Warm-mixing SMA (styrene maleic anhydride)-modified asphalt concrete modified particle and preparation method thereof

A technology for modifying asphalt and concrete, which is applied to building insulation materials, building components, and climate change adaptation. It can solve problems such as low construction efficiency, high energy consumption, and short storage time, and achieve enhanced rigidity and strength, avoiding time-consuming and troublesome, The effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

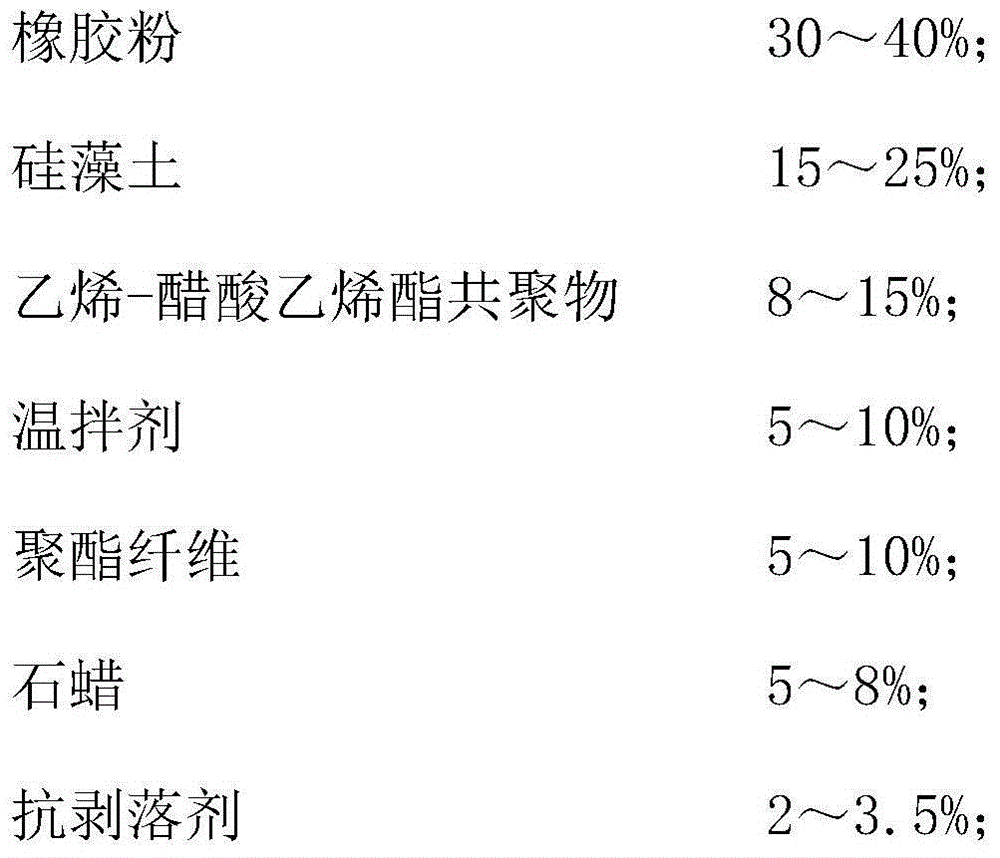

[0028] Embodiment 1 of a warm-mixed SMA modified asphalt concrete modified particle of the present invention comprises the following components, and each component is respectively according to mass percentage:

[0029]

[0030]

[0031] The modified particles are cylindrical particles with a particle diameter of 8-13 mm and a particle length of 15-30 mm. The size design of the modified particles can enable them to melt rapidly and participate in the reaction during the asphalt modification process.

[0032] The preparation method of the warm mixed SMA modified asphalt concrete modified particles comprises the following steps in sequence:

[0033] Step 1. Mix diatomaceous earth, warm mixing agent, polyester fiber, paraffin wax and anti-stripping agent in a high-speed mixer, then add rubber powder and ethylene-vinyl acetate copolymer, and continue mixing until uniform to obtain a premixed thing;

[0034] Step 2. Put the premix obtained in Step 1 into the silo of a 75-typ...

Embodiment 2

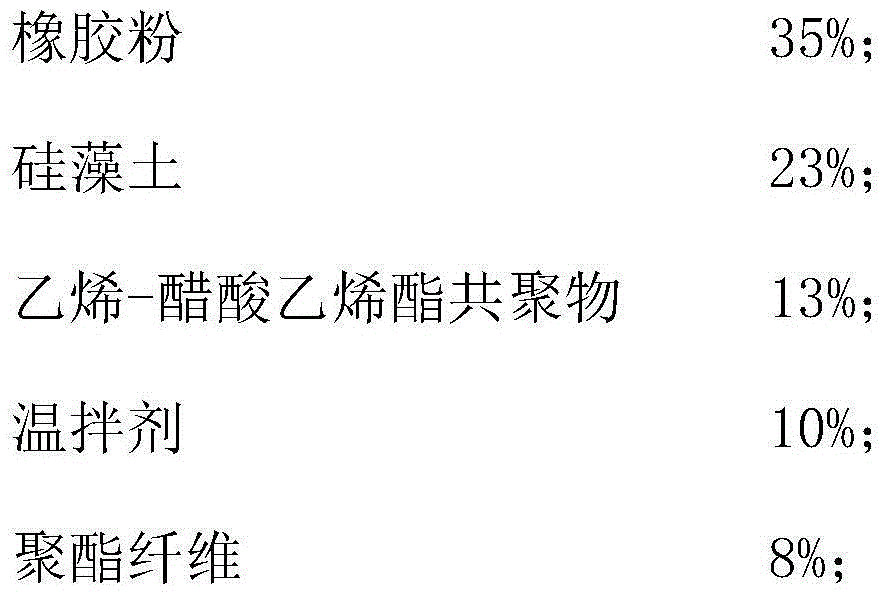

[0036] A warm-mix SMA modified asphalt concrete modified particle embodiment 2 of the present invention includes the following components, and each component is respectively according to mass percentage:

[0037]

[0038]

[0039] The preparation method of the warm mixed SMA modified asphalt concrete modified particles is the same as that of Example 1.

Embodiment 3

[0040] Embodiment 3 of a warm-mixed SMA modified asphalt concrete modified particle of the present invention comprises the following components, and each component is respectively according to mass percentage:

[0041]

[0042] The preparation method of the warm mixed SMA modified asphalt concrete modified particles is the same as that of Example 1.

[0043] The warm-mixed SMA modified asphalt concrete modified particles of the present invention and the preparation method thereof have been put into practical application, and good results have been obtained in practical application, and the efficiency of on-site construction is improved by 30% compared with that of traditional SBS asphalt modification technology. 50%, and there is no need to add various single-performance modifiers to modify the base asphalt and aggregates during the construction process, and it also avoids various dust pollution during the modification process and the modification process is complex and time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com