Oil product circulating purification device based on polyamide melt-blown filter element

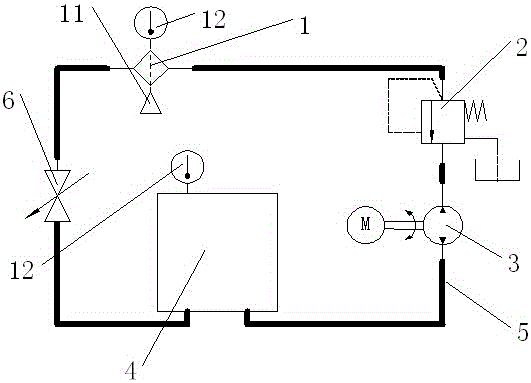

A melt-blown filter element and cyclic purification technology, which is applied to fixed filter element filters, filtration loops, filtration and separation, etc., can solve the problems of poor filtration function and indicators, difficulty in practical promotion, and complicated film production process. Achieve the effect of improving fuel efficiency, protecting the engine and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

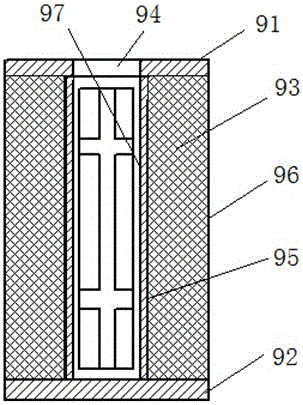

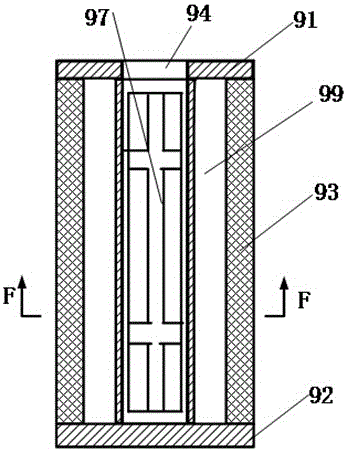

[0067] Embodiment 1: the material is PA6; the length of the filter material cylinder is 200mm, the outer diameter of the filter material cylinder is 100mm, the thickness of the filter material cylinder is 10mm, the average pore diameter of the outer layer of the filter cartridge is 10 μm, and the average pore diameter of the inner layer of the filter cartridge is The average diameter of melt-blown fiber filaments is 0.1 μm, and the porosity is 80.2%; the type of filter oil is gasoline; the filtration effect applied to gasoline filters: the filtration efficiency of 5-10 μm particles is 99.09%; The capacity is 60.11g, when the rated volume flow rate is 10L / min, the original flow resistance is 10kpa, and the oil-water separation rate is 98.99%.

Embodiment 2

[0068]Embodiment 2: the material is PA6; the length of the filter material cylinder is 200mm, the outer diameter of the filter material cylinder is 100mm, the thickness of the filter material cylinder is 10mm, the average pore diameter of the outer layer of the filter cartridge is 100 μm, and the average pore diameter of the inner layer of the filter cartridge is The average diameter of the melt-blown fiber filament is 80 μm, and the porosity is 91.2%; the type of filter oil is lubricating oil; the filtering effect applied to the oil filter: the filtration efficiency of 5-10 μm particles is 92.01%; The capacity is 122.01g, when the rated volume flow rate is 10L / min, the original flow resistance is 12.01kpa, and the oil-water separation rate is 91.88%.

Embodiment 3

[0069] Embodiment 3: the material is PA6; the length of the filter material cylinder is 200mm, the outer diameter of the filter material cylinder is 100mm, the thickness of the filter material cylinder is 10mm, the average pore diameter of the outer layer of the filter cartridge is 100 μm, and the average pore diameter of the inner layer of the filter cartridge is The average diameter of the melt-blown fiber filament is 25 μm, and the porosity is 90.2%; the type of filter oil is lubricating oil; the filtering effect applied to the oil filter: the filtration efficiency of 5-10 μm particles is 92.05%; The capacity is 101.88g, when the rated volume flow rate is 10L / min, the original flow resistance is 12.35kpa, and the oil-water separation rate is 90.53%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com