Soft PP flame retardant with ultrahigh fluidity

A fluid and fuel-resistant technology, applied in the field of polymer flame retardant materials, can solve the problems of PP, flame retardants and various auxiliaries easily decomposing harmful gases, affecting the appearance of products, difficulty in molding and processing, etc., to achieve molecular weight distribution. Easy spinning, easy dyeing, good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

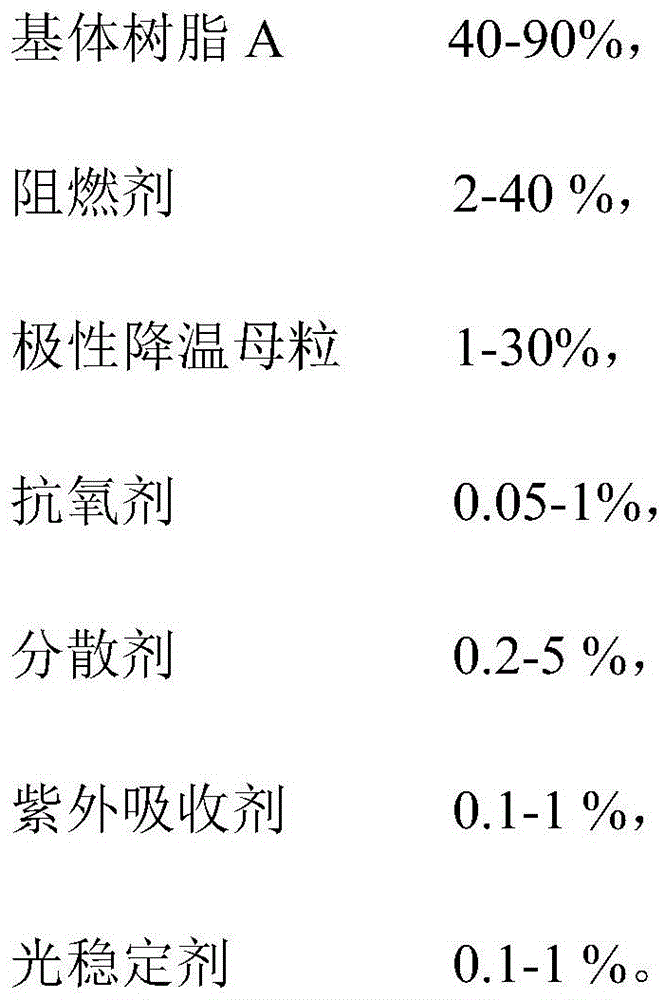

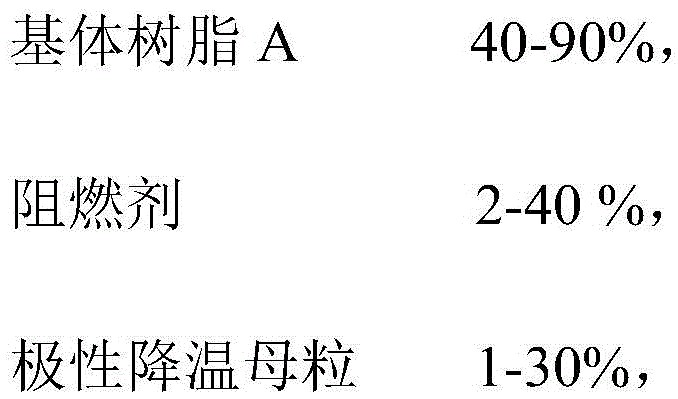

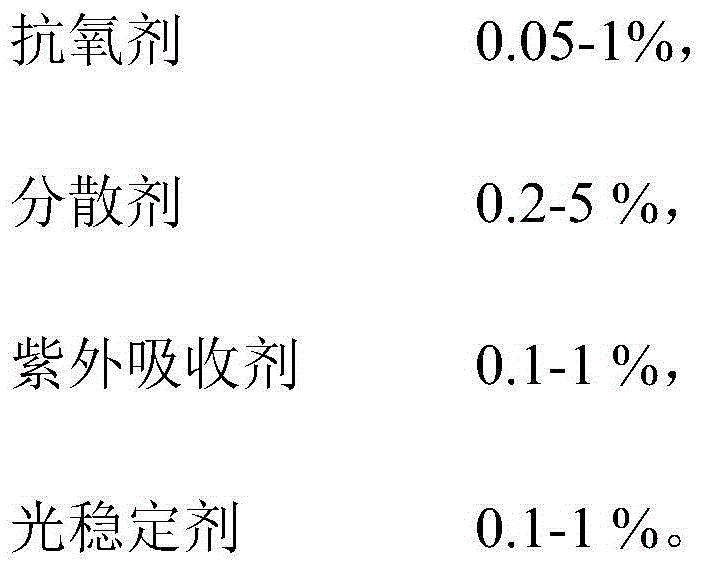

[0033] A soft and ultra-high fluidity PP retardant material, in terms of mass percentage, is made by mixing the following components:

[0034]

[0035]

[0036]The matrix resin A is selected from one or more of polypropylene, polypropylene elastomer, ethylene-butene copolymer, ethylene-octene copolymer, and propylene-ethylene copolymer. The flame retardant is selected from antimony trioxide, tris(2,3-dibromopropyl) isocyanurate, aluminum tripolyphosphate, hexabromocyclododecane, octabromoether, decabromodiphenyl Ethane, tricresyl phosphate, tris(2-chloropropyl) phosphate, tris(2.3-dichloropropyl) phosphate, tris(β-chloroethyl) phosphate, triphenyl phosphite, methyl Dimethyl phosphonate, compound phosphorus-based flame retardant, nitrogen-phosphorus-based intumescent flame retardant, tris(2,2-dibromomethyl-3-bromopropyl) phosphate, ammonium polyphosphate, pentaerythritol, melamine, red One or more of phosphorus, aluminum hydroxide, magnesium hydroxide, chlorinated paraff...

specific Embodiment example 1

[0039] PP formula:

[0040] Matrix resin A: polypropylene (Taiwan chemical fiber, S2035), 84.5wt%

[0041] Flame retardant: Decabromodiphenylethane, 6wt%

[0042] Polar cooling masterbatch: 5wt%

[0043] Dispersant: PP wax, 2wt%, silane coupling agent KH-570, 1.5%

[0044] Antioxidant: n-octadecyl β-(4-hydroxy-3,5-di-tert-butylphenyl)propionate, 0.5wt%

[0045] UV absorber: 2,4-dihydroxybenzophenone, 0.3wt%

[0046] Light stabilizer: tris(1,2,2,6,6-pentamethylpiperidinyl) phosphite, 0.2wt%

[0047] The preparation method of ultra-high fluidity flame-retardant PP, its steps are as follows:

[0048] (1) Preparation of polar cooling masterbatch

[0049] Weigh 100 parts of polypropylene (Taiwan chemical fiber, S2035), 0.3 parts of maleic anhydride, 2 parts of dicumyl peroxide and 1 part of acetone in parts by weight, add them to the mixer and mix them evenly, and then blend and react at 190 ° C to extrude and cut Granules, deodorization and purification to obtain polar cool...

specific Embodiment example 2

[0053] PP formula:

[0054] Base resin A: polypropylene elastomer (Exxon, 6202), 60wt%

[0055] Polar cooling masterbatch: 8wt%

[0056] Flame retardant: tris(β-chloroethyl)phosphate, 27wt%

[0057] Dispersant: EBS, 2wt%, silane coupling agent KH-570, 1.5%

[0058] Antioxidant: tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, 0.5wt%;

[0059] Tris(2,4-di-tert-butylphenyl)phosphite, 0.5 wt%

[0060] UV absorber: bis-2,2,6,6-tetramethylpiperidinol sebacate, 0.3wt%

[0061] Light stabilizer: 4-benzoyloxy-2,2,6,6-tetramethylpiperidine, 0.2wt%

[0062] The preparation method of ultra-high fluidity flame-retardant PP, its steps are as follows:

[0063] (1) Preparation of polar cooling masterbatch

[0064] Weigh 100 parts of polypropylene elastomer (Exxon, 6202), 0.2 parts of maleic anhydride, 1 part of tert-butyl peroxy-2-ethylhexyl carbonate and 1 part of acetone into the mixer by weight Mix evenly, perform blending reaction at 140°C, extrud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com