Method for preparing high-flux composite membrane from dopamine-modified nanometer material

A nanomaterial, dopamine technology, applied in chemical instruments and methods, dyed polymer organic compound treatment, membrane technology and other directions, can solve the problem of not improving the dispersibility of titanium dioxide, achieve the improvement of water flux and anti-pollution ability, and easy to operate Easy, performant results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0017] Weigh 0.025g, 0.05g, 0.075g, and 0.1g of dopamine respectively and add them to 50ml of Tirs-HCl buffer solution with a concentration of 10mM. After the dopamine is completely dissolved, adjust the pH value to 8.5 with HCl to prepare concentrations of 0.5g / l, 1.0g / l, 1.5g / l, 2.0g / l dopamine solution. Add 0.5g nano-TiO to the dopamine solution 2 (P25), the prepared solution was shaken in a shaker for 24 hours at a temperature of 30° C. and a rotation speed of 150 r / min. The modified solution is black. Dry the modified solution at 105°C to obtain a black solid. After grinding, a black powder is obtained, which is TiO modified with different concentrations of dopamine. 2 .

example 2

[0019] The film making process is carried out according to the following steps. First, the unmodified TiO 2 TiO modified with dopamine 2 (take 1.5g / l concentration as an example) into the DMAc solution, ultrasonic 30min to make it evenly dispersed, then weigh a certain amount of PVDF and pore-forming agent PVP into the organic solvent, mix and stir evenly at room temperature for 6h, Make it form a stable casting solution, and the ratio of the casting solution is shown in the table below. After stirring, let it stand for defoaming. The obtained film casting solution was scraped on a glass plate with a scraper knife to make a thin film with a thickness of 250um, and then the liquid film and the glass plate were immersed in deionized water. The PVDF film solidified and peeled off automatically to form a new film. Soak in deionized water for 24h for performance test. Other different concentrations of dopamine modified TiO 2 Composite membranes with PVDF are all prepared by th...

example 3

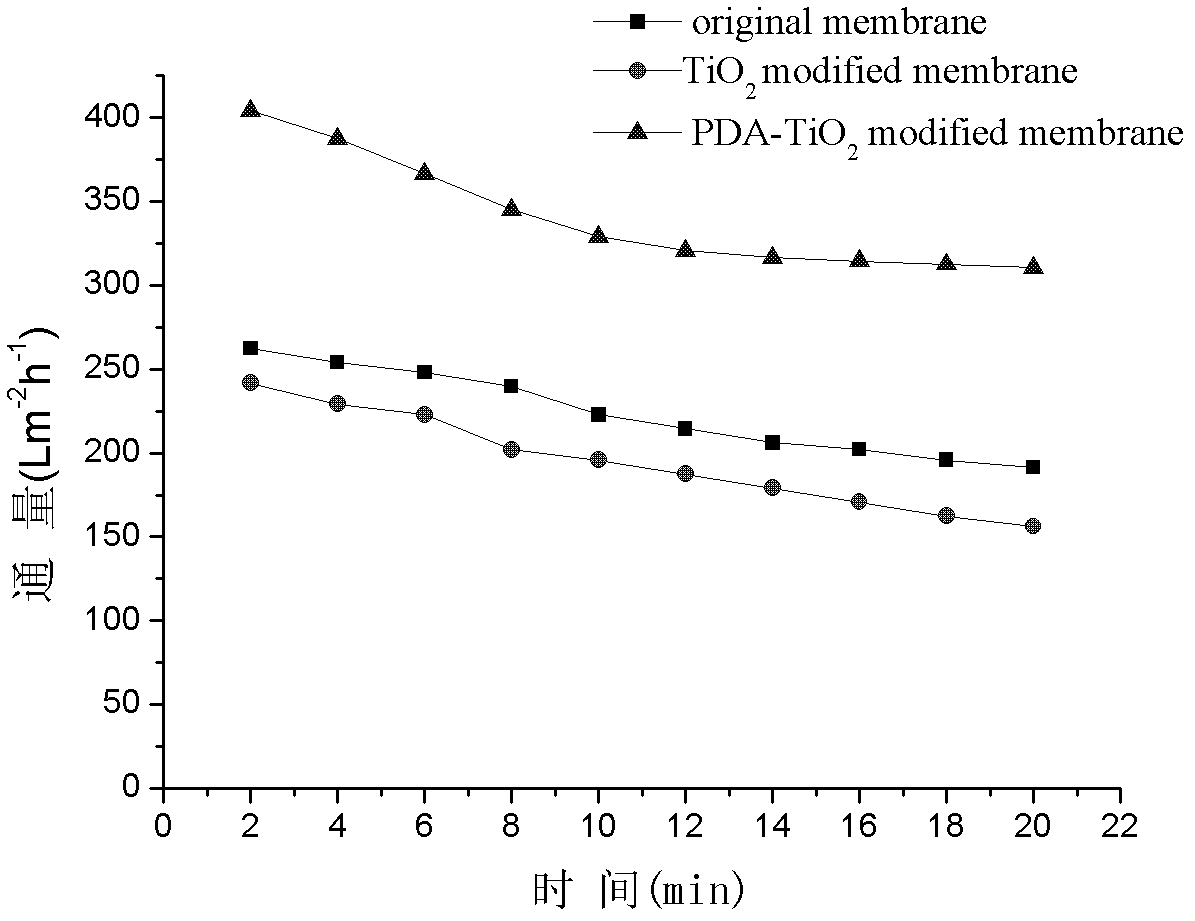

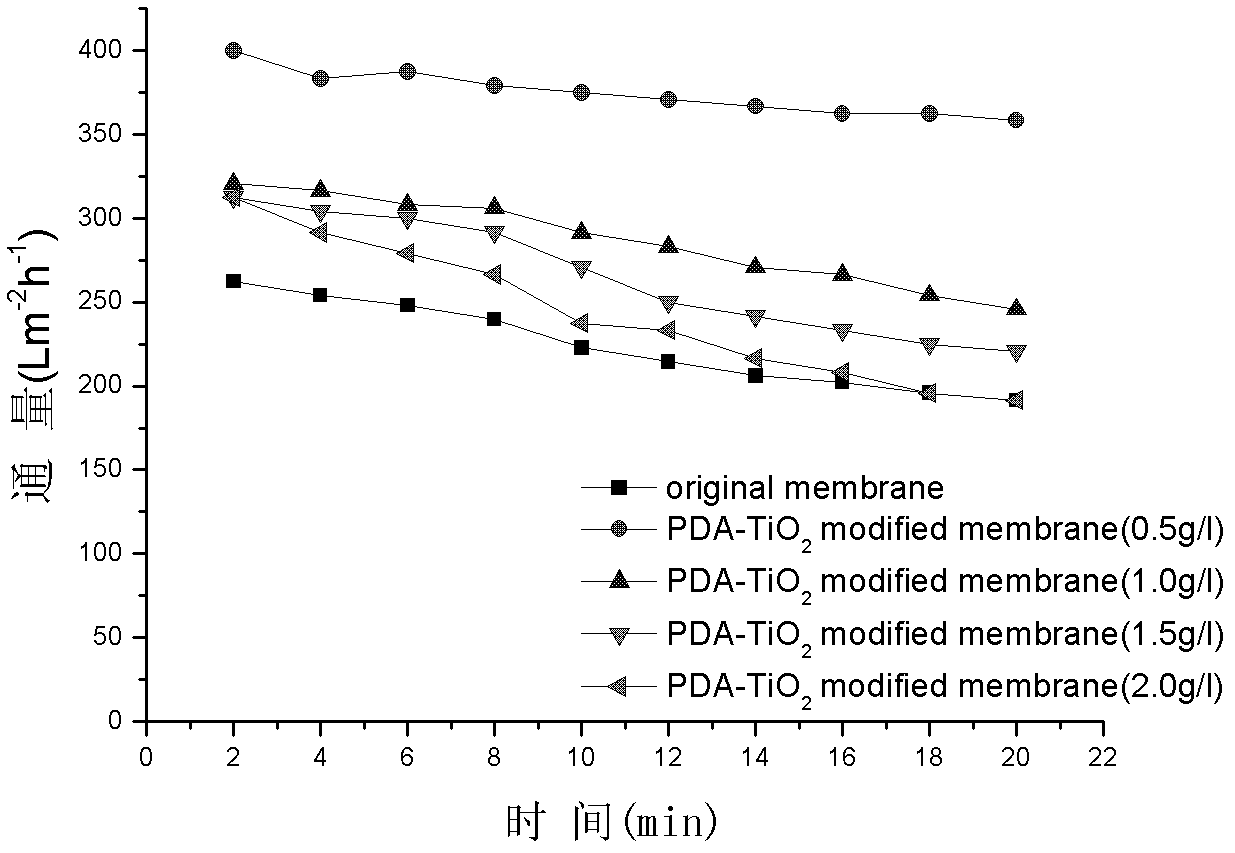

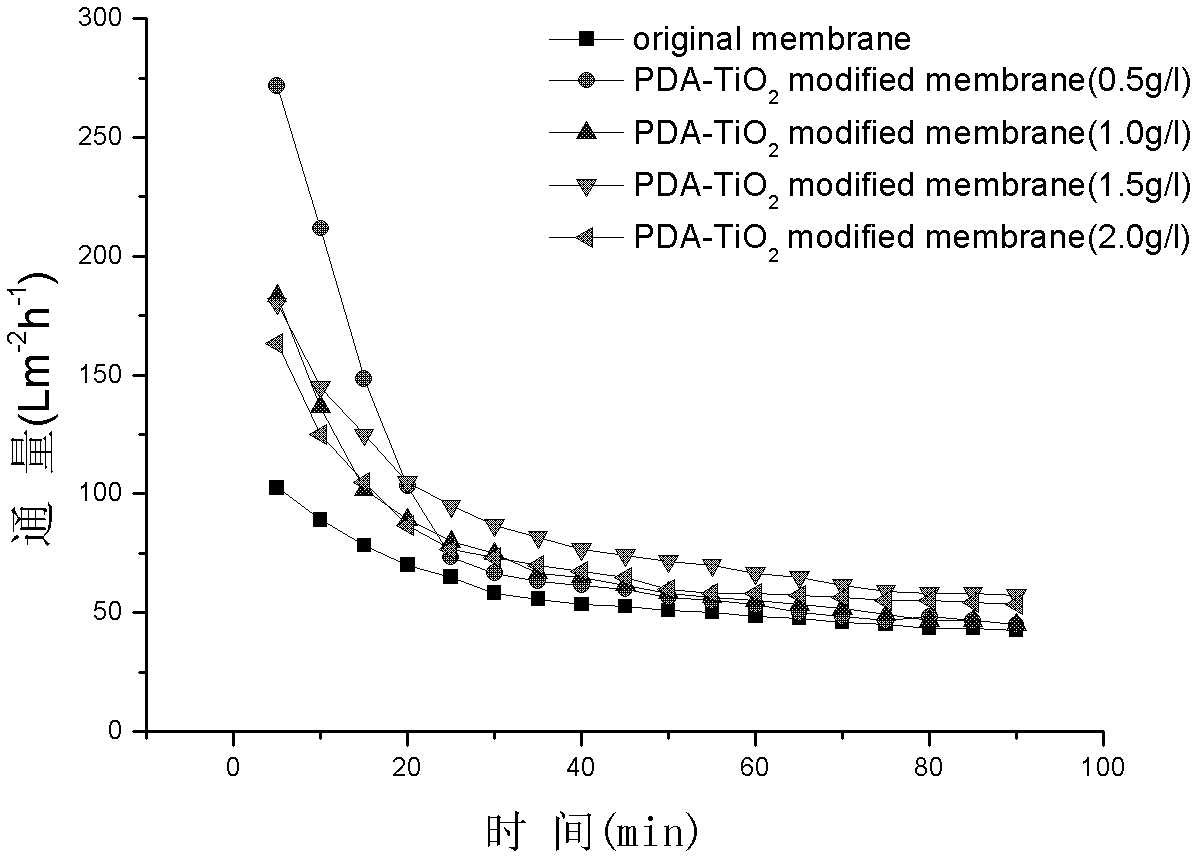

[0023] For different concentrations of PDA-TiO prepared 2 / PVDF composite membrane was used to measure the flux of clean water and the anti-pollution ability in suspension solution. Using the constant pressure filtration method, the prepared membrane was installed on the membrane module (effective area 0.072m 2 ), use a peristaltic pump to pump water, use a vacuum gauge to control the pressure to 0.01MPa, adjust the pump speed to control the constant pressure, and measure the water flux as figure 1 shown. Prepare a yeast suspension solution with a concentration of 1g / l, measure the anti-pollution performance in the reactor, and the aeration intensity is 0.15m 3 / h, the pressure is 0.01MPa, the measured flux changes as figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com