High-temperature resistance radar wave absorbing coating and preparation method thereof

A technology of high temperature resistance and radar wave, applied in the field of high temperature resistant absorbing coatings and their preparation, can solve the problems of rising temperature and poor impact resistance of absorbing materials, and achieve the effects of high adhesion, light weight and simple process

Active Publication Date: 2013-05-01

UNIV OF ELECTRONICS SCI & TECH OF CHINA

View PDF3 Cites 22 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

During the flight and maneuvering of the aircraft, the temperature of the absorbing material increases due to friction and heat transfer, which requires the absorbing coating attached to its surface to withstand high temperatures, and is usually used as a binder for absorbing materials There are epoxy resin systems, acrylic resin systems, etc. Although they have good adhesion, the three-dimensional network microstructure formed after curing leads to obvious deterioration in flexibility and impact resistance. Withstand high temperature use conditions, whether it can meet the high temperature resistance becomes the key indicator to determine whether this type of absorbing coating can be used

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0039] The component and component content of the coating of the present embodiment are:

[0040]

Embodiment 2

[0042] The component and component content of the coating of the present embodiment are:

[0043]

Embodiment 3

[0045] The component and component content of the coating of the present embodiment are:

[0046]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

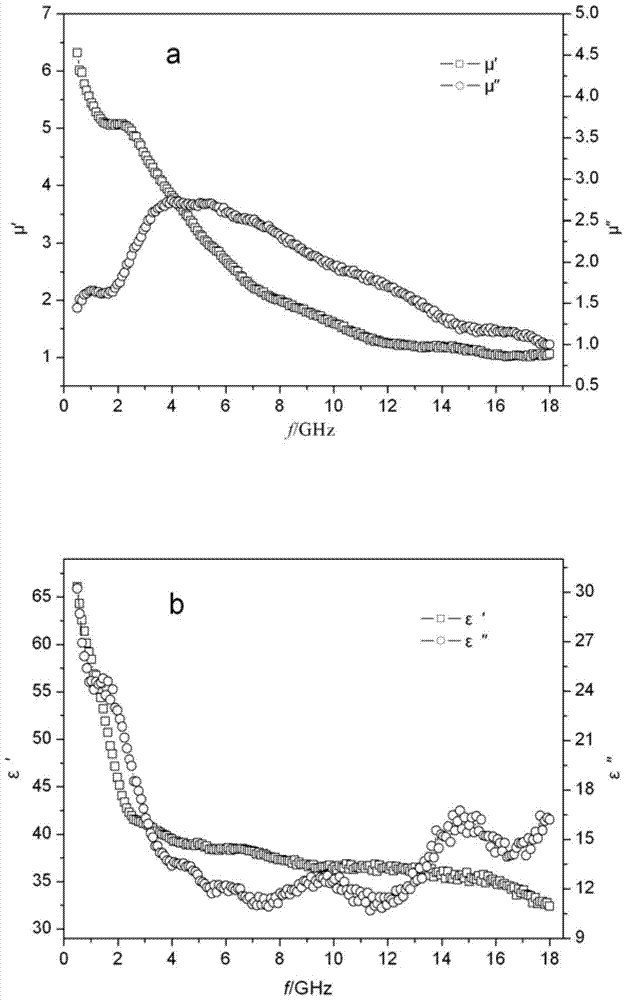

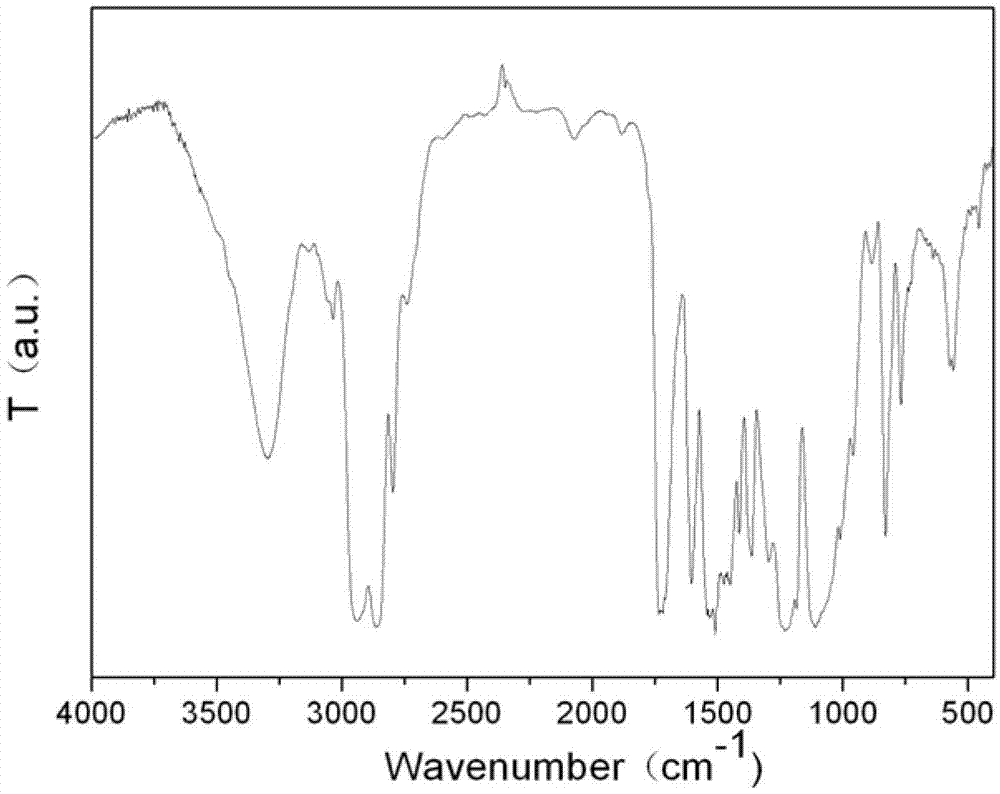

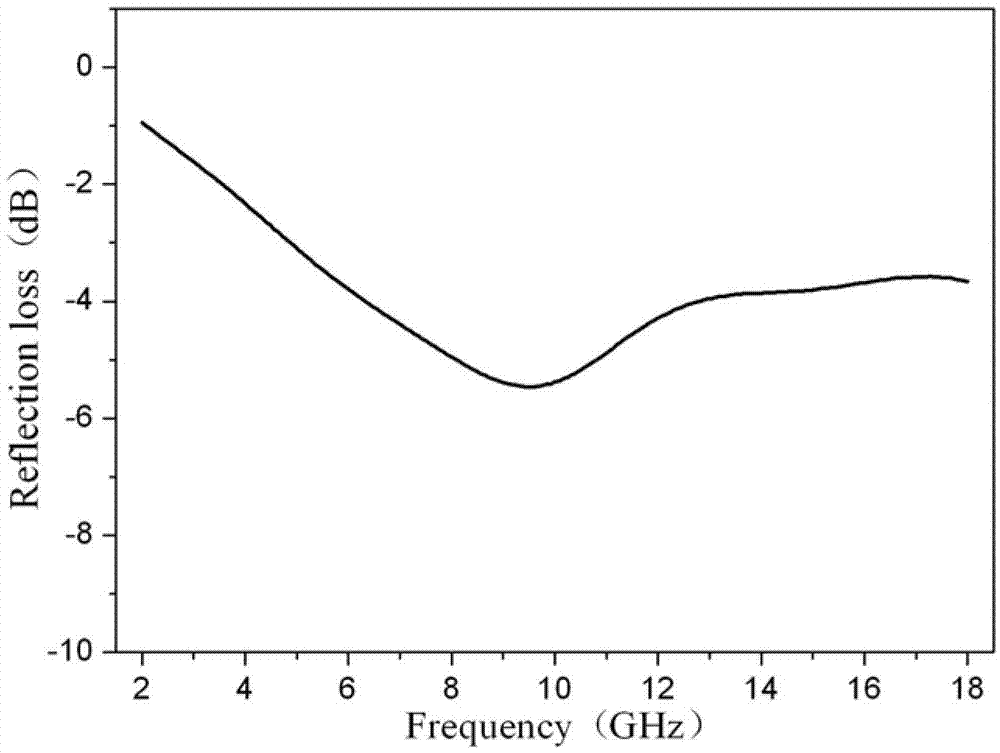

The invention discloses a high-temperature resistance radar wave absorbing coating and a preparation method thereof, and relates to an electromagnetic wave absorbing coating. The absorbing coating comprises the following components: carbonyl iron powder, epoxy resin, polyurethane prepolymer, silane coupling agent and mixed ketone organic solvent, and particularly comprises the following components in part by weight: 65-69 parts of carbonyl iron powder, 19-22 parts of epoxy resin, 30-33 parts of polyurethane prepolymer, 0.4-0.8 parts of KH560 silane coupling agent and 25-35 parts of butanone and cyclohexanone mixed solvent. The absorbing coating provided by the invention can be applied to a wide range of frequency bands, and the application frequency of the absorbing coating can achieve a loss effect of more than minus 3.5 dB in a range of X, Ku wave bands (8-18 GHz).

Description

technical field [0001] The invention relates to an electromagnetic wave absorbing paint, in particular to a high temperature resistant absorbing paint and a preparation method thereof. Background technique [0002] In 1975, the U.S. Air Force first listed "reducing characteristic signals" as an important part of the advanced fighter concept in "Advanced Tactical Fighter Technology Evaluation and Integration". With the rapid development of electronic communication technology, various detection technologies continue to breakthroughs, the stealth performance of aircraft has increasingly become one of the key factors in the "air dominance" capability [0003] Stealth mainly includes radar detection and infrared detection stealth. Two methods are usually used in stealth design at home and abroad: the first is the appearance structure design stealth, such as the sawtooth structure design on the edge to enhance the scattering of electromagnetic waves, reduce the vertical structure ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D175/04C09D175/06C09D175/08C09D163/00C09D7/12C09D5/32C08G18/48C08G18/10

Inventor 邓龙江宋镇江谢建良梁迪飞彭佳宁唐裕沛

Owner UNIV OF ELECTRONICS SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com