Compound plastic and lithium ion battery and battery pack manufactured by using same and assembling method thereof

A technology of lithium-ion batteries and composite plastics, which is applied in the direction of battery pack parts, final product manufacturing, non-aqueous electrolyte storage batteries, etc., and can solve problems such as electrolyte corrosion resistance, thermal conductivity, low mechanical strength, and poor thermal conductivity. , to achieve the effect of solving the insulation problem between single lithium-ion batteries, reducing production costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

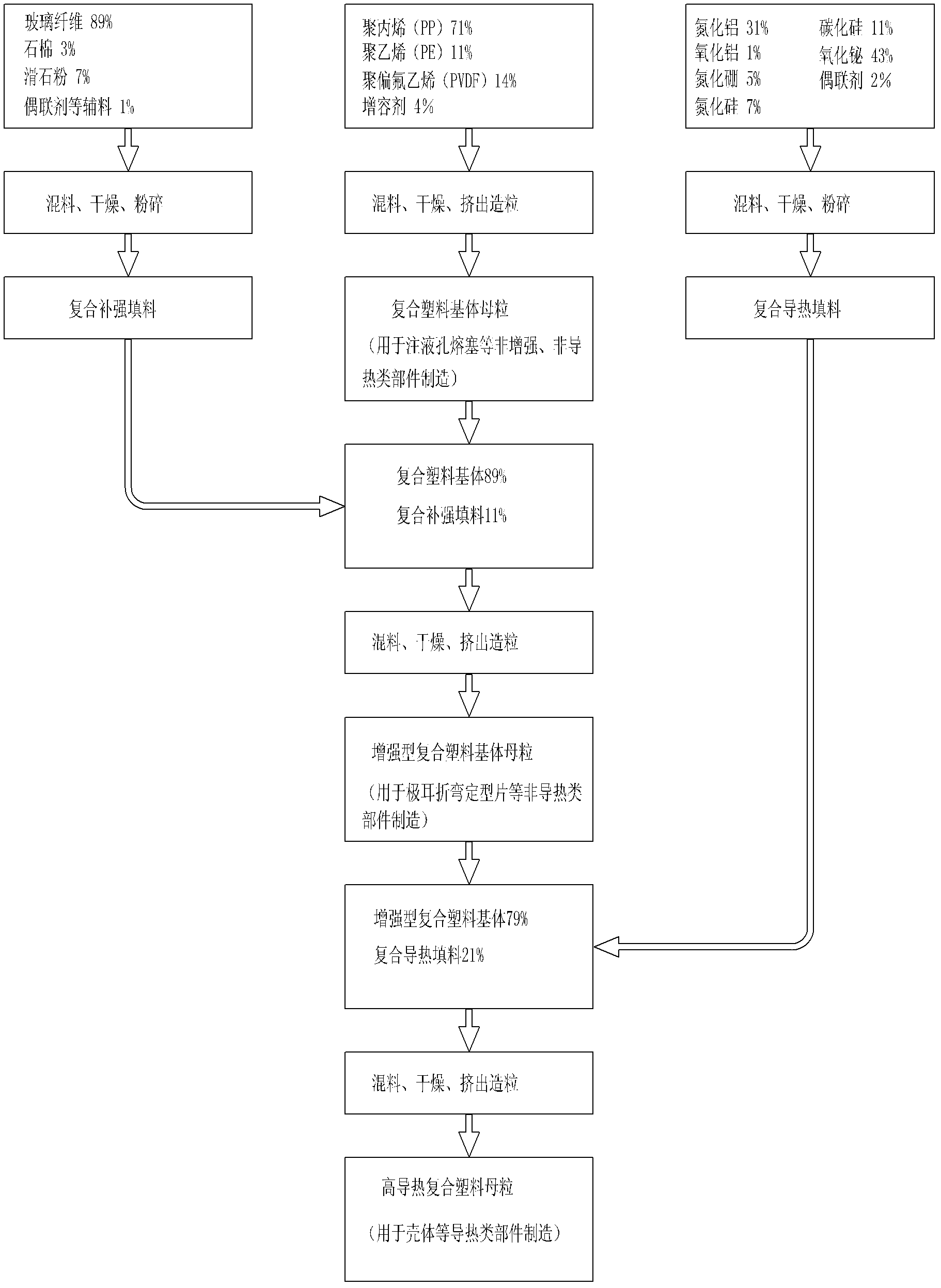

[0045] see figure 1 , which is a preparation flow chart of a preferred embodiment of a composite plastic matrix based on polypropylene in the present invention.

[0046] Step 1: Blending polypropylene (PP), polyethylene (PE), polyvinylidene fluoride (PVDF), and compatibilizers in the ratios shown in the table below. Composite plastic matrix composed of propylene. The composite plastic matrix obtained in this step has higher dielectric constant, higher toughness, higher melt adhesion and lower cost, and can be directly used for injection molding to manufacture the liquid injection hole melt of the lithium-ion battery case. Rubber plugs and other parts.

[0047] Polypropylene

Compatibilizer

71%

14%

11%

4%

[0048] Adding polyvinylidene fluoride according to the ratio in the above table can significantly improve the dielectric constant of the composite plastic matrix based on polypropy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com