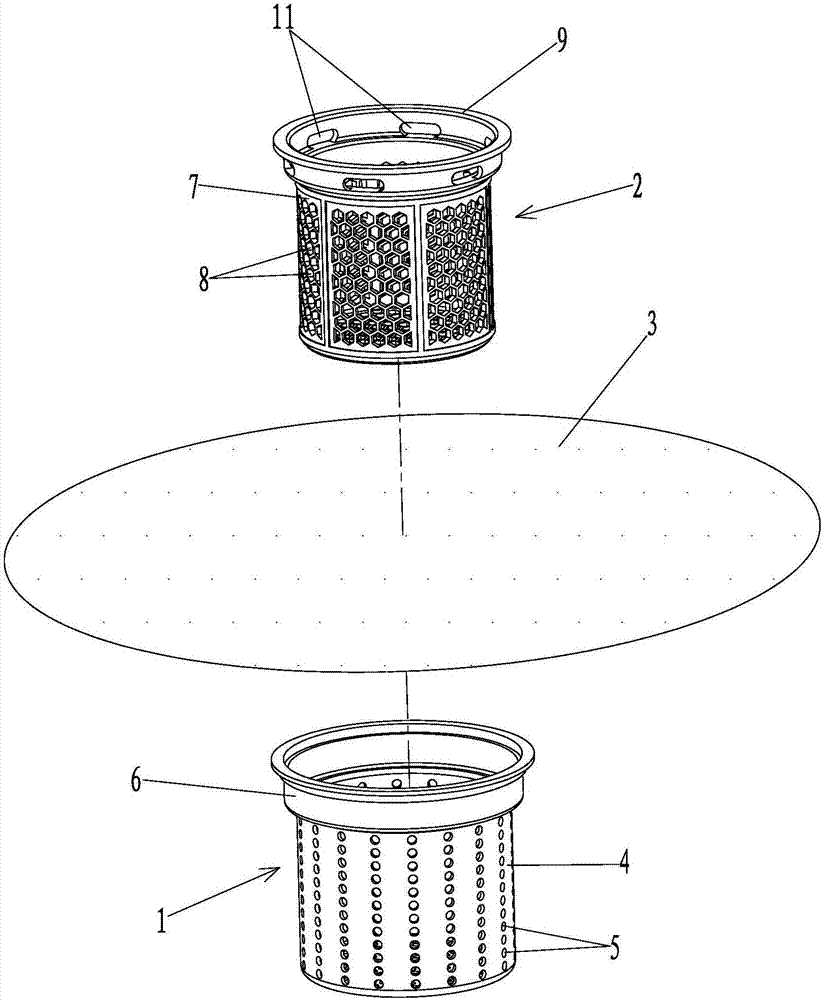

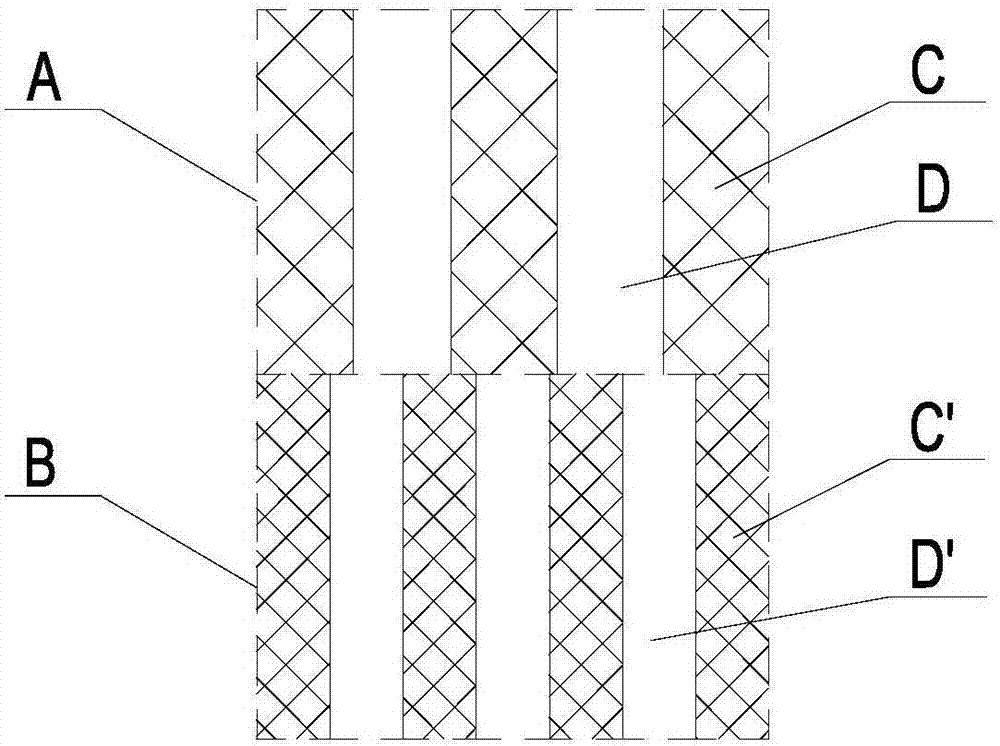

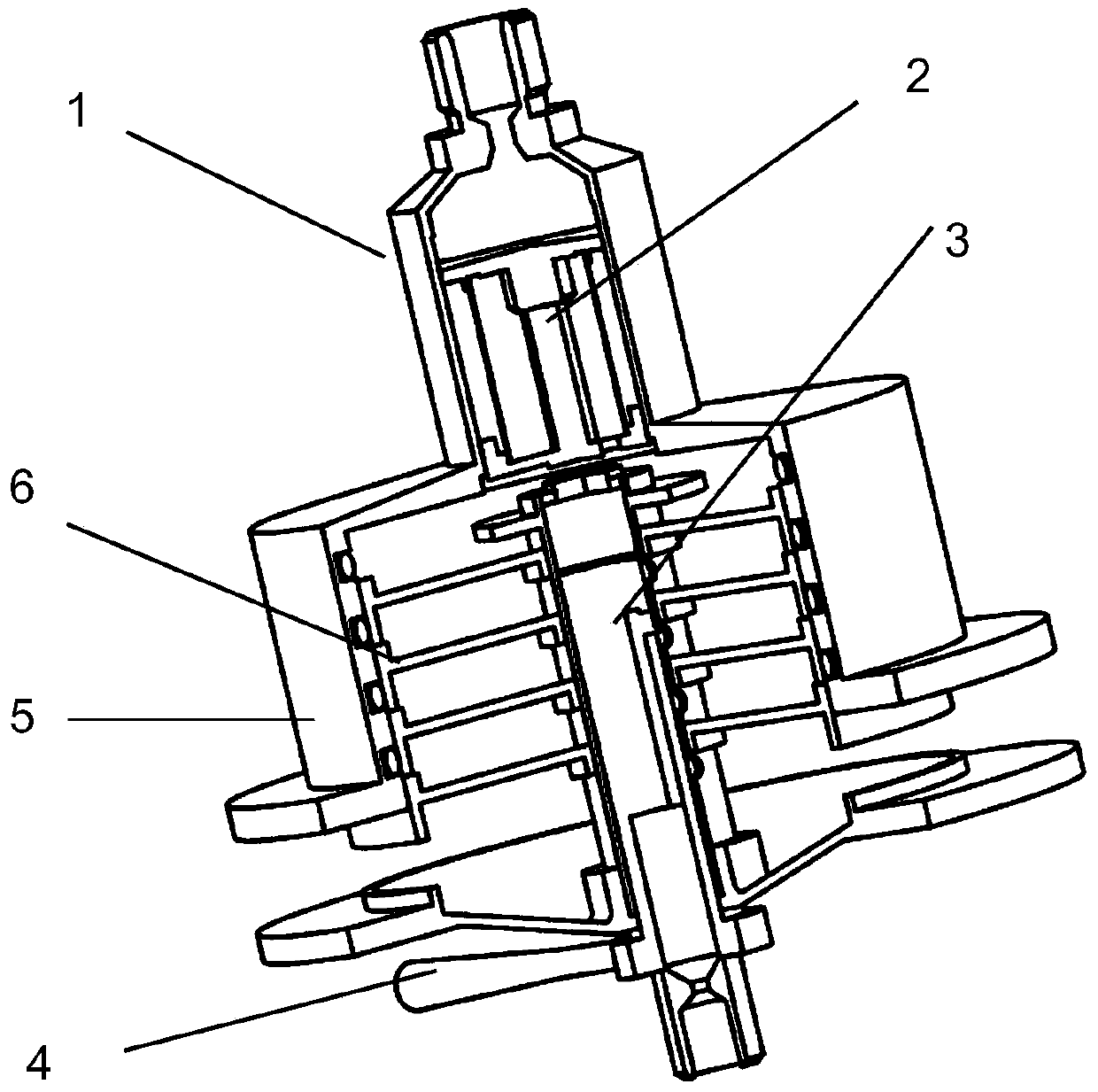

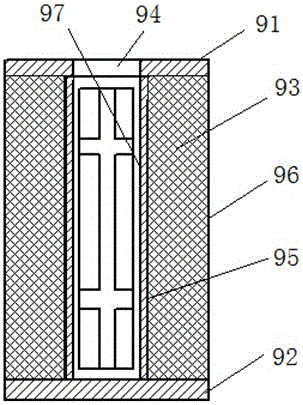

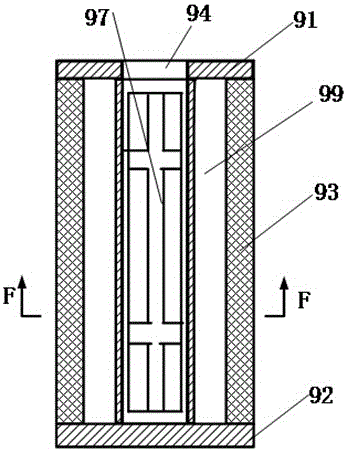

Filter element structure and processing method thereof

InactiveCN107050961ASimple methodSimplify the assembly processMembrane filtersGravity filtersEngineeringAssimilative capacity

The invention discloses a filter element structure and a processing method thereof. The filter element structure comprises two cylindrical or conical filter cartridge frameworks which are arranged together in a sleeved mode and are provided with opened upper ends and closed bottom ends, wherein the bottom ends of the cartridge frameworks are planer or protruding spherical surfaces, a nuclear hole film is clamped between the two filter cartridge frameworks and forms a bag-shaped structure close similar to a filter cartridge framework structure, and the upper ends of the two filter cartridge frameworks are connected together. The processing method of the filter element structure comprises the steps that the nuclear hole film is put on the upper end face of the filter cartridge framework having the larger inner diameter, the filter cartridge framework having the smaller inner diameter extends into the lower end of the inner cavity from the upper end of the filter cartridge framework having the larger inner diameter, and meanwhile the nuclear hole film is pressed into the lower ends of the two filter cartridge frameworks. The upper ends of the two filter cartridge frameworks are sealed and welded together. The filter element structure is integral and is convenient to replace and more convenient to use, a processing and assembling process is simple, the manufacturing cost is low, the assimilative capacity is strong, the filtering efficiency is high, and the replacement frequency is reduced.

Owner:上海谷奇核孔膜科技股份有限公司

Stainless steel high-pressure filter

InactiveCN106731264AClosely connectedSimple structureDispersed particle filtrationArchitectural engineeringProduct gas

The invention relates to a stainless steel high-pressure filter. The stainless steel high-pressure filter comprises an upper shell, a lower shell, a lead screw, a first filter element, a second filter element, an upper end cover and a lower end cover, wherein the upper shell and the lower shell are connected through an external thread and an internal thread; a first ventilation opening and a second ventilation opening are formed in two sides of the end part of the upper shell respectively; a partition is used for isolating the first ventilation opening from the second ventilation opening; the interior of the lower shell is provided with a cavity; the lead screw is arranged on the upper shell; the top end of the lead screw is fixed on the inner wall of the upper shell; the upper end cover is arranged in the middle of the lead screw; the tail end of the lead screw is fixed on the lower end cover; and the first filter element and the second filter element are arranged between the upper end cover and the lower end cover. The stainless steel high-pressure filter is simple in structure, compact in design and convenient to use, the upper shell and the lower shell are tightly connected, the high pressure resistance effect is good, the filter is applicable to purification of compressed air in the cavity, air in the cavity is filtered for the two times through the first filter element and the second filter element, the filtering effect is better, and the assimilative capacity is higher.

Owner:WUXI UNITE PURIFICATION EQUIP CO LTD

Single-material gradient filter element

InactiveCN106975274ANot easy to squeeze and deformExtended service lifeSynthetic resin layered productsFiltration separationYarnFiltration

The invention provides a single-material gradient filter element. The filter element comprises at least two filter layers which have the same density and are formed by hot-melting and winding of polypropylene fiber yarns; and polypropylene fiber yarns of the filter layers from outside to inside have different thicknesses, and polypropylene fiber yarns of the outer layer are thicker than those of the inner layer. According to the single-material gradient filter element, gradient filtration of the filter element can be realized by changing thickness of the polypropylene fiber yarns of different filter layers. According to the gradient filtration realized by the manner, the density of each filter layer is the same, namely the compact degree of each layer is the same, so that the filter element has relative good strength and strong tensile strength, and has a relatively long service life since the filter element cannot be easily extruded and deformed in the filtering process. Furthermore, due to relatively high strength, a frame structure does not need to be added inside the filter element for supporting, so that the filtration flux and assimilative capacity can be ensured, and materials can be saved.

Owner:杭州卧特松环保科技有限公司

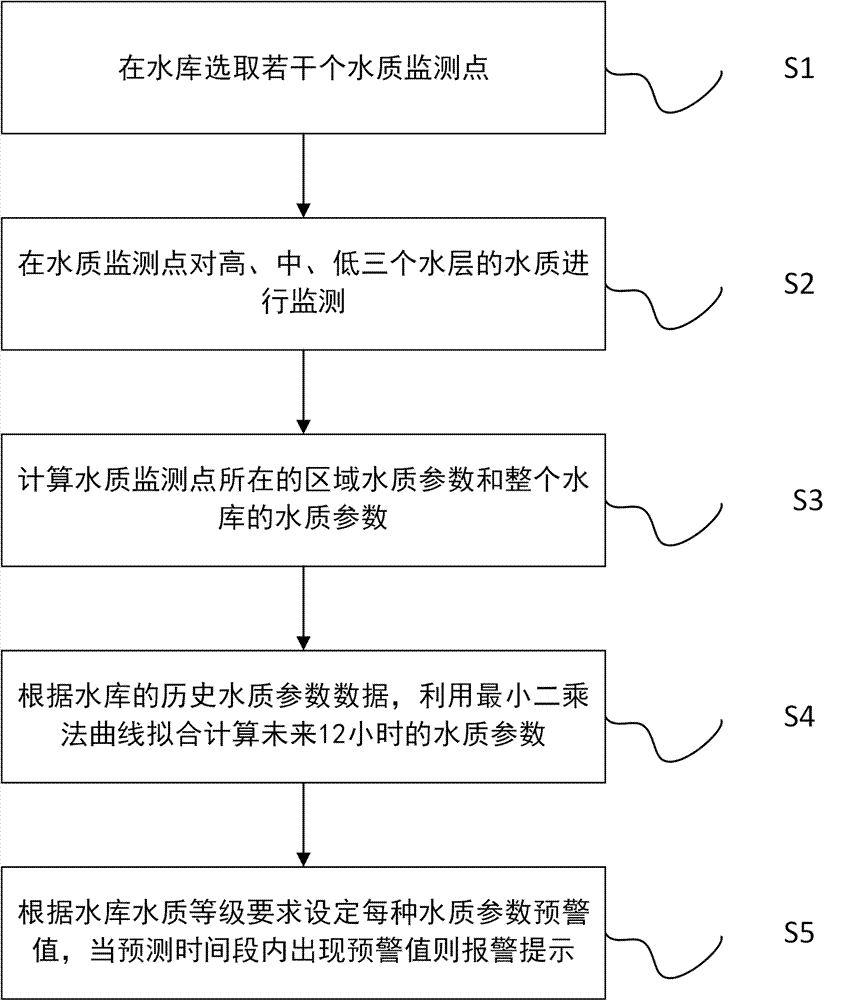

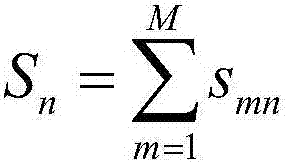

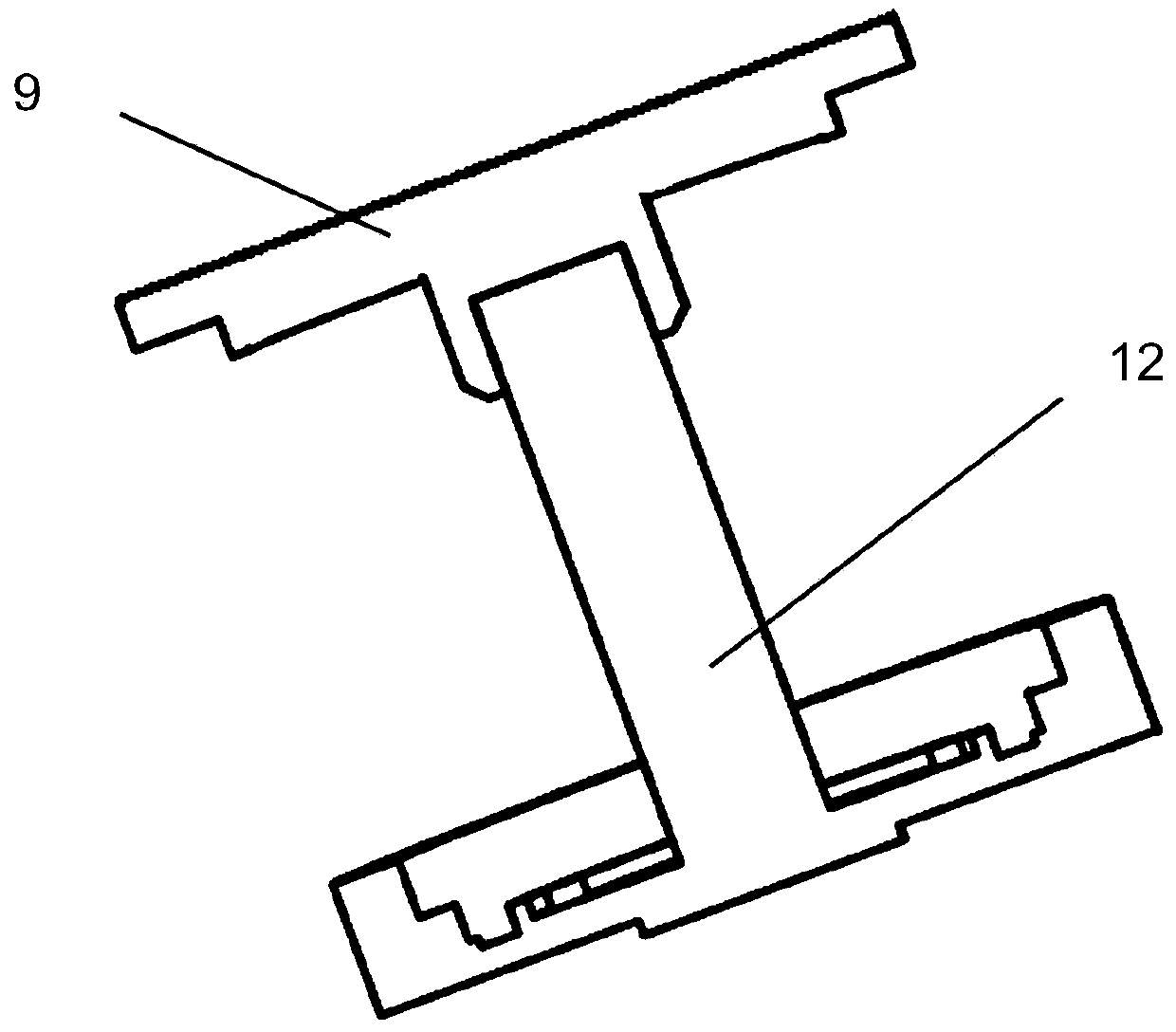

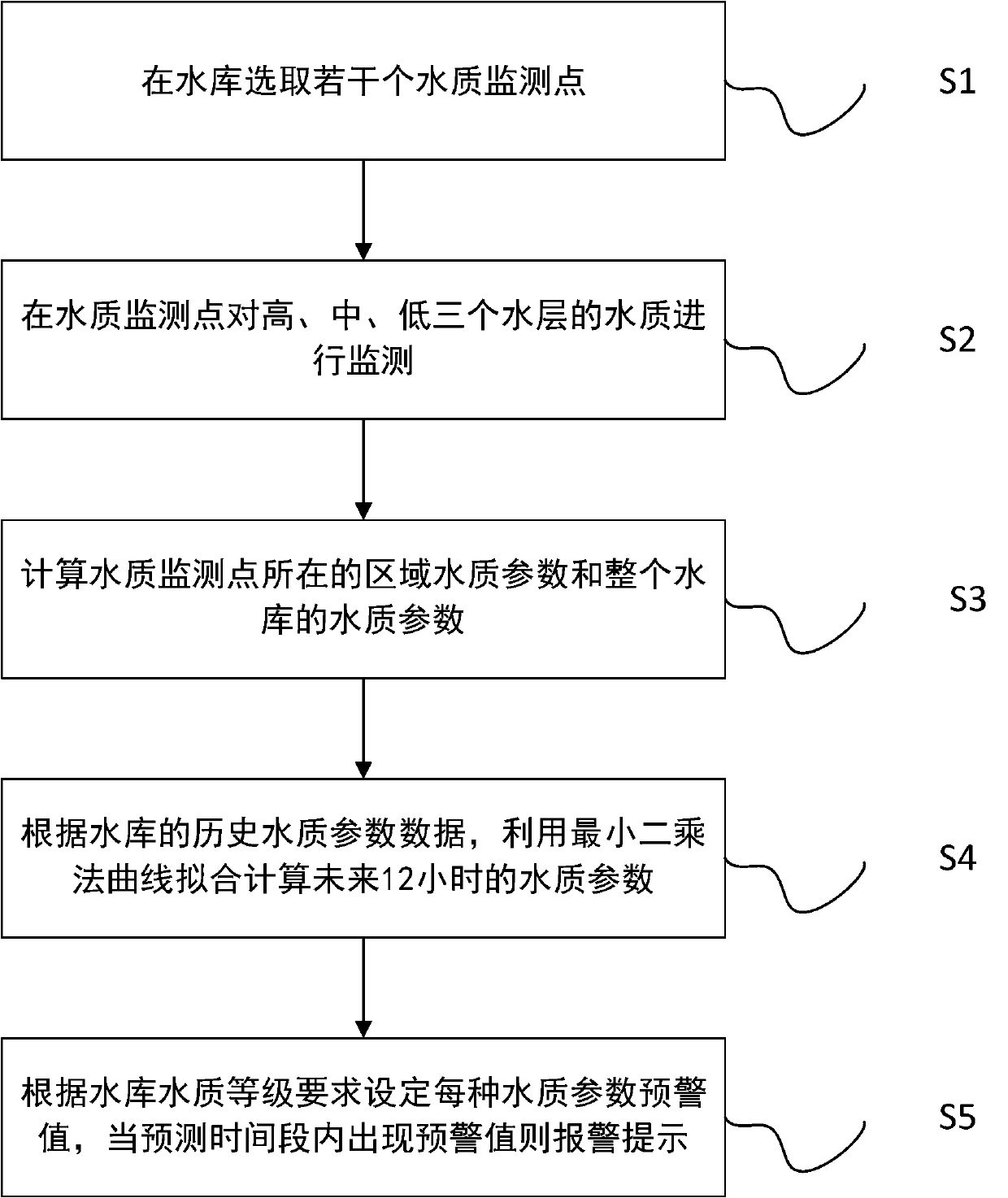

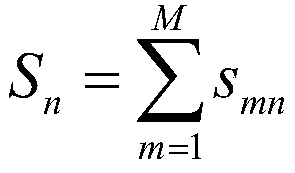

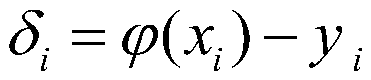

Pre-warning method for assimilative capacity of reservoirs based on least squares method

ActiveCN107576771AData objectivity is highImprove real-time performanceTesting waterReservoir waterData optimization

The invention discloses a pre-warning method for assimilative capacity of reservoirs based on a least squares method. The method comprises the following steps: (1) selecting a plurality of water quality monitoring points in a reservoir; (2) monitoring the water quality of high, middle and low water layers of the monitoring points; (3) calculating reservoir water quality parameters; (4) calculatingthe water quality parameters in the next 12 hours by utilizing least squares curve fitting based on historical reservoir water quality parameters; (5) prompting when a pre-warning value in a predicted period of time appears. According to the method provided by the invention, the function fitting is carried out after optimizing the monitoring data, and the reservoir water quality parameters in thenext 12 hours are predicted so as to provide assistant decision for the management staff.

Owner:SICHUANG TECH CO LTD

Two-stage multi-channel water filtering device

ActiveCN103463864AExtended service lifeReduce volumeFiltration circuitsTelecommunicationsWater filter

The invention discloses a two-stage multi-channel water filtering device which comprises a channel selection device, a rough filtering unit, a fine filtering unit and a housing, wherein the rough filtering unit and the fine filtering unit are serially arranged in the housing; the channel selection device penetrates the interior of the fine filtering unit and are fixedly connected with the fine filtering unit and the rough filtering unit respectively; the fine filtering unit comprises a plurality of fine filtering plates; the fine filtering plates locally cling to each other and are coaxially and serially arranged; the channel selection device comprises a central barrel and a plunger; the central barrel and the plunger form a plug valve structure; the plunger is a cylindrical valve core in which a plurality of channels are formed; different channels are selected for filtering by rotating the plunger. According to the two-stage multi-channel water filtering device, the filtering precision is improved and the overall volume and the weight of the filtering device are reduced; the working states of the multiple layers of filtering plates of the plug valve structure can be switched, so that the areas of the filtering units are enlarged, the assimilative capacity is increased, and the service life of the filtering device is prolonged; the filtering device is compact in structure and convenient to operate.

Owner:BEIJING SATELLITE MFG FACTORY

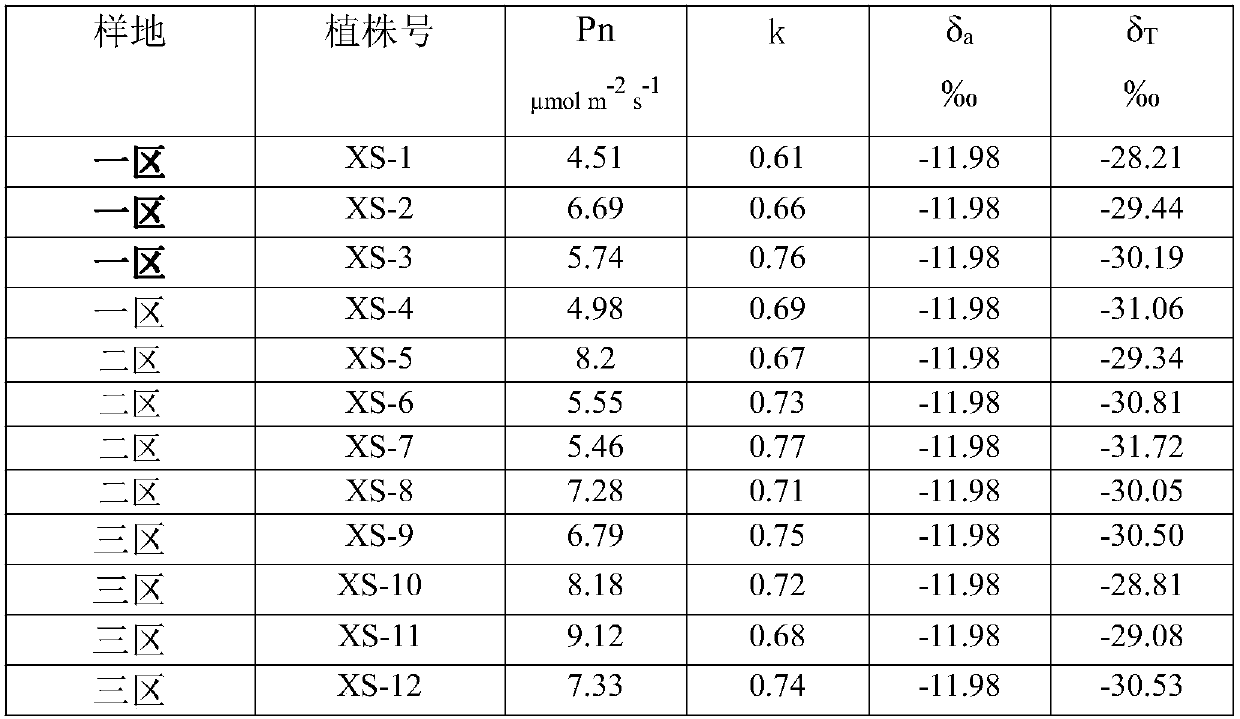

Method for obtaining total assimilative capacity of plant inorganic carbon under outdoor ecological environment

ActiveCN108508156ARapid determinationAccurate measurementTesting plants/treesEcological environmentBiology

The invention discloses a method for obtaining the total assimilative capacity of plant inorganic carbon under an outdoor ecological environment, and belongs to the fields of a crop information detecting technology, a plant physiological information detecting technology and ecological environment management. The method is characterized by calculating the share of actually assimilated carbon dioxide of plant leaves according to a stable carbon isotope fractionation value of completely assimilated carbon dioxide of the plant leaves and the stable carbon isotope fractionation value of the actually assimilated carbon dioxide of the plant leaves; converting the total assimilative capacity of the plant inorganic carbon according to actual carbon dioxide assimilative capacity measured through a portable photosynthesis system. According to the method disclosed by the invention, the carbon dioxide utilization shares of plants in different seedling ages and different growth periods under the outdoor ecological environment can be quickly, conveniently and accurately obtained in real time, and meanwhile, the bicarbonate utilization capacity of the plants under the outdoor ecological environment can also be obtained.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

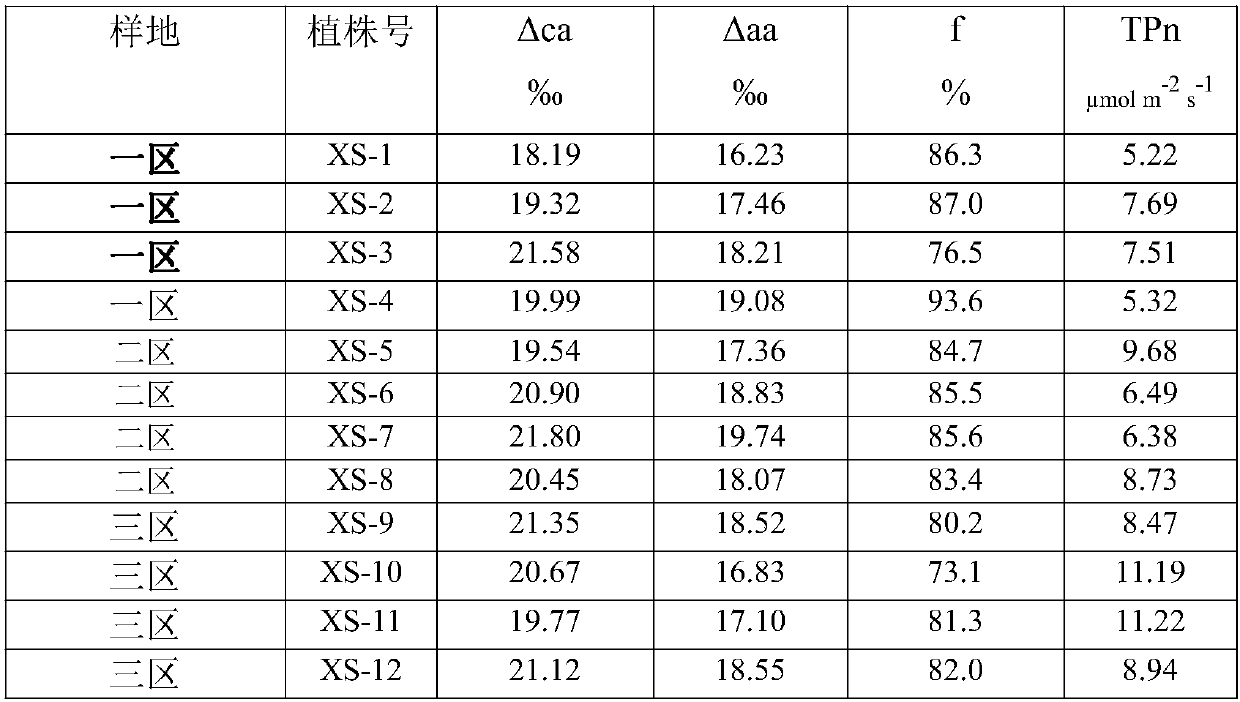

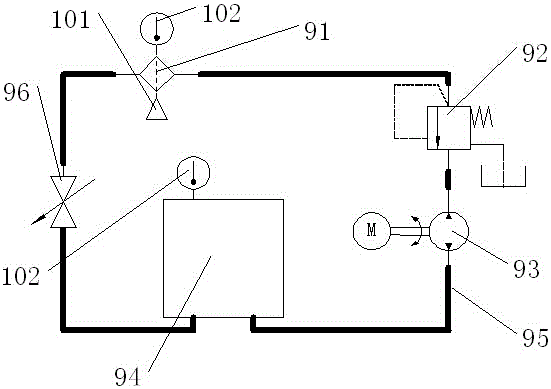

Oil product circulating purification device based on polyamide melt-blown filter element

InactiveCN105709478AClean thoroughlyExtended service lifeMachines/enginesRefining by filtrationHydraulic pumpPolyamide

The invention discloses an oil product circulating purification device based on a polyamide melt-blown filter element. The oil product circulating purification device comprises an oil storage device, a hydraulic pump and a filter which are connected through pipelines; an oil product needing to be filtered is pumped into the filter from the oil storage device to be filtered by the hydraulic pump through the pipeline and then flows back into the oil storage device; the filter filters the oil product by adopting the polyamide melt-blown filter element, the filter element comprises an upper end cover, a lower end cover and a polyamide filter material, the polyamide filter material is obtained by treating a polyamide material through a melt-blowing technology, and superfine fibers blown out through the technology are mutually bonded and wound to form a hollow barrel-shaped structure; the filter material is of a loose structure, and filter holes of the different hole diameters are formed; the hole diameter size of the filter holes is distributed in the mode that the hole diameter size is sequentially and gradually decreased from the outer layer to the inner layer of the barrel-shaped structure. The oil product circulating purification device has the higher filter precision, assimilative capacity and oil-water separation capacity, has the advantages of resisting oil product corrosion, being high in reliability and the like and meets the filter requirement of the common oil products.

Owner:XIAN TIANHOU FILTRATION TECH

An early warning method of reservoir pollution-holding capacity based on the least square method

ActiveCN107576771BImprove real-time performanceTesting waterMonitoring siteEnvironmental engineering

Owner:SICHUANG TECH CO LTD

Vacuum pipeline device of oil filter

InactiveCN106267993AExtended service lifeImprove dirt holding capacityFiltration separationElectromagnetic valveOil filter

Owner:HARBIN HONGWANZHI SCI & TECH DEV

Oil product cyclic purification device with two-stage integrated combined filter core

The invention discloses a two-stage integrated composite filter element oil circulation purification device, which comprises an oil tank, a hydraulic pump and a filter connected through a pipeline, and the hydraulic pump transfers the oil to be filtered from the oil tank through the pipeline. The middle suction filter is filtered and then returned to the oil storage device; the filter is filtered by a two-stage integrated composite filter element, the folded filter paper is sleeved on the outer ring of the inner protection tube, and the polyamide filter material is sleeved on the folded filter paper or the outer protection tube. For the outer ring of the tube, the polyamide filter material is made of polyamide material through the melt-blown process. The melt-blown superfine fibers are bonded and entwined to form a polyamide melt-blown non-woven fabric. The polyamide melt The spray non-woven fabric is a loose structure with filter holes arranged on it. The invention has higher filtration precision, dirt holding capacity and oil-water separation capacity, and has the characteristics of oil corrosion resistance, high reliability, etc., and meets the filtering requirements of common oil products.

Owner:XIAN TIANHOU FILTRATION TECH

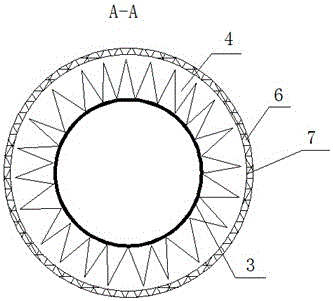

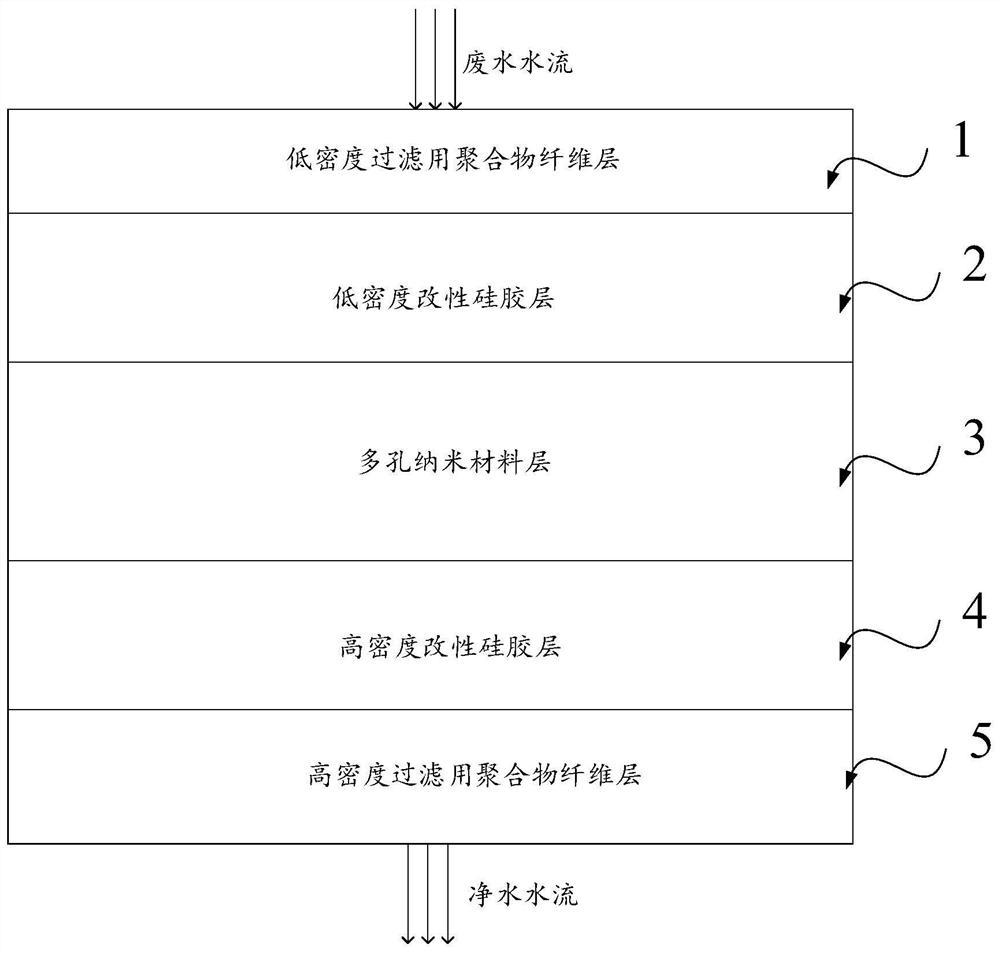

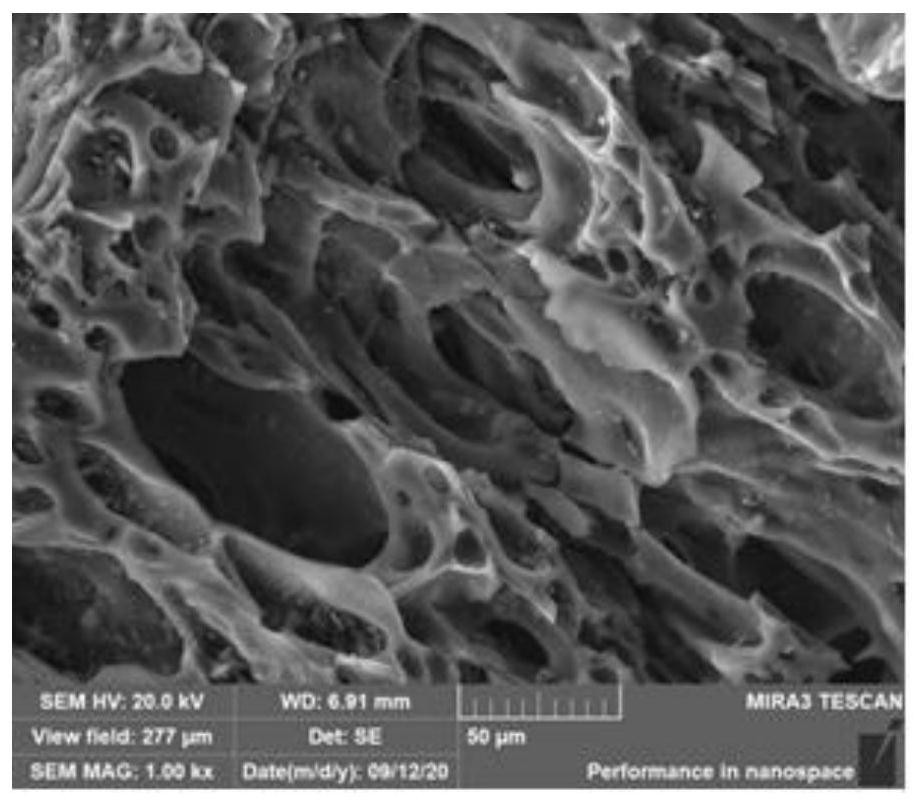

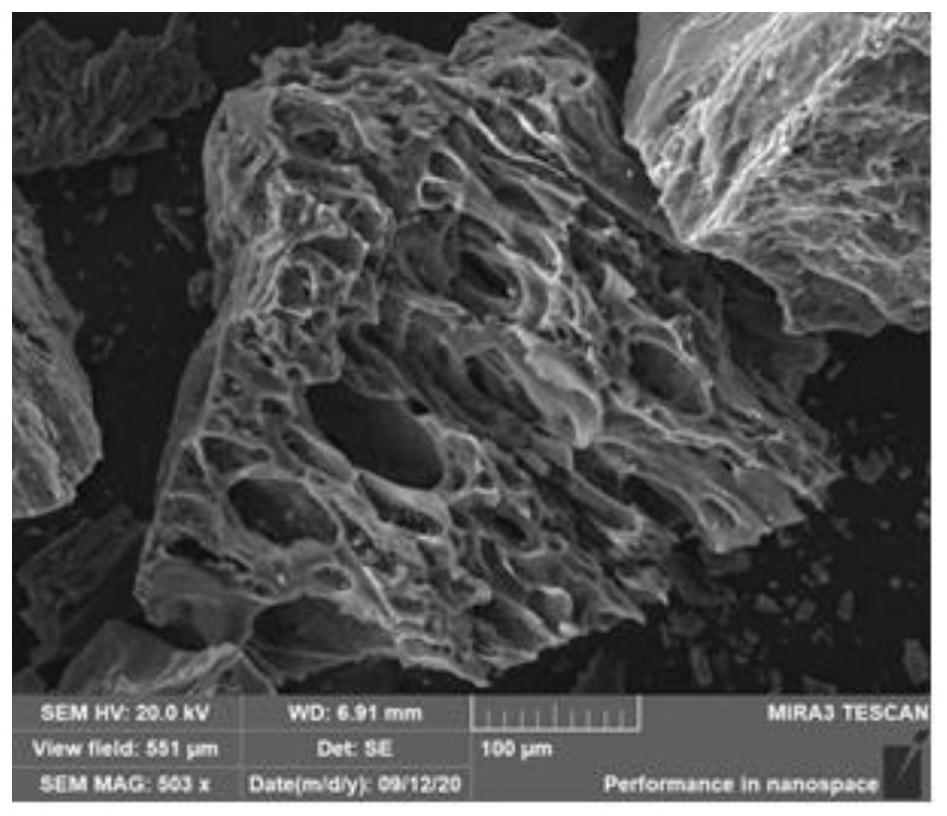

Multi-stage filtering unit, water purification filtering head and wastewater purification system

PendingCN113041702AReduce turbidityEfficient removalWater treatment parameter controlSeawater treatmentViscoseWater flow

The invention discloses a multi-stage filtering unit, a water purification filtering head and a wastewater purification system, and relates to the field of wastewater purification treatment. According to the invention, the multi-stage filtering unit comprises a low-density filtering polymer fiber layer, a low-density modified silica gel layer, a porous nanometer material layer, a high-density modified silica gel layer and a high-density filtering polymer fiber layer which are sequentially arranged in a water flow direction so as to effectively remove suspended solids and viscose particles in water to reduce the turbidity of the water; when the multi-stage filtering unit is used for filtering, each stage of filtering material automatically forms a sparse-first and dense-second state along the water flow direction, so that the quality of discharged water can be ensured under various operation conditions; and the water purification filtering head has the advantages of being simple in structure, high in assimilative capacity, long in service life, small in occupied space and the like, can carry a low-pressure lifting pump, ensures the high filtering speed and the high outlet water quality under the low pressure, and achieves repeated recycling of dust removal wastewater.

Owner:深圳市彤石科技有限公司

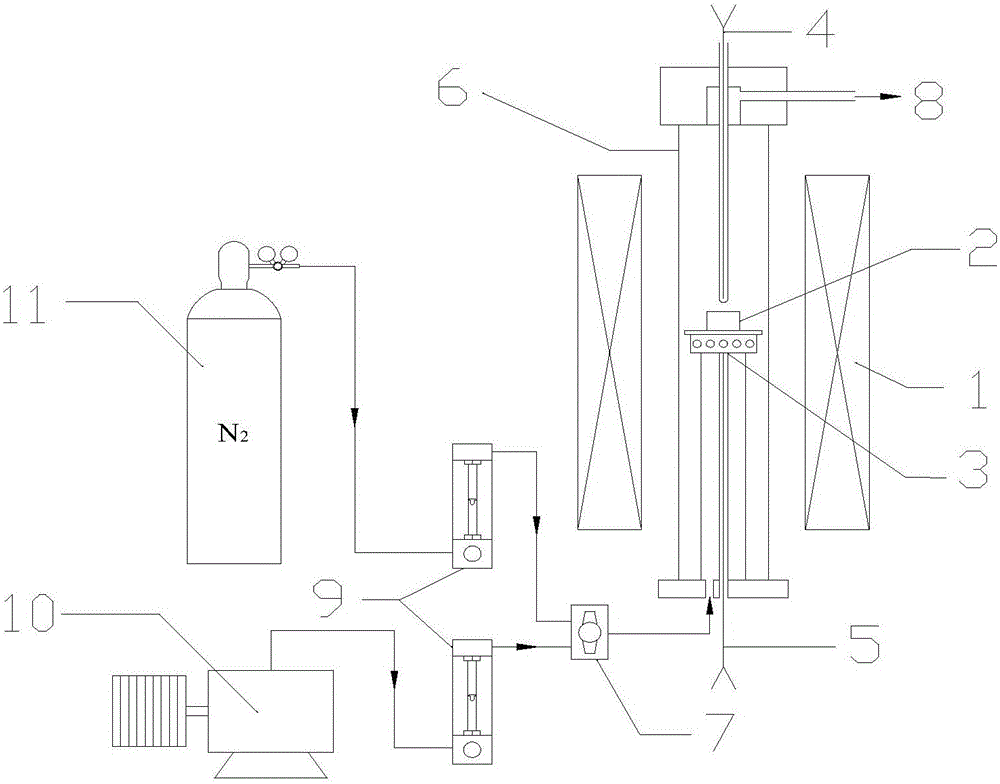

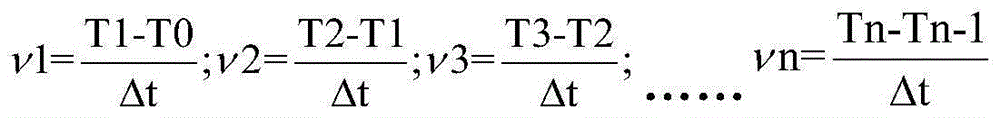

Iron ore powder assimilation test method and device

ActiveCN103529168BAssimilation speed accurately reflectsMaterial analysisMaterials scienceAssimilative capacity

The invention discloses a method and a device for testing assimilability of iron ore powder. The method comprises the steps as follows: the iron ore powder and lime are calcined firstly, and the sintering process is simulated; then the assimilative lime amount is tested; and finally, the assimilation data of the iron ore powder is obtained according to a ratio of the assimilative lime amount to the assimilative area of the iron ore powder, so that the assimilability of the iron ore powder is represented. According to the method and the device for testing the assimilability of the iron ore powder, in consideration of the phenomenon that the assimilative capacity and the assimilative speed can be represented by the thickness change of a product due to uncertainty of the reaction direction in a sintering process, the thickness of the reaction product is adopted as an evaluation basis of the assimilability of the iron ore powder, and the three-dimensional assimilation data is obtained by testing the ratio of the assimilative lime amount to the assimilative surface area, so that the assimilability of different types of iron ore powder is represented and distinguished accurately, data of the assimilative speed and the assimilative temperature sensibility can be obtained accurately, and accordingly, the temperature sensibility of the assimilation reaction of the iron ore powder as well as the assimilation speeds of different types of iron ore powder under the same test condition are reflected accurately.

Owner:武汉钢铁有限公司

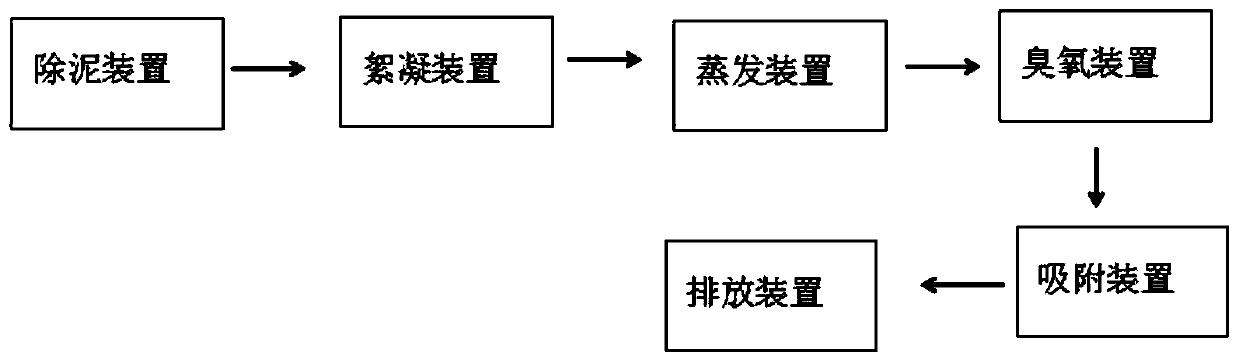

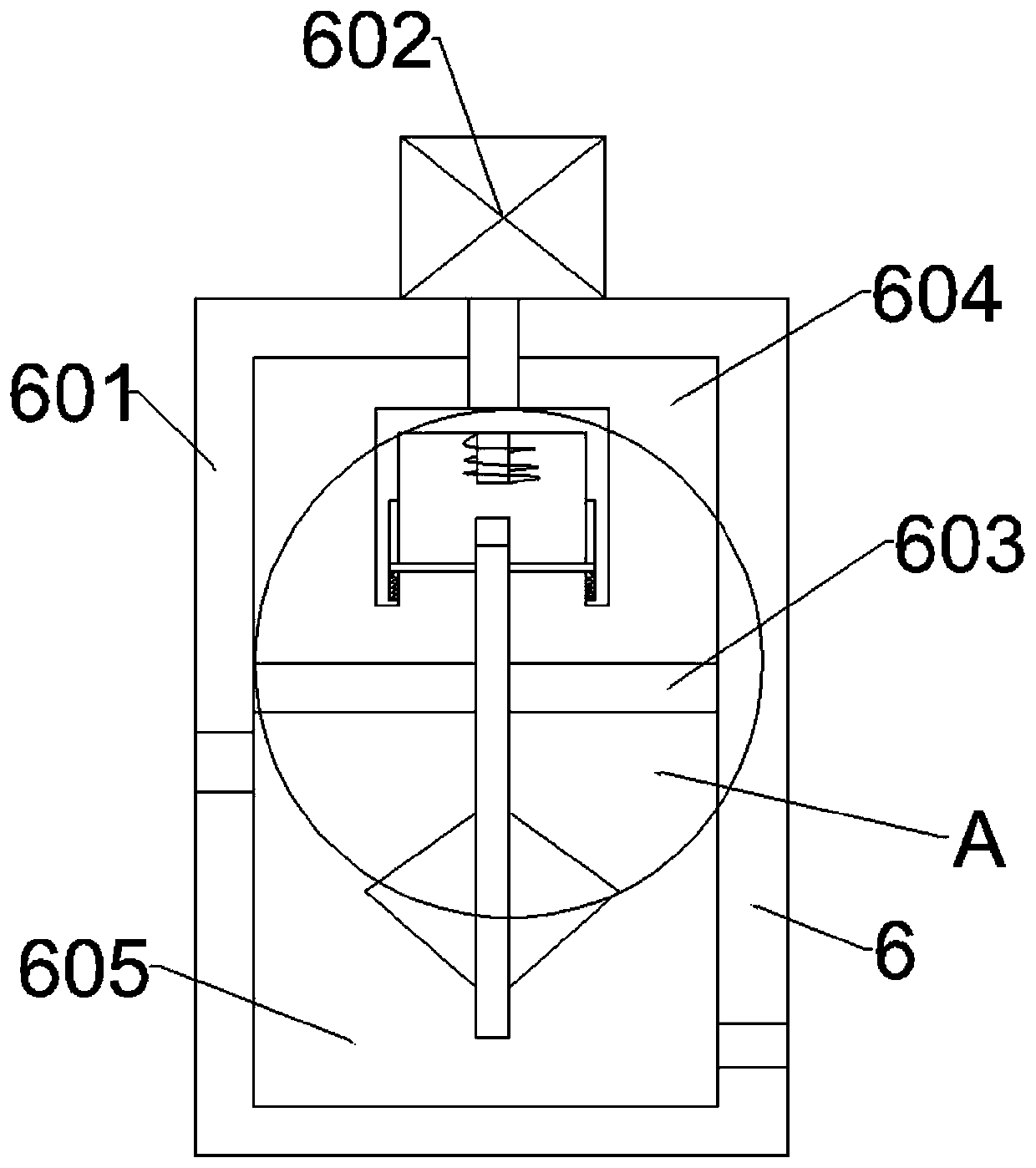

Biodialysis system and decontamination method

InactiveCN103011414APromote growthRestores and Enhances Self-Cleaning AbilityMultistage water/sewage treatmentSustainable biological treatmentSludgeSelf purification

The invention discloses a biodialysis system which comprises a purification tank, wherein one or multiple water delivery units extend in the purification tank; each water delivery unit is provided with one or multiple water drainage devices which are communicated with the water delivery unit; each drainage device extends towards the top surface of the purification tank; and each water delivery unit is further connected with a water supply unit. According to the invention, pollutants in sewage or sludge can be subjected to physical / chemical / biological purification processes under the action of water, so that the water ecology can be restored, and the basic and important self-purification capacity and assimilative capacity of the water body can be restored and enhanced. Thus, the biodialysis system and the decontamination method have the advantages of energy saving, emission reduction, low carbon, sustainability and environment friendliness.

Owner:季国辉

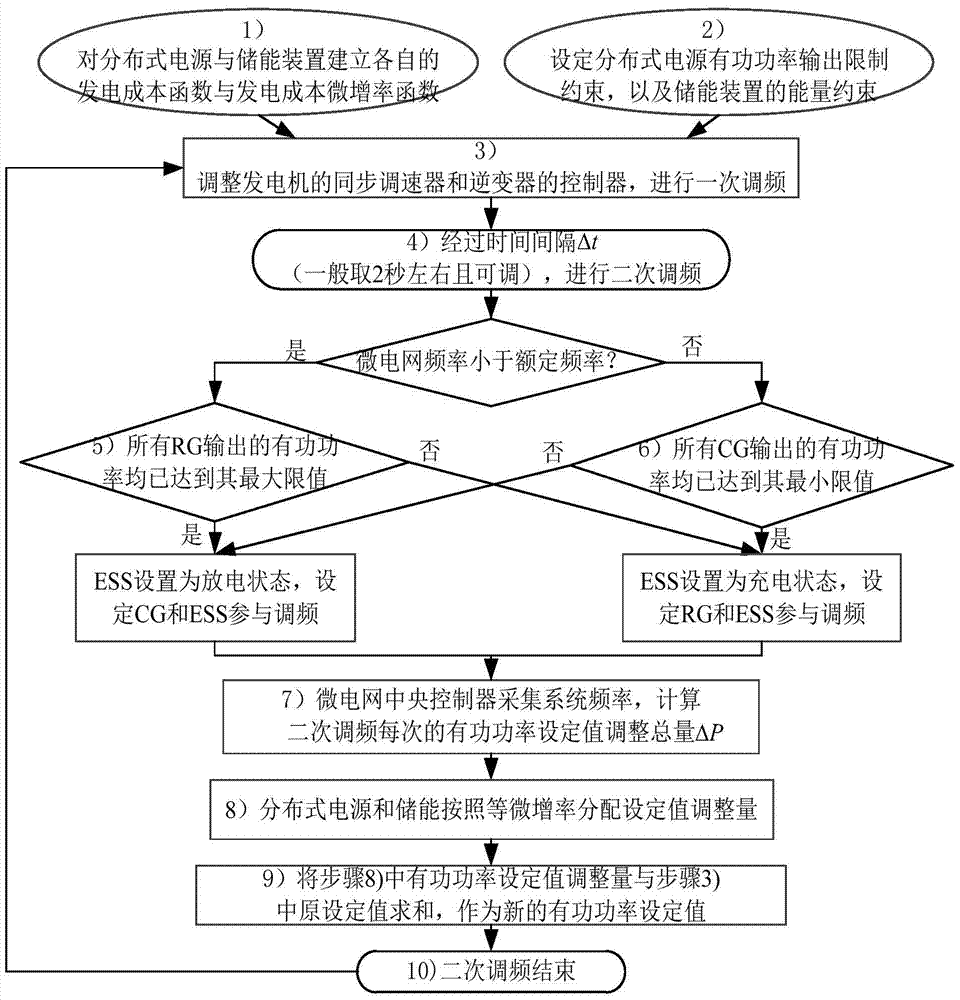

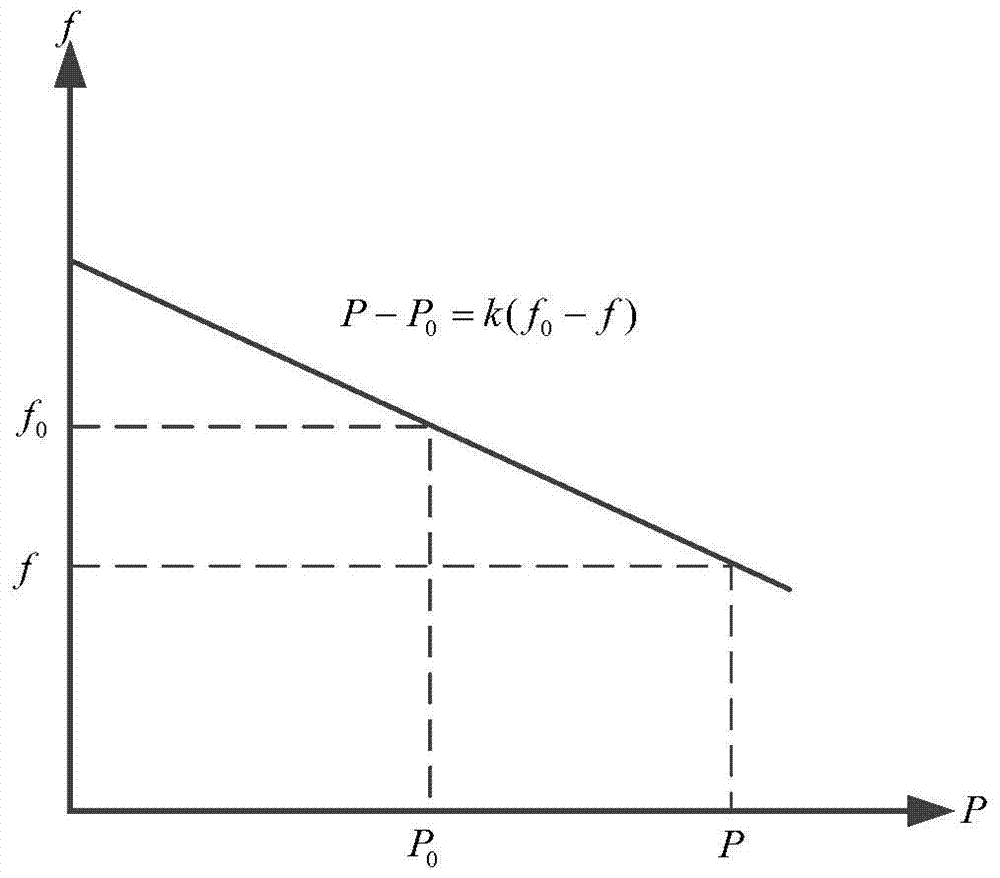

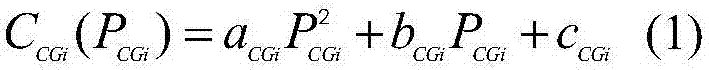

A Microgrid Frequency Regulation Control Method for Minimizing Power Generation Cost

InactiveCN105140936BShortened time scaleEliminate hierarchical control system designSingle network parallel feeding arrangementsPower oscillations reduction/preventionPower control systemElectric power system

The present invention proposes a micro-grid frequency control method that minimizes power generation costs, which belongs to the technical field of power system operation and control. The method includes: establishing respective power generation cost functions and power generation cost micro-increase rate functions; Power output limitation constraints, and energy constraints of energy storage devices: adjust the synchronous governor of the generator and the controller of the inverter, perform frequency modulation once, perform frequency modulation twice after time intervals, collect system frequency and calculate second frequency modulation each time The total amount of active power set value adjustments is distributed to all distributed power sources or energy storage devices participating in frequency regulation, and the active power set value adjustment amount and the original set value are summed as For the new active power setting value, perform frequency modulation again to maintain the system frequency stability. The method of the invention can maximize the utilization rate of renewable energy, can improve the absorbing capacity of the microgrid renewable energy, and is convenient to realize and simple to control.

Owner:GUIZHOU POWER GRID INFORMATION & TELECOMM +1

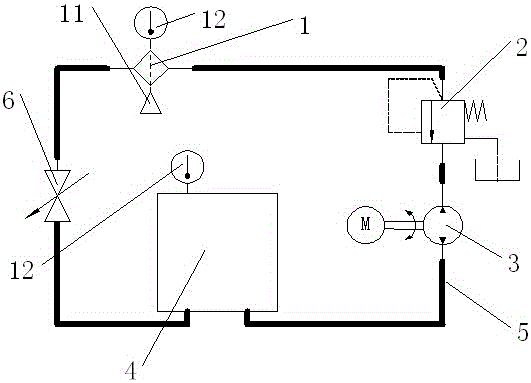

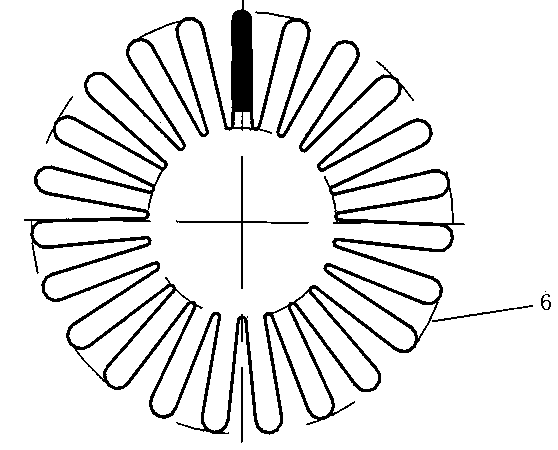

Filter element with high-assimilative-capacity structure

PendingCN107670362ALarge filter areaImprove dirt holding capacityFluid-pressure actuator componentsStationary filtering element filtersBobbinAdhesive

The invention discloses a filter element with a high-assimilative-capacity structure. An upper end cover skeleton, a filtering layer and a lower end cover are connected into a whole body through solidification of high-temperature glue; a filtering layer spiral groove is processed at the position of mounting the filtering layer along the axis of the upper end cover skeleton; liquid flowing holes are drilled in the spiral groove uniformly in the circumferential direction. The upper end cover and the skeleton adopt an integrated structure, a larger filtering area is provided for the filter element, a novel corrugated molding technology is adopted, the filtering area is larger under the condition of equal mounting space, and under the conditions of equal mounting space and equal work environment, the filter element with the structure has higher assimilative capacity and longer service time when being compared with the filter element with the ordinary structure.

Owner:XINXIANG HUAHANG AVIATION HYDRAULIC EQUIP

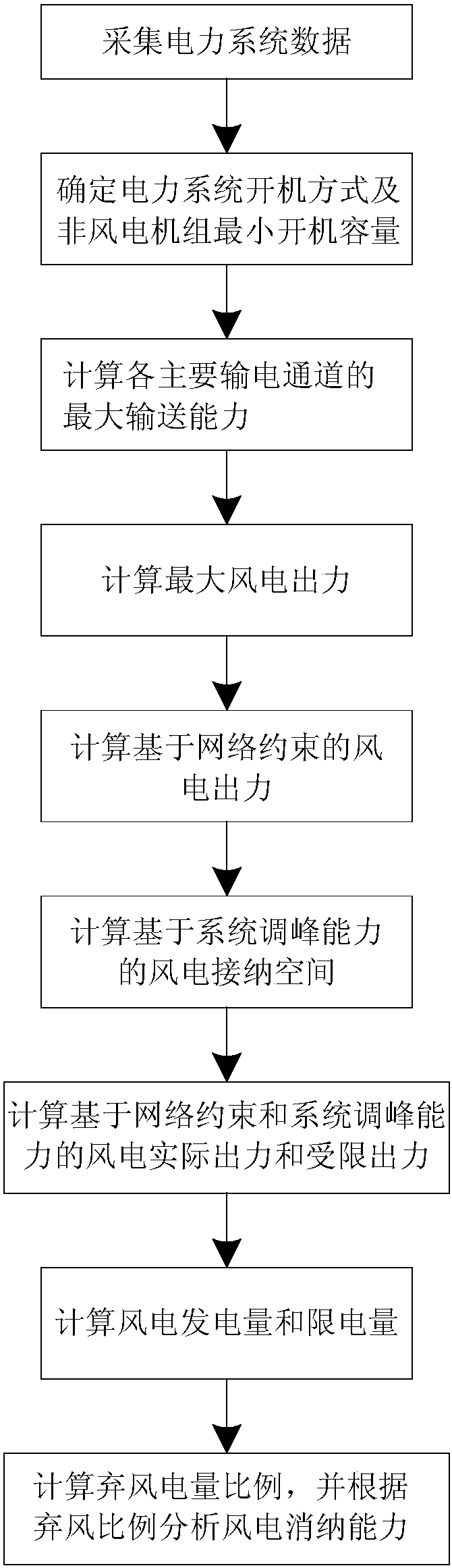

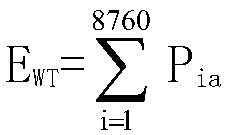

A Method for Analyzing Wind Power Absorbing Capacity

ActiveCN105703395BSimplify design stepsEasy to operateSingle network parallel feeding arrangementsTechnology managementElectric power systemStart up

The invention relates to a wind power consumption ability analysis method. The method comprises the following steps: 1) data of a power system are acquired; 2) the start-up mode of the power system is determined, and the minimal start-up capacity of a non-wind turbine generator is determined according to the start-up mode of the power system; 3) the thermal stability limit and the transient stability limit of each main transmission channel and the maximal transmission capacity of each main transmission channel are calculated; 4) the maximal wind power output provided by each hour is calculated; 5) the wind power output based on network constraints is calculated; 6) the wind power accommodation space based on the system peaking capability is calculated and obtained; 7) the actual wind power output and the maximal transmission capacity of each main transmission channel are calculated, and the limited output of each main transmission channel in the power system is calculated respectively and correspondingly; 8) wind power generation is calculated, and the wind power limit is calculated; and 9) an abandoned wind power ratio is calculated. The method of the invention can intuitively and accurately represent the wind power consumption ability by the power system.

Owner:STATE GRID CORP OF CHINA +2

combined filter

ActiveCN104759142BReduce depositionReasonable structureTurbine/propulsion fuel supply systemsFiltration circuitsFilter materialTurbine

The invention belongs to the technical field of contamination control of an aviation turbine fuel system, and particularly relates to a combined filter. The combined filter comprises a self-washing oil filtering framework, wherein an oil return opening of the self-washing oil filtering framework is connected with a self-washing oil filtering oil return pipe; an inlet end of the self-washing oil filtering framework is fixedly connected with a turbulence promoter; an inlet end of the turbulence promoter is connected with a self-washing oil filtering inlet pipe; the self-washing oil filtering framework is provided with a self-washing oil filtering screen; a self-washing oil filtering oil outlet connected with a turbulence oil filtering inlet pipe is formed in the turbulence promoter in a position corresponding to the self-washing oil filtering screen. The combined filter is simple and reasonable in structure, can effectively solve the problems of poor assimilative capacity and short maintenance cycle of an existing combed filter in the operation process, can greatly reduce the pollutant deposition on the surface of a filter material, and effectively prolong the maintenance cycle of the combined filter.

Owner:中国航发控制系统研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com