Single-material gradient filter element

A gradient and filter element technology, applied in the field of single-material gradient filter elements, can solve the problems affecting the filtration flux and dirt holding capacity, blocking the flow of water, reducing the filtration flux, etc., so as to ensure the filtration flux and dirt holding capacity, save The effect of strong material and compressive capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be clearly and completely described below through specific embodiments in conjunction with the accompanying drawings.

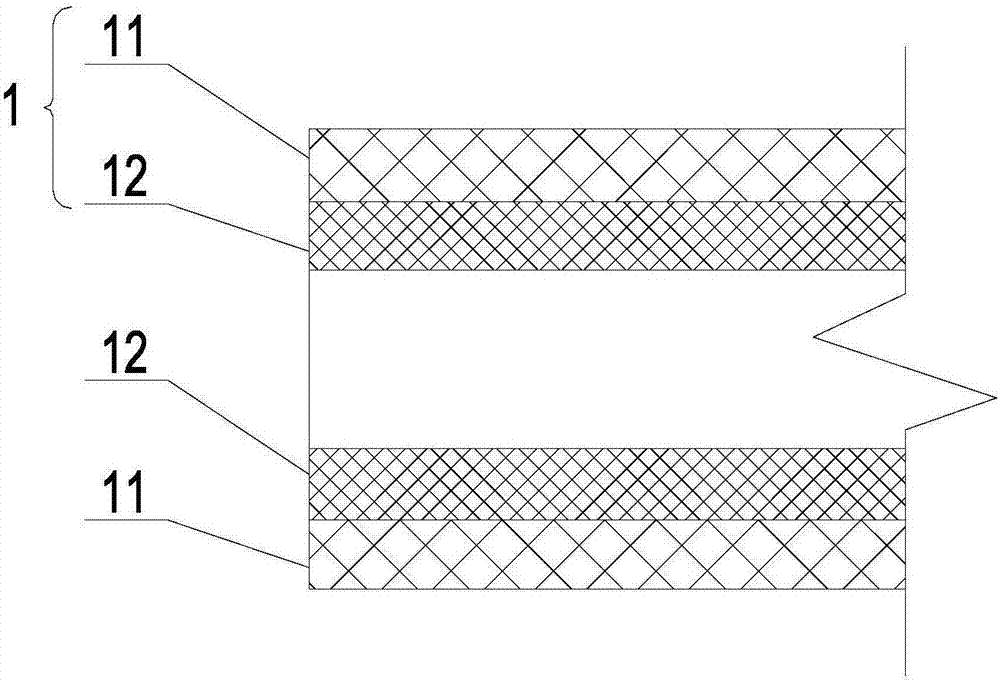

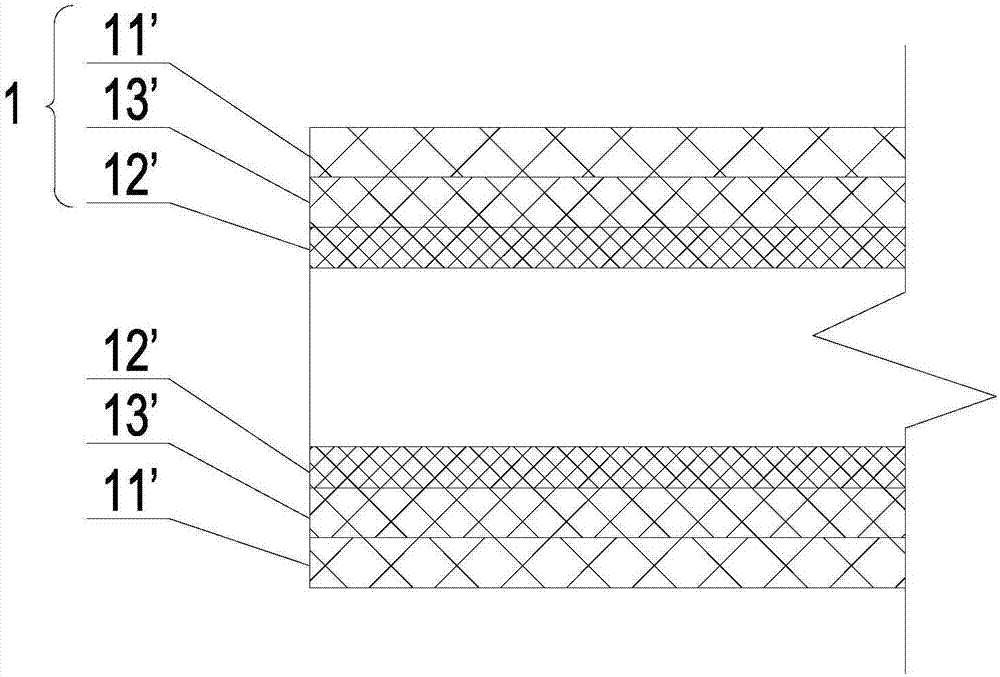

[0018] Please refer to figure 1 As shown, the present invention provides a single-material gradient filter element, which includes at least two filter layers 1, each of which has the same density. The at least two filter layers 1 are made of polypropylene fiber filaments by heat-melt entanglement. The filter layer 1 has different thicknesses of polypropylene fiber filaments from the outside to the inside. The polypropylene fiber filaments of the outer filter layer 1 are thicker than The inner filter layer 1 polypropylene fiber filaments.

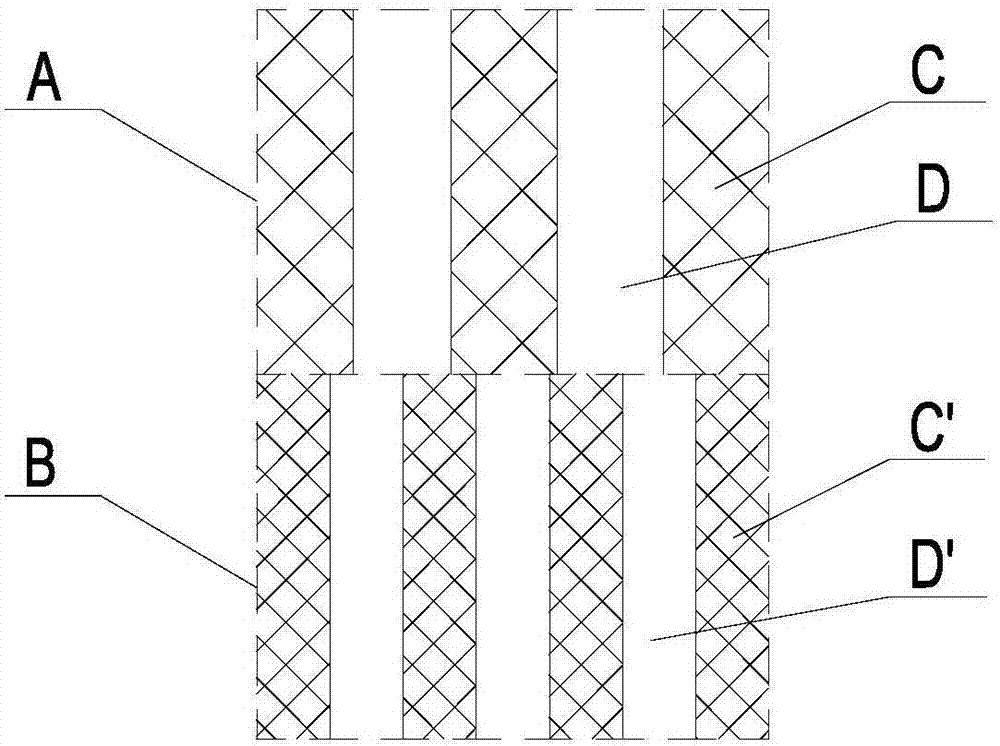

[0019] Please refer to figure 2 As shown, taking two filter layers as an example, the dashed frame A in the figure shows a cross-sectional view of the polypropylene fiber yarn per unit volume of the outer layer, and the dashed frame B shows the polypropylene fiber yar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com