Cavity applying steam oven and steam oven

A steam oven and cavity technology, applied in the application, roaster/barbecue grid, kitchen utensils, etc., can solve the problems of shortening the service life of the steam oven, extremely high rust prevention requirements, complex processing procedures, etc., and achieve post-processing and manufacturing. Cost reduction, the effect of solving yellowing and high temperature resistance, and avoiding structure loosening or falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

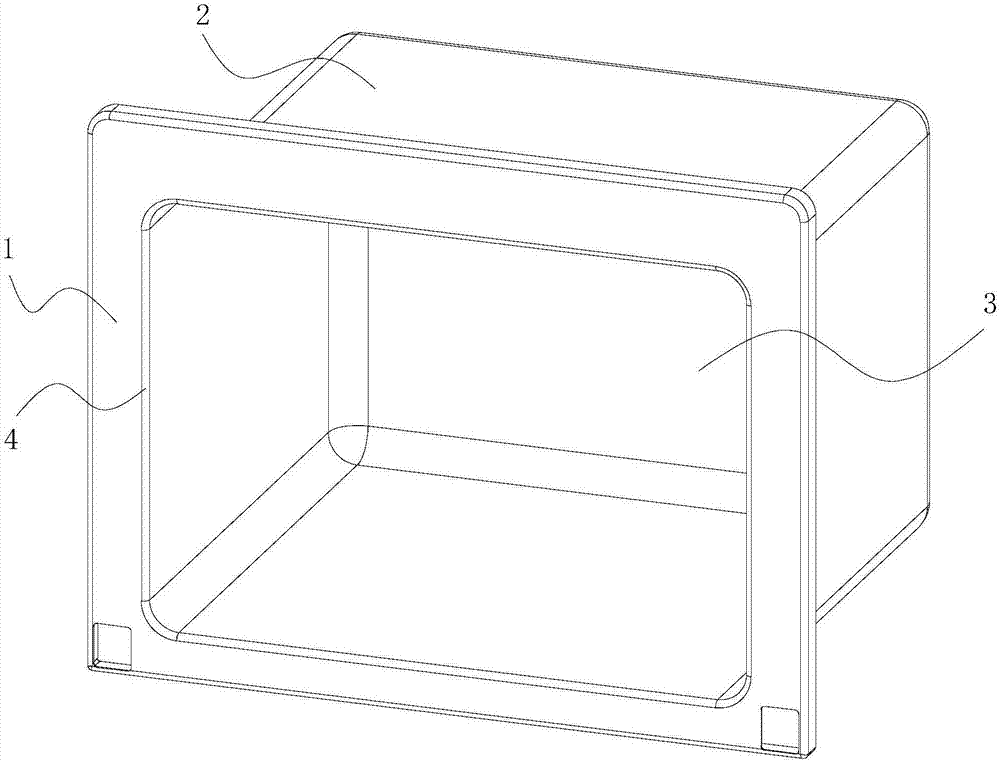

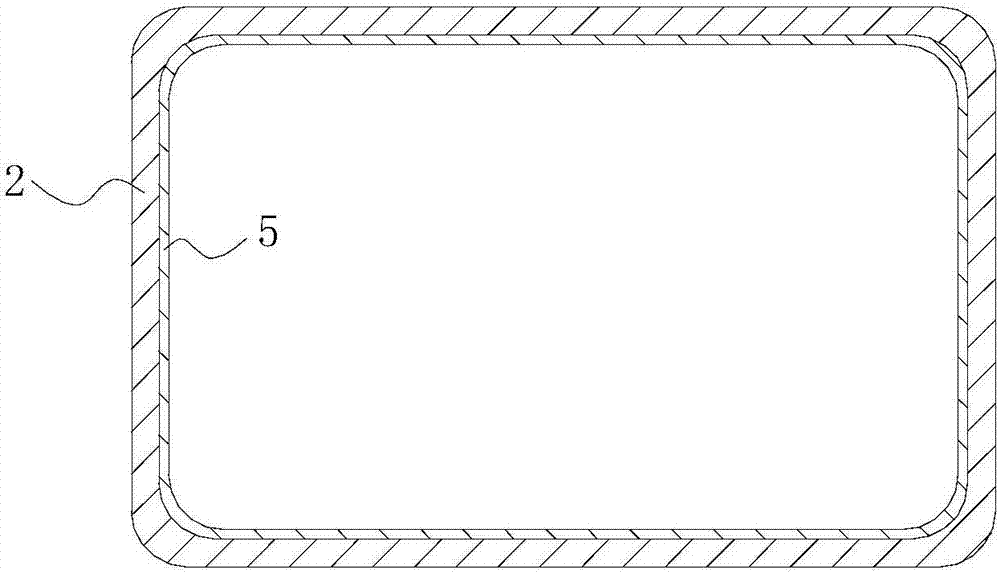

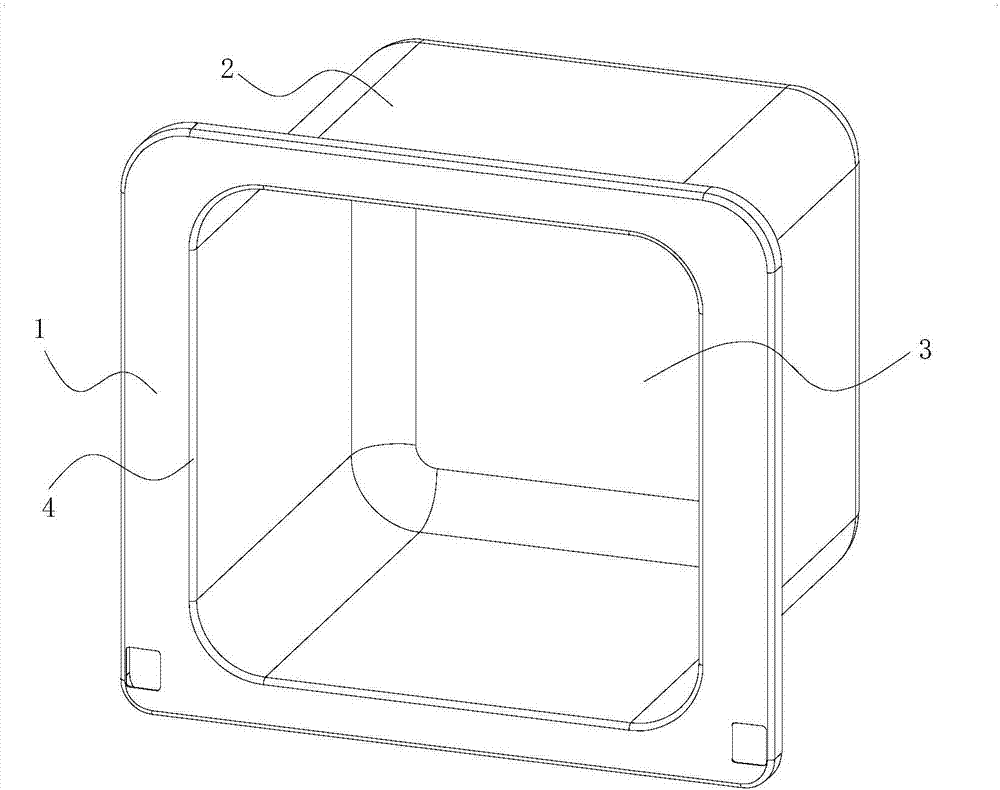

[0040] On the one hand, provide a cavity applied to a steam oven, such as figure 1 As shown, the cavity is made of metal integral stretch forming, and the cavity includes a front mounting plate 1, a U-shaped frame 2 and a rear plate 3, and the cavity is formed by combining the front mounting plate 1, the U-shaped frame 2 and the back plate 3 are made by one-shot stretch molding, such as figure 2 As shown, the inner surface of the cavity after integral stretching is coated with inorganic glass material 5, and the metal matrix of the cavity and the inorganic glass material 5 are coated and adhered by enamel process.

[0041]In this embodiment, the front mounting plate 1 is arranged at one end of the U-shaped frame 2 , and the rear plate 3 is arranged at the other end of the U-shaped frame 2 . The U-shaped frame 2 is an annular thin-walled structure with a through hole in the middle, and the rear plate 3 is arranged at one end of the U-shaped frame 2 and seals one end of the th...

Embodiment 2

[0046] The difference between this embodiment and Embodiment 1 is:

[0047] The outer surface of the cavity after integral stretching is also provided with inorganic vitreous material, and the metal matrix of the cavity is connected with the inorganic vitreous material through enamel process. The inorganic vitreous material is enamel. By arranging inorganic vitreous materials on the inner and outer surfaces of the cavity, the entire surface of the cavity can be protected, and any part of the cavity can be prevented from rusting in all aspects. The coastal area is especially important, which can effectively extend the service life of the product.

Embodiment 3

[0049] The difference between this embodiment and Embodiment 1 is:

[0050] Such as Figure 6 and 7 As shown, the inner heat shield 6 is provided on the rear plate 3 of the cavity, and the inner heat shield 6 is integrally formed with the rear plate 3 through deep drawing process, and the inner heat shield 6 Inorganic vitreous material is arranged on it. In this embodiment, the inner heat shield 6 is a groove structure recessed toward the inside of the cavity along the rear plate 3 , for providing installation space for the rear heating pipe and the convection fan.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com