Two-component high-temperature-resisting adhesive for assembling loudspeaker and preparation method thereof

A technology of high temperature resistant adhesive and high temperature resistant additive, applied in the direction of adhesives, adhesive additives, natural rubber adhesives, etc., can solve problems such as viscosity increase, and achieve the effect of easy operation, simple method and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the two-component high-temperature-resistant adhesive for speaker assembly provided by the present invention comprises the following steps:

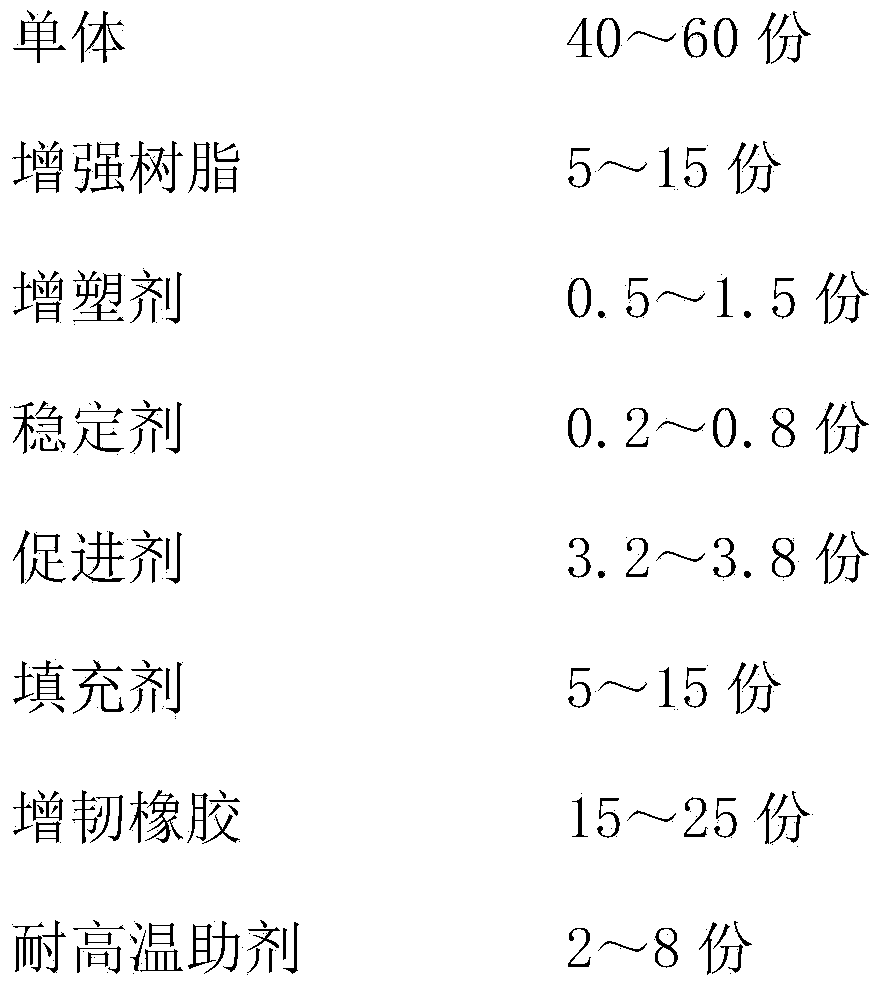

[0035] (1) Preparation of the main ingredient: mix the monomers, reinforced resin, toughened rubber, plasticizer, accelerator and filler in proportion, put them into the reaction kettle and stir at 60-70°C for 10-15 hours, Make it into a uniform liquid, when the temperature returns to room temperature, add a stabilizer and a high-temperature-resistant additive in proportion, and stir for 1 to 2 hours to obtain the main ingredient;

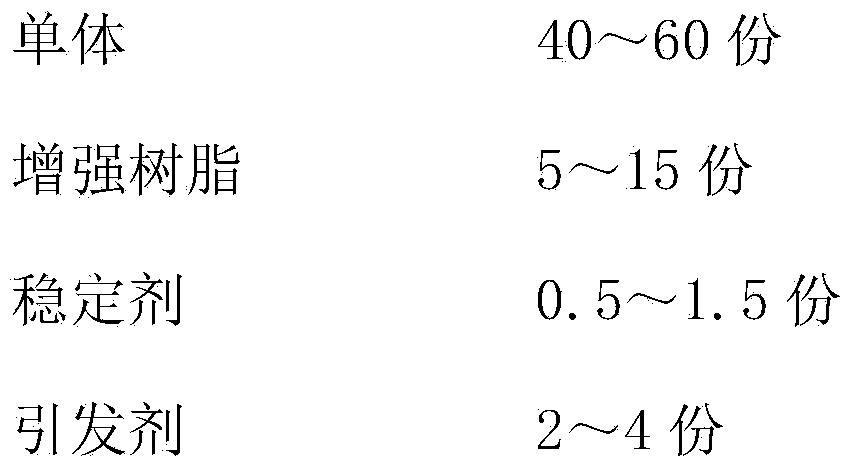

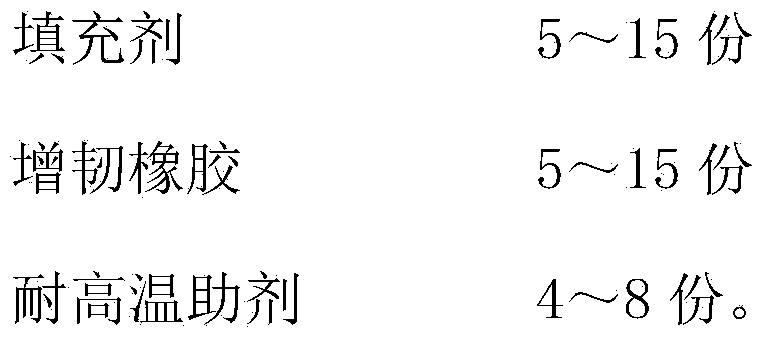

[0036] (2) Preparation of curing agent: After mixing the monomers, reinforced resin, toughened rubber and filler in proportion, put them into the reaction kettle and stir at 60-70°C for 10-15 hours to make it a uniform liquid. When returning to room temperature, add stabilizer, initiator and high-temperature-resistant additive in proportion, and stir for 1 to 2 hours to obtain...

Embodiment 1

[0039]

[0040] The ratio of main agent and curing agent is 1:1.

Embodiment 2

[0042]

[0043]

[0044] The ratio of main agent and curing agent is 1.2:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com